Turquoise Energy News

Report

#178

Covering March

2023 (Posted April 8th 2023)

Lawnhill BC Canada - by Craig Carmichael

(CraigXC at Post dot com)

www.TurquoiseEnergy.com = www.ElectricCaik.com

= www.ElectricHubcap.com

Special Feature:

Federal,

Provincial

and Municipal Local Volunteer Grievance Panels: No

cost, timely and fair adjudication of minor disputes between

Individuals and Government (See in "In Passing")

Month In "Brief"

(Project Summaries etc.)

- Magnetic Variable Torque Converter - Renewable Energy Symposium

#2 - Magnetic Cooling with Gadolinium? Nah! - Copper Heatsinks? - A

Better Air Compressor? - A Working Battery! (for a while)... Exploring

Battery

Making Video Series - Solar Frame Fix - Magnetic Variable

Torque Converter - "New Chemistry" Battery Research & Development -

A Second Means of Taming Zinc Ions! - Exploring Battery Making Videos -

Plastic Recycling 2.0 - EV from Victoria Visit - Gardening

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Federal, Provincial & Municipal Local Grievance Panels

- Scattered Thots - ESD

- Detailed

Project Reports -

Electric Transport - Electric Hubcap Motor Systems

* Magnetic Variable Torque Converter with Planetary Gear: The Future of

the Automotive Industry!

Other "Green" & Electric

Equipment Projects

* Open Loop Air Heat Pumping

Electricity Storage:

Batteries

* This month's progress

Electricity Generation

* My Solar Power System:

- The Usual Latest Daily/Monthly Solar Production log et

cetera - Monthly/Annual Summaries, Estimates, Notes

This month has a special

feature outside the realm of 'green energy' and electric transport. I'm

relating what I believe should be a big help for people who seem to be

getting treated unfairly by government or big faceless corporations -

especially telecom companies - often by some part of a bureaucracy

applying bylaws and statutes in an unreasonable manner, making

unreasonable charges or providing poor service. A volunteer Grievance

Panel in each town or region, similar to a municipal Board of

Variance but broader in scope, gives people somewhere to turn when

they feel they are being or have been treated unfairly.

I have been thinking about this for some time, and have

finally written it up in semi-coherent form in the In Passing

section, below. I didn't get it finished until April... and then came

up with a couple of valuable modifications, broadening the scope to

include any "major institution" rather than just government

bureaucracy, even after I had initially posted this report. So I

rewrote it and reposted it a couple more times, and wasn't satisfied it

was good enough until April 10th. The changes are worth it! I will be

sending a paper copy to my member of parliament, who is someone that

just might like the idea and promote it energeticly.

Magnetic Variable Torque Converter

I tried for much of the month to get a piece of pure alume

for the rotor, to get more electromagnetic interaction with the magnet

rotor than with alloy. Double might be about right. I knew it wasn't

common, but I wasn't prepared for this... Nobody seemed to have it. at

all. One place said they could get it in but I'd have to buy a whole

sheet. That would be well over 1000$ - plus shipping! Finally one place

said they would sell me a piece, 1/4 inch thick instead of 1/2 inch, 2

x 2 feet... for 1100$! Yow!

At that point, I decided copper would be (much) cheaper,

available, and after all the best - the most conductive - more than

double the alume alloy, so I could use a thinner piece. Then someone

had many Kg of copper bits and I bought them from him at copper spot

price. So instead of buying a slab I started thinking I would cast the

rotor in copper. A concern is that the crucible only holds 1Kg of bits,

where the rotor will need about 2-1/2 Kg of copper. Will it work okay

if the copper is cast in two or three melts to fill the mold instead of

all at once? Somebody on youtube said you shouldn't do that. I guess

I'll find out. But first I'll try casting copper heatsinks for a

Peltier cooler for practice, and also to see how much better the cooler

performs than with alume alloy.

Another guy on youtube said he made crucibles out of fire

extinguishers. I could perhaps make one large enough for 3Kg of copper

out of a propane bottle. (carefully purged before cutting!) That

wouldn't fit in my little metal furnace, but perhaps I could fit it

into my mini-kiln. OTOH, he was just melting alume [alloy, sigh!], a

lower temperature, and he said they only lasted a few pours. Would it

last one pour with copper?

This is sure some serious "scope creep" just to get a

metal disk I thought I could simply buy!

There was a

second Renewable Energy Symposium on the 11th &

12th, at the Haida Heritage Museum, following the one in September 2018

in Old Masset centre. I decided to get a table and show mainly the

battery and torque converter work I had been doing, plus the updated

handheld bandsaw mill and some "Plastic Recycling 2.0" molds and

moldings.

There was a

second Renewable Energy Symposium on the 11th &

12th, at the Haida Heritage Museum, following the one in September 2018

in Old Masset centre. I decided to get a table and show mainly the

battery and torque converter work I had been doing, plus the updated

handheld bandsaw mill and some "Plastic Recycling 2.0" molds and

moldings.

I said I was interested in "TLL Yhada" and the 2 MW solar

project at Masset Airport. The panels will cover the grassy field to

the side of the runway, and batteries will provide power at night.

The previous HDPE

melts had had no discernible smell in the kitchen oven, but the odor

with the PP

ropes that started out with a big air space between the mold's lid and

the wall was quite objectionable.

I did a few

new "sample size" pieces in the kitchen oven the week before to take to

the event, where I discovered, since I could control the temperature,

that 400°F was about right for both PE and PP.) I started typing up

information pages about the battery research on the 5th, even before

finishing the February TE News Report.

I did a few

new "sample size" pieces in the kitchen oven the week before to take to

the event, where I discovered, since I could control the temperature,

that 400°F was about right for both PE and PP.) I started typing up

information pages about the battery research on the 5th, even before

finishing the February TE News Report.

BTW - Smell of Melting Plastic: It would seem from this limited

experience that melting polyethylene has little or no odor, but

polypropylene smelled pretty strongly.

I will not hesitate to do even a big piece of HDPE or UHMW

in the oven in the kitchen next time, but an outdoor oven seems to be

needed for polypropylene.

The weekend went by quickly with much talking to

interested people. I said to those that stopped, "Here it is: four

totally different projects." There were people interested in each of

them.

Mid morning of the 15th

("afternoon" according to the clocks, which for no apparent reason and

seemingly against the wishes of much the general population have gone

ahead a second hour onto "afternoon wasting time"): Yet another dusting

of snow last night, and now it's again pouring rain or sleet, 3.6°

outside my door. It's been like this daily since mid to late February,

except sometimes with strong wind too. Occasionally there's a bright

spot in the clouds where the sun is. I'm getting tired of it, and it's

keeping all outdoor projects at bay.

Magnetic Cooling with Gadolinium? Nah!

I saw a youtube video about air conditioning. Something

stressed as a "horrible problem" was the amount of electricity they

use, putting a strain on power grids. Somebody has to explain to me why

air conditioners wouldn't be powered by solar panels. Opposite of

heating where there's no solar power when heat is needed, the hotter it

is the more likely there's plenty of solar power to run an air

conditioner.

Another thing in this video was a brief mention of "other

ways" besides compressor/refrigerant cooling, including magnetic

refrigeration. That of course would use gadolinium. That got me

thinking again that there are surely means of heat transfer to and from

the gadolinium by solid copper (or graphite) instead of the complex

(and may I say bizarre?) ways of doing it with helium gas and the like.

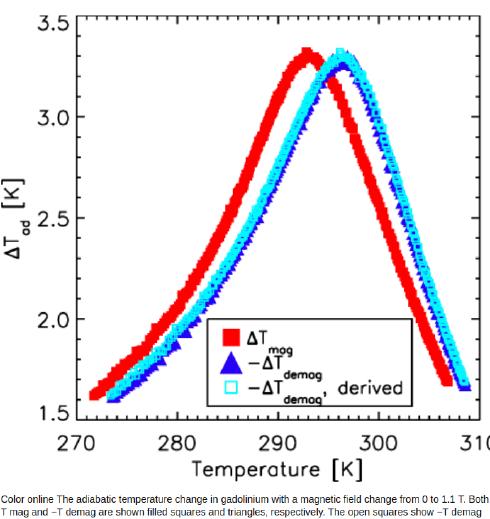

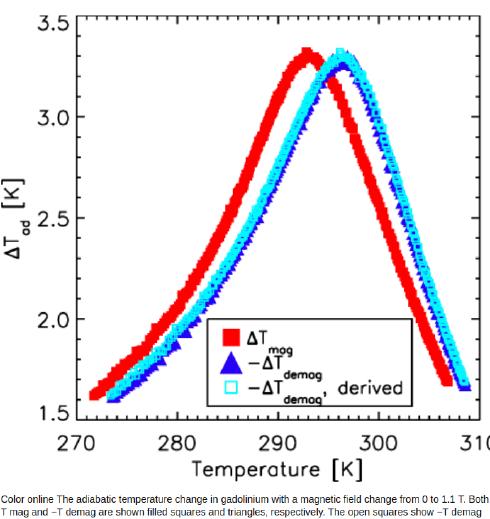

A graph shows temperature change in gadolinium entering or leaving a

1.1 Tesla magnetic field being about 2 to 3.5°C or °K, maximum effect

around 295°K (22°C) and down to 1.6° change at freezing. (Gadolinium

alloys can modify the center temperature, so maybe 3° everywhere in a

fridge or freezer, so maybe 8 stages to allow 24° fridge cooling?) One

Tesla is "neo magnet" permanent magnet territory. Or maybe the field

can be got up to 2 or 3 Teslas (Hallbach magnet configuration?) and

need fewer cooling stages.

I visualize a

piece of gadolinium coated on opposite sides with copper or graphite,

perhaps moving back and forth. On its outward swing it contacts a

graphite coated magnet, which is cooled by a fan. So it heats up, but

its heat is drawn through the copper and or graphite. Then it goes the

other way where it cools as it exits the magnetic field. Here the other

face (or better, somehow the same face) contacts the cooling side

copper and transfers its coolness into that. If instead of a back and

forth "swing" it is traveling say in a circle, the copper/graphite heat

transfer contacts could be rollers - or the Gd could be in the form of

a roller - to avoid friction. Each stage transfers to the next by a

solid copper or graphite bar, hot to cold, hot to cold.

