Turquoise Energy News

Report #200

Covering

Research & Development Activities of January 2025

(Posted February 9th 2025)

Lawnhill BC Canada - by Craig Carmichael

New: Now at craigcarmichael.substack.com

***

[Subscribe: email to CraigXC at Post dot com ; request

subscription]

Main URL: TurquoiseEnergy.com

Month In "Brief"

(Project Summaries etc.)

* New Unipolar BLDC "Electric Hubcap" motor (for Sprint Car) - Hot-wire

Foam Cutters - Faraday Cabin: Insulation, Some floor joists - "SCABA"

devices (Self Contained Arctic Breathing Apparatus) - More Practical

Magnetic Refrigeration?

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* Scattered Thots - ESD

- Detailed

Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* Unipolar Electric Hubcap Motor Construction

Other "Green" & Electric

Equipment Projects

* Hot-Wire Plastic Foam Cutters - small one - "plastic mill" - large

one &

cutting styrene foam

* "Faraday Cabin" Construction - insulating with styrene foam - Some

floor joists

Electricity Storage:

Batteries (no report on battery development)

* My 36V Power Systems: Charging the LiFePO4 Cells

* Some Thoughts on Storing Solar Energy as Heat: "Dump Loads" -- Sand

Battery Experiment for February

Electricity Generation

* My Solar Power System: - Latest

Daily/Monthly Solar

Production log et cetera - Monthly/Annual Summaries, Estimates,

Notes

Unipolar "Electric Hubcap" Axial Flux BLDC motor: Construction

Finally Started

Building on my original "Electric Hubcap" motors and their

unique designs, I've had a number ideas for this for many years now,

and have added the odd refinement to the concepts in the last few. The

unipolar idea needs to have an even number of coils for balance, at

least twelve, driven by six electrical phases, so I couldn't adapt the

nine-coil ("Hubcap") or six coil ("Caik") original motors. Of course

the housings

mostly can't be metal for electromagnetic reasons. Thinking I was

going to make molded polypropylene or PP-epoxy housings, and with the

CNC table not working for the longest time, I couldn't begin.

Then, with the CNC table finally working, at the end of

December it finally occurred to me I could make a housing out of

plywood and

to rout out the special shapes for the stator directly in the wood.

With that I

decided to drop the project of converting the old Baldor motor to 36

volts and

build the motor I've really wanted for so long.

Now I've found 1/2 inch thick "polypropylene copolimer"

(PPC) sheets: tough, dimensionally stable and good for 100°C

temperatures and beyond. I should be able to rout PPC just as

easily as plywood. I'll still make it a square case for simplicity.

I

fitted together the rotary parts and welded a flange to a 1 inch "weld

on hub". I couldn't seem to find anyone to do my weld. My own ugly weld

should work.

I

fitted together the rotary parts and welded a flange to a 1 inch "weld

on hub". I couldn't seem to find anyone to do my weld. My own ugly weld

should work.

After working out all the

trigonometry etc. and creating a G-code file to run the course, I

routed a test copy of the desired

magnet placement jig from thin plywood - the first thing I've actually

routed on this CNC router. I didn't have a big enough piece of slippery

UHMW-PE that epoxy wouldn't stick to, so I got a piece of also

non-sticky HDPE instead. But it would seem HDPE routs differently from

UHMW: the "sawdust" stuck in the kerf and melted it right back

together. So I contrived to mount my DeWalt router (which has a speed

control) in the CNC table carriage by cutting off edges of its flange

and drilling new mounting holes. But even its lowest speed was too fast

to rout HDPE - same result.

So finally I made a jig to place magnets on the rotor from a slab of PP

I had melted from ropes off the beaches. (It's still on the rotor

awaiting more magnets. I may have trouble getting it off.)

So finally I made a jig to place magnets on the rotor from a slab of PP

I had melted from ropes off the beaches. (It's still on the rotor

awaiting more magnets. I may have trouble getting it off.)

I decided to double stack the 3/8 inch thick magnets to

3/4 inch

tall and then ordered some 50 x 20 x 10 mm magnets as matching

"sideways"

magnets for the hallbach configuration rotor. On the original "Electric

Hubcap" motors there were 12 supermagnets. Here that becomes 40: two

layers of 16 'regular' plus 8 sideways magnets. All configured as eight

Hallbach alternating poles. If the original

supermagnet rotors had huge magnetic fields, this one will be

MONSTEROUS. The motor should be super efficient and have Huge torque.

And with improvements to the magnet bonding onto the rotor by roughing

all surfaces up first, I anticipate perhaps 3500 RPM should be safe

instead of just 2000, despite it being almost 13 inches diameter

instead

of 10 inches.

I put the rotor away pending the other magnets arriving.

Then I added

to the G-code file for making the stator inner side, adding a lot

of ventilation holes. I also did holes so I could put the wire ends

through the plate to do the coil wiring on the outside where there's

lots of room. (These files take considerable time to do and then to

adjust.)

Then I added

to the G-code file for making the stator inner side, adding a lot

of ventilation holes. I also did holes so I could put the wire ends

through the plate to do the coil wiring on the outside where there's

lots of room. (These files take considerable time to do and then to

adjust.)

After a couple of false starts and then adjustments to the

CNC machine

configuration, I tried to test rout a test sample from 12mm plywood. It

drilled a bunch of holes fine,

but the routed coil contours cut too deep. Where the plywood curled up

just

slightly on one side, the bit went right through. I stopped it.

But it gave me a sample to

see how the coils would fit.

But it gave me a sample to

see how the coils would fit.

I describe the

planned/expected

characteristics of the motor in the detailed

report.

Hot-wire Foam Cutters

Having filled a few wall stud spaces with foam rubber and

then polyethylene foam, I asked myself why I would want to work with

ucky fiberglass? I would happily do the rest of the structure with

these

friendlier materials.

Fiberglass wool batts: R 3.5 (per inch - R 12 in 2 by 4 wall cavities.)

Foam rubber: R ?

Polyethylene Foam: R 3

Beady Styrofoam: R 4

Extruded polystyrene: R 5

I figure even the polyethylene foam is probably better

than

fiberglass because it stops the air movement better. I could be wrong,

but 3 inches thick plus "R 1" for a 1/2 inch air gap should be at least

R 10. 3 inches of beady styrofoam would be R 13 and extruded would be R

16.

I

put an ad in Haida Gwaii Trader that I was looking for foam for

insulation. But it was all taking too long - hours for a 12 foot tall

wall space with three layers of one inch expanded styrene foan. The

worst was slicing through the material with a knife. The first person

who responded to my ad had saved some styrene packaging foam. She said

she had been planning to make a hot wire cutter for it but had never

got around to it. That gave me the idea.

I

put an ad in Haida Gwaii Trader that I was looking for foam for

insulation. But it was all taking too long - hours for a 12 foot tall

wall space with three layers of one inch expanded styrene foan. The

worst was slicing through the material with a knife. The first person

who responded to my ad had saved some styrene packaging foam. She said

she had been planning to make a hot wire cutter for it but had never

got around to it. That gave me the idea.

