Turquoise Energy News Report #188

Covering

January 2024 (Posted February 13th 2024)

Lawnhill BC Canada - by Craig Carmichael

[CraigXC at Post dot com]

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Month In "Brief"

(Project Summaries etc.)

-

"Everlasting" Cu-Zn

Battery Development - [Electro]Magnetic Torque Converter:

Better Designs - Open Loop Air Heat Pumping: - Even Better Air

Compressor & Decompressor Designs - Recap: How OLAHP Works

-

Better Peltier Module Project

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Scattered

Thots: Tinnitus Measurement in dB - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Perfecting the Magnetic Variable Torque Converter: Video - An Even

Better Design!

Other "Green"

& Electric Equipment Projects

* Even Better Air Compressor Design! for Open Loop Heat Pumping

("OLAHP")

Electricity Storage:

Batteries

* Copper-Zinc cell is fantastic! - Many Builds and Tests etc, etc, etc,

etc...

Electricity Generation

* My Solar Power System: - The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

Over the cold, wet months of November, December and

January (and on into February) I got back to the "new chemistry"

battery project and started

making breakthroughs. And

I did other energy project project work and gave a lot of thought to

three

other designs, detailed below "battery development":

* Not finding time to do any work on it, I made a video "Perfecting the

Magnetic Torque Converter". As soon as I had done that, after watching

another video on the subject I came up with a major

improvement to make it

"ultra-efficient", rendering part of my design "obsolete". I think I

ought to tackle building the extra component and putting the new design

in the truck.

* I found a better rotary air compressor design for open loop air

heat

pumping (OLAHP) - and improved on it. I also thought of using a

"pelton

wheel" system as the simple rotary decompressor to complete the "most

efficient" compressor-decompressor unit, one of the three main

components

required to gain super high coefficients of performance for indoor

heating. (eg COP 10 at 0°C?)

* And I wrote a recap of how OLAHP works for those who missed

my spring 2020 concept or who want a refresher.

(COP=10 in freezing weather or 1000W of heat

per 100W of electricity, or "How to heat a house almost for free.")

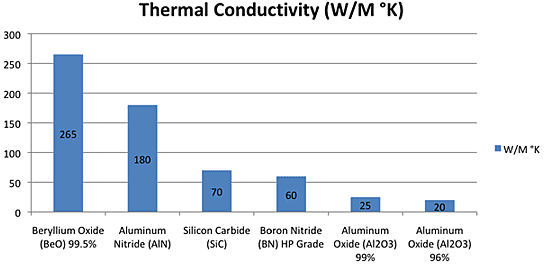

* I ran across a company with thin boron nitride ceramic disks to make better

Peltier

modules with super low thermal resistance and ordered some,

as

well as apparently "the best" thermal heat sink compound on the market.

All for when I have time again. When weather permits I'll

have to focus on my cabin construction (just started putting in the

stairs), and gardening and firewood cutting season approaches. So I

expect I'll have to put the energy projects largely on the shelf, maybe

even until about the same time next winter. (But it would be really

nice

to get the OLAHP going and need much less firewood next winter!)

"Everlasting" Cu-Zn

Battery Development

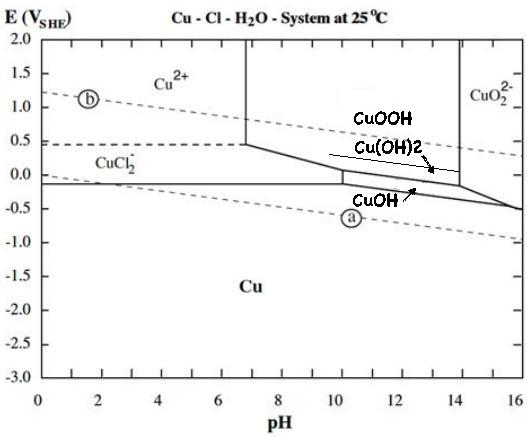

It was exciting to find that copper in a positive

electrode probably charges through four states, not three, to make a

copper-zinc cell of amazingly high energy density despite the low

discharge voltages. No one previously seems to have discovered the

highest energy state, perhaps because previous copper cells (according

to the literature) all used copper oxide (CuO), which seemingly does

not convert to hydroxide Cu(OH)2 under any circumstances.

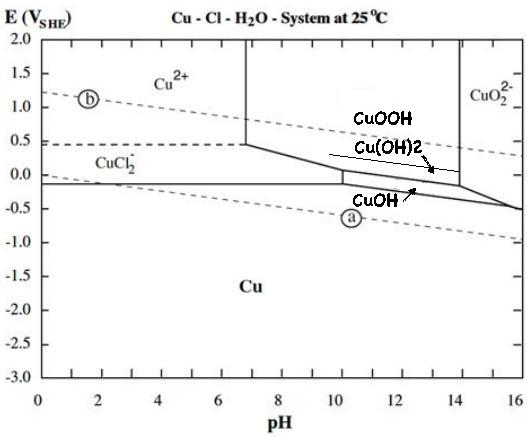

from:

- metallic copper powder, to

- CuOH (~+1.0V), to

- Cu(OH)2 (~+1.1V), to

- CuOOH (~+1.2V). This form, copper at valence III, isn't found

in any battery literature or Pourbaix diagram. It is a rare but known

substance.