I visualize a

piece of gadolinium coated on opposite sides with copper or graphite,

perhaps moving back and forth. On its outward swing it contacts a

graphite coated magnet, which is cooled by a fan. So it heats up, but

its heat is drawn through the copper and or graphite. Then it goes the

other way where it cools as it exits the magnetic field. Here the other

face (or better, somehow the same face) contacts the cooling side

copper and transfers its coolness into that. If instead of a back and

forth "swing" it is traveling say in a circle, the copper/graphite heat

transfer contacts could be rollers - or the Gd could be in the form of

a roller - to avoid friction. Each stage transfers to the next by a

solid copper or graphite bar, hot to cold, hot to cold.

But I'm still waiting... since about 2015 now... for a

breakthrough Peltier module with a higher COP at higher temperature

differentials. That would probably make the whole magnetic cooling idea

obsolete and not worth pursuing. I think it will happen.

Somebody was recently claiming a room temperature

superconductor (seen on WION, youtube -- I heard of one in the 1980's

or 1990's, too! The new one sounded like a quite different alloy.) and

I'm sure various such "groundbreaking" things are inevitable given

enough time.

Copper Heatsinks?

I did have one further thought: If I have to cast a copper

rotor for the torque converter, maybe I should try casting something

smaller and simpler first? How about sand casting a copper heatsink, in

a simple, open mold? In fact, having recently charted the performance

of the Coleman camping cooler with its alume heatsinks (TE News $174), I could

take impressions of those in sand, fins down, and cast them, then see

how much colder the cooler would get. Shouldn't need air vent holes

that way. I'll have to see how flat or bulging the top flat face comes

out. It has to be honed to a perfect flat.

It would be interesting to see how those perform in the

cooler. (If they do as well as I hope, I'll do a big one for my Peltier

module shallow chest fridge!)

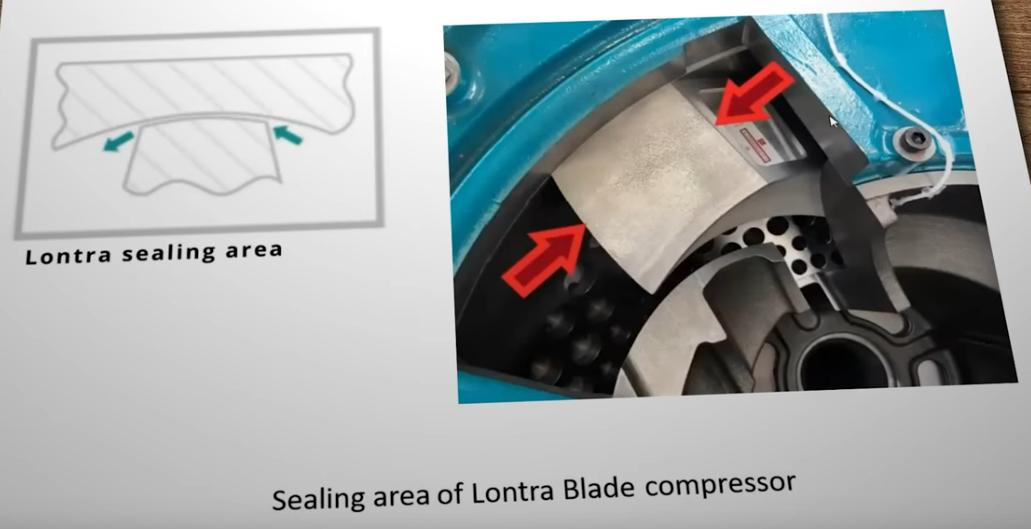

A Better Air Compressor?

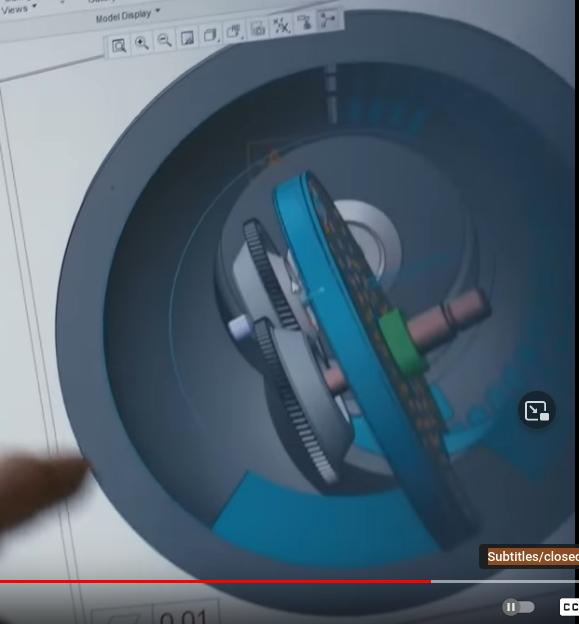

Moving right

along... also on youtube I saw a rather radicly new design of air

compressor, the "Lontra", much more efficient than any previous one. It

had two rotors at 90° to each other. Through most of the cycle the main

rotor acted like a circular bicycle pump, pushing air out the outlet

port. Then it reach the "end" just past the output port, and the gap in

the other rotor, spinning synchronously, reached the gap in the main

one and they passed through each other, virtually but not quite

touching, letting almost no air pass between and closing off the output

port. Meanwhile the whole circle behind the main "piston" had filled

with new air to be compressed on the next cycle. With narrow air gaps

covered by wide pieces for low leakage there were no parts in friction

with each other, and motion was continuous rotation rather than

reciprocating.

Moving right

along... also on youtube I saw a rather radicly new design of air

compressor, the "Lontra", much more efficient than any previous one. It

had two rotors at 90° to each other. Through most of the cycle the main

rotor acted like a circular bicycle pump, pushing air out the outlet

port. Then it reach the "end" just past the output port, and the gap in

the other rotor, spinning synchronously, reached the gap in the main

one and they passed through each other, virtually but not quite

touching, letting almost no air pass between and closing off the output

port. Meanwhile the whole circle behind the main "piston" had filled

with new air to be compressed on the next cycle. With narrow air gaps

covered by wide pieces for low leakage there were no parts in friction

with each other, and motion was continuous rotation rather than

reciprocating.

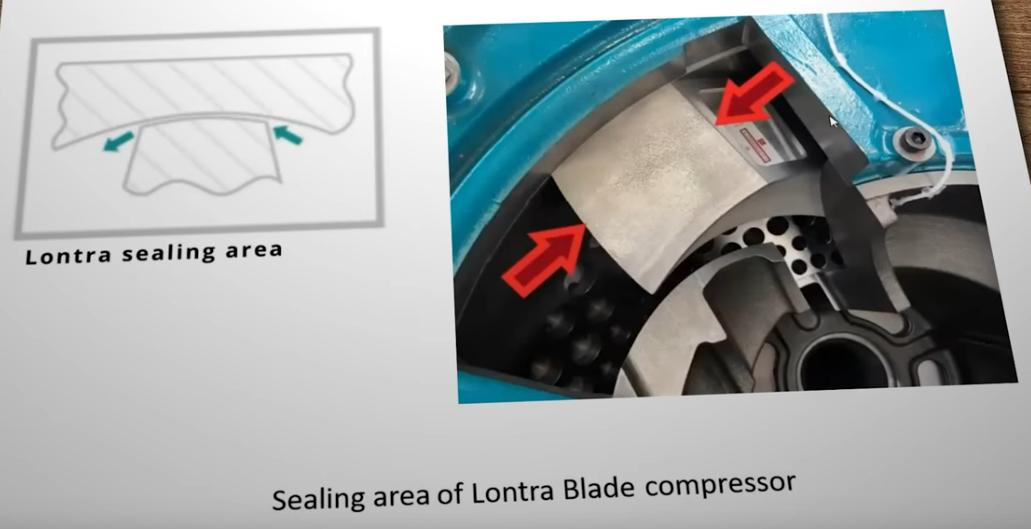

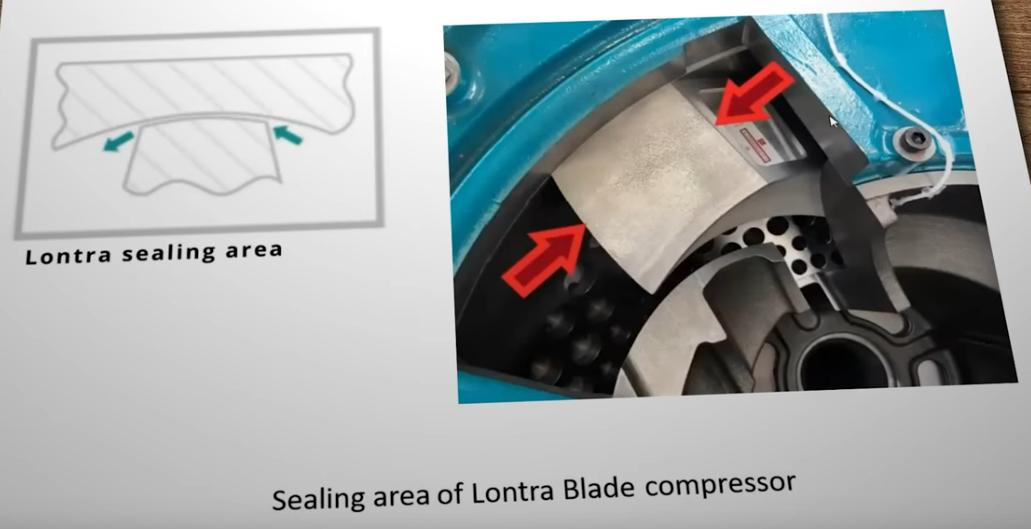

The wide "seal" coverage in a

small area - a tiny air gap with no parts touching - has much

The wide "seal" coverage in a

small area - a tiny air gap with no parts touching - has much

less leakage than a "screw compressor's" large area seals with narrow

coverings of the gaps.