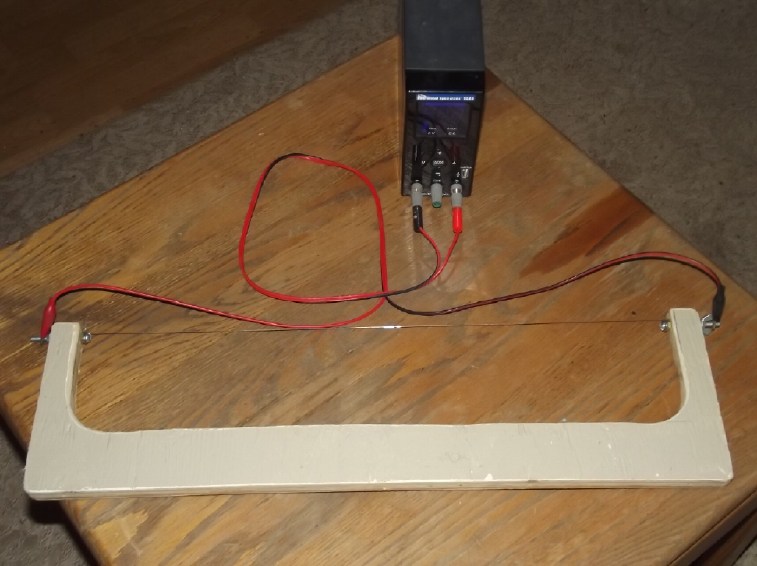

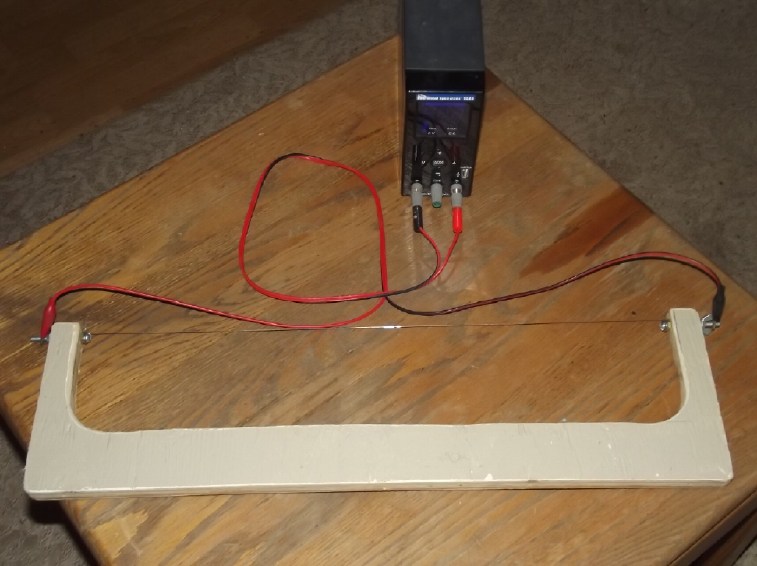

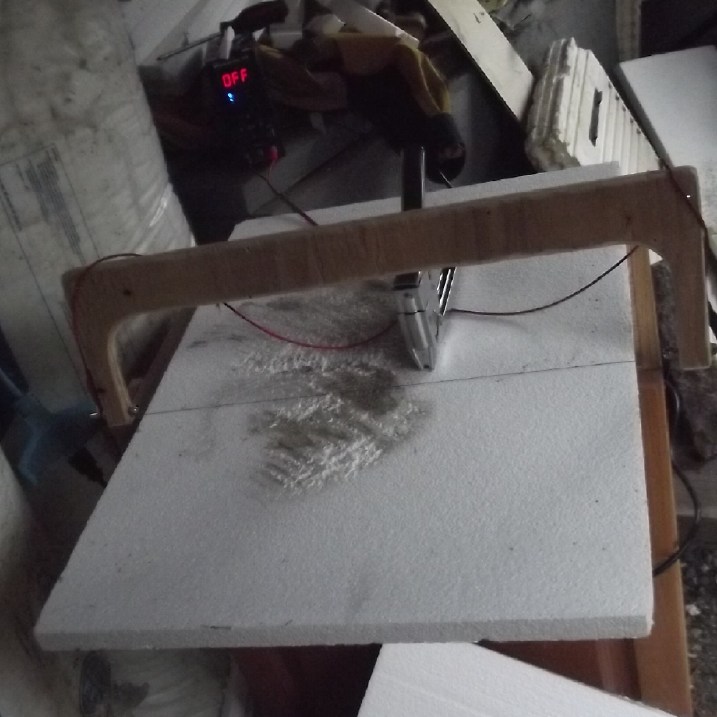

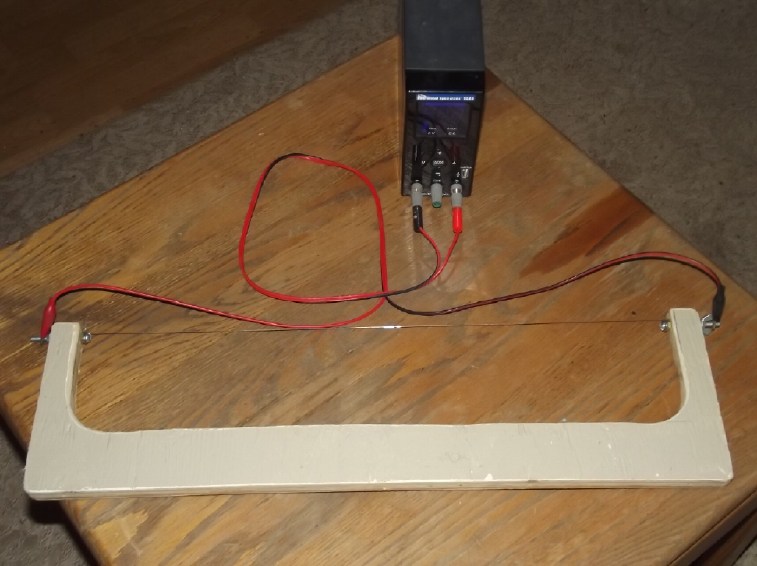

[January 1st] I had some ni-chrome

resistance wire that I got on AliExpress a few years ago to make

plastic recycling heaters, before I got the idea just to melt plastics

in an oven. I cut a foot long piece of the wire and connected it with

alligator clips to a power supply. It got really hot. I turned the

power down to 5 volts and, holding the alligator clips and a piece of

plastic (did I have three hands?) I pushed it in. Wow! It went like the

proverbial "hot knife through butter!" I pulled back and it came out

another way, cutting out a triangular piece.

Then I made a

"bow saw" piece of plywood and put bolts through the ends. I cut a

longer wire to fit and attached it. I put in a couple of cable staples

to hold the alligator clip leeds better. Then I took it with the power

supply out to the cabin and cut a piece of foam.

Then I made a

"bow saw" piece of plywood and put bolts through the ends. I cut a

longer wire to fit and attached it. I put in a couple of cable staples

to hold the alligator clip leeds better. Then I took it with the power

supply out to the cabin and cut a piece of foam.

A project started and completed in an hour!

The setting was 14 volts, where it drew about 2-1/2 amps.

That's just 35 watts. (3 to 3-1/2 amps or more is faster. At 3-3/4 the

wire starts to glow dimly.)

I found the

best way to cut was to lay the saw's wire on the line to be cut

(placing the cut just over the edge of a work table), hold the handle

balanced above, then turn the power On. The weight of the saw alone

pushed it through. The one inch thick pieces took about six seconds,

then power off again.

I found the

best way to cut was to lay the saw's wire on the line to be cut

(placing the cut just over the edge of a work table), hold the handle

balanced above, then turn the power On. The weight of the saw alone

pushed it through. The one inch thick pieces took about six seconds,

then power off again.

This way there was minimal smell from the plastic and it

cut fast.

I did the second of the two tall wall cavities in maybe an

hour and a half. Yes, it's still more labor intensive than fiberglass.

One layer of foam 2+ to 3 inches thick would be a lot

easier than three layers of 1 inch.

I tried

cutting a side off a cooler box by hand. It was pretty wavey.

I

was trying to figure out how to make a jig to cut the sides off

straight. I came up with one plan, then I realized that box sides would

hit the

handle.

I

was trying to figure out how to make a jig to cut the sides off

straight. I came up with one plan, then I realized that box sides would

hit the

handle.

In the evening I realized I could simply C-clamp the saw

upside down to the side of a workbench.

This worked quite well. I set the plastic right in front

of the "blade", turned on the power, pushed, and melted through the

wall

thickness (15 seconds?) then drew the piece back and shut off the

power. I had to shut off the power between cuts because the wire sagged

when it was hot. It sprung back up as it cooled.

(The image perhaps isn't very clear. The C-clamped left end 'post' of

the 'saw' is at the very left; the right end is behind the end of the

steel ruler. The 'invisible' wire between is cutting the last side off

a cooler.)

By the time I

retired for the night I had cut two cooler boxes into 12 fairly flat

pieces. All this still on the same day I made the 'saw' - January

first, my 70th birthday.

Someone told me there was a big,

ugly chink of

float foam at a nearby beach.