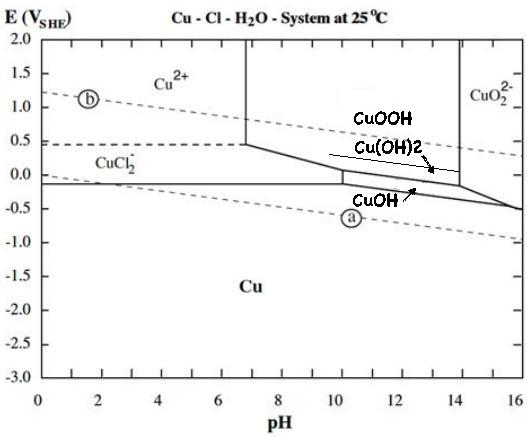

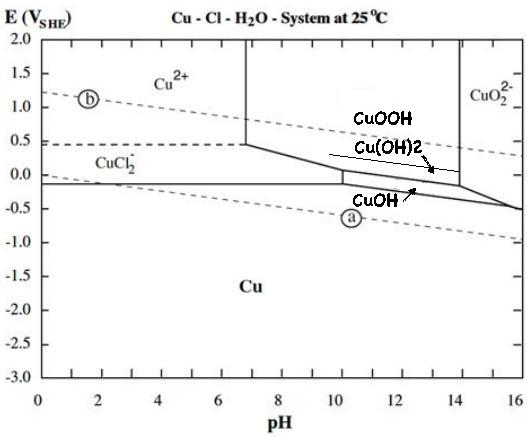

So instead of moving just one electron per atom like

nickel, copper can move up to three. I made (modified) my own Pourbaix

diagram for copper in salt solution. For some reason where I started by

forcing the pH to 12, the cell seems to work just as well at neutral

pH, so perhaps it dissolves at a lower pH than shown:

Whereas a nickel-zinc cell needs 3 to 5 times as much of

the nickel hydroxides substance as the zinc, for copper they're about

equal, greatly shrinking a cell of similar capacity. It may even be

possible to make them with Elon Musk's estimate that one would want

"400 WH/Kg" for electric aircraft, tho 300 is probably more achievable

and 200 should be simple. 200 WH/Kg is good for long range EV's, but

with the low cost main elements, high safety factors, super long life

and high recycleablity I see them as being especially great for

off-grid solar and utility grid scale energy storage.

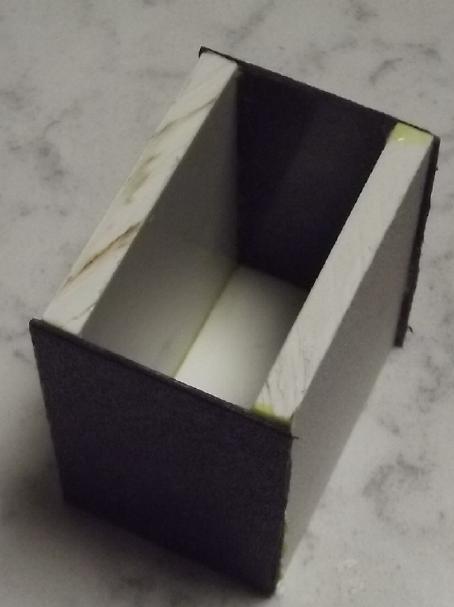

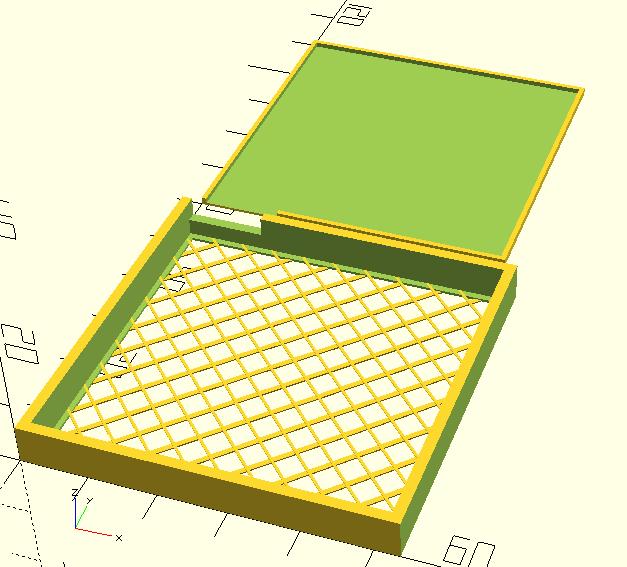

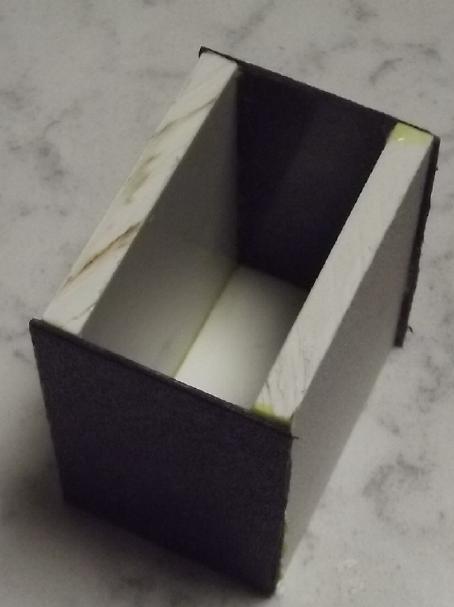

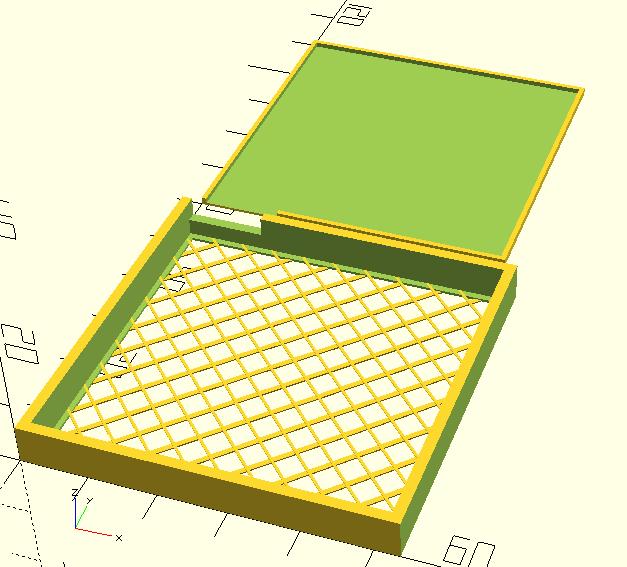

This was again the main focus of the month. I started with

another cell design concept, a square or rectangular box with multiple

small electrodes. I chose 50x50mm for the active material faces. The

box would have multiple double faced electrodes end to end and the box

ends would be strong enough to prevent bulging with loss of internal

electrical conductivity. In trying to do flat cells I could never

countenance having two faces as thick as the two electrodes inside, as

they need to be to prevent bulging. But if the cell is to have multiple

trodes stacked up the thickness penalty is no greater.