This might be just what is

needed for high performance with the open loop air heat pumping.

Apparently a company with a number of large compressors was saving 30%

on electricity for them by switching to these. That's huge! That's as

much saving as recovering the remaining compression after extracting

the heat from the compressed air. (If it could use the remaining

compression of the cooled air too, perhaps with a separate piston ring,

the COP could go up, up! If COP 10 sounded unrealistic before, it's

definitely getting closer with these!)

Sounds like it's just as well I never got around to

building the tricky "ROVACS" or the complex "Liquid Piston" rotary

design compressor yet! This would have to be simpler to make, and I

can't help but think there must be a way of making a small "Lontra"

type with just one rotor and some air closing flaps, and some even

simpler end-of-stroke "move away to let the piston past" mechanism.

(Hah! - Have a steel piston moved along by magnets in an enclosed

non-magnetic tube needing no leaky openings to connect it to the motor?

And the magnets also move/activate the "end-of-stroke" mechanism? And

if the pressure is too high, the magnets can't hold the piston and let

it slip, preventing dangerous pressure buildup if something is blocked?

Hmmmm! Fantastic idea... or just Silly?)

OTOH, for a small, low power compressor, why wouldn't an

actual reciprocating "bicycle pump" mechanism with low inertial mass be

just as good, or close enough? It would certainly be simpler to make

than any "Lontra knock-off" I can think of making. It only needs to go

up to 50 or 60 PSI for the heat pumping application. (Most compressors

shut off around 120 PSI.) The lower pressure should relax the

requirement for robustness considerably.

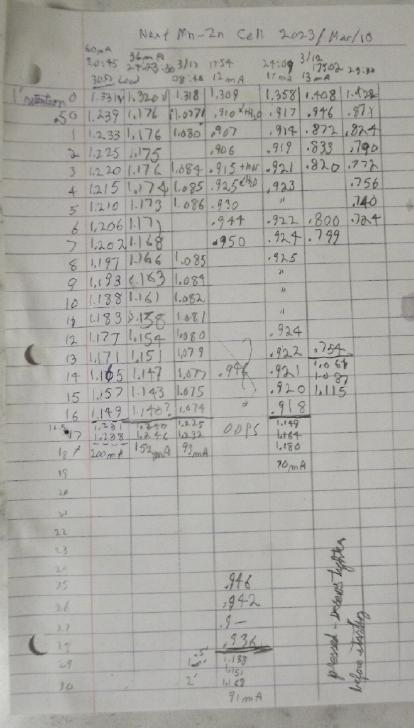

A Working Battery! (For a while)

I started the month by trying manganese-zinc with all the

new techniques. I was hoping that the acetone treatment would make the

Mn2O3 / MnOOH (valence III) recharge to MnO2 (valence 4), but it didn't

work. Performance continually deteriorated.

So I took out the MnO2 side

and put in a nickel oxide (NiO) mix also containing my usual monel

(cupro-nickel ~65:35), samarium oxide and calcium oxide. With all the

latest refinements. With a [leaking] wax seal. This did work. As usual

starting apparently totally discharged, the performance gradually

increased over two days and more, and it would put out 4 or 5 amps. A

for real, working battery!

How ironic to start out with the idea that there must be

battery chemistries that haven't been tried, and end up with common

nickel-zinc as the first combo that's working well. But even in that

there are things in that that are new and unique. Nobody seems to have

done it before with KCl salt electrolyte, and no one else seems to have

discovered that unlike all single element metals, cupro-nickel doesn't

oxidize away in the positive electrode at moderate alkaline pH levels.

Somehow the copper and nickel seem to protect each other.

Hopefully the nickel powder mix can't penetrate the

methyl-benzene treated paper and the zinc ions can't penetrate the

sodium dodecylbenzenesulfonate painted into the same paper and so

nothing will start making low resistance paths between electrodes.

Solving the zinc ion problem (as I've said before) has been a "holy

grail" of battery making for 150 years - including another 15 since I

began my own experiments.

The other thing that has revolutionized my previous

generally poor results is soaking the positive electrode powder mix in

acetone (methyl-methyl keytone). I can't say I understand it clearly,

but I think it dissolves the oxides and makes for epitaxial crystal

growths, mixing different substances at a more molecular level instead

of just separate jumbled powder particles. The difference is a couple

of orders of magnitude in current capacity.

But the cell leaked. I kept filling it, but after a while

performance started deteriorating. Thinking about it, the SDBS in the

separator sheet might become more and more diluted among other

problems. pH would start to drop if the Ca(OH)2 got too diluted, too. I

think I'll go back to the idea of potting the cells in epoxy to prevent

any chance of them leaking.

Toward the end

of the month I turned the cell design sideways and put some tiny holes

in, to let gas bubbles rise over a short path and into the upper

reservoir, which can hold more liquid.

Toward the end

of the month I turned the cell design sideways and put some tiny holes

in, to let gas bubbles rise over a short path and into the upper

reservoir, which can hold more liquid.

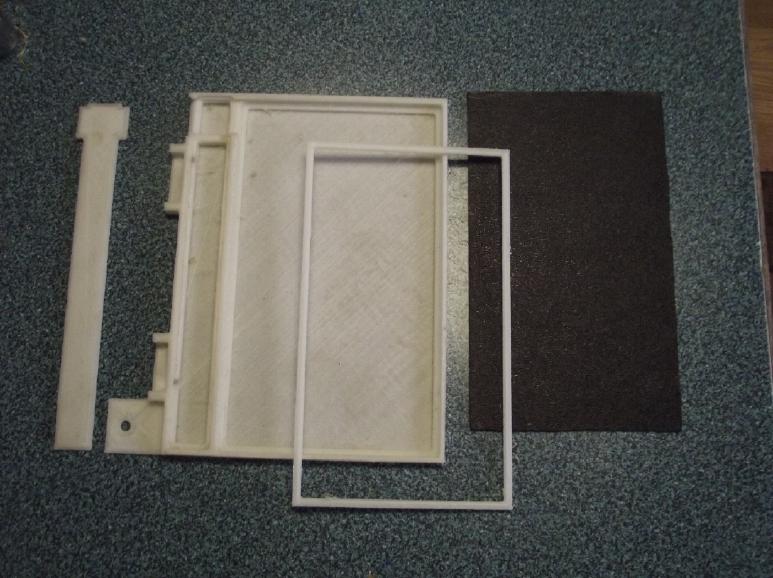

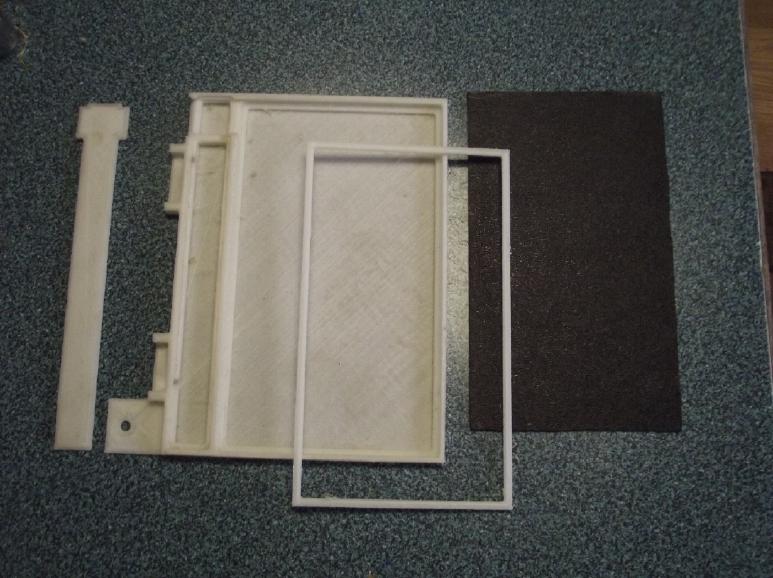

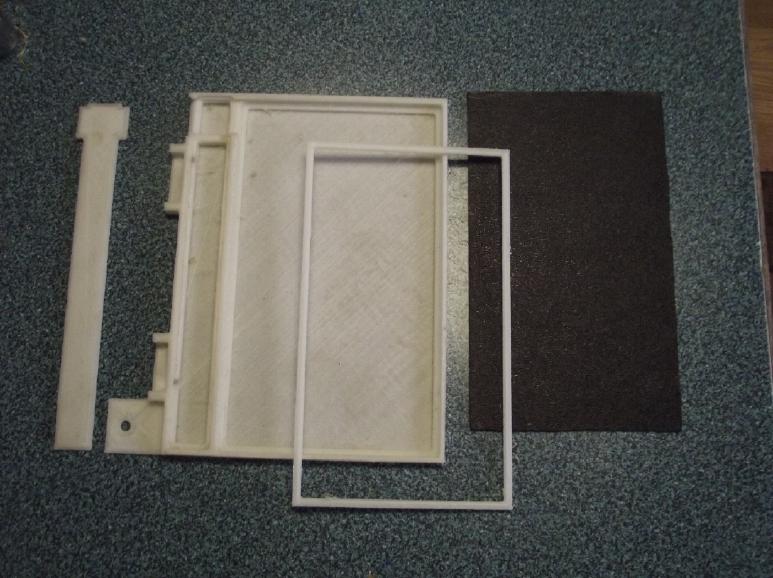

I started

making a new cell (3D printed front cover) but didn't get it finished

owing to competing attractions. (Just needs compacting + epoxy, and a

new shape of alume clamps.)

I started

making a new cell (3D printed front cover) but didn't get it finished

owing to competing attractions. (Just needs compacting + epoxy, and a

new shape of alume clamps.)

Another Means of Taming Zinc Ions!