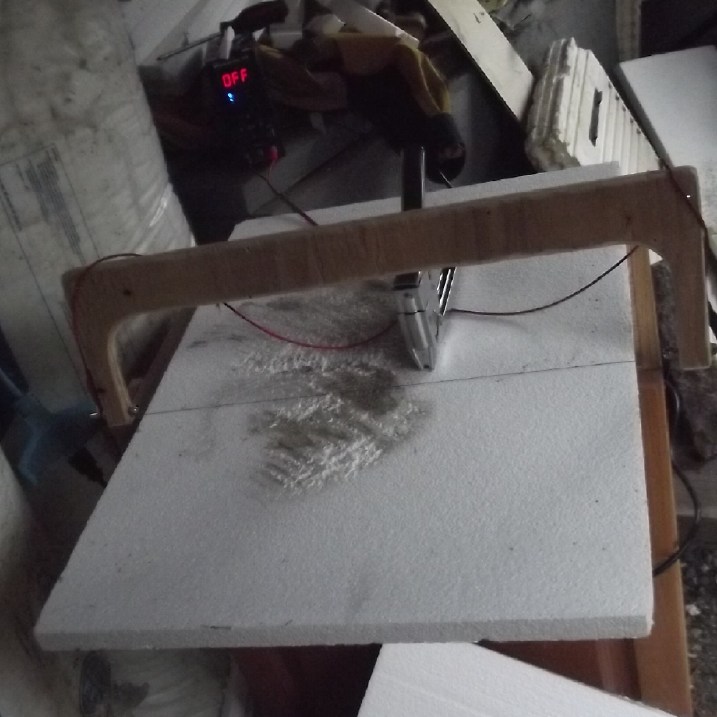

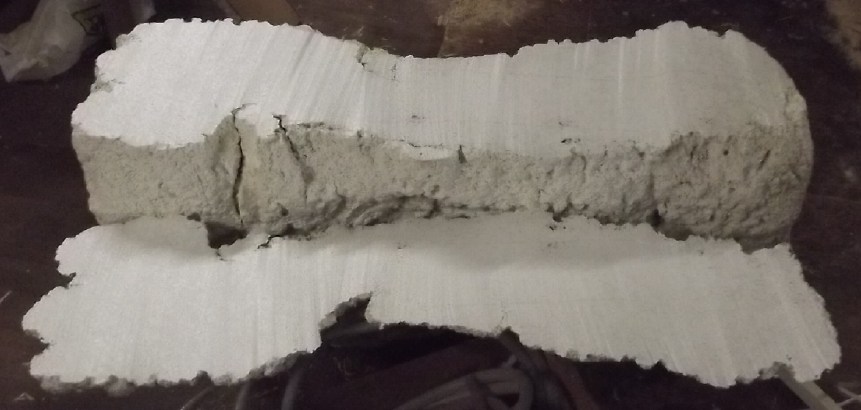

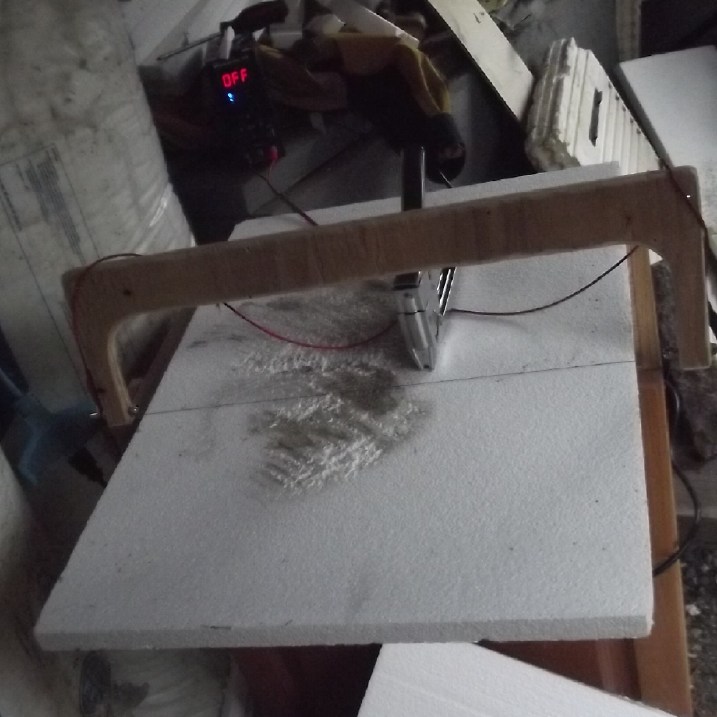

I had scrounged

a 30 inch wide piece of countertop a while back. I now employed it: I

set it on a work table and turned it into a hot-wire 'table saw/mill'.

I had scrounged

a 30 inch wide piece of countertop a while back. I now employed it: I

set it on a work table and turned it into a hot-wire 'table saw/mill'.

The wooden arms are C-clamped on the sides and the wire is strung

between them at the desired height/thickness.

One turns on the power and pushes the block of foam through, along the

smooth surface, however fast it wants to go.

In 10 or 15 minutes: Presto! Four smooth slabs from the big chunk.

[15th] I made

a third foam cutting hot-wire saw, for cutting long edges. This one was

essentially a five foot

long copy of the first, with the refinements of having its own wiring:

a 12 foot cord and 36 volt DC plug -- and a switch.

[15th] I made

a third foam cutting hot-wire saw, for cutting long edges. This one was

essentially a five foot

long copy of the first, with the refinements of having its own wiring:

a 12 foot cord and 36 volt DC plug -- and a switch.

Wide (20") spaces above a window done with the float foam, edges cut

with the long saw. The missing fourth

(& best) piece was in the car to show to people.

Wide (20") spaces above a window done with the float foam, edges cut

with the long saw. The missing fourth

(& best) piece was in the car to show to people.

Faraday Cabin Construction

Of course, all the above foam cutting and fitting is part of the cabin

construction. But it deserved its own title. Aside from that, I put in

some of the floor joists in the southwest quarter.

Of course, all the above foam cutting and fitting is part of the cabin

construction. But it deserved its own title. Aside from that, I put in

some of the floor joists in the southwest quarter.

An Approved Solar Collector System

I gave up waiting for the solar contractor to return to

the island and return my messages. Tho the web site was still up, I

wasn't even sure she still did it any more. After a less than thorough

web

search I inquired from "Solacity.com" in Ontario about getting a "7 KW

Solar Kit" -- twenty 350 watt solar panels with ten dual microinverter

grid ties, and all rail mountings & clamps, boxes and bits &

pieces. I went with a Canadian company offering a whole "kit" because I

didn't want to be missing needed parts if I ordered them individually,

or find some of the items couldn't get Canadian electrical code

approval. All being arranged, on the 31st I finally bit the bullet and

payed the 11,000 $ for the kit, on line with a credit card. Naturally

I'll be taking advantage of BC Hydro's 75% subsidy offered for new

rooftop solar installations where the local power grid is fed with

diesel generators.

Bandstra said they would handle the entire shipping from

Ontario to my place on Haida Gwaii. I dread to find out the cost. (Even

worse than I feared: 4500$!)

Gardening

(no report. Things are still growing under the LED lights inside and

I've had a couple of tiny cabbage and cauliflowers from the greenhouse.)

"SCABA" devices (Self Contained Arctic Breathing Apparatus)

I decided the "SCABA" (Self Contained Arctic Breathing

Apparatus) Looked like a nice piece of low-hanging fruit, and if I put

it off until summer I couldn't even test it. I cut twentytwo 8x8 inch

pieces of old coroplast and washed them.

I put them together and drilled holes for two bolts to

hold them together. There things got messier. After trying to fit some

rigid plastic cut from an old motor oil container, I taped pieces of

plastic bag onto the edges. But it wasn't much of a plan: breathe in

one hole and out the other by mouth. Evidently the corner between

'inhale' and 'exhale' needs to be really well sealed, because I could

feel my warm breath coming out both the 'in' and the 'out' edges. I

stopped.

In the meantime, while I worked it finally occurred to me to check on

line and see if such a thing already existed. There were some "heat

exchange masks" available and they had their enthusiasts. One said he

could actually wear lighter clothing in extreme cold because of the

body heat saved. But there was nothing that would hold a lungful of air

or separate the exhaled air from the inhaled as in real heat exchange

devices.

In the meantime, while I worked it finally occurred to me to check on

line and see if such a thing already existed. There were some "heat

exchange masks" available and they had their enthusiasts. One said he

could actually wear lighter clothing in extreme cold because of the

body heat saved. But there was nothing that would hold a lungful of air

or separate the exhaled air from the inhaled as in real heat exchange

devices.

Then I looked on Youtube and found a video from 2015 of a

young inventor who had done something very similar to my idea. Rather

than corolite he had wound a long strip of alume to form two adjacent

spiral air passages for 'in' and 'out'. And he had used an actual mask

(a gas mask) to fit to his face and put two one-way flaps in it for

'inhale' and 'exhale'.

My main concern about this construction is that

condensation could build up in the bottoms of the loops, freeze, and

block the 'out' air passage. In my design, the 'out' air goes down at

45 degrees with no twists or bends and can drip out the end. Still,

ideally one would want to try both designs and see if one actually

works better in practice in cold air. Small holes if needed could let

condensation drip out -- or even back into the inhaled air to moisten

it.

Cold Weather Mask Heat Exchanger (1st working prototype)

https://www.youtube.com/watch?v=hFA5sEzijH4

Inhale Exhale Heat Exchanger Test Results

https://www.youtube.com/watch?v=k1Q8WKGKDTg

He talked about how a finished product would be more

compact and better than his working prototype. Here I have finally

found an inventor who is a worse promoter of his designs than I am.

(Was I as inarticulate as that when I was his age? Maybe!)

So his design has (AFAIK) languished for a decade. Again I

suggest that there should be a government "Department of Progress" that

among other things can connect inventors of products with entrepreneurs

or businesses looking for something worth selling, while (unlike with

the present worthless patent system) giving the inventor something

worthwhile for his invention so that he has the financial freedom to

live and continue inventing. (Each invention is unique and so is each

inventor, so "contracts", "patents" or "agreements" would probably have

to be custom deals in each case but would be enforced by the

government, who would collect the royalties from every company making

use of the invention. Doubtless some "precedents" or other guidelines

would soon be established.)

[16-18th] I

finally looked at my own corolite stack again. The layers seemed a bit

spread open on the "inner" corner so I put through another bolt. Not

seeing an easy way to incorporate a mask with valves for what was only

going to be a simple test, I used some modeling clay, alume foil and

packaging tape, and just made two holes, one to breathe in and one for

out. So I had to shift it back and forth to use it and breathe through

my mouth.

[16-18th] I

finally looked at my own corolite stack again. The layers seemed a bit

spread open on the "inner" corner so I put through another bolt. Not

seeing an easy way to incorporate a mask with valves for what was only

going to be a simple test, I used some modeling clay, alume foil and

packaging tape, and just made two holes, one to breathe in and one for

out. So I had to shift it back and forth to use it and breathe through

my mouth.

Trying it outside in cold weather, once I had exhaled

through the "out" hole a few times, with my mouth and with my tongue, I

could feel the difference in incoming air temperature between the "in"

hole and just outdoor air. That's about the best that can be said. But

the general idea was demonstrated.

I could also feel that some warm air was coming out the

"in" side as I exhaled, and so surely cold air was coming in the "out"

side keeping it from being warmer. I figure only the top 1/4 of the

unit nearest my mouth was really working very well. Bigger manifolds

and better seals all around would surely have helped a lot.

But I'm leaning toward the spiral alume idea. Thin alume

has the best heat transfer and the spiral a large surface area. If I

was going to pursue it further, which I'm not.

Bulky as they will need to be to hold a lungful or two of

air going each direction, they might hang at the chest with a strap

from the neck. I'm sure there's a good fortune to be made producing

such units for the clothing stores in really cold climate places.

Someone will do it someday.

More Practical Magnetic Refrigeration?