I made a very

small one, 53x60mm x 25mm "long" inside

dimensions, to have just one double electrode in the middle and two

single end electrodes, to be 6:12:6 mm, the end ones being single

faced. A larger one might be for example 6:12:12:12:12:12:6

(|Cu:Zn|Zn:Cu|Cu:Zn|Zn:Cu|Cu:Zn|Zn:Cu|), 72mm long inside. (Now I

really need more 3/16"

or 1/4" ABS sheet. I'm about out of what I moved up to Haida Gwaii

with.)

I made a very

small one, 53x60mm x 25mm "long" inside

dimensions, to have just one double electrode in the middle and two

single end electrodes, to be 6:12:6 mm, the end ones being single

faced. A larger one might be for example 6:12:12:12:12:12:6

(|Cu:Zn|Zn:Cu|Cu:Zn|Zn:Cu|Cu:Zn|Zn:Cu|), 72mm long inside. (Now I

really need more 3/16"

or 1/4" ABS sheet. I'm about out of what I moved up to Haida Gwaii

with.)

But I only put in one single sided zinc electrode and

tested it with various copper powder and copper hydroxide tries,

filling the extra spaces with

pieces of plastic. The zinc has lasted the month with no sign of

letting any dendrites get through or other deterioration. (except I

abraded some of its watercolor paper away putting in and pulling out

various copper electrodes to test them. That doesn't seem to have

killed it yet.)

I

designed

electrode "boxes" with porous faces. I ended up

deciding to use them for the copper side but to just wrap the zincs in

treated watercolor paper. In the first boxes the metal current

collector, separator paper and powder all had to be

stuffed in the top edge. The edge was then sealed with heat glue. It

was tedious trying to stuff powder through a thin slit and I changed

them to having an open face. (...two for double faced boxes) Everything

(separator paper, active

powder, current collector) was laid into it flat, then the other face

was glued on with methylene chloride or ABS cement. Only a bit of heat

glue was needed around the terminal tab.

I

designed

electrode "boxes" with porous faces. I ended up

deciding to use them for the copper side but to just wrap the zincs in

treated watercolor paper. In the first boxes the metal current

collector, separator paper and powder all had to be

stuffed in the top edge. The edge was then sealed with heat glue. It

was tedious trying to stuff powder through a thin slit and I changed

them to having an open face. (...two for double faced boxes) Everything

(separator paper, active

powder, current collector) was laid into it flat, then the other face

was glued on with methylene chloride or ABS cement. Only a bit of heat

glue was needed around the terminal tab.

At first

I was using copper powder. That's the "most discharged" form, and

prohibitively expensive to buy. How could one possibly make economical

batteries?

At first

I was using copper powder. That's the "most discharged" form, and

prohibitively expensive to buy. How could one possibly make economical

batteries?

Then I thought

to make copper hydroxide powder from solid copper pieces. It didn't

work very well in potassium chloride.

Then I thought

to make copper hydroxide powder from solid copper pieces. It didn't

work very well in potassium chloride.

It was somewhat better with

magnesium sulfate.

It was somewhat better with

magnesium sulfate.

And about there I started using flat sheets of copper (cut

& flattened pipes) hung from a wire in a jar.

Black ? copper hydroxides using

KCl, brown

mostly CuOH (I presume) from MgSO4.

Black ? copper hydroxides using

KCl, brown

mostly CuOH (I presume) from MgSO4.

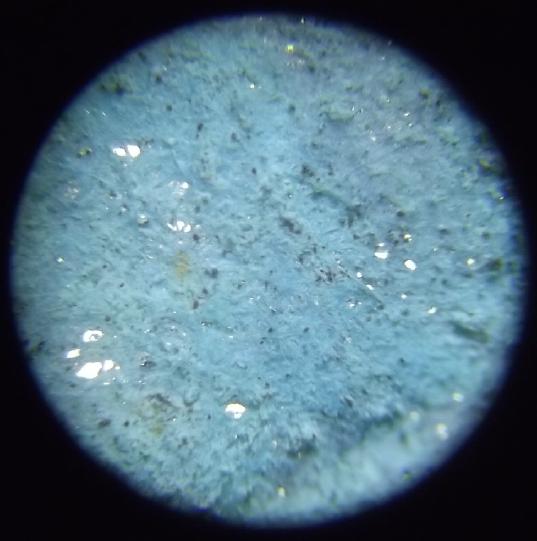

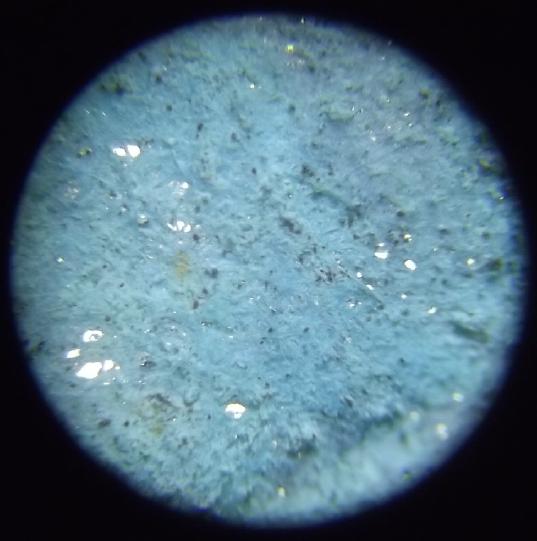

But far and away the best salt, as shown in

a youtube video, is sodium nitrate. It gives beautiful sky blue

relatively pure Cu(OH)2.

But far and away the best salt, as shown in

a youtube video, is sodium nitrate. It gives beautiful sky blue

relatively pure Cu(OH)2.

I ran into a hitch - Westlab wouldn't sell me any.