Assuming indeed using SDBS stops zinc ions as it seems to

in my experiments so far and hence makes a zinc cell last far, far

longer, there now seem to be two ways of doing it, because someone else

claims to have prevented zinc ion migration with modified chitosan

(crab shell material). I plan to look at this further as their

technique of using it was different than mine of painting it into the

separator sheet. They impregnated their material with zinc (powder?)

and then put it right on the surface of the zinc of the electrode.

Exploring Battery Making Videos

Regardless of success or lack thereof, I have accumulated

a number of exciting developments/discoveries worth sharing and I

started my planned Battery Making video series on Youtube with four

videos:

Exploring Battery Making with Craig - Intro (Long - 25

minutes)

https://youtu.be/R0_ZkBFefDk

Exploring Battery Making #2 - Preparing a Separator Sheet

https://youtu.be/8-MaCfFwvbY

In this I've given away two of my greatest "secrets":

about the toluene for preventing penetration of the paper by

nano-powders, and about the SDBS which I believe is the answer to the

150 year quest for trying to keep zinc ions from killing batteries.

Exploring Battery Making #3 - Getting/Making Sodium

dodecylbenzenesulfonate

https://youtu.be/F_7Vj8SDw0w

This one is about extracting SDBS from Lemon Fresh

Sunlight dishsoap by ersatz "chromatography" in case others find it

as hard to buy as I did.

Exploring Battery Making #4 - A Zinc Electrode

https://youtu.be/JjwtgkQnwzM

I had also earlier taken clips of making the powder for a

nickel manganates electrode. I put them together and added another one

at the end about dissolving the powders in acetone to get everything

mixed at the molecular level within epitaxial crystals. So I have the

video. But I haven't proven that I've made ~~NiMn2O4 yet, or that it

works as a rechargeable electrode.

Then, with the next cell all ready to close up and epoxy,

didn't get back to it in March. I want to make sure it actually works

before I publish the nickel manganates video, and to put up the actual

electrode assembly video and at least initial testing of the cell at

the same time. But somehow it's "work outside" season again and the

days have too few hours.

Solar Frame Fix

In February a

powerful wind with even more powerful gusts blew over my "A" frame of

solar panels on the carport roof. These three panels installed in this

sunny location out of the tree shadows at a good angle (45°) last May

(2022) add more output to the system than any other three panels. After

waiting for better weather I finally got the frame repaired and screwed

back up on the 22nd and 23rd. One panel was broken so I set it up with

two. (I don't think I could have lifted it with all three panels on it!)

In February a

powerful wind with even more powerful gusts blew over my "A" frame of

solar panels on the carport roof. These three panels installed in this

sunny location out of the tree shadows at a good angle (45°) last May

(2022) add more output to the system than any other three panels. After

waiting for better weather I finally got the frame repaired and screwed

back up on the 22nd and 23rd. One panel was broken so I set it up with

two. (I don't think I could have lifted it with all three panels on it!)

Then it got windy so I stayed off the roof, and then I cut

down three alder trees. The biggest one was leaning and in spite of a

rope on it didn't fall in the direction I cut the hinge. It hit my

neighbor's tractor shop and bent the gutter. (thankfully not worse! and

thankfully he's not around at the moment.) I had to repair that and get

the limbs and tree off his property, so other things got put off.

But after well over a month

since the wind incident I couldn't bear to start April with one pane

still missing, so I went up on the morning of March 32nd, got a new one

up on the roof without dropping it on the way up, bolted it on and

reconnected the wires. I soon saw 850 watts on the power monitor from

those three panels plus the two on the pole. It started out a nice day,

but a couple of hours later it was snowing!

The 2 solar panes on the pole and

the 3 on the carport roof are quite visible from the highway...

The 2 solar panes on the pole and

the 3 on the carport roof are quite visible from the highway...

so if nothing else it's bad publicity to have them broken or missing!

I must confess that I had

been careless in the original (and in fact never quite finished)

installation. Some of the "no screws showing" roofing sheets on the

carport had slid down a bit, and I had wanted to reposition them before

putting in screws on a couple of legs of the frame, so a couple of the

six legs weren't fastened. And other screws only went through the sheet

metal roof into nothing. Those ripped out, then with the back free the

frame would have tipped forward in a blast of wind and the screws on

the front side were yanked out or broken. (I had just used 3 inch #10

deck screws, but I'm pretty sure they'd have held fine if all all the

legs had been secure.) This time I had adjusted the slidden roofing (as

easy as tapping the bottom edge with a hammer with a wooden block

between - if only I'd known) and I fastened pieces of wood in the

"ceiling" under the roofing to securely hold the screws of the three

back legs. It would take a substantially bigger hurricane to yank it

off now. (Then again, looking at some tornado-destroyed towns in

southern USA in March, anything is possible these days.)

EV from Victoria Visit

Someone named

Angus showed up here on the 9th in an old Subaru Brat 4 wheel

drive pickup truck he had converted to electric. It had a

Nissan Leaf motor and three big Tesla car batteries behind the seat.

(36KWH? or was it more?) I forget what the motor controller was (a

Tesla model, IIRC), but there wasn't room under the hood for the

regular Leaf controller, and he had got up to 320KW out of the motor

that the Nissan controller normally limits to 80KW!

Someone named

Angus showed up here on the 9th in an old Subaru Brat 4 wheel

drive pickup truck he had converted to electric. It had a

Nissan Leaf motor and three big Tesla car batteries behind the seat.

(36KWH? or was it more?) I forget what the motor controller was (a

Tesla model, IIRC), but there wasn't room under the hood for the

regular Leaf controller, and he had got up to 320KW out of the motor

that the Nissan controller normally limits to 80KW!

It seems there are now enough EV's at auto wrecking yards

that one can do some lovely economical EV conversions if one can figure

out the microcontroller stuff that commercial EV's are full of for the

batteries and controllers. He got the truck in Mexico and so it was in

good condition instead of rusted out.

He had come up from Victoria to

work tree planting, and someone there (Tom!) said he should stop in and

see me.

He had come up from Victoria to

work tree planting, and someone there (Tom!) said he should stop in and

see me.

He had 3D printed a J1772 fitting. He charged his truck at

my charging station and we talked about EV's and such for a couple of

hours.

He had also charged at a new charging station in Masset.

Fine thing - I've been waiting for them to put one in there for years

and I have to find out it's been done from some visitor to the island!

He had designed some coupler plates and other fittings to

fit the Leaf motor to his transmission et al, and found there was a

market for them, so he started BratIndustries.net and now sells them

for several vehicle models.

He had driven it to Rose Spit along the beach at low tide.

Yup, you want a four wheel drive to do that. That beach is notorious

for claiming vehicles that get stuck in the sand until the tide comes

in!

Gardening

Well, it was too cold to do

much outside. Even into April it was pretty chilly. (and in 3 weeks the

blackflies will be out!) I was too busy to get any seedlings going.

(Ag, I'm late!) Over the winter the cherry tomato and peppers in the

bay window with a light over it continued producing fruit. I had put up

'tablecloth' curtains to reflect the light back at the plants, but that

made it pretty dreary inside and I mostly unhooked them. The lettuce

under the LED light also kept making leaves, which I plucked as desired.

Vainly hoping it just might come back in the spring, I

kept watering the walnut tree daily all winter. (If only I had done

that when it had leaves!) No sign of anything so far.

I put down some cardboard from grocery boxes to kill the

grass for gardning. The idea was great. But from last time I did it 3

years ago, I'm still plucking bits of packaging tape from the garden,

so this time I decided to pull it off the boxes in advance. It's a

party killer! 2-1/2 hours of peeling tape off the cardboard, and then

ten minutes to lay them out on the ground. The fact of packaging tape

stuck on the boxes magnified the time I spent doing it tenfold!

Overgrazing

makes deserts. Here, although it's too damp for a desert, my own

chickens illustrated overgrazing when I moved their yard over a little

bit. The green strip didn't last.

Overgrazing

makes deserts. Here, although it's too damp for a desert, my own

chickens illustrated overgrazing when I moved their yard over a little

bit. The green strip didn't last.

I'm making a smaller yard, with wheels, that will be far

easier to move to new sections of lawn. This large, pivoting-corners

one was supposed to be able to move easily, one wall at a time, but

when I had to staple chicken wire over the roof to keep critters out,

it didn't really work. (And chicken wire isn't good enough anyway.

Raccoons can rip it off or tear it. I'm using heavier fencing wire on

the new one.)

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Grievance

Panels

of Local Volunteer Citizens

to Hear and Rule On

Individual Complaints about Dealings with Major Organizations

(Concept Outline)

PREAMBLE

In a democracy ultimate power of decision rests with the

people. Individual leaders come and go. Autocracy in any form cannot be

sustained over a long term. Only representative democratic government

can be made socially sustainable over the generations, and only if its

enduring institutions are structured so that they can evolve and solve

each underlying problem that arises in ways that benefit society, as

that society grows and changes over the years, decades and generations.

With the gradual rise of large, bureaucratic institutional

organizations, new structures of governance have been needed for long

over a century to bring effective representative/democratic government

back on course. The problem is that until a new structure has been

invented, until a new concept is brought to light, we don't know what

it might be and we are groping in the dark to "put out fires" because

we have not created a structure for solving the underlying problems

that cause the fires.

Here is an idea that I believe could go a long way toward

restoring fair and equitable treatment of society and individuals by

institutions and the bureaucracies that have grown up around them. It

is surely only one of several new things that need to be created to

obtain social stability and eventually social sustainability, but I

think it fills in one existing "democracy power vacuum" blank in the

picture quite well.

Major institutions or organizations have over many decades

built bureaucracies which are faceless and anonymous. Examples of

"Major Institutions" include government at all levels local through

national, corporations especially such as utilities, and educational

and health institutions.

When members of the public have a problem with one, they

are generally unable to meet or to be heard, directly or indirectly, by

those heads of such institutions who have the decision making power -

only with employees who are not empowered to solve or smooth over many

of the problems an individual or the public in general may have in

their relations with that institution. Many examples could be cited. (A

few follow down below.)

