If

I didn't get it in last issue, at the start of the month I mounted

the indoor radiator unit for the open loop air heat pumping on the

wall

near where the other components are. The fan runs. (Such a small

accomplishment for a

month!)

If

I didn't get it in last issue, at the start of the month I mounted

the indoor radiator unit for the open loop air heat pumping on the

wall

near where the other components are. The fan runs. (Such a small

accomplishment for a

month!)

I

finally skinned the first half of the east wall that I had bought

interlocking metal pieces for. All except one were a few inches

longer

than they needed to be. Since the store wouldn't cut angled ends,

I had

to cut them all myself with the angle grinder anyway, and a bit

too

long is Far better than a bit too short. There really wasn't much

waste.

I

finally skinned the first half of the east wall that I had bought

interlocking metal pieces for. All except one were a few inches

longer

than they needed to be. Since the store wouldn't cut angled ends,

I had

to cut them all myself with the angle grinder anyway, and a bit

too

long is Far better than a bit too short. There really wasn't much

waste. And I

started

on the

permanent 36V DC wiring, using under the stairs as a wiring closet

and

place for the batteries. It's really nice to have two ceiling

lights

with switches by the entries.

And I

started

on the

permanent 36V DC wiring, using under the stairs as a wiring closet

and

place for the batteries. It's really nice to have two ceiling

lights

with switches by the entries. I put

the

battery under the stairs near the base. I need to make a cover for

it

before I accidently short it out with some bit of metal or wire.

I put

the

battery under the stairs near the base. I need to make a cover for

it

before I accidently short it out with some bit of metal or wire. I ran across a

video about a 1938 car, the Schlörwagen Pillbug that was

designed (by Shlör, pictured) to have an absolute minimum

coefficient of

drag (COD) or drag coefficient (DC). The lower the COD,

the

less extra fuel the vehicle needs to counter wind resistance at

higher

and higher travel speeds. Typical cars are in the .3 to .4 range.

Actual drag results from the shape and size plus skin friction. At

higher speeds it is proportional to the square of the velocity.

I ran across a

video about a 1938 car, the Schlörwagen Pillbug that was

designed (by Shlör, pictured) to have an absolute minimum

coefficient of

drag (COD) or drag coefficient (DC). The lower the COD,

the

less extra fuel the vehicle needs to counter wind resistance at

higher

and higher travel speeds. Typical cars are in the .3 to .4 range.

Actual drag results from the shape and size plus skin friction. At

higher speeds it is proportional to the square of the velocity.

I hope

bears

don't venture out across my lawn to where the apple trees are. For

the

first time it looks like I'm going to get a good crop. This

'liberty'

tree has never had more than seven apples before.

I hope

bears

don't venture out across my lawn to where the apple trees are. For

the

first time it looks like I'm going to get a good crop. This

'liberty'

tree has never had more than seven apples before.

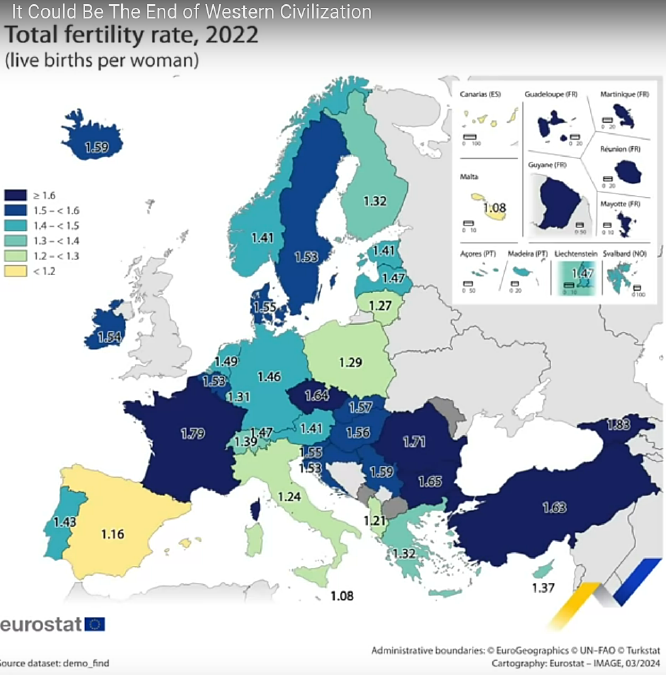

* Are the

white races

coming to an end? It takes about 2.1-2.2 children per woman to

replace

the population. For half a century we've been below that and

dropping.