Apparently it's a "controlled substance" sold only "to corporations for

business purposes". I gave them my Turquoise Energy Ltd. info, but they

haven't replied since. I made some from nitric acid (expensive) and

baking soda to get started. (There's another way with ammonium-aluminum

nitrate "cold packs", but it's complicated.) Then I ordered some from

Sigma-Alderich (or is it "Millipore Sigma"?) on line, where I

previously got an account to get the sodium dodecylbenzenesulfonate. It

arrived in February.

My cells

(various electrodes in the same container) worked but had very low

currents. I started

trying to increase current drive. First I discovered that the parchment

paper I was using was too closed. It wasn't letting the electrolyte

ions flow freely. Poking a couple of hundred holes in it with a needle

improved current flow substantially.

My cells

(various electrodes in the same container) worked but had very low

currents. I started

trying to increase current drive. First I discovered that the parchment

paper I was using was too closed. It wasn't letting the electrolyte

ions flow freely. Poking a couple of hundred holes in it with a needle

improved current flow substantially.

But what to use? Finally I hit

on paper from basket

coffee filters - great open non-woven cellulose fiber sheets that

somehow manage to keep coffee clear, not letting any fine coffee powder

through.

Then I made the "perforated" plastic box faces more of an open "basket

weave" to assist current flow, counting on the coffee filters to keep

the copper hydroxide

powders in and the cell ends to prevent bulging. [looks like they may

be inadequate. use 2 layers?] These things got short

circuit currents up from around 4 or 5 mA/sq.cm to 17. A reasonable

target, however, is more like 50, so I was only 1/3 of the way there.

Then I remembered to try dissolving the electrode powders (just copper

hydroxide and graphite for this electrode) in acetone to reform into

epitaxial crystals mixed at molecular levels instead of being separate

particles. [February: That seems to be helping too.]

But what to use? Finally I hit

on paper from basket

coffee filters - great open non-woven cellulose fiber sheets that

somehow manage to keep coffee clear, not letting any fine coffee powder

through.

Then I made the "perforated" plastic box faces more of an open "basket

weave" to assist current flow, counting on the coffee filters to keep

the copper hydroxide

powders in and the cell ends to prevent bulging. [looks like they may

be inadequate. use 2 layers?] These things got short

circuit currents up from around 4 or 5 mA/sq.cm to 17. A reasonable

target, however, is more like 50, so I was only 1/3 of the way there.

Then I remembered to try dissolving the electrode powders (just copper

hydroxide and graphite for this electrode) in acetone to reform into

epitaxial crystals mixed at molecular levels instead of being separate

particles. [February: That seems to be helping too.]

When I thought

I had everything "perfected" I

still got

variable results. Copper seems to have some idiosyncrasy of charging,

loads and currents and I haven't figured it out yet. It's certainly not

the only electrode that does. Lead batteries for example may be left on

trickle charge for a long time, and then they deliver very poorly and

don't run very long, but if they are then run down and charged again,

perhaps more than once, they are restored to strength. Copper seems to

be - somewhat - similar?

When I thought

I had everything "perfected" I

still got

variable results. Copper seems to have some idiosyncrasy of charging,

loads and currents and I haven't figured it out yet. It's certainly not

the only electrode that does. Lead batteries for example may be left on

trickle charge for a long time, and then they deliver very poorly and

don't run very long, but if they are then run down and charged again,

perhaps more than once, they are restored to strength. Copper seems to

be - somewhat - similar?

Going into February it

seemed copper works great a time or

two, then it starts recharging about like manganese - poorly if at all.

But I bleached the electrode, which should oxidize it without

electricity, and it was, if anything, worse. So it looks more like,

having fully charged, it won't discharge. This may explain why I've

never seen mention of anyone making a rechargeable cell with copper.

(Another reason is that others started with copper oxide. It doesn't

convert to hydroxide.) But the cupro-nickel sheets that got me started

before trying copper and copper hydroxide powders

worked better. They too had problems with deterioration, but

considering the way they did I think I see an answer: to make

acetone-mixed

copper-nickel oxides, similar to what I was doing with nickel-manganese

oxides earlier - except to only charge to copper's reaction voltages,

not

nickel's higher one. When copper is working it performs really well and

I

see great potential.

Also, running the cell down to .5 volts with a 10 Ω load

repeatedly and then recharging seems to strengthen it a little each

time. It looks like I need to make that automatic cycle runner and just

keep cycling them until they work well?

I was hoping to do a special feature on great, working

batteries. Well into February I do seem to be figuring things out, so

maybe next month. BTW The nickel seems superfluous. And it looks like

the art paper around the zinc is gradually "clogging" with copper

substances. That is probably the 'deterioration' problem. ...Better

separator papers!

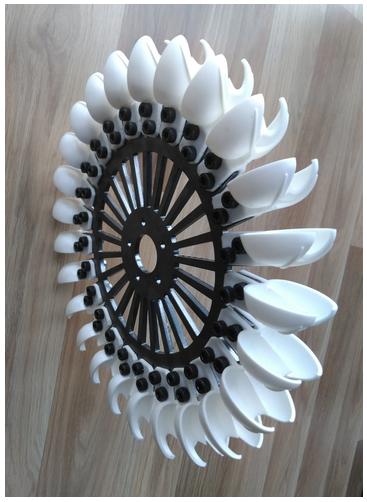

ElectroMagnetic Torque Converter: Better Designs

I thought my magnetic variable torque converter was a

great design, but I saw another one by Robert Murray Smith on youtube

and realized it would be more efficient. He had just put it together

with 3D printed

plastic gears, but it illustrated the concept nicely. It had a similar

idea: rotate the body of the planetary gear as well as the "input" and

"output" shafts, to create variable conversion ratios. But instead of

two magnet disks, he put an outside-toothed ring gear around the

planetary, to be

driven from a motor with a spur gear. This gave programmable control

over the conversion ratio. My system made waste heat, where his

motor's power actually would add to the propulsion.

Toyota did something like this in the Prius, too. But I

didn't like having a motor that had to be controlled externally, and

with no

intrinsic torque or speed feedback. I once thought of something like it

myself

but it seemed too complicated to build. In addition, this motor would

have to

run faster and faster with vehicle speed. It and its gear would be

whizzing away on the highway.

Another way besides a motor would be a generator.