As a result, our major institutions have become feral.

They are no longer bound to be and too often are not, tame, civilized,

responsive and reasonable in their dealings with the people and society

they exist to serve.

Sometimes an employee may even be part of the problem.

Civil enforcement officials may apply bylaws or terms in situations

which were not envisioned by legislators, and the results work harm

instead of good, often to individuals, families or small business

owners caught by unreasonable demands.

What recourse do people have? They can hire a lawyer and

go to an overworked court of law, but the verdict may not come soon

enough to matter, and even after all the expense and time taken from

their productive work -- which may generally cost them more than their

budget can bear and more time than they have, the judge might have to

rule that, yes, such is the law and it has to be applied equally and

complied with regardless of its appropriateness or fairness in this

individual situation.

So with "the cure being worse than the disease" (and

perhaps ineffective too) people usually simply submit to what they feel

is an injustice, undesired by society as a whole and unintended by

their elected representatives but demanded by bureaucracy.

The Grievance Panel provides a local place

for the Complainant to be heard in good time by his

respected peers to gain what they collectively, on the facts presented,

consider to be a fair decision or settlement in his dealings with any Major

Institution without the lengthy and costly process of filing

suit in a formal court of law, and unlike in a court regardless of

whether a demand being made is technically legal or not, and

without reference to "precedents" of similar but rarely identical

situations. Panel judgments based on interpretations of reasonable

versus unreasonable, fair versus unfair, will

help prevent misapplication or abuse of authority and of corporate

power. Repeated complaints on a specific issue or directed at a

specific institution will help point out problem areas.

A local Grievance Panel would be similar to the present municipal

Board

of

Variance, but of broader scope, operating in each locality

on complainants' issues regarding any major institution, public or

corporate. It is composed of peers - volunteer citizens not in the pay

of the government or the corporation involved, who have not contributed

to the antecedents of the situation and who have no personal stake in

the outcome.

While most complaints about government are likely to

relate to property, and most complaints about utility corporations to

unfair charges or poor service, the scope of the panel is not to be

limited to those areas.

All panel decisions may be appealed to a court of law if

either party is dissatisfied with the ruling. The onus is on the losing

party to initiate legal action if desired. Rulings in favor of the

complainant may require the government or a corporation to cancel a fee

or fine levied or to promptly refund money already paid, to cease

restrictive requirements, to permit actions it was prohibiting, or to

provide a service it was withholding.

In the event that panel members are really unsure how to

rule, if the case is too complex or vague, they may elect to not make a

ruling. A tie vote is also considered to be "no ruling". The ruling (or

lack thereof) will be written down and signed by the panel members, and

both parties will receive a signed copy on paper.

Here are some suggested parameters. These have not been

thoroughly thought out or researched, and so further consideration

before actual implementation is desirable.

1. These local panels give individuals a place to turn for a speedy

decision if they believe that a major institution or an agency or agent

of that institution has demanded something unreasonable, unfair or

unjust from them, or is refusing to provide something it should. It

hears only civil matters, not criminal, involving only disputes between

any major institution and a citizen, household

or personal small business, and its decisions may be overruled

by any court. The onus is on the disagreeing party to take it to court

if it wishes to contest the decision. The scope of the panel is not

limited to any particular subject or area.

2. This is a volunteer advisory panel comprised of one's peers,

concerned local citizens. It is anticipated that many or most civil

disputes will be settled agreeably at this local level without recourse

to law courts. Preferably the panels will come to have some experienced

and respected people as well as a few younger students or beginners.

Judgment should always be a group function to reduce the effect of

individual biases and there must be more than two persons on a panel.

(I'm anticipating three will be the most popular number - after all

they are volunteering their time - but four or five or even more is

certainly possible, especially if new members are in training.)

3. An individual who believes a demand or problem related to an

institution is unfairly harming his interests may apply to be heard by

the panel by any convenient means. This complainant (or applicant)

will

be

heard personally, and no monetary charge will be levied for the

hearing.

If, for example, a fine, fee,

action demand or refusal to act itself was asked by the institution,

the institutional party will be asked if they wish to present their

case, in writing or at the hearing or both. Preferably the applicant

should also make his case in writing before being heard live. A form

for doing so may be provided. "In writing" may include submission on

line. In addition to releasing the complainant from a demand, or

demanding that the institution act to provide service to the

complainant, the panel in finding for an applicant may rule that fees

or penalties pending or applied should be promptly canceled or refunded.

4. The panel will meet regularly not less than monthly (or more often

as is deemed desirable) at scheduled times posted in advance, in an

agreed public meeting space provided free in a government building. If

there is insufficient time to hear all cases, another meeting shall be

held within 2 weeks to clear the backlog, and every two weeks

thereafter if and as necessary. If there is more than rarely too much

work to render speedy judgments for all, a second panel of further

volunteers may be required even in the same locale.

5. Selection of Grievance Panel members. Any citizen may volunteer or

may nominate someone to be a member of the panel, and if seconded such

nomination shall stand for three years. I have no clear idea who should

select members from the volunteer list. Perhaps present panel members

should select them, or at least have a good say. Members of nearby

panels might also be called in for the decision. Terms will be for

(?)two years, and no one shall serve for more than two consecutive

terms. (ie, (?)four years.) Those with violent criminal records should

be excluded, and others with criminal records as well unless the seven

year statute of limitations has passed and they have committed no new

breaches. (Again they would still have to found acceptable by the other

members.) Municipal councils might perhaps have a veto power over known

"troublemakers" - the antisocial and those not of sound mind.

I anticipate that owing to the local, volunteer and

plentiful nature of grievance panels and their diverse fields of

activity, it should be very difficult to "stack" grievance panels in

any meaningful way to the benefit of any one major institutional entity

or related group of entities, but perhaps this aspect of panel member

selections should be thought through to pinpoint any possible

"loopholes".

6. For the purpose of eligable institutions, "major" should

be defined, or specific institutions should be denominated as "major"

and the list updated when required.

7. The volunteer panel members shall not be liable to penalties or fees

as a result of their decisions, including if a decision is overturned

by a court.

8. Doubtless parameters already exist for the operation of municipal

boards of variance, and one suspects they may differ by municipality,

in different provinces, or in different countries. At least a few of

these should be studied before going too much farther than the above on

setting up operating parameters for grievance panels.

Some Examples of Apparently Unfair or Unintended Situations

Potentially Warranting Complaint

1. (This happened to a friend of mine - his own parents' property after

they passed on. He tore down the old house and was going to build a new

one. And I'm pretty sure I've heard of similar cases, although

specifics aren't coming to mind. The municipal inspector made no effort

to help him solve the difficulties his requirements imposed. He had

nowhere to complain about these requirements.)

The homeowner can't get needed permits for months or even years. He has

nowhere to complain and finally sells the property as-is in

frustration, but the developer who buys it quickly has all the needed

approvals - surely because he knows how to "grease the wheels".

2. A BC couple decided to buy farm land in a rural area in Nanoose and

grow produce, and to make their own restaurant serving that produce on

the property. They looked into everything first and carefully planned

it, but when they actually went to do it one absurd hurdle after

another was set before them by local officials.

One I recall was that while they had not intended to serve

alcohol at all, but owing to a BC bylaw intended to protect BC local

wineries they were forced to get a liquor license, divert acreage to

growing grapes and hops and serve alcohol. If they weren't even going

to serve alcohol, their restaurant should have been completely outside

the scope of this bylaw.

There were others. The last one, having already seriously

diverted and delayed their plans and spent tens of thousands of extra

dollars to comply, was that they weren't permitted to build their long

planned house because they already had built the restaurant and weren't

permitted to have two buildings on one farm. [Huh?]

They were in a rural area where there was no Board of

Variance because rural regulations are supposed to be few and simple.

Any rational person on a grievance panel surely would have looked at

any of the demands and said that they were outrageous. (And if that got

the unreasonable employee(s) tamed or fired, so much the better for

everyone! I'm sure no elected officials had any idea all this was

happening and would have been aghast. But would they have been able to

fight their own bureaucracy and change it? A grievance panel would (I'm

certain) rule in favor of the enterprising couple.) I saw the story on

youtube.

3. I have heard that BC decided after some years of severe forest fires

to ban burning after March 31st. That may be reasonable in the south

where it's already starting to get a bit dry, but in the north the snow

hasn't even melted yet, and even here on the coast it was too cold to

work outside until the last few days of March. I'm cutting trees for

firewood into early April ASAP before there's too much sap. Now I'm

supposed to leave the branch piles on my lawn to get tinder dry, until

next winter? That's definitely more of a fire hazard than burning them

this spring after they dry enough to burn. But if I do might I get a

$1000 fine? In some areas burning might not be practical until May or

June. Perhaps not the concept but the specific dates applied to the

whole province need to be modified by region. (OTOH we already had laws

about burning and fire hazard ratings that depend on whether it's wet

or dry! Don't those make more sense? And aren't most forest fires

started by lightning?)

4. There was a news story (USA) where police shut down a childrens'

lemonade stand for "running a business without a business license". (I

think they may have fined the parents... can't remember. The whole

story sounded absurd.)

5. Someone (USA) had grown a vegetable garden in their fenced front

yard for years. A municipal employee came along and told them to rip it

up and plant lawn immediately or be fined 1000 $/day! (After hearing of

this the municipal council specifically made a new bylaw permitting

vegetable gardens in front yards, so what the employee demanded was

clearly not the intent of the city's bylaws! By then they had had to

rip out their garden.)

6. The Old Tobacco Shop (I probably have the name not quite

right), for ages in downtown Victoria, was told by a municipal employee

that advertising tobacco was illegal and that he would be fined if he

didn't take the store sign down. Another municipal employee said his

sign was antique and came under heritage designation, and that he would

be fined if he removed it.

Likewise, someone was told to remove a dam on his property

or be fined. (IIRC he actually wanted to remove it.) But the dam had

been built by beavers and the wildlife department told him he would be

penalized if he removed it.