If each

generation is just over half the size of the

previous, and if the incredible mass migrations into Europe and

North

America continue, will the white races not vanish faster than the

North

American red skinned natives did?

* Are the

white races

coming to an end? It takes about 2.1-2.2 children per woman to

replace

the population. For half a century we've been below that and

dropping.

If each

generation is just over half the size of the

previous, and if the incredible mass migrations into Europe and

North

America continue, will the white races not vanish faster than the

North

American red skinned natives did?

I hope

bears

don't venture out across my lawn to where the apple trees are. For

the

first time it looks like I'm going to get a good crop. This

'liberty'

tree has never had more than seven apples before. The pear trees

are

still a complete wipeout for the eighth year. The new anjou

purchased

last year was covered with blossoms but set no fruit, and there

was

just ONE little cluster of flowers on one of of the two older

pears and

again no fruit.

I hope

bears

don't venture out across my lawn to where the apple trees are. For

the

first time it looks like I'm going to get a good crop. This

'liberty'

tree has never had more than seven apples before. The pear trees

are

still a complete wipeout for the eighth year. The new anjou

purchased

last year was covered with blossoms but set no fruit, and there

was

just ONE little cluster of flowers on one of of the two older

pears and

again no fruit.

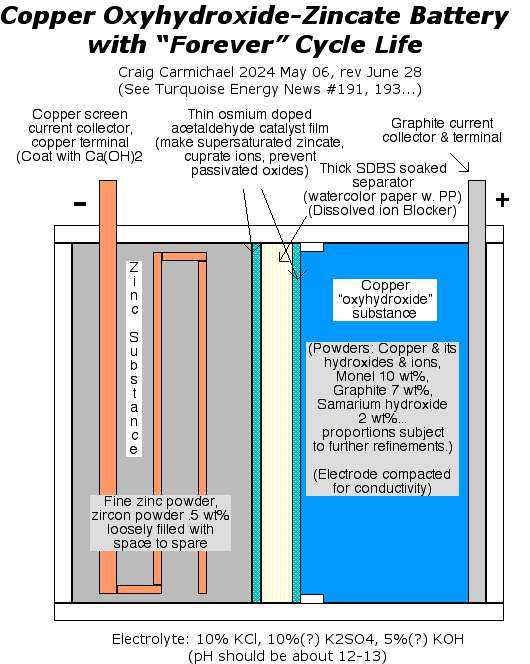

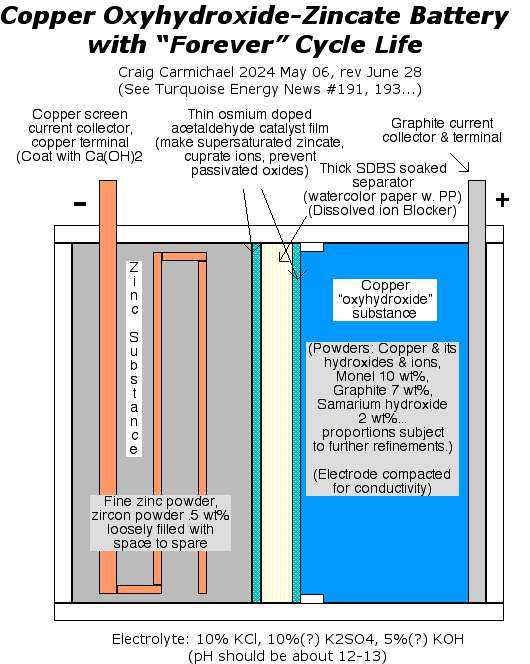

[2nd] Melting

holes into the PVC pipe didn't work well. If I used the

smallest pin frogs heated on an electric 'hot plate' burner, I

could

push the pipe down into the frog points, but it wasn't easy. I

thought to raise the temperature for the next try, then found that

the

lead was giving way and the pins were bent over and loose. And the

whole pipe heated up so much over the burner that it warped. So

much

for that method! If the pin frogs had a stronger base it might

have

worked - alume maybe. Lead was too soft.