The harder the generator works, the the more resistance to turning the

planetary gear body would have. The power generated could simply be fed

back to "B+" to run the main motor.

A way to do that with the desired intrinsic feedback would

be with a differential gear on the side of the drivetrain. One side

would be driven by the motor

shaft and the other by the gear body's rotation. The generator would go

to the common center and be turned by the difference in rotation

between the two, generating more current and hence resisting the free

slipping of the planetary body more and more with increasing torque,

thus responding automaticly to torque and speed. This configuration

does again entail spur(?) gears on the differential spinning faster and

faster with vehicle

speed.

But there's a way to make a generator that's reactive to

torque and speed without extra, fast spinning gears: have it as a

component on the main shaft, with big, low RPM components - even the

same 10 inch magnet rotor I'm now using and a matching stator with

coils. Have the "stator" rotate on the planetary gear body and the

"rotor" rotate on the motor shaft. (or vise versa) Then the amount

generated would depend on the slip between them, as with my magnet and

copper rotors. Drawbacks to this would be the need for slip

rings/commutator to

make the electrical connections and that the stator must be strong

enough to spin, at up to perhaps 2200 RPM on the truck, or 1000 on the

car with direct drive to the wheels (for 100 KmPH).

While I early on found that a copper disk's reaction to

magnets doesn't increase

much after a certain point of speed, a generator coil's reactions do. A

big chunk of solid copper (or alume) starts getting current migration

to the surface at quite a low interaction speed, but one must get to

quite a high frequency before the diameter of wires in coils becomes a

significant factor. In the generator the wires go across the magnetic

field and the current is forced to flow through them rather than

eddying around. Wires would thus have more electromagnetic interaction

than the solid rotor, with far less copper. Then by putting in the slip

rings and a diode bridge to recover the energy as electricity to "B+"

for

the motor eliminates even the small amount of wasted energy and heat.

The amount of slip becomes unimportant energy-wise and can be tuned to

the reduction

ratios desired at various torques and speeds. Thus a 10 to 1 or even 5

to 1 planetary gear should be great and the transmission will be super

efficient regardless. There's no need for super high reduction

planetary gearsets.

That should work fabulously and I think it's the design I

ought to do. ...When have

time to make and install it.

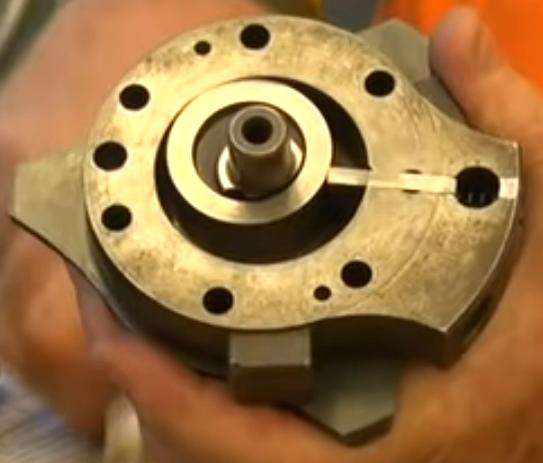

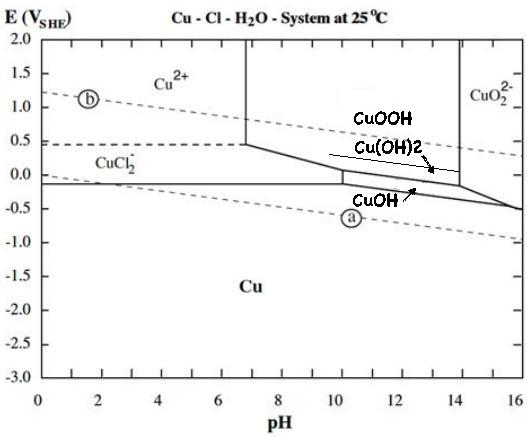

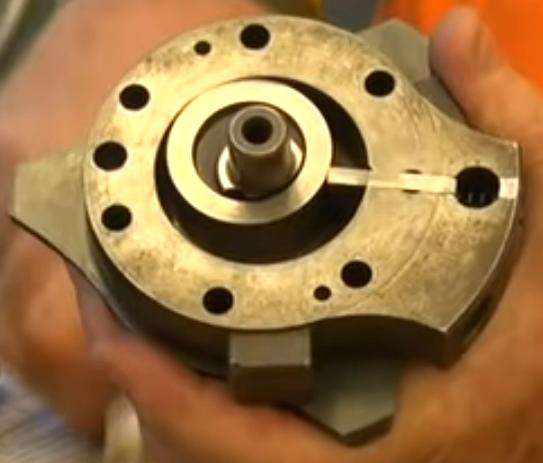

Open Loop Air Heat Pumping (OLAHP)

I didn't do

much actual work on this - but I improved the

design. First I found a better rotary compressor - a real one

(apparently made by "Carrier"). It had a single in/out sliding vane in

the outside housing, and I

realized there's actually no reason to have more than one. The air can

be scooped through the whole circuit and pushed out the output port.

I didn't do

much actual work on this - but I improved the

design. First I found a better rotary compressor - a real one

(apparently made by "Carrier"). It had a single in/out sliding vane in

the outside housing, and I

realized there's actually no reason to have more than one. The air can

be scooped through the whole circuit and pushed out the output port.

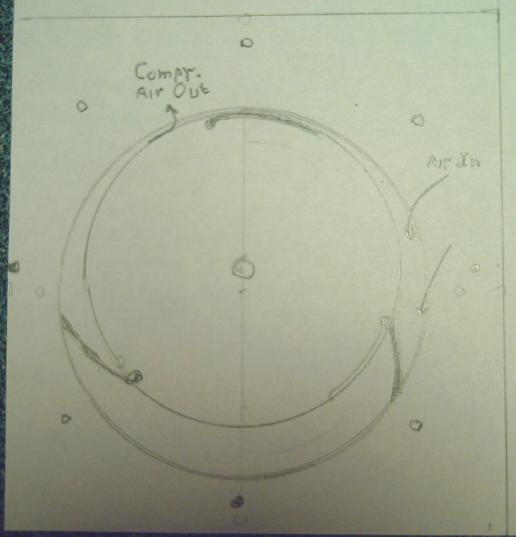

But I

improved on that concept. With the spring loaded - sliding - vane in

the outside housing the whole rotor had to be eccentric. That's not

balanced and it probably vibrates a lot. I'll have the housing

eccentric and the - pivoting - [lower friction] vane on the

rotor. Basicly that makes it the same as last month's design (shown

here) except with just one vane instead of three and the air intake

close to the top.