7. Not only government but other large institutions sometimes need to

be reigned in. Feral Canadian telecommunications companies are

notorious. One fraud was perpetrated by Telus in (?)2009: when people

(fed up with high monthly charges) switched en masse to Shaw

phone/internet/cable TV service, which had recently solved technical

problems and become widely available. Telus pretended to not know and

continued billing people as if nothing had changed. They did it to me.

They lied to me twice on a phone call. Most people would fear for a

black mark on their credit rating and pay for some extra months. As an

electronics tech I had tested the line and knew they had cut it from

their office when I switched. A formal complaint to the "commissioner

of complaints for telecommunications services" ("CCTS") in Ottawa got my

fraudulent charges dropped - it didn't start a criminal fraud

investigation or help anybody else. As usual it wasn't worth any

individual's time to take Telus to court or start a class action

lawsuit.

Then in 2017 when I moved from Victoria to Haida Gwaii,

people simply couldn't get through to me. It turned out later that

Telus was deliberately and brazenly blocking calls to cell phones all

across Northern BC. The motive would seem to have been to force

everyone to switch their mobile phone service from "whoever" to Telus.

The orders for such outrages have to come from the head. No subordinate

would dare attempt to foist such schemes on the public.

After who knows how much trouble they caused to how many

people, the CRTC forced them to stop blocking calls. But instead of

arresting this CEO for Betrayal of Public Trust, in 2021 or so

a former head of Telus was appointed head of the CRTC - doubtless this

same criminal who had caused all the trouble in previous years! (He was

soon spotted in a pub having a beer with the CEO of Bell Telephones, a

company that the CRTC is supposed to be regulating.) What are the

chances now of getting positive action from the CRTC when there's a

problem with Bell, Telus or other major telecom companies?

Dozens of complaints upheld by independent grievance

panels across a region or nationally could not be hidden away in a

drawer at the CRTC and would in fact constitute abundant evidence of

failure of fairness by the institution or criminal conduct by its

leader.

Probably all of us can think of things that have been unfairly/unjustly

put upon people, even on themself. I should think an impartial place to

take such complaints to be heard by one's peers, those unpaid

volunteers who didn't help create the situation and who have no legal

obligation to say "Well, I'm afraid that's the law (or "the way it is")

so suck it!", is exactly what's needed to iron out many of the problems

individuals have with major institutions, to bring some fair decision

making power back to the people and, with local Grievance Panels

everywhere, to get timely decisions instead of too costly and too long

delayed.

An Opposite Example

Here's what can happen when there's an impartial volunteer

panel of one's peers to complain to:

1. Long ago (1978?) I met someone who took his complaint to a Municipal

Board of Variance. A corner of his garage stuck out a few inches and

the eaves at that corner maybe 18 inches too far onto the boulevard and

he was told by a city official to move or demolish the garage. It had

been that way since before he bought the place and was in no ones' way.

No one had complained about it. Technically the official was within the

law, and a court would probably have so ruled. It's easy for government

to put heavy burdens on individuals and families virtually on a whim

when there is no penalty to itself for doing so.

He said he went in with all kinds of documents, photos and

arguments, ready to fight. They looked at his application for a

variance for a moment, and probably the photographs, (or had already

looked at the submission?) and without further comment the head of the

board said "Granted." and it was signed. No need to tear down his

perfectly good garage!

Isn't that how it should be? My proposal is essentially to

extend the scope of such independent local tribunals, and allow them to

work with a complaint of any sort against any major institution.

Grievance panels everywhere may pass on unspecified minor matters of

contention, bringing the power of thousands and thousands of volunteers

from all around the country to adjudicate according to "reasonableness"

the many individual disputes not warranting the attention of the few

paid workers, a court or a lone "ombudsman".

[Some further remarks are in the next issue, TE News 179, and in

defience of chronology I am adding this link here.]

Scattered

Thots

* For a number of years, farmers have been going out of business in

droves. Rising costs for everything, poor weather and now scarcity and

cost of fertilizers has reduced crop yields and now rising interest

rates on their large loans have tipped more of the remainder over the

edge. Billionaires like Bill Gates buy up the land cheap, hundreds or

thousands of farms. They're "just an investment" - they have no

intention of farming. So there are no farms to be had by erstwhile new

farmers, and a staggering amount of producing acreage has been and is

being lost.

And the reduced yields are of course affecting those

farmers that remain. As food costs rise (50% food inflation over 3

years according to Neil-McCoy-Ward on youtube), the Canadian government

has decided hand out extra money to those on pensions and assistance to

help cover the increasing costs.

What I want to know is how this helps farmers to stay in

business and to increase the food supply? Prices can only continue to

rise rapidly if there isn't enough to go around. Ah well, all the

disastrous bad decisions by those of influence are doubtless all part

of the "Great Reset" or Christ Michael's "Correcting Time" plan or

whatever it is you want to call what is rapidly coming to a head like

an oncoming derailed train.

* We Discovered Why Trains Keep Derailing

https://www.youtube.com/watch?v=olnVwQzQZRs&ab_channel=MorePerfectUnion

-- Now 1700 derailments per year. It turns out it's the wheel bearings.

When the grease dries up the wheels melt off. Of course there are a few

other factors like the railroads now being owned by "hedge funds" who

have no interest in or knowledge of running railroads, and who have

pared labor and maintenance to the bone for a temporary increase in

profit margin.

-- 31G$ merger tween CANADIAN PACIFIC and Kansas City Southern was just

approved by US REGULATORS! When did CANADIANS approve anything like

this?

-- "Six major railroads left IN AMERICA after mergers over the decades"

One was CN! When did CN become an AMERICAN railroad?!?

* In a mine near the town of Ytterby, Sweden, four elements were first

discovered and all named for the town: Yttrium, Ytterbium, Erbium and

Terbium. Someone went to Sweden and while he was there he asked just

how that town name was pronounced: "Ooterboo." (!) This seems to make

little sense except that in Cryllic alphabet "Y" is pronounced "oo".

(But the rest of the letters are latin. ? )

This means that two of the elements would be "as written"

but the other two apparently are correctly pronounced "Ootrium" and

"Ooterbium". ? And that's probably how they're pronounced in Sweden.

* People keep "finding" or is it "creating" "new elements". But the

highest atomic numbered element that can be created by neutron

bombardment is 100, Fermium. And the Urantia Book says that if there

are more than 100 electrons orbiting a nucleus, it disrupts virtually

instantaneously. And this element, #100, is the highest numbered

element that was found in the fallout from hydrogen bomb tests, along

with all of the lower numbered elements.

Thus we see that anything beyond Fermium is a highly

artificial, short lived curiosity that never could nor will ever be

found in nature. Anything beyond that doubtless exists only as a

positively charged ion with no more than 100 electrons orbiting it. It

bugs me seeing these silly names of "elements" beyond 100 that can

never be seen or made use of in any way, absurdly "extending" periodic

tables. (Apparently Fermium was named not for Enrico Fermi, but for the

French word "Fermé" - "Closed" as in "case closed, there's no more

elements".)

* Colonel Douglas MacGreggor was saying all fall and winter that he

expected the Russians to make a main assault sweeping through Ukraine

as soon as the ground froze hard so they could roll through the open

fields instead of just along the paved roads. Recall that in WWII the

Germans were stopped in the autumn by the mud in Ukraine. (There

weren't any paved highways in Ukraine back then!) His theory was never

put to the test because it stayed warm and stayed warm -- there was

virtually no winter in Ukraine, and indeed all Europe was asking "What

happened to winter this year?" (That also surely prevented a disaster

with heating fuels. But I digress.)

Now it is expected that they are waiting for the spring

rains to end and the ground to harden for the same purpose, because

still or again it's all mud and that has hampered even local operations

on both sides. My next question is: will it rain all summer now? That

would seem to be the fitting next step to keep this senseless war from

ending.

It has become a grueling and horrendous war. Since autumn

it has become like World War One with trenches and fortifications and

neither side daring or able to advance very far, very fast, even when

it makes some sort of breakthrough, because units on the move are

spotted by observation drones and become artillery targets for mass

annihilation. Weapons of destruction are advancing to the point that

the combatants seldom even see each other. Soldiers are killed at too

great ranges, mostly by artillery including shells, rockets, missiles,

"suicide drones" and now "thermobaric" weapons. Strategy and tactics

are changing rapidly and radicly.

* D. Trump claims if elected president again he would end the Ukraine

war "within 24 hours". I've said before that Biden could do the same

any time he wanted, but I gave him a week. Remember how after the 2014

US sponsored coup in Kiev the BBC and other journalists were so

concerned about the rise of neo-nazism in Ukraine? Then remember how

the issue died out of view for four years? The shelling of civilians in

Donetsk petered out. It all seemed to go into low gear as the

military-industrial-congressional-banking oligarchy in Washington had

to work behind Trump's back, because he surely would never have

approved of what was being done.

Now with this "threat" to end the war and make vital

reforms ringing in their ears, fearing he might regain the office, they

presume to arrest him on what are at most minor misdemeanors that (even

if true and if the statute of limitations has not long since expired on

them) might merit a fine or two -- and that no other "honest Abe",

"clean as a whistle" political figure seems to have ever been penalized

for.

* As long as people with hearts full of greed and hatred are in charge

including behind the scenes in unelected positions of influence - and

such types have now managed to expel nearly everyone else - our

societies will continue to deteriorate into chaos. National and

regional governments will finally fail and as I've said before,

civilization will have to be rebuilt from the family and community

level up.