I ran across a magnetic refrigeration system system that

looked more practical than others with helium gas designs, and

doubtless more practical than my 2016 design where the magnet would

pick up

a gadolinium wafer as it passed, then it would fall back, tossing it

back and forth between two

heatsinks. (TENews somethingorother)

This one ran flowing water through

gadolinium alloy particles in multiple chambers inside a rotating drum

containing

magnets. Each chamber had two

inlets and two outlets, with valves. When the magnet was passing and

heating the

gadolinium, the warmed water flowed toward the heat radiator. After the

magnet had passed and the alloy became cooled, the other pair of pipes

fed

the water toward the refrigerated section. If the exact configuration

of the water flow was shown, I didn't see it. It would make sense

that the chambers were thermally in series so that cooled water from

the first was further cooled in the second and so on. (The water would

doubtless be a closed loop and deoxygenated so as to not corrode the

rare earth metals it flowed through.)

Such a unit might be no more efficient than a compressor

based refrigerator, but it should be quieter. The modest effort

described only cooled a few bottles of wine. The video:

Domestic wine cooler operated by a magnetic refrigeration system

developed by Polo - UFSC

https://www.youtube.com/watch?v=wMUPdGRA9ck

But my bet is still on someone coming up with more

efficient Peltier modules for practical and reasonably efficient solid

state refrigeration. Quietest. That would make everything else obsolete

for kitchen fridges. ...still waiting.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Scattered

Thots

* I talked with one Craig at the recycling centre in DG. He said that

he used to have tinnitus, but that it was gone now. He also said he had

moved from a house to a boat at the wharf. There is electricity at the

wharf, but of course no high voltage lines (14,400V) nearby, and the

120V is run in conduct pipes ending in metal boxes - shielded - so any

electric power EMF field down on the boats would be miniscule. He uses

a diesel heater and batteries. He recharges the batteries at work, so

he probably has no AC power on his boat at all.

Strike up one more circumstantial evidence report that

everlasting tinnitus is caused by 60 Hz AC power EMF fields, but takes

a long time - days - to fade!

* Some people are excited about the idea of people going to and living

on

Mars. Personally I think that if people could actually get there

without

suffering from serious radiation sickness from "cosmic rays" long

before even arriving, the experience of being there would quickly

dampen enthusiasm. Within a day, a week, a month or a year - maybe even

a few

hours - most people would be saying "There's no place like home!" and

booking a return flight.

Robot spacecraft are exploring the solar system better

than manned missions possibly could and such projects will increase and

improve. And perhaps with the "Dragonfly" drone to Titan and the ESA

probe to orbit

Ganymede space scientists will notice that these worlds already

glimpsed by probes are both covered with life. (...And then kick

themselves for having completely glossed over all the unexpected and

fascinating evidence and images and not being curious enough to

decipher them!)

Then someday we will be able to make and control the

powerful magnetic fields needed to deflect the "cosmic rays" health

hazard as well

as to navigate through space. Who knows, that may yet be within my

lifetime. No one had ever launched a satellite into Earth orbit when I

was born and a trip to Pluto was expected to take 100 years. The

transistor had recently been invented and the stupendous strides in

electronics have given us the internet and world-wide connectivity

between individuals. I certainly never thought I would see such things

happen.

Then we will visit. Maybe even just one time, like the

Apollo moon project. Aside from the stupendous excitement of new

discovery and the feat of getting there, there's probably no sufficient

real reason to stay. If there is, it's probably just the excitement of

exploration, scientific research, or for a small team of people try to

find and mine

exceptionally rare minerals. (Who wouldn't want a kilogram of osmium or

iridium? I already have a kilogram of dysprosium. Completely useless to

me. oops.)

ESD

(Eccentric Silliness Department)

* Remember when scuba was

S.C.U.B.A., laser was L.A.S.E.R. and NASA was N.A.S.A.? Then sometime

(1960's IIRC) everybody finally got fed up with putting the dots on the

ever

growing number of abbreviation-words and quite suddenly they became

"acronyms". Then some of them weren't even capitalized any more and

people have forgotten what the letters stand for.

* A.M.: "ante meridian" The time before the sun reaches its zenith.

Somehow this has become "the time before the government tells you it's

12 o'clock" - even if it's 2 hours before actual noon.

* Everybody always overexaggerates everything way, way too much.

"in depth reports"

for each project are below. I hope they may be useful to anyone who

wants to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought of and not tried... and even of how not to do something - why

it didn't work or proved impractical. Sometimes they set out inventive

thoughts almost as they occur - and are the actual organization and

elaboration in writing of those thoughts. They are thus partly a diary

and are not extensively proof-read for literary perfection,

consistency, completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Finally:

Unipolar

"Electric Hubcap" Motor Construction !

Resuming Long Delayed Project

Having thought of making & routing a prototype motor body out of

wood, instead of molding it from PP or PP-epoxy, the big bottleneck to

constructing my long planned unipolar motor was

bypassed.

That seemed like a great reason to abandon rewiring the

old, traditional "clunky" design Baldor induction motor to 36 volts

before going any farther. It's not just the motor: either motor will

have to have a new motor controller wired in and will have to be

mounted into the car and connected to the wheel with a planetary

reducer. All this work would have to be redone in order to change to a

different type of motor with quite different dimensions. Of course, I

could put the new motor in the Toyota Echo instead and turn it into a

hybrid. But either way I might never get to the second project.

So now that it looks doable I would much rather work on

the "ultra efficient" axial flux, BLDC motor design Instead rather than

in addition, later. There's been far too much "for later" on this motor!

Now it seems there's no physical difference between this

as a regular

BLDC motor and my planned unipolar BLDC motor. It's just in how the

coils are wired, which is fairly easy to change. So I still have two

options: make the unipolar motor with the special controller for it, or

if that gets to be too much or isn't working out well, buy a typical

500 amp, 36 volt BLDC motor controller (Kelly controller?) and rewire

it for that. (If this motor can hit about 20 peak horsepower at 3500

RPM, that's a little over 400 amps at 36 volts.)

Later I found Polypropylene-Copolymer (PPC) in 1/2" thick

sheet. I could rout it the same way as wood and it's an even better

choice

of material for the housing than PP.

Motor Features

* Robust automotive 'trailer wheel' rotating parts with robust, low

friction cup & cone bearings on one inch 4140 HTSR steel shaft. 4

inch,

four stud bolt pattern on both rotor and stator. "Wheel hub" with cup

& cone bearings (center of

stator) is turned in a lathe to a shorter than usual length as required

to fit. Any length axle shaft may be employed as required.

* Polypropylene-copolymer (PPC) housing is strong, tough, dimensionally

stable and relatively high temperature (100°C, 150° peak). It will be

made from

flat 1/2" sheet PPC material as a 15 x 15 x 5.5" cube, cut and CNC

router

milled shapes as required. (A metal casing,

except on the face behind the rotor, would create electromagnetic

interference with the rotor magnets, causing heat and inefficiency.)

* A 12.68" (322mm) rotor and stator magnetic outer diameter to provide

huge torque. The

large diameter also distances the rotating magnets sufficiently from

the steel center assembly.

* 12 stator coils with 2" O.D. x 1" tall iron powder toroidal cores and

27

turns of #11 AWG magnet wire. The wire will be epoxied to the cores

with

ilmenite impregnated epoxy, with extra coats to thicken the ilmenite on

the outside. The ilmenite (iron-titanium oxide mineral, ferromagnetic

plus paramagnetic)

completes the magnetic path so each coil is an

independent unit. In most motors all the coils have to mount on a

common

metal backing with magnetic paths going between coils. This inevitably

ends up as a less-efficient complete

assembly of all coils including the backing, made of die cut laminated

iron, for

which costly custom punches and dies are required. I first tried rutile

(titanium oxide paramagnetic mineral, TE News #36), which helped, but

ilmenite proved even more effective. (TE News #38,46,54.)

* 8 powerful magnet poles (40 magnets!) in Hallbach configuration. With

some 'sideways' magnets for Hallbach, most of the flux comes out on the

"business" face of the rotor facing the stator coils. Owing to the

little flux coming out the back, the rotor is a 1/8 inch steel plate

instead of 1/4 inch or thicker, making it lighter. Main magnets are 2 x

1 x 3/4 inches (here as a stack of two @ 3/8 inch). Hallbach magnets

are 50 x 20 x 10 mm, set on edge between rotor magnet poles. (20mm is

just over 3/4 inch.) All magnets are high strength, N48 or N52. With

roughened surfaces and a pool of the best epoxy on the rotor going half

way up the magnets, high RPM's should be safely attainable.

* The flux gap between rotor and stator is about 1/2 an inch, as is

common in axial flux motors. This allows a protective PPC plate between

them making separate rotor and stator compartments.

* A Hall Effect magnetic sensor assembly detects rotor magnet positions

for the

unipolar motor controller.

* A centrifugal fan spins behind and with the rotor, drawing air though

openings

in the rotor end housing and blowing it across the motor. Holes around

the

coils in

the other face force the cooling air to exit past the coil wires and

through the core centers for best cooling.

* Unipolar operation runs each coil in only one direction: north OR

south. Iron remagnetization (hysteresis) losses are avoided and the

controller is

theoreticly less prone to destructive "shoot-though" currents. 1/3

of the coils are energized at a time instead of 2/3, with a modified

rotational sequence. There are six phases instead of three, each phase

powering opposite-side pairs of coils for balanced magnetic attraction

between rotor and stator. (This is the reason there need to be 12 coils

rather than the nine or six of my previous motors. Other than that I

want it to power a car anyway.)

* Some expected ratings are 3500 RPM max., 15 KW (20 HP) peak (= 414

amps

at 36 volts), peak efficiency over 95%, full load efficiency 75%,

torque 50-60 foot-pounds.

Design Considerations

The rotating assembly was previously done in steel with

trailer wheel type parts, and the magnet rotor plate was cut and bolt

holes drilled. The case and

assembly

would attach that at the coils end with the four bolts to the

cut-down "trailer wheel" hub.