[2nd] Melting

holes into the PVC pipe didn't work well. If I used the

smallest pin frogs heated on an electric 'hot plate' burner, I

could

push the pipe down into the frog points, but it wasn't easy. I

thought to raise the temperature for the next try, then found that

the

lead was giving way and the pins were bent over and loose. And the

whole pipe heated up so much over the burner that it warped. So

much

for that method! If the pin frogs had a stronger base it might

have

worked - alume maybe. Lead was too soft. What

was an

alternative? I put a new piece of pipe in an unmounted vise, in a

tray

to catch the sawdust. Then I got out the

'dremmel' tool and a tiny drill bit, maybe 1mm or so, and started

drilling holes, one at a time. It probably took 20-30 minutes to

fill

the pipe with tiny holes all the way around and along the length.

I

smoothed it off inside and out with 'scotchbrite'. (I probably

should

have used a substantially bigger bit. After all, it's the treated

paper

that holds the powder in. Small holes just restrict the flow of

electrolyte.)

What

was an

alternative? I put a new piece of pipe in an unmounted vise, in a

tray

to catch the sawdust. Then I got out the

'dremmel' tool and a tiny drill bit, maybe 1mm or so, and started

drilling holes, one at a time. It probably took 20-30 minutes to

fill

the pipe with tiny holes all the way around and along the length.

I

smoothed it off inside and out with 'scotchbrite'. (I probably

should

have used a substantially bigger bit. After all, it's the treated

paper

that holds the powder in. Small holes just restrict the flow of

electrolyte.) I

scrunched it down - farther and farther - in the

hydraulic press. By the time it was around 500Kg of pressure and

the

powder 2/3(?) of its original height, I decided that was surely

enough.

There were two problems. The first I had foreseen: I couldn't push

the

CuNi terminal/current collector into the compacted powder. But I

had

bent it into an "L" shape, much stronger than just flat, and cut

it to

a point at the bottom end. I drilled into the powder with a long

drill

bit (which went surprisingly slowly) and then pounded the terminal

into

the loosened center area. (At least, I hope it went straight in

and

didn't munch the separator paper around the edge.

I

scrunched it down - farther and farther - in the

hydraulic press. By the time it was around 500Kg of pressure and

the

powder 2/3(?) of its original height, I decided that was surely

enough.

There were two problems. The first I had foreseen: I couldn't push

the

CuNi terminal/current collector into the compacted powder. But I

had

bent it into an "L" shape, much stronger than just flat, and cut

it to

a point at the bottom end. I drilled into the powder with a long

drill

bit (which went surprisingly slowly) and then pounded the terminal

into

the loosened center area. (At least, I hope it went straight in

and

didn't munch the separator paper around the edge. The

cell, such

as it was, started charging at

just 5mA.

Ouch! And I had neglected to measure the internal resistance of

the

monel powder before I had covered it up and got it wet. (Surely

lower

than last time, with all that pressure?) In a while it rose to

9mA.

Load voltages and times very gradually rose.

The

cell, such

as it was, started charging at

just 5mA.

Ouch! And I had neglected to measure the internal resistance of

the

monel powder before I had covered it up and got it wet. (Surely

lower

than last time, with all that pressure?) In a while it rose to

9mA.

Load voltages and times very gradually rose. But

I did make a bracket to hold the 'dremmel' tool on the CNC table's

carriage.

But

I did make a bracket to hold the 'dremmel' tool on the CNC table's

carriage. In the

evening

I decided to drill the holes the immediately fastest

way... by hand again. This time I used a 7/64 inch drill bit.

These

"huge" holes occupying a much greater percentage of the surface

should

let an awful lot more electrolyte through. I glued a bottom piece

on.

In the

evening

I decided to drill the holes the immediately fastest

way... by hand again. This time I used a 7/64 inch drill bit.