* We could go far beyond just "ending the war". If it were possible I

would prefer to see the Ukraine issue settled the democratic way. Each

oblast (or perhaps regions broken up even smaller) would be offered

something like the following choices, in a manner not so dissimilar to

parts of Europe after World War One:

1. Be part of Ukraine

2. Be part of a new "Western-Rus" country (by whatever name it might

pick)

3. Become part of Russia

4. Become part of Belarus

5. Become part of Poland

There might even be a few more choices - Hungary and

Bulgaria (IIRC) as well as Poland (Lvov region) and Russia (at least

Donbass, Crimea) lost lands to Ukraine by decree under Stalin and

Khrushchev. And the boundaries of the plebiscite might extend somewhat

beyond Ukraine's present borders in case some nearby might want to join

Ukraine or one of the other options. (East of the Dniester in Moldova

("Transnistria") where they speak Russian might like the "Western-Rus"

option... and why does poor Moldova have no access to the Black Sea, so

near? Can we not fix that at the same time?) And if Lvov might want to

rejoin Poland, perhaps the part of Germany given to Poland should also

have a vote as to which administration they would prefer to be under?

Voting would of course be by choice ranking so that voting

for what one wants most doesn't prejudice one's chance of getting what

one wants second most or even third. Obviously each region would be

interested in specific choices and not in all of them. Fine! This is

the voting system that will work in all cases.

Wouldn't that produce the best outcome - the bulk of

everyone getting what they most - or at least second most - want? No

fuss. No war.

There may be many who would prefer the "Western-Rus"

option. We will probably never know. Presently the regions under

Russian control were only offered whether to join Russia or not, under

conditions where they desperately need Russia's military help and while

Russia has a brilliant and well liked leader who will be gone some day

not so far off. So it's no surprise they voted over 90% "Da!" (Two

choices is of course far better than no choice at all - as is presently

the case in all the regions under Kievan control!)

Unfortunately there's far too much politics and too many

politicians with too many agendas, with too little imagination and too

few ideals to allow adoption of such a satisfactory, democratic

solution under present conditions. So we have war instead.

* I thought we in the West didn't like Lenin, Stalin or Khrushchev? Yet

we want to restore Ukraine's 1991 boundaries, the very boundaries those

despots created by transferring more and more bordering regions into

Ukraine? Why do we want to ratify and approve of Lenin, Stalin and

Khrushchev creating this polyglot region which subsequently became a

"country"?

* Putin has canceled 20 billion US$ of debt owed to Russia by African

countries. These debts were mostly accumulated during the Soviet era by

countries espousing the USSR's communist philosophy. Doubtless some of

the original debt has been long since repayed, and one wonders how much

of this remainder could ever have been when nations across central

Africa are now starving. Still it is a magnanimous gesture. The USA

never forgave Britain its World War Two debt. IIRC the last payment was

finally made well after Y2K.

* I had found that my cell phone was making my leg vibrate and pulsate

right where it sat in my pocket. I stopped carrying it and the problems

gradually went away. Then I thought some trouble with my right leg must

be from my car key fob, and I stopped carrying that too. But nothing

changed. Now I think the key fob had nothing to do with my right leg

troubles. It is surely far lower power than the cell phone, and

hopefully not transmitting very much.

(I think it's little mites coming off the firewood and

getting into my pores in my thigh. I've been wearing a glove now to

keep them off my hands, and killing them on my leg with a drop of witch

hazel, applied and wiped off after a moment. But they keep coming back.

I got a whole bunch again recently, all at once. I was perplexed and

then realized it was from the sawdust (complete with mites) coming off

the chainsaw and hitting my right leg when cutting firewood! I'll wear

rain pants or something else impervious next time. Is it only me they

manage to infest?)

ESD

(Eccentric Silliness Department)

* Lightning never strikes the same shrub twice.

* Master mathematician Jesus warned us that "Greed is the square root

of all evil."

* Military spokesman says "enemy underground stronghold must be raised

to the ground."

* "There are consequences for abolishing consequences." - "Uncle Frank"

(Youtube video comment)

"in depth reports" for each project are below. I

hope they may be useful to anyone who wants to get into a similar

project, to glean ideas for how something might be done, as well as

things that might have been tried, or just thought of and not tried...

and even of how not to do something - why it didn't work or

proved impractical. Sometimes they set out inventive thoughts almost as

they occur - and are the actual organization and elaboration in writing

of those thoughts. They are thus partly a diary and are not extensively

proof-read for literary perfection, consistency, completeness and

elimination of duplications before publication. I hope they may add to

the body of wisdom for other researchers and developers to help them

find more productive paths and avoid potential pitfalls and dead ends.

Electric

Transport

Magnetic Variable Torque Converter with Planetary Gear

One day I drove the truck

out of the garage to show it to someone. Well out of the garage,

something went clunk and it was slipping. Murphy's law in action! We

pushed it back in.

But this gave me an idea: I could cut a short keyslot into

the socket of the driveshaft - not the usual "drifting" (is that the

right name?) for which I had no tool, but carefully cutting right

through one wall with the angle grinder, making a key to fit, and

putting a pipe clamp (or something much heavier) over the whole thing.

It would be much harder for it to break loose and slip if there was a

shaft key in it. (I am simply assuming that's the join that's slipping.

could be rong.)

[10th] I was rong. It was the alume rotor again. (I'll do the above

shaft key anyway.) The SDS hub just wasn't tightening down on the

shaft. I think I'll cut deeper grooves into it so it reduces diameter

more easily. Also I'm looking for a thicker and slightly bigger chunk

of pure alume to make a new rotor with stronger magnetic interaction,

so I'll be changing that whole little assembly. (Somehow I have a

feeling there's a piece or two at the refuse transfer station, but the

snow has kept me from being able to see much there. I keep thinking

it'll be gone in a day or two like usual, but no luck for weeks so far.

When some melts, it soon snows again.)

[21st] I contacted a metal company in Winnipeg about getting 1/2 inch

pure alume for the disks, including looking forward to doing a 12.5

inch one for the Sprint (or the Echo?). I asked for 10.5 inches, since

the magnetic field of the 10 inch magnet rotor doesn't stop abruptly at

its outer edge. The web site said they had "1100 alloy" (pure alume)...

but they didn't.

[29th] I tried a couple more places over some days. I knew pure alume

isn't as common as alloy, but I didn't know it was virtually impossible

to get. Metal Supermarket said I would have to buy a whole sheet (5

feet by 10, was it?); they wouldn't cut it. Just the shipping would be

horrendous, never mind the price of the whole sheet. Only one place

offered me a cut piece: 1100 $ for 2x2 feet, 1/4 inch thick! (I suspect

that might be the same price as a whole sheet: they would cut it and

keep the rest!) Did I have to melt down pop and beer cans? But even if

I did, I couldn't cast the whole rotor in one melt with my small

crucibles, and pieces melted separately absolutely haven't the

slightest tendency to stick together.

Later someone mentioned that only the main part of the can

was pure alume. The top and the tab are alloy. In that case one would

have to melt down an awful lot of cans to get a kilogram for a rotor.

Cast Copper Rotor?

At that point I started thinking buying copper would be

cheaper - or at least, available - as well as being even more

conductive. (Something like 401 versus 237 for pure alume versus 167

for alume alloy). If I used copper I could go thinner. 1/4 inch or 5/16

inch copper, closest to the magnet rotor, would probably work about as

well as 1/2 inch+ of pure alume. I could even cast just a ring of

copper (ie, with no center) to interface with the magnets, and bolt it

to the present rotor?

This day I visited Steve. I lucked out. He had 5(?)

containers full of scrap copper bits, which were sitting on the front

steps at that moment because he was moving from his house (he sold it)

to a nearby one (free rent for fixing it up). Come to think of it, I

have a few scraps myself, but he had a lot weight of copper. He wasn't

sure what he was going to do with them. And I had that new furnace for

melting metals including copper. So now I thought of casting it instead

of buying a piece and having it shipped here. Maybe (unlike alume) if I

cast copper in two or more pieces they would fuse together? It was

still likely to be a couple of hundred dollars or more to buy a 10.5

inch square piece, 1/4 inch thick.

He said to take a couple of the containers. I got them

home and weighed them 31 pounds - 14 Kg! That should be way more than

enough, which would be 2-3 Kg... perhaps castable in one melt, tho with

a very full crucible. A larger (12.5 inch) one for the Sprint might be

5 or 6 Kg, so it would do me for that potential project as well. Also

at the present spot price of copper, that's over 150 $ worth, which

I'll pay him. Plenty potentially for both rotors, and even at that

price much the cheapest idea yet.

And copper should give the optimum result. Why would I

settle for anything less, anyway? It's easy to separate the rotors a

bit if the interaction is too strong. "Too strong" is the opposite of

the problem so far.

I think I need some more molding plaster and silica to

make a smooth high temperature mold. I've had some in a bag for years,

but looking at it, it's only enough for a piece of jewelery or

something. Or maybe I could use sand and just use the plaster/silica

mix to make the inner face smooth? So... looks like a mold box, and a

model disk/ring piece from (?)plywood must be next.

Hmm... the thin but tall graphite crucible that came with

the little furnace holds 1Kg of copper pieces. The ceramic cup crucible

that I thought was bigger holds 750 grams. So much for perceptions!

Someone who's done it before recommended I not try casting

copper. I plan to anyway. Outside of course. Safety gear. I do note

that I should be blowing the air away and not breathe any. I think the

electric furnace will offgas much less than the oxyacetylene torches

I've seen people using to melt copper on youtube. (And they were

melting only tens or 100 grams or so. Melting a Kg would use up a lot

of gas!)

One other consideration he mentioned was that melted

copper can turn to "jello" and not pour. In that case zinc had to be

added. But these scraps are about 3% zinc already. I trust that's not

enough zinc to seriously reduce the conductivity but enough to solve

the potential problem.