The rotating assembly was previously done in steel with

trailer wheel type parts, and the magnet rotor plate was cut and bolt

holes drilled. The case and

assembly

would attach that at the coils end with the four bolts to the

cut-down "trailer wheel" hub.

It seems to me that while the motor spins in a circle, the

case could be a square box. That should make making and mounting it

simpler, and metal bolts and pieces could attach in the corners,

farther away from the spinning magnets to create the minimum of

electromagnetic drag. Plywood PPC should make for best

excellent dimensional

stability.

The stator end that attaches the rotor assembly needs to

be very stiff, so I think two pieces of plywood epoxied together for

that, maybe 1/2 inch plywood making an inch. (or is it 12mm making 24mm

these days? Measure and size accordingly!) Then, the four outer sides

and the rotor end simply form an enclosure, screwed or bolted to the

one inch "main plate". They too can be 1/2 inch plywood. The end of the

box will have holes toward the center to allow air in, as there will be

a fan blades rotor right behind the magnet rotor to drive a powerful

air flow around the rotor through to the coils end, where the air will

exit near the wires and cores. (While the end behind the magnet rotor

is the one piece that could be a steel plate, there is no point because

with no attachment except to the sides, it takes no stresses and won't

even get warm. Sheet metal would probably vibrate and make noise.)

346mm should be large enough for the inside of the square

box, so (w. 12mm plywood), 370mm (14.6 inches) outside dimensions. I

don't want to make it any bigger than necessary as it'll be hard to fit

that large a diameter under the hood. And the larger it is, the more

the angle on the CV shaft joint while driving straight.

Only one piece of the end plywood, and an inside plate (3/8 inch?) for

the inside ends of the coils need to be fitted out on the CNC router

table with "mounting pads" for the toroidal cores and air spaces around

the coil wires.

I decided I would have to use the iron powder toroidal

cores despite their 70°C max rating and similar rating for the epoxy to

"glue" the coil wires on. One change from my previous motors will be to

mix the ilmenite into the epoxy so all the wires will be coated in

between and direct to the core piece as well as an extra coat/layer or

two around the outsides. Hopefully that will further improve magnetic

performance as well as make sure none of the ilmenite coating flakes

off as has been the case with mixing "liquid rubber" and ilmenite for

my previous coils.

[12th] I checked over and adjusted the gcode file to route out the

magnet holder jig/template. (I wrote it a couple of years ago when the

rotor disk was cut, by CNC plasma.) I found a sufficient piece of HDPE

to

make it from - a plastic breadboard I bought a decade ago for just such

a purpose. (What a junk collector I am. Sometimes it pays.)

Motor Plywood Body Assembly

[13th] I bought a piece of 12mm plywood to cut the motor body parts

from, and I cut the outer end plate, 370mm square. I got the

inspiration to "skin" the unit with epoxied PP cloth. I still might

paint that with high temperature paint on the stator inside surfaces.

In fooling around fitting things I had been using trailer

stub axles, but now I realized that the best combination would simply

be a length of one inch round machine shaft (4140 HTSR steel) with a

cut-down trailer wheel hub, and a "wheel bolts pattern" four inch

flange

welded to a one inch I.D. "weld on hub". Too simple! (except for the

welding. ug.) The only thing the stub axle had going for it was that

the flange was already welded to it. Other than that it was heavier,

only so long, and

would be harder to turn the end to 24mm on a lathe.

In fooling around fitting things I had been using trailer

stub axles, but now I realized that the best combination would simply

be a length of one inch round machine shaft (4140 HTSR steel) with a

cut-down trailer wheel hub, and a "wheel bolts pattern" four inch

flange

welded to a one inch I.D. "weld on hub". Too simple! (except for the

welding. ug.) The only thing the stub axle had going for it was that

the flange was already welded to it. Other than that it was heavier,

only so long, and

would be harder to turn the end to 24mm on a lathe.

[14th] I cut the inner

piece of plywood; the one that will need to have

the CNC routing to make "pads" for the toroid coils, including the bolt

and center holes, and screwed the two pieces together. (epoxy together

later.) I figured out a fit that worked with the existing parts, adding

a shaft collar (found - Yay! - with a search to the very back of an odd

drawer) and some spacer washers on the shaft. The

stator's "trailer wheel hub" wasn't ideal, with the two bearings being

needlessly close together, but since the motor is to drive a planetary

gear and there'll be no forces pushing to one side, it should be fine.

The fan

will be made from a separate circle of sheet metal with the fins bent

out from it, behind and flush against the magnet rotor.

[14th] I cut the inner

piece of plywood; the one that will need to have

the CNC routing to make "pads" for the toroid coils, including the bolt

and center holes, and screwed the two pieces together. (epoxy together

later.) I figured out a fit that worked with the existing parts, adding

a shaft collar (found - Yay! - with a search to the very back of an odd

drawer) and some spacer washers on the shaft. The

stator's "trailer wheel hub" wasn't ideal, with the two bearings being

needlessly close together, but since the motor is to drive a planetary

gear and there'll be no forces pushing to one side, it should be fine.

The fan

will be made from a separate circle of sheet metal with the fins bent

out from it, behind and flush against the magnet rotor.

Later I cut the sides and back end - the magnet rotor end.

Even in these small sizes the plywood was visibly warped. Ug.

Rotor to "Weld-On Hub" Welding

[16th] To weld

the one inch hub to the "wheel" rotor plate, I was going

to ask someone who would know if he knew any good welders, but he

didn't come to the cafe that day. I went across the street to the

garage but no one was around. (No one around and doors wide open. Who

would dare do that in most places these days?) So I went home and

welded it myself. (No one has seen such ugly welding as mine! But I got

lots of steel on it. It won't break.)

[16th] To weld

the one inch hub to the "wheel" rotor plate, I was going

to ask someone who would know if he knew any good welders, but he

didn't come to the cafe that day. I went across the street to the

garage but no one was around. (No one around and doors wide open. Who

would dare do that in most places these days?) So I went home and

welded it myself. (No one has seen such ugly welding as mine! But I got

lots of steel on it. It won't break.)

It seems I didn't get it quite straight. But with a very

thin shim under one side it ran straight. It also wobbled in and out,

which turned out to be play in the bolt holes. I'll have to figure

something out for that.

The next day I ran across a hacked-up "disk brake rotor"

with a one inch hub center in my junk. I would only have had to drill

the four

holes in it (without play!) for the bolts. It would have been perfectly

straight, and lighter. There's often more options than one suspects.

Gcode Program to Route Stator

[15th] I started on the file for the routing of the plywood stator

plate, using a sreadsheet to work out all the sines and cosines for a

twelve coil circle. I included many 6mm ventilation holes, inside the

iron powder toroid core centers, under the coil wires outside of the

core and a few more between coils and toward the center of the motor.

(6mm is the size of the router bit as well as being a bit too small to

stick a pencil into.)

As I spent a couple of hours on a number of laborious

trigonomic calculations and their conversion into G-code I couldn't

help but think there's CAD programs to generate .gcode files more

easily. Oh well, there's a learning curve to those too, and I make new

motor

designs rather rarely. There's one such program I never got very

familiar with and I forget how to use it between designs, so the

learning curve - and the install on another computer - seems to be

"each time" instead of "once". And once I had the design, last time I

couldn't find a program to convert its .dxf file to .gcode. So forget

it! I'll still need to route it onto a scrap piece and probably make

adjustments until I like the result.

[16th] Continued. I got as far as test running the gcode program on the

router and being pretty happy with the result. I thought it would need

more ventilation holes. I ended up with 16 at each coil position, four

in the donut center and 12 around the outside under the wires. That's

192 holes, in the best places to cool the coils. Enough?

Making Magnet Placement Jig

[19th] I did

some final adjustments to the magnet rotor gcode and did a

dry run, with the router above the table and turned off. It seemed to

me it was all somewhat too small. I found in the router configuration

the default "200" for the "turns-per-inch" of all axes. Hadn't I

adjusted that, again around two years ago? I remember laboriously

measuring how far it would move when I told it to go (eg) "6 inches".

When I was adjusting I had ended up making three configuration files.

In the third one I found I had been changed to "324.0". I changed the

file I was presently using and tried again. It looked much better, so I

routed a piece of 1/4" plywood. The bolt holes were just a bit far from

the center. The outside dimension was 13.68" instead of 13.4" (or

somewhere close to those figures). Okay (whatever they exactly were):

13.4/13.68 = 313.368. I put that in and assumed it would be the correct

figure.

[19th] I did

some final adjustments to the magnet rotor gcode and did a

dry run, with the router above the table and turned off. It seemed to

me it was all somewhat too small. I found in the router configuration

the default "200" for the "turns-per-inch" of all axes. Hadn't I

adjusted that, again around two years ago? I remember laboriously

measuring how far it would move when I told it to go (eg) "6 inches".

When I was adjusting I had ended up making three configuration files.

In the third one I found I had been changed to "324.0". I changed the

file I was presently using and tried again. It looked much better, so I

routed a piece of 1/4" plywood. The bolt holes were just a bit far from

the center. The outside dimension was 13.68" instead of 13.4" (or

somewhere close to those figures). Okay (whatever they exactly were):

13.4/13.68 = 313.368. I put that in and assumed it would be the correct

figure.

I was a bit concerned by how close together the magnets

are at the inner ends. There wasn't much plywood between them holding

the jig together, and a couple of the crappy plywood "leafs" broke off.