But I

improved on that concept. With the spring loaded - sliding - vane in

the outside housing the whole rotor had to be eccentric. That's not

balanced and it probably vibrates a lot. I'll have the housing

eccentric and the - pivoting - [lower friction] vane on the

rotor. Basicly that makes it the same as last month's design (shown

here) except with just one vane instead of three and the air intake

close to the top.

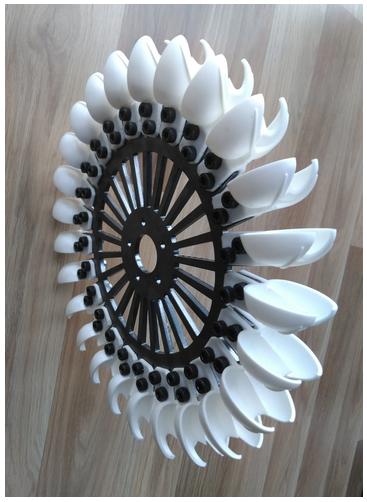

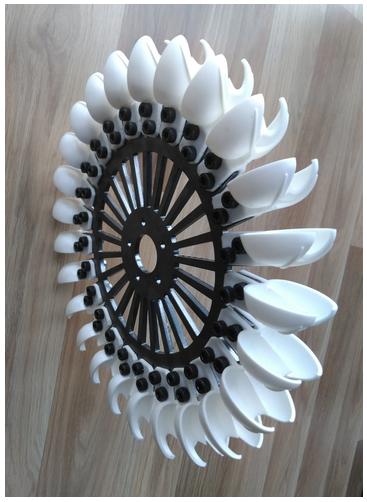

Then I realized there's a

simpler way to do the

decompressor. Instead of feeding air into the center like a rotating

sprinkler (requiring some sort of rotary slip joint in the piping), it

can be fed into the edge of a chamber to drive a Pelton wheel, similar

to hydro power. The pelton wheel would be on the same shaft as the

compressor or geared to it. Having radiated its heat almost down to

outdoor temperature, after decompressing by driving the wheel the (by

now very cold) air is vented outside. It might need a condensation

drain jar underneath, or even a small heater to prevent ice build-up

and clogging.

Then I realized there's a

simpler way to do the

decompressor. Instead of feeding air into the center like a rotating

sprinkler (requiring some sort of rotary slip joint in the piping), it

can be fed into the edge of a chamber to drive a Pelton wheel, similar

to hydro power. The pelton wheel would be on the same shaft as the

compressor or geared to it. Having radiated its heat almost down to

outdoor temperature, after decompressing by driving the wheel the (by

now very cold) air is vented outside. It might need a condensation

drain jar underneath, or even a small heater to prevent ice build-up

and clogging.

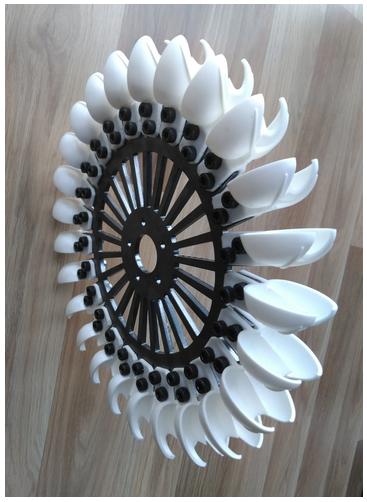

I was going to buy a 10 inch pelton wheel, but I wonder if

I can make a decent one easily with the 3D printer or the CNC router or

both? And I wonder if the traditional "split spoon" shape is ideal for

air or if a single "cup" or "spoon" might be better? Or perhaps an

airfoil shape profile might be the most effective?

Five lengths of the

indoor-outdoor heat

exchanger pipes, counting the two shorts to be used as one length.

Five lengths of the

indoor-outdoor heat

exchanger pipes, counting the two shorts to be used as one length.

(The sixth, not shown, is two shorter lengths of 1/2 inch copper pipe I

made my own square alume fins for some years ago.)

In actual work, I just cut some pieces of wood for the

outdoor heat exchanger, which will be located indoors against an

outside wall. Since its performance is fundamental to achieving very

high coefficient of performance (COP) for the entire system, I'll make

it the best I can do.

I'll be 2 feet tall by five long and 8 inches thick, with

all my six lengths of finned pipes inside it in a single line that

goes back and forth and in and out, with air channels around the pipe

fins and lots of polystyrene foam insulation. And the better it

is, the more heating capacity the whole system can have and with the

highest COP. 1000 watts of heat from a 100 watt compressor is great,

but 3000 watts from a 300 watt compressor will heat a larger space.

With the first outdoor heat exchanger in 2020 (just one finned pipe) I

noticed the highest COP I got (only 3 or 4) was with the 60 watt

compressor and it went down from there with increasing compressor power.

The piping is to be sloped gradually from top to bottom to

drain condensation. At the bottom a collection/inspection jar will hang

underneath to be emptied as required.