Other "Green" & Electric Equipment Projects

Open Loop Air Heat Pumping

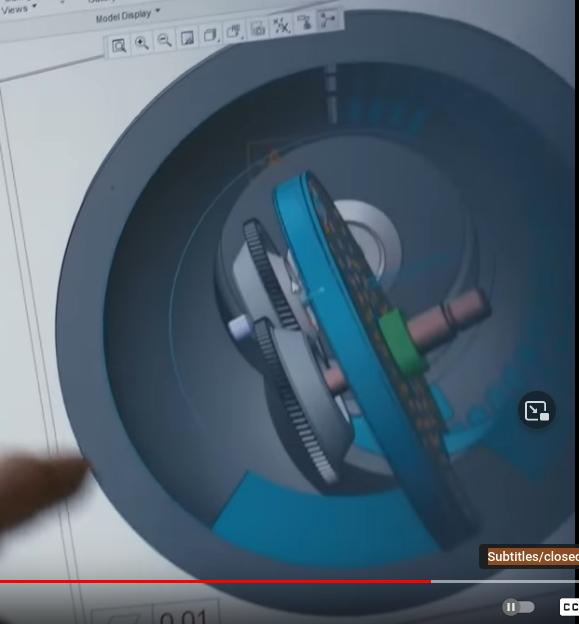

[24th] I saw the "Lontra" air

compressor, essentially a "bicycle tire pump" bent around into a circle

and always pumping around that circle. It was said to be 20 or 30 %

more efficient than any other large air compressor. And hence probably

30 or 40 or 50 % more efficient than a small compressor. This would

start to bring to life that promise for a heating COP of 10 or more

that the technology (including the passive outdoor heat exchanger)

seems to hold.

How could it be made more simply? Something I might manage

to do. On this morning an answer came to me. The circular piston

assembly could be an inside [or outside] ring gear, with the teeth of

the gear even with the inside edge of the piston so as to span 360°

without interruption. At the point in the outer pipe where air is

brought in anyway, a gear would go through the inner side to mesh with

the ring. Bearings on the piston ring assembly or inside the pipe would

guide the assembly so it never rubbed on a stationary wall, instead

"floating" on the bearings. The end valve that blocks the circle pipe

while the air is compressing would have to be double and fit around the

piston gear assembly. (Dang, a leaky spot!) The two pieces would

retract to the top and bottom as they were hit by the piston itself so

it could pass to begin the next stroke. (Of course there would be a

one-way flap or valve to prevent the compressed air, once having left

the circular pipe, from returning.)

How to get the piston ring assembly into the pipe? On the

face of it, this looks virtually impossible. It would seem that the

pipe will have to be made as a top and a bottom side that bolt

together. Materials: alume pipe and UHMW-PE piston assembly? Rats, I

have an entirely too coarse set of gear cutters. I'll need to order one

that cuts much finer teeth. (And how will I hold the ring to cut the

gears, unless it is very small? Well, maybe it doesn't need to be

anything like as big as I've been thinking? Maybe I'll keep it under 10

inches diameter so it fits on my lathe, too.) And in fact, maybe it

doesn't need to be gears... maybe for a small unit it could just be a

rubber(?) cylinder rolling against the side fo the ring? Bonus: if the

pressure got too high owing to some blockage, the cylinder and ring

would slip. (Is that a bonus or just a way to fast wear-out?)

...Or maybe an actual simple "bicycle type" pump with a

long, narrow tube with a low mass piston and reciprocating parts, would

also be quite efficient? The worst inefficiency in a bicycle pump is

the skinny hose the compressed air has to go out through. That can

easily be changed! It only needs to make 50 or 60 PSI, so it doesn't

need to be as robustly built as a higher pressure one. I'm sure it

would be much the easiest to make, which could finally get the project

moving along. I'm now leaning to this. But I'm still wondering for it

how to employ the cooled, exhausting, but still compressed air to help

pump the new air, which as I recall saves 29% of the energy.

Electricity Storage

New Chemistry Batteries

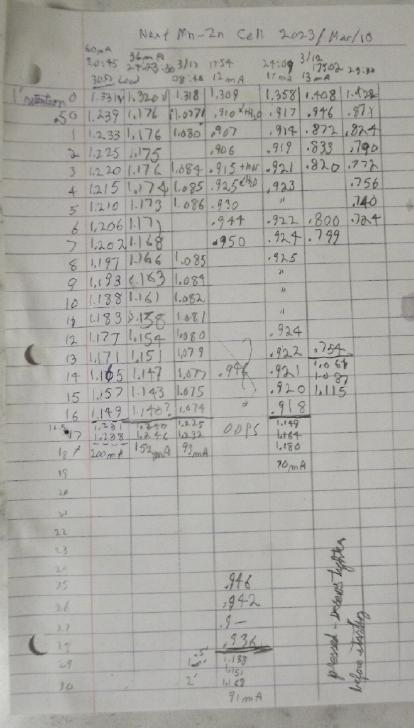

At the end of February I

had wrecked my nickel mix by accidently soaking it in toluene instead

of acetone. I figured it probably wouldn't work well after that and

discarded it.

So instead I put together a revised manganese-zinc cell

about the start of the month. I used wax to "pot" it, but this wasn't

very successful as it still leaked even after taking a heat gun to it

and remelting it.

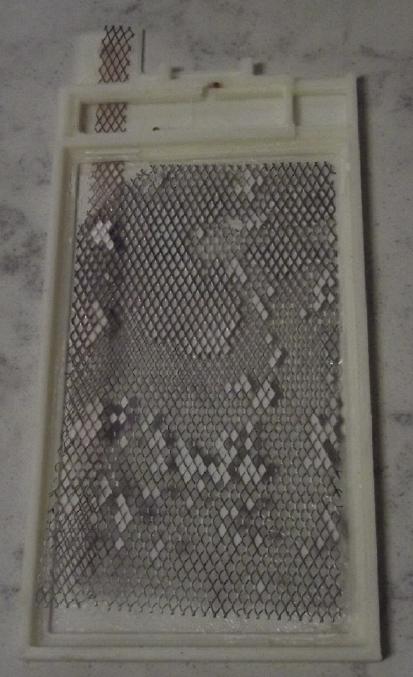

I put in a copper mesh current

collector and painted it

I put in a copper mesh current

collector and painted it

with zirconium silicate to raise the hydrogen overvoltage.

It didn't seem to discharge itself between electrodes, but

it was somewhat short on MnO2. I had simply used all the dry cell

MnO2+graphite (+Sm2O3) that was left over, a few grams. The voltage

dropped much faster in a discharge test than the previous cell, and it

only put out one amp. Charging current also seemed to be halfed. It did

gradually charge up to 1.5 volts, but it took a couple of days and

after half a day it was only drawing 12mA.

Subsequent tests showed continually reducing capacity, so

maybe trying to recharge to MnO2 just wasn't working well. Nobody else

has got it to work, so should I be surprised? But I also consider that

the fine dry cell nano-powder isn't the best for all the particles. I

found some coarser "granular" manganese dioxide in my stash. I also

looked at Mn metal powder and regular MnO2 powder under the microscope

- three quite different shapes and sizes. Variety might help? What else

could I try? What would be a good additive or process? Monel powder?

[7th] It seemed to stabilize... at the unsatisfactory low level, but it

wasn't getting worse. It might have to do with the cell leaking, too,

so I should try again to seal it up. Instead I decided to redo the MnO2

electrode and see if I could get better performance.

[9th] I took the cell apart by melting the wax with a hot air gun (the

big advantage of wax over epoxy).

Neither the MnO2 powder nor the zinc came cleanly off the

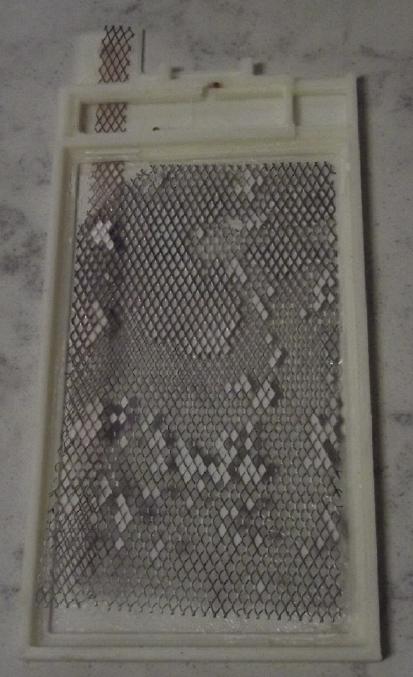

separator paper so it ripped up and I redid it. I cut 5 new separator

papers from a sheet of watercolor paper and soaked them with methyl

benzene (toluene, toluol) twice, the second time being just as they

were about dry from the first time.

When the toluene was dry I painted them with sodium

dodecylbenzene sulfonate. At first I had the SDBS mixed quite thickly,

but it seemed to me it wasn't penetrating much into the paper, so I

thinned it with more water to be sure it would soak in.

I changed the manganese electrode completely. Instead of

dry cell MnO2 I used the somewhat "granular" MnO2 from the pottery

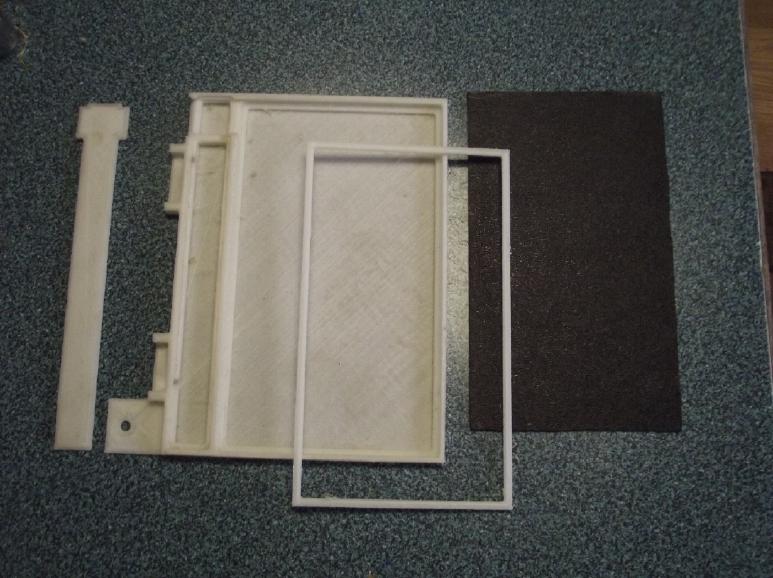

shop. Instead of graphite to raise conductivity I tried monel powder