I'll hope the actual plastic jig (that epoxy won't stick to) is

sturdier stuff. The spacing of the magnets of course had determined the

smallest diameter rotor I could get away with, and when I had learned

of the superior Hallbach configuration I had had to increase it to hold

the extra magnets. Luckily that was just days Before I had the rotor

cut with a plasma cutter. So nothing was lost! (Just as well - later I

discovered that the stator coils as well needed the extra space.) The

Hallbach rotor is

1/8" steel instead of 1/4" because of the small magnetic flux capacity

needed behind the magnets, so even with a slightly increased diameter

and eight added 1/2 x 1/2 x 2 inch magnets, it's lighter.

In checking it out, I

noticed that unlike smooth steel, it

was very hard to drag a 1/2 x 1 x 2" magnet across the rotor with its

surface rust. I could hardly move it. No doubt the epoxy would adhere

really well to the roughness. It would be nice to be able to spin this

motor with its huge diameter up to around 3500 RPM without fear that

the magnets might break loose. High torque, good speed... that might

give it a peak of around 20 horsepower. I decided to just rub off any

loose rust with a cloth and make it no smoother.

In the almost 8 years since I moved up here this is the

first time I've ever actually successfully routed something. I'm sure I

would have been far better off to have abandoned (or never acquired)

this router table, working fine tho it was mechanicly, and bought a new

one complete with stepper motor drivers, collet chucks and bits that

fit each other, computer and everything all set up and ready to go -

maybe even with some good CAD-CAM software installed - off Aliexpress.

IIRC they started at well under a thousand dollars.

[20th] I drilled a couple of holes in the plastic and screwed it to the

table. Then I tried to rout it. The first time it was obviously trying

to cut too fast. The router jammed. I carefully re-homed it to where it

had drilled the first five holes and tried again. I slowed down the

feed speed, then way down, but got a similar result twice more. At

least the router bit didn't break. Then I thought the plastic was just

too tough and it would have to be milled a little at a time, say 3mm

depth 4 times until it had completed the 11mm thickness. But I ran out

of time with other things to do.

[21st] I did

that. The chief problem seemed to be that no matter how

little or much depth was being cut, the plastic melted almost back into

place as the router went by. I surmise that it is turning much too fast

even for a little 6mm diameter bit, but this router has only one speed.

What a cheap piece of crap for an otherwise nice CNC table! Half way

around, I guess as the bit warmed up - it started melting the plastic

into blobs. Where it came near the edge of the piece, a big blob

actually went over the edge and dripped down over the side. A little

farther on it got stuck - the router stalled! Ouch! Apparently I'm not

cutting plastic with this crappy router. I knew from the moment I saw

it that I didn't like it with its tiny body diameter and no speed

control, but only now that I try and use it are my worries confirmed.

It occurred to me afterward that I could have paused the program,

turned it off and let it cool. But I didn't know it was going to fail.

And that was only the first, painfully slow, pass of four or five! What

were my chances of getting a good finished jig?

[21st] I did

that. The chief problem seemed to be that no matter how

little or much depth was being cut, the plastic melted almost back into

place as the router went by. I surmise that it is turning much too fast

even for a little 6mm diameter bit, but this router has only one speed.

What a cheap piece of crap for an otherwise nice CNC table! Half way

around, I guess as the bit warmed up - it started melting the plastic

into blobs. Where it came near the edge of the piece, a big blob

actually went over the edge and dripped down over the side. A little

farther on it got stuck - the router stalled! Ouch! Apparently I'm not

cutting plastic with this crappy router. I knew from the moment I saw

it that I didn't like it with its tiny body diameter and no speed

control, but only now that I try and use it are my worries confirmed.

It occurred to me afterward that I could have paused the program,

turned it off and let it cool. But I didn't know it was going to fail.

And that was only the first, painfully slow, pass of four or five! What

were my chances of getting a good finished jig?

I had a look at my DeWalt woodworking router. It had a

variable speed dial. It would have to have a mounting made to attach it

to the CNC table carriage, and I would have to recalculate all the

dimensions again for a .25 inch bit instead of 6mm. This is definitely

a setback. As long as I don't move the piece of plastic on the CNC

table I can probably manage to have it cut in "exactly" the same places

again and haven't lost it. It's my only piece and there's nowhere to

buy another one around here.

I took the crap router out of its cradle (if that's the

right word) and noticed that the DeWalt's base would fit in it if I

chopped off a bit of the bottom flange on each side and at the back,

and drilled four holes in the cradle bottom to match the DeWalt's

threaded bolt holes. After the cutting, careful drilling and then a

bunch of filing anyway to get the holes to line up, it seemed to

fit nicely. Much simpler than making a whole new "cradle".

Then problems started appearing. Being held at its bottom

instead of in the middle, the carriage wouldn't lower down anywhere

near the worktable. In fact, the router bit couldn't go below the

carriage bottom. I finally made a plate to extend the router cradle

down several inches. But the vertical carriage holder stuck into the

path. So I used both the original plate, as a spacer, and the new one.

And

my off-position holes weren't the first ones on this machine: the

original plate fit better one way around than any other way. I used

1/4" bolts to hold the cradle to the new plate. The ones I could see

just cleared the bottom of the carriage. The ones on the other side hit

it and jammed. I had to take it apart again and redo that side with

flat head (AKA countersunk) bolts. (It turned out a screw was loose at

the bottom. It fell right out later.)

Then problems started appearing. Being held at its bottom

instead of in the middle, the carriage wouldn't lower down anywhere

near the worktable. In fact, the router bit couldn't go below the

carriage bottom. I finally made a plate to extend the router cradle

down several inches. But the vertical carriage holder stuck into the

path. So I used both the original plate, as a spacer, and the new one.

And

my off-position holes weren't the first ones on this machine: the

original plate fit better one way around than any other way. I used

1/4" bolts to hold the cradle to the new plate. The ones I could see

just cleared the bottom of the carriage. The ones on the other side hit

it and jammed. I had to take it apart again and redo that side with

flat head (AKA countersunk) bolts. (It turned out a screw was loose at

the bottom. It fell right out later.)

Finally I realized that the power switch on the router was

hard against the plate. And it must have been held in its middle

position because I tried to simply leave it On and use the switch on a

power bar, but it wouldn't run. At that point the day was done -

overdone because I was neglecting everything else I should be doing. So

much for a two hour morning job!

[22nd] One more time... take apart and

put back together, this time

cutting a big square out of the new plate to accommodate the On-Off

switch. (Oops no pictures)

The other half of the problem was the trig. Then trial runs again

and then hoping the previous routing's gouges and blobs of plastic

wouldn't mess things up. The 6mm bit wouldn't tighten down in the

DeWalt's 1/4" collet chuck - one may hope, but not a surprise. It

looked like the other router's 6mm collet was the same O.D. and would

fit in the DeWalt's housing. But the collet in the DeWalt was locked

into place! It would spin, but even tapping it with a hammer wouldn't

push it out. Crap! And the threads were wrong for the other router's

collet holder. I'm not a fan of either the imperial or the metric

system, but mixing them up 50 years after Canada supposedly went metric

sure makes a lot of trouble. Prices in the grocery are still in pounds,

or "bilingual". 12mm plywood is 4 by 8 feet in size.

Then I looked on line for a 6mm router bit with a 1/4"

shank. Sure enough, they have them. (Why did I never search two years

ago for a 1/4" bit with a 6mm shank?) I ordered a few, but of course

they will take time to arrive.

So I redid the gcode for 1/4 inch router bit. While I was

doing that and thinking about how hard it seemed to be to rout that

dense, 12mm thick piece of HDPE plastic, I came up with the

idea to make a thinner but still substantial jig by melting down a

couple of old 5 gallon HDPE bucket pieces in one of my plastic molds in

the kitchen oven. Or some of my odd scraps or router shavings of

UHMWPE? (I saved them in a bucket for something like this!) Maybe about

4-5mm thick? The big disk mold should be good!

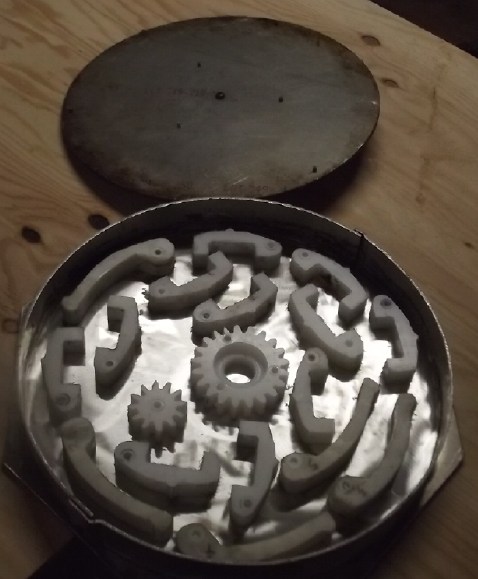

[23rd] UHMW - ultra high molecular weight polyethylene. Millions of

atoms per polymerized molecule. I didn't really think about it...

polyethylene is polyethylene, right? But as I think about it, I had

never tried remelting UHMW before. I thought melting it would be much

the same

as HDPE - high density polyethylene.

I

used some pieces from previous experiments out of the

bucket, thinking that shavings might end up full of air bubbles. First

I repolished the bottom of the disk mold because there were bits of

PP(?) stuck to it from previous ropes off the beach. (I suspect some of

them weren't PP.) I put a concrete brick under the oven rack to help

support it. Then the mold and about 30 pounds of weight on top, that

being my hazy memory of a good amount for this mold. From TE News #178

I found the right temperature was around 400°F. I set the oven to that

and put it on for an hour. After an hour the lid hadn't sunk down much

if at all. I put it on for another hour. UHMWPE Does melt at the same

temperature as HDPE, doesn't it?