These

"huge" holes occupying a much greater percentage of the surface

should

let an awful lot more electrolyte through. I glued a bottom piece

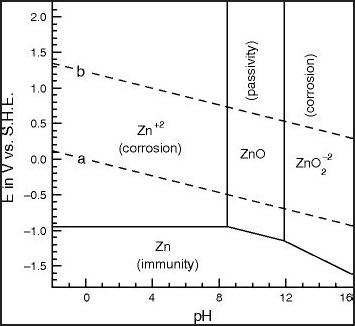

on. [11th] How

Zinc/Zincate

Electrode Works

[11th] How

Zinc/Zincate

Electrode Works It occurred to me

that if the copper might form Cu(OH)4--, that was pretty

similar to zinc forming Zn(OH)4--. Would it, then, similarly form

a

solution of valence 2 cuprate ions? (or valence 3, perhaps as

Cu(OH)5---?) Would such a solution

gradually turn to "passivated" CuO similar to zinc turning to ZnO,

and

block the electrolyte ions? Dissolved ions wasn't my conception of

what

was happening, but considering that every cell (which now appears

to be

every copper electrode) seems to gradually deteriorate over days,

this

may well be the case.

It occurred to me

that if the copper might form Cu(OH)4--, that was pretty

similar to zinc forming Zn(OH)4--. Would it, then, similarly form

a

solution of valence 2 cuprate ions? (or valence 3, perhaps as

Cu(OH)5---?) Would such a solution

gradually turn to "passivated" CuO similar to zinc turning to ZnO,

and

block the electrolyte ions? Dissolved ions wasn't my conception of

what

was happening, but considering that every cell (which now appears

to be

every copper electrode) seems to gradually deteriorate over days,

this

may well be the case. I

put in three doubled pieces of monel wire, dumped in the 27.5

grams of

powder, and poked it somewhat compact. It only occupied 1/3 of the

tube. I started to conceive that it was going to be something like

the

zinc, dissolving to ions as it charged, plating onto the monel

wires as

it discharged. And so I was probably wrong about the powder

needing to

be compacted much. (Then why was I using the tube shape, again?)

I

put in three doubled pieces of monel wire, dumped in the 27.5

grams of

powder, and poked it somewhat compact. It only occupied 1/3 of the

tube. I started to conceive that it was going to be something like

the

zinc, dissolving to ions as it charged, plating onto the monel

wires as

it discharged. And so I was probably wrong about the powder

needing to

be compacted much. (Then why was I using the tube shape, again?) [14th] I made a

shorter

tube that wouldn't take so darn much monel, and would fit under

the

lid. I didn't put holes near the top. The idea was the electrode

wouldn't come up to the top of the tube. I could put a plug in as

a top

cap, one that would fill the tube with a friction fit, so that

once it

was pushed in it wouldn't willingly push out again and would hold

the

material compacted. If performance dropped it could be pushed

harder,

pushed in a little more, by as much as half an inch.

[14th] I made a

shorter

tube that wouldn't take so darn much monel, and would fit under

the

lid. I didn't put holes near the top. The idea was the electrode

wouldn't come up to the top of the tube. I could put a plug in as

a top

cap, one that would fill the tube with a friction fit, so that

once it

was pushed in it wouldn't willingly push out again and would hold

the

material compacted. If performance dropped it could be pushed

harder,

pushed in a little more, by as much as half an inch. Now

trusting

neither cupro-nickel nor monel - at least not such thin monel wire

- I

thought of the old standby: graphite. I took a 3/8 inch diameter

graphite rod and cut it to 4 inches long, then sanded one end down

to a

point, tapered along the length of the electrode. That way as I

pushed

(or lightly pounded) it in, it would continue to compact the

material a

bit more and at the same time make the best contact. (I had 1/4

&

5/8 inch rod as well, but the pipe was a bigger diameter than I

had

wanted anyway, so a bit of extra filler that also made for a

"thinner"

active electrode and more contact area to the current collector

seemed

to be all to the good.)