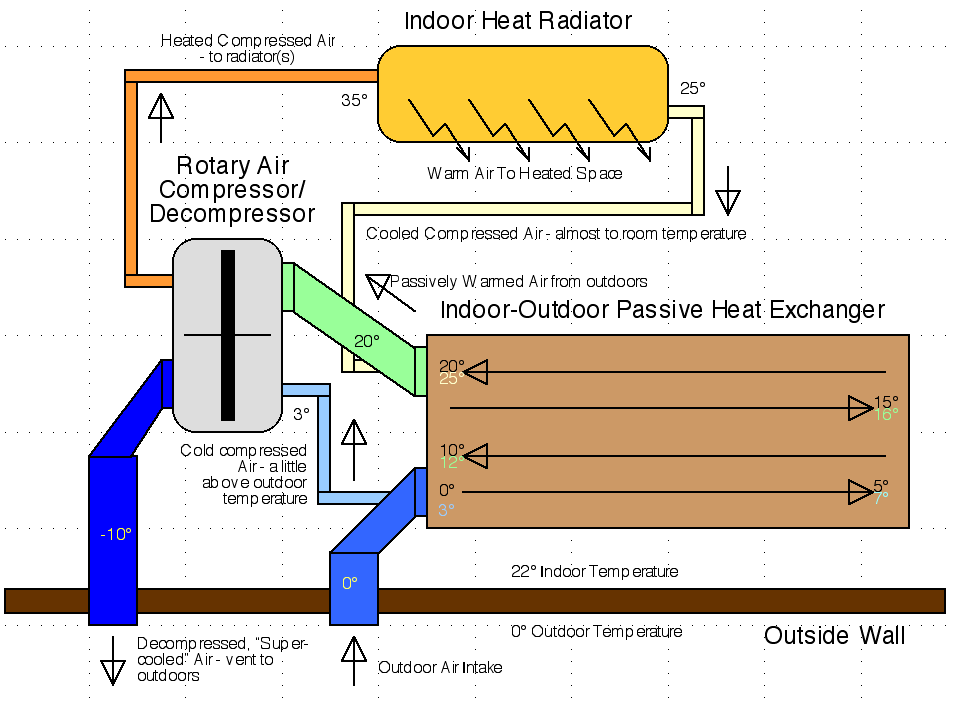

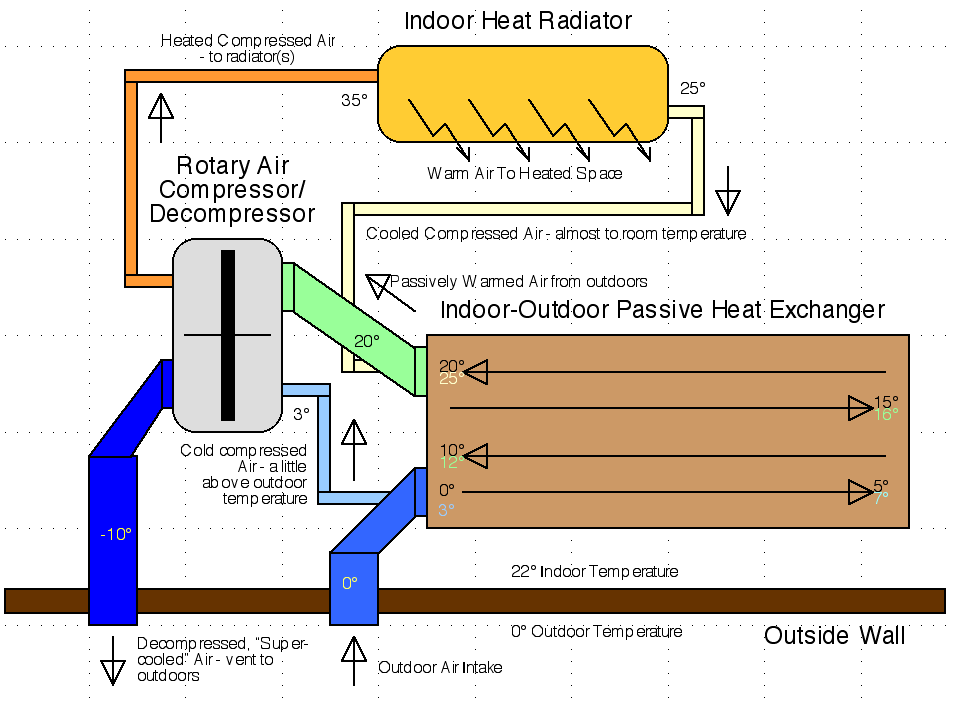

Recap: How OLAHP Works

To recap the open loop air heat pumping (OLAHP)

concept and layout, The efficient

rotary air compressor (see above) draws air from the passively warmed

air

coming out of the indoor-outdoor heat exchanger by direct connection,

or indirectly simply by drawing room air. Drawing room air will

likewise create a suction causing air to flow into the space from

outdoors through the exchanger. (This has the advantage of proving a

flow of fresh air into the space, but a disadvantage of also drawing in

cold air through any leaks in the walls or windows.)

The compressed (and hence heated) air goes into the indoor

radiator to supply heat to the space. In doing so it is cooled to near

room temperature. Note that if the compressor only heats the air by

15°C, say from 20° to 35°, the maximum potential COP is

about 20. [293°K / (308°K-293°K) = 19.533] So if the system

overall is (say) only 50% efficient at 0° outdoor temperature, the

effective COP is around 10. Higher system efficiency or lower

temperature lift by the compressor could give even higher COP values. A

radiator that can radiate enough heat into the space from 30°

instead of 35°

would give a theoretical COP limit of 30 instead of 20.

The still compressed air, now just a little warmer than

room temperature, then goes through the pipes in

the indoor-outdoor heat exchanger, being cooled toward outdoor

temperature as it warms the outdoor air

coming in through the channels surrounding the finned pipes. The more

effective this heat exchange is, the less work the compressor needs to

do and the higher the COP will be. This unit is located indoors,

drawing fresh outdoor air through a duct in the wall.

Finally the compressed air, now perhaps just above outdoor

temperature, is vented into the rotary decompressor (Pelton wheel) to

assist the compressor and the decompressed air is vented outside,

colder than the outside air. (& away from the air intake.) This is

the "open loop" aspect, where the passive heat exchanger draws fresh

air at outdoor temperature and doesn't have to reheat the same air it

has "super cooled", as a closed loop refrigerant based system has to.

So there is no "outdoor radiator" unit.

Open Loop Air

Heat Pump

Open Loop Air

Heat Pump

Better Peltier Module Project

Having received no answer about beryllium oxide ceramic

'plates' or powder some months ago, but instead a warning about the

high toxicity of beryllium oxide from a reader, I had set this aside.