I

used some pieces from previous experiments out of the

bucket, thinking that shavings might end up full of air bubbles. First

I repolished the bottom of the disk mold because there were bits of

PP(?) stuck to it from previous ropes off the beach. (I suspect some of

them weren't PP.) I put a concrete brick under the oven rack to help

support it. Then the mold and about 30 pounds of weight on top, that

being my hazy memory of a good amount for this mold. From TE News #178

I found the right temperature was around 400°F. I set the oven to that

and put it on for an hour. After an hour the lid hadn't sunk down much

if at all. I put it on for another hour. UHMWPE Does melt at the same

temperature as HDPE, doesn't it?

It didn't help. Then I let it cool (over an hour) to where

I wouldn't burn something or myself and opened it. Some of the pieces

around the edge were a little deformed; that was it. I guess UHMW needs

a higher temperature? 500°F had scorched the HDPE at the time of TE

News #177. I reassembled it and put it back on for an hour at 450°.

That didn't seem to help either.

Then I looked it up on line. Supposedly it melts around

270°F! I upped the oven to 475°F anyway, for an hour. If it melts at

270°, it's sure one awfully viscous liquid! Maybe it needs 300 pounds

of weights instead of 30?

When I took it

out, some pieces had sagged but others

hadn't even deformed. They all looked pretty scorched. So I went back

on line and found this: "Unlike most thermoplastics, UHMW plastic does

not become a liquid when heated above its "melting point". Because of

its high melt strength, it can be handled and shaped above its

crystalline melting temperature of 265°F." Yep, is is indeed an

"awfully viscous liquid". It would seem then that it didn't need

anything like such a high temperature, but it does need hydraulic

pressure or that "300 pounds" of weight to form it. My simple pan

molds, and my oven, couldn't possibly take that sort of stress. I guess

I won't be trying UHMW again. Not without a new plan, anyway. At least

it didn't have an odor - or burn - when heated so hot.

When I took it

out, some pieces had sagged but others

hadn't even deformed. They all looked pretty scorched. So I went back

on line and found this: "Unlike most thermoplastics, UHMW plastic does

not become a liquid when heated above its "melting point". Because of

its high melt strength, it can be handled and shaped above its

crystalline melting temperature of 265°F." Yep, is is indeed an

"awfully viscous liquid". It would seem then that it didn't need

anything like such a high temperature, but it does need hydraulic

pressure or that "300 pounds" of weight to form it. My simple pan

molds, and my oven, couldn't possibly take that sort of stress. I guess

I won't be trying UHMW again. Not without a new plan, anyway. At least

it didn't have an odor - or burn - when heated so hot.

I guess I should use HDPE

from old 5 gallon buckets per my

first thought. Another website differentiates between them that

HDPE "is easily remoldable", even ten times. At least I know it seems

to melt down and form okay at 400°F.

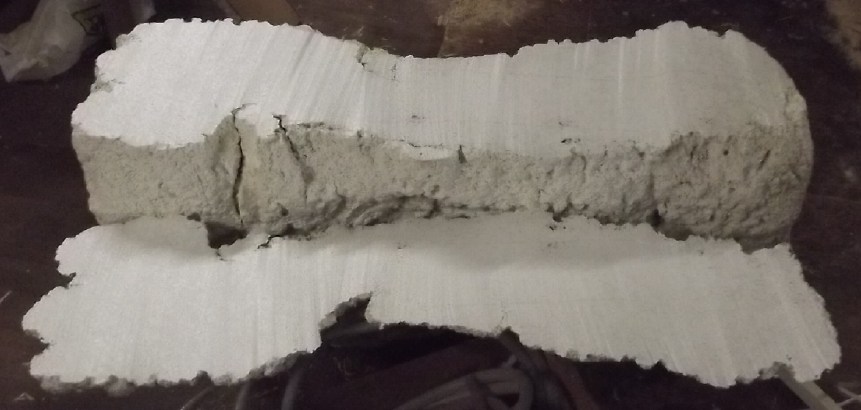

[24th] I

molded a disk with HDPE - A black 5 gallon bucket and a yellow lid

for the same type. I put the two colors in somewhat randomly. I tried

cutting the bucket with the foam cutter. It cut slowly and made smoke.

That might have been all right, but the cut sealed itself up again

behind the hot wire. It was a fair struggle with chisel to pry it

open and extract the cutter. After that it was the skillsaw and then

the radial arm saw to get the curved pieces down to some semblance of a

reasonable size to fit in the mold.

[24th] I

molded a disk with HDPE - A black 5 gallon bucket and a yellow lid

for the same type. I put the two colors in somewhat randomly. I tried

cutting the bucket with the foam cutter. It cut slowly and made smoke.

That might have been all right, but the cut sealed itself up again

behind the hot wire. It was a fair struggle with chisel to pry it

open and extract the cutter. After that it was the skillsaw and then

the radial arm saw to get the curved pieces down to some semblance of a

reasonable size to fit in the mold.

I wanted to put the clamps on the sides of the mold, but

the lid wouldn't close down to where the sides were. If I put the

clamps on the lid wouldn't fit in and press down on the plastic as it

melted.

I left it in the

oven at 400°F for maybe around 90 minutes,

returning after 20 or 30 to push the lid down. I had intended to put

the clamps on at this point, but I decided not to bother. This led to a

lot of dripping HDPE oozing out the edges. (I didn't return when it

turned off, so I don't know how much longer it was in. The HDPE was

definitely

well melted. It came out 6mm thick at one side and 15mm at the other.

Ideally it should have all been about 6mm. Obviously I used way too

much plastic - maybe 3 times too much. The 6mm minimum depth is set by

the screws in the lid hitting the bottom plate, otherwise it might have

been vanishingly thin on one side and even thicker on the other. (If I

had wanted a piece this thick, I would have used longer screws.) I did

a lot of cutting with scissors both left and right handed to get all

the oozed out plastic off from around the edges.

I left it in the

oven at 400°F for maybe around 90 minutes,

returning after 20 or 30 to push the lid down. I had intended to put

the clamps on at this point, but I decided not to bother. This led to a

lot of dripping HDPE oozing out the edges. (I didn't return when it

turned off, so I don't know how much longer it was in. The HDPE was

definitely

well melted. It came out 6mm thick at one side and 15mm at the other.

Ideally it should have all been about 6mm. Obviously I used way too

much plastic - maybe 3 times too much. The 6mm minimum depth is set by

the screws in the lid hitting the bottom plate, otherwise it might have

been vanishingly thin on one side and even thicker on the other. (If I

had wanted a piece this thick, I would have used longer screws.) I did

a lot of cutting with scissors both left and right handed to get all

the oozed out plastic off from around the edges.

I was however going to try routing it to make the magnet

jig.

[January 26th]

I tried again to route the original piece of HDPE. I

tried cutting part way through but concluded that the only way it might

work was cutting all the way through at once. This time the CNC table

ran the course, but even with the router on its lowest speed the

plastic melted back together behind the cut and it was a disaster. I

cut off the piece but it was clear that it wasn't going to clean up

nicely in any length of time I wanted to devote to it. And already one

leaf had broken off the jig.

[January 26th]

I tried again to route the original piece of HDPE. I

tried cutting part way through but concluded that the only way it might

work was cutting all the way through at once. This time the CNC table

ran the course, but even with the router on its lowest speed the

plastic melted back together behind the cut and it was a disaster. I

cut off the piece but it was clear that it wasn't going to clean up

nicely in any length of time I wanted to devote to it. And already one

leaf had broken off the jig.

I had only routed UHMW before, not HDPE. I had thought it

would be the same, but considering how differently they behaved in a

mold in the oven, I figured it was the material: HDPE couldn't be

routed except at a router speed slower than even my adjustable router

would

go. Hmpf! That meant that the new piece I had molded wouldn't work

either.

I could buy

some very small pieces of UHMW from just one store

on AliExpress. One arguably just big enough to "make do". And wait

weeks

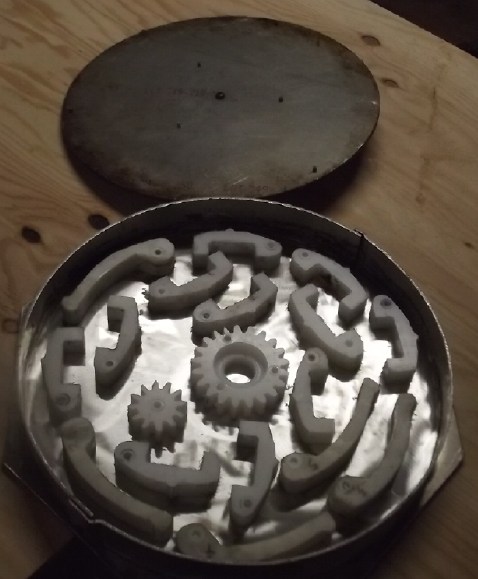

for it to come. I took an earlier molded disk of polypropylene (from

ropes off the beaches) and tried that. It Looked the same as the HDPE,

but the chaff clogging the gaps behind the cutter pushed out easily,

and when it had run the circle, the outer ring dropped away. Now the

only problem is that epoxy seems to adhere to PP -- at least, to PP

fabric. But I was just reading something on line about how the fabric

fibers

behave differently from the solid block material. One website says you

can epoxy PP, another says it won't stick. I hope I won't have to

chisel it off the rotor once I have the magnets on!