Now

trusting

neither cupro-nickel nor monel - at least not such thin monel wire

- I

thought of the old standby: graphite. I took a 3/8 inch diameter

graphite rod and cut it to 4 inches long, then sanded one end down

to a

point, tapered along the length of the electrode. That way as I

pushed

(or lightly pounded) it in, it would continue to compact the

material a

bit more and at the same time make the best contact. (I had 1/4

&

5/8 inch rod as well, but the pipe was a bigger diameter than I

had

wanted anyway, so a bit of extra filler that also made for a

"thinner"

active electrode and more contact area to the current collector

seemed

to be all to the good.) Hmm...

Let's

start at the beginning. I opened up a couple of nickel-metal

hydride

"D" cells and unwrapped the rolled up electrodes in one. I put a

separator paper (toluened, SDBS'ed, PP ironed in, but not

osmiumed)

into the 4 inch PVC tube with the large holes.

Hmm...

Let's

start at the beginning. I opened up a couple of nickel-metal

hydride

"D" cells and unwrapped the rolled up electrodes in one. I put a

separator paper (toluened, SDBS'ed, PP ironed in, but not

osmiumed)

into the 4 inch PVC tube with the large holes. Then I wrapped

some 'sheets' of the nickel hydroxide substance into it around the

outside. I cut a 5 inch section of the 3/8 inch graphite rod,

sanded it

into something of a cone, and put it in the middle. I put in

enough dry

cell stuff that it was a tight fit. The pieces came up to the top

so

rather than make a new end cap I used heat glue to seal the top. I

estimate it was around half the nickel side of one 10 amp-hour "D"

cell, maybe 4 or 5 amp-hours.

Then I wrapped

some 'sheets' of the nickel hydroxide substance into it around the

outside. I cut a 5 inch section of the 3/8 inch graphite rod,

sanded it

into something of a cone, and put it in the middle. I put in

enough dry

cell stuff that it was a tight fit. The pieces came up to the top

so

rather than make a new end cap I used heat glue to seal the top. I

estimate it was around half the nickel side of one 10 amp-hour "D"

cell, maybe 4 or 5 amp-hours. It

didn't seem to work. It was

as if there was no cell connected. I finally wondered if maybe the

nickel side wouldn't work with the SDBS in the separator paper. I

took

it apart and put in an un-SDBS'ed paper. Still nothing. I moved

the

alligator clip connection to the zinc side - again - and suddenly

it

all worked. (Dang alligator clips!) Crap, now I don't know if the

nickel would have a problem with the SDBS. I have no reason to

think it

would, but now it has a paper without it instead of with it. Oh

wait...

the zinc paper has SDBS, so there's an SDBS'ed paper between the

nickel

and zinc anyway. I wonder if a nickel side would last forever if

gelled

with SDBS instead of just for 500-1000 cycles? I don't see why

not.

It

didn't seem to work. It was

as if there was no cell connected. I finally wondered if maybe the

nickel side wouldn't work with the SDBS in the separator paper. I

took

it apart and put in an un-SDBS'ed paper. Still nothing. I moved

the

alligator clip connection to the zinc side - again - and suddenly

it

all worked. (Dang alligator clips!) Crap, now I don't know if the

nickel would have a problem with the SDBS. I have no reason to

think it

would, but now it has a paper without it instead of with it. Oh

wait...

the zinc paper has SDBS, so there's an SDBS'ed paper between the

nickel

and zinc anyway. I wonder if a nickel side would last forever if

gelled

with SDBS instead of just for 500-1000 cycles? I don't see why

not. But what

about

copper? On the fourth I had made a bracket to mount my 'dremmel'

drill

onto the CNC table. Now I decided to make the "rotisserie" for the

CNC

table to drill holes in plastic electrode tubes. I thought of

using a

coupling nut, and after that everything became simple. I only had

3/8"

ones, which turned out to be just right. That was too big for the

stepper motor shaft, but I dug out another stepper with a 3/8"

shaft. I

drilled out the threads so the nut would slip onto the motor

shaft, and

put in a set screw hole & screw to hold it. I would have

rather had

a smaller bolt (1/4") and hence more gap into which to drill the

holes

before hitting it, but the space should be sufficient if all is

carefully set up.

But what

about

copper? On the fourth I had made a bracket to mount my 'dremmel'

drill

onto the CNC table. Now I decided to make the "rotisserie" for the

CNC

table to drill holes in plastic electrode tubes. I thought of

using a

coupling nut, and after that everything became simple. I only had

3/8"

ones, which turned out to be just right. That was too big for the

stepper motor shaft, but I dug out another stepper with a 3/8"

shaft. I

drilled out the threads so the nut would slip onto the motor

shaft, and

put in a set screw hole & screw to hold it. I would have

rather had

a smaller bolt (1/4") and hence more gap into which to drill the

holes

before hitting it, but the space should be sufficient if all is

carefully set up. Then I

found

a piece of 90° angle with holes in it and mounted the motor onto

that. The lower side fits onto bolts on the CNC table. Presto!

Then I

found

a piece of 90° angle with holes in it and mounted the motor onto

that. The lower side fits onto bolts on the CNC table. Presto! [July 1st] I changed

the

program a bit to put a little more space between holes also with a

couple of adjustments to go faster - it had taken over an hour

with

considerable wasted movements. When I went to drill a new tube,

everything went crazy. The drill pulled out of the collet and the

tube

was gouged.

[July 1st] I changed

the

program a bit to put a little more space between holes also with a

couple of adjustments to go faster - it had taken over an hour

with

considerable wasted movements. When I went to drill a new tube,

everything went crazy. The drill pulled out of the collet and the

tube

was gouged. After

that the

real problem turned out to be that while I had edited the G-code

program in the text editor, and told the CNC program to "reload

G-code"

a couple of times, the program had started up by opening a sample

G-code routing program and I hadn't opened the real one. All the

useless and annoying safeties in the CNC program merely distracted

from

the broad view - it did crazy things because it was running the

wrong

G-code file entirely! Why would it load some useless sample

milling

routine as a default instead of starting blank and waiting for the

user

to pick one? Ah well, caveat emptor... It was good to get that

weak

vertical axis fixed anyway as it probably would have messed up

jobs in

the future.

After

that the

real problem turned out to be that while I had edited the G-code

program in the text editor, and told the CNC program to "reload

G-code"

a couple of times, the program had started up by opening a sample

G-code routing program and I hadn't opened the real one. All the

useless and annoying safeties in the CNC program merely distracted

from

the broad view - it did crazy things because it was running the

wrong

G-code file entirely! Why would it load some useless sample

milling

routine as a default instead of starting blank and waiting for the

user

to pick one? Ah well, caveat emptor... It was good to get that

weak

vertical axis fixed anyway as it probably would have messed up

jobs in

the future.

| Days of __ KWH |

June 2024 (18 Collectors) |

May 2024 (18 C's) |

June 2023 (18 C's) |

| 0.xx |

|||

| 1.xx |

|||

| 2.xx |

|||

| 3.xx |

|

||

| 4.xx |

|||

| 5.xx |

|

||

| 6.xx |

|

|

|

| 7.xx |

2 |

1 |

|

| 8.xx |

2 |

1 |

|

| 9.xx |

1 |

3 |

1 |

| 10.xx |

4 |

||

| 11.xx |

1 |

3 |

1 |

| 12.xx |

3 |

1 |

1 |

| 13.xx |

5 |

2 |

2 |

| 14.xx |

3 |

4 |

1 |

| 15.xx |

3 |

2 |

|

| 16.xx |

5 |

1 |

4 |

| 17.xx |

2 |

2 |

2 |

| 18.xx |

1 |

|

2 |

| 19.xx |

1 |

||

| 20.xx |

1 |

1 |

5 |

| 21.xx |

|

1 |

3 |

| 22.xx |

2 |

2 |

|

| 23.xx |

2 |

2 |

|

| 24.xx |

1 |

1 |

|

| 25.xx |

1 |

2 |

|

| 26.xx |

|||

| 27.xx |

|||

| 28.xx |

|||

| 29.xx |

|||

| Total KWH for month |

420 |

405 |

540.12 |

| Km Driven on Electricity |

~1465 Km 190 KWH |

1091.9 ~145 KWH (ODO 108799) |

1407.7 Km (190 KWH?) |