I could buy

some very small pieces of UHMW from just one store

on AliExpress. One arguably just big enough to "make do". And wait

weeks

for it to come. I took an earlier molded disk of polypropylene (from

ropes off the beaches) and tried that. It Looked the same as the HDPE,

but the chaff clogging the gaps behind the cutter pushed out easily,

and when it had run the circle, the outer ring dropped away. Now the

only problem is that epoxy seems to adhere to PP -- at least, to PP

fabric. But I was just reading something on line about how the fabric

fibers

behave differently from the solid block material. One website says you

can epoxy PP, another says it won't stick. I hope I won't have to

chisel it off the rotor once I have the magnets on!

[27th] I realized that if I

mounted the

jig a little off the rotor with washers on the bolts, it should get no

epoxy on it

to stick it to the rotor. Or at least not much. So the PP

jig should work! That hurdle finally overcome, it was time to epoxy

magnets onto the rotor. First, check them out... Plenty of 1 x 2 x 3/8"

magnets. Not a lot of 1 x 2 x 1/2" left, but plenty for the eight 1/2 x

2 x 1/2 sideways magnets to make it "Hallbach" configuration.

Especially as I was cutting four in half to make the eight.

Then I started thinking 3/8" magnets were a little thin.

The

magnetic

field

wouldn't be as deep as with 1/2". Would stacking them up to make 3/4"

be too thick? We want TORQUE. Torque comes from FLUX. Then I'd have to

use the full size 1 x 2

x 1/2" ones on edge for the sideways ones? But then unless I cut them

down to 3/4", they'd stick out 1/4" above the others. Possible with

axial flux's wide flux gap, but probably better if they don't stick

out. Or should I cut them as 1/2" tall after all? Then they'd be 1/4"

shorter than the others. Would that provide sufficient "Hallbaching"

flux? Considering the flux 3/4" thick will have already, I figured that

would

be "good enough".

So, next job: cut four magnets in half.

Then check out TE News #162 where I remember I had hit on

a more

secure way to glue the magnets to the rotor. It was to roughen the

surface of the rotor and of the magnets so the epoxy has a super grip,

and to put lots of epoxy around the magnets, 3 or 3 coats. This would

include roughing up all sides of the magnet except the top, and if two

are to be stacked, to also rough the top of the lower one. The rotor I

figured was already rough with surface rust. The epoxy should really

grip

that. All I did to it was rub it with a cloth to remove loose rust.

There wasn't much - the cloth just looked a bit orange.

[27th] Cutting supermagnets isn't

recommended... but. They're to tough to cut with anything but a zip

disk. And tedious with that. Since I want them to work, I can't

overheat them. That means cutting a stroke, waiting a moment for the

heat to diffuse from the cut into the rest of the magnet, doing this a

very few times, and then leaving it for ten minutes for the whole

magnet to cool. I may be being overcautious, but that's how I'm doing

it. And they're still almost bound to demagnetize some right by the cut

line.

I split one magnet, and then thought, "Why am I doing 1/2

measures? Why not just order some 2 x 3/4 x 1/2" on line and wait for

them to arrive?" But when I looked, there weren't any that size. I

could have made them up from 3 or 4 thin ones that were 2 x 3/4".

Sanding off all those faces (to roughen them) and then epoxying them

together sounded as tedious as what I was doing. And I would have to

wait for them to ship. I guess I should slice eight of the "regular" 2

x 1 x 1/2" down to 2 x 3/4 x 1/1". Twice as much tedium.

Then I looked on AliExpress.com . There were more

sizes, but they were all metrick. There were some 50 x 20 x 10mm - okay

for length and only slightly tall (.787" instead of .75"), but pretty

skinny (.394" instead of .500"). N35 wasn't very strong... wait, more

searching found some N52. That convinced me. FLUX, TORQUE! They would

be loose side

to side in the slots but if I glued them on first they wouldn't try to

flip over. Of course now I have to wait a month or so for them to

arrive. At the rate I'm going I can work on the stator for a month. Any

"spare" time I have I can get the faraday cabin farther along.

[28th] I

decided to put the first layer of magnets on anyway, with some

spacers to hold the positions of the sideways magnets. If I need to

I'll clamp those down until the epoxy sets. So I spent the

day sanding the slick epoxy coating on all six sides of 16 magnets with

#120 sandpaper so they would adhere better to the new epoxy and have a

strong grip on the rotor. Then I got out what I think is the best

epoxy, "System Three

for oily hardwoods" and epoxied them to the rotor. Two got away on me

and clamped on top of other magnets. (& gave me a blood blister on

my thumb.) As I was trying to pry the first one off, I had the thought

that since I was going to have two layers anyway, and it already had

epoxy on the bottom, I should just leave it. When I ran out I got out

two more magnets and filled the last two positions.

[28th] I

decided to put the first layer of magnets on anyway, with some

spacers to hold the positions of the sideways magnets. If I need to

I'll clamp those down until the epoxy sets. So I spent the

day sanding the slick epoxy coating on all six sides of 16 magnets with

#120 sandpaper so they would adhere better to the new epoxy and have a

strong grip on the rotor. Then I got out what I think is the best

epoxy, "System Three

for oily hardwoods" and epoxied them to the rotor. Two got away on me

and clamped on top of other magnets. (& gave me a blood blister on

my thumb.) As I was trying to pry the first one off, I had the thought

that since I was going to have two layers anyway, and it already had

epoxy on the bottom, I should just leave it. When I ran out I got out

two more magnets and filled the last two positions.

I'm not as well organized for this as I once was. I didn't

clamp the rotor down, so it could turn and jump up with magnetic

forces, and I didn't have a wooden jig that covered the magnets

adjacent to the one I was trying to mount. After the first magnet got

away I hacked up my old wooden jig and it helped, but it didn't fit

properly since it was for the original 10 inch rotors with twelve

magnets. With the bottom layer (& 2 on top) done I left it for the

epoxy to set.

[29th] In getting more 2 x 1 x 3/8" magnets

from the box I had to separate three

adjacent rows. I pried off the first row of 7 without trouble. I wanted

to put the two longer rows, ten magnets each, in a vise, but I thought

about how hard they would clamp onto that vise... and tried by hand.

They came apart at one end, then suddenly both rows folded and two

caught

my finger, completely pinching out a chunk of flesh. (More than skin

deep.) Bleeding

was profuse. I quit for a while. (None of four pics was in focus. Of

course new tissues have to grow in from the sides to replace what was

lost. It still hasn't healed, but seems to be headed in the right

direction with some massage - Feb. 7th Getting there - Feb 9th.)

[29th] In getting more 2 x 1 x 3/8" magnets

from the box I had to separate three

adjacent rows. I pried off the first row of 7 without trouble. I wanted

to put the two longer rows, ten magnets each, in a vise, but I thought

about how hard they would clamp onto that vise... and tried by hand.

They came apart at one end, then suddenly both rows folded and two

caught

my finger, completely pinching out a chunk of flesh. (More than skin

deep.) Bleeding

was profuse. I quit for a while. (None of four pics was in focus. Of

course new tissues have to grow in from the sides to replace what was

lost. It still hasn't healed, but seems to be headed in the right

direction with some massage - Feb. 7th Getting there - Feb 9th.)

Of course one

must take responsibility for one's actions and safety. But there are

always contributing factors. I must say I have never thought much of

the hollow rectangle plastic spacers used to separate these neo

magnets. And this is by far the most common size magnet for many

electric motor and generator projects, deserving extra consideration.

The spacers

don't even extend out to the edges. Perhaps this is done for some

automatic pick and place tongs that grab magnets from stacks, but they

are needlessly hazardous to human handlers. By not coming to the edges

they will spit out one side and the magnets snap together if there's

sideways pressure on the stack.

Of course one

must take responsibility for one's actions and safety. But there are

always contributing factors. I must say I have never thought much of

the hollow rectangle plastic spacers used to separate these neo

magnets. And this is by far the most common size magnet for many

electric motor and generator projects, deserving extra consideration.

The spacers

don't even extend out to the edges. Perhaps this is done for some

automatic pick and place tongs that grab magnets from stacks, but they

are needlessly hazardous to human handlers. By not coming to the edges

they will spit out one side and the magnets snap together if there's

sideways pressure on the stack.

The spacers should cover five sides of the magnet - one

face and the edges. That way the stack is enclosed except for the end

magnet, preventing the powerful forces when two magnets actually touch.

The spacers can't slide out and even if the

magnets snap over sideways anyway, there's still a spacer between them.

The end magnet can still be twisted sideways and then pulled off the

end without danger that the plastic separator will come loose and shoot

away before the magnet has been removed.

Here one can see all the spacers that snapped out in my

accident. These magnets are now difficult to separate. What cost a

better cheap piece of plastic for safety?

(Somehow I was short a couple of spacers while doing the

rotor magnets. My wooden ones shown at least extend to the edges and

hold the

magnets farther apart.)

Well, I bought these a decade ago. Hopefully the magnet

makers have already figured this out, because doubtless I'm by no means

the only person to have injured myself with these "accidents waiting to

happen" magnet spacers. (And of course, these powerful magnets are

"accidents waiting to happen" whenever they are being handled!)

I had intended to take the

placement jig off and raise it

up for the second layer of magnets. But when the magnets were being

placed they were smearing epoxy onto it. Some of it seemed rather well

stuck and I decided to leave it where it was. The first two second

layer magnets placed by accident were exactly on top of the first, so

perhaps they didn't need the jig. But the sideways magnets, when they