(I was aware of the toxicity, but I hadn't considered that it might be

a bad material to sell to unaware consumers who might, like me, do

"DIY" peltier module projects with it.) But on

the 17th I

have found a place on AliExpress that has boron nitride round disks,

40mm x 1mm thick. That's close enough to give it a try.

Just to make sure of my memory, I went back to TE News #182 and found

this:

Boron nitride

("graphite" structured)> 30

or 600, depending on orientation

("diamond" structured) 740

Two figures looked fabulous, but the "30" was no better than aluminum

oxide. The store's offering was called "white graphite". (boron nitride

that's like graphite except white.)

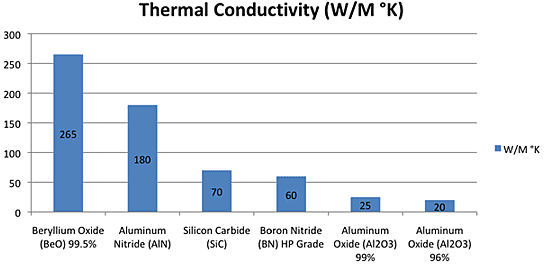

Then I went to

TE News #183 where there was this thermal conductivity chart. Aluminum

nitride, which I found they also have, is said to be six

(or more) times as thermally conductive as aluminum oxide, presumably

in

any direction of heat travel, and so much more certain to give good

results.

Then I went to

TE News #183 where there was this thermal conductivity chart. Aluminum

nitride, which I found they also have, is said to be six

(or more) times as thermally conductive as aluminum oxide, presumably

in

any direction of heat travel, and so much more certain to give good

results.

In fact, it is slightly more conductive than actual alume

metal

alloy,

so spreading the heat out by using (eg) a 50x50mm plate to cover a

40x40mm peltier module should considerably assist getting the heat from

the module into the heatsink.

I ordered 10 pieces, 40mm diameter by 1mm thick. (That was

the size. Not square, nothing bigger. I'm sure I can work with

that as well as with any.) For "when I have time" to look at this

project again. But I haven't even begun to look at how one deposits

copper to form a "printed circuit board" by an additive process onto a

piece of ceramic. Nor am I confident of successfully placing and

soldering all those tiny thermocouples by hand. But I have the ceramic!

:)

Also: I found

and bought what is reputedly the best heatsink grease available,

"Kryonaut", raved over by CPU overclocking fans. I have been planning

to see if just using that gives still better results with the copper

heatsinks. (when I have time, of course!) A peltier module that can

drop a camping cooler's temperature by 20°C or more instead of just

10 to 13° would make them a whole lot more useful! The copper

heatsink got mine improved from a 12.5° temperature drop to 16°

[TE News #181], so copper

heatsinks instead of alume alloy ones get it half the way there. That

leaves the heatsink paste and the electricly insulating skin of the

module

itself as thermal blockages. Then there's the thermocouple elements

themselves. I'll have to leave possible better designs of thermocouples

to

others. (And I still wonder why no one else has tried these other

things to improve the thermal conductivity aspects of Peltier modules.)

Cabin Construction

Over the cold, dark winter months construction has been

lagging, not to say stalled. That of course is why I've had time to

look into creating batteries again. However, cabin construction and

outdoor work are going to be very high on my priorities as the weather

improves and daylight lengthens. Maybe this summer I can complete the

walls, windows and doors, and work on the finishings at a leisurely

pace from inside?

Gardening

Not much to say. The chickens have been scratching up the

garden beds, but they're not very good at digging out grass and weed

roots.

In

Passing

(Miscellaneous topics, editorial comments & opinionated

rants)

Scattered

Thots

* Tinnitus Measurement I had been thinking there was no way to

measure the intensity of the ringing in one's ears, when there is no

external audio sound. But I've thought of one. Turn on a signal

generator with a tone similar to the ringing. (don't buy one, there are

web sites) and set the intensity so that it is similar in volume to the

tinnitus. Use a decibel meter near your head to measure the intensity.

The result may be somewhat crude, but it should be able to

tell 10 dB from 30 dB from 50 dB from 70 dB. Since I moved to this

house on Haida Gwaii much too close to the 14400V power line, mine has

been awful. I'll find out: I ordered a nice looking dB

meter claiming good specs from AliExpress for just 20$ or so.

It came in early February and while there's much

uncertainty, I twice measured it and got around 42 dB, plus or minus

maybe 3. There were some suspicious things. It read that ambient noise

was around 35-37 dB wherever I went (a little more if there was any

slight noise I could hear), which seemed odd. Even if I stuck it

between two pillows it didn't drop, or not much. (I think I got it down

to 34 once.) Another problem was that it didn't seem to respond well to

frequencies over around 3500-4000 Hz despite its claim of responding to

20-20000 Hz ±1 dB, so I couldn't set the on-line signal

generator to a pitch near the high frequency tinnitus. I could hear the

sounds clearly from the speakers, yet the meter read under 40 dB. A

third trouble was that even the pitches it did sense were very

direction sensitive. I could hear them clearly or even not hear them

depending on the position and orientation of my head, including in one

ear or the other, and the meter's microphone also could locate the

"nodes" of higher and lower volume.

ESD

(Eccentric Silliness Department)

* Insidious spyware: There are a million microphones in a phone.

* Someone saw the tax agent coming. He got out his wallet and started

tossing money at him. This is known as "spontaneous remission".

"in depth

reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

"Perfecting the Magnetic Variable Torque Converter": Video

[12th] I had a new idea about the variable torque converter. It was

hard to get enough magnetic interaction between the magnet disk and the

metal disk (copper, alume). If it needed less flux requirements could

be relaxed. I had also noted in my calculations the reduction ratios

decreasing quite rapidly at rather low vehicle speeds, which is

probably not best for good acceleration at low speeds. I had bought the

highest ratio single stage planetary gear available, 10 to 1. I'm sure

the solution to both problems is a higher intrinsic reduction ratio - a

two-stage planetary gear. A 30 to 1 gear would multiply the magnetic

forces by 30 instead of 10, considerably easing the requirements for

the flux interaction. A 40 to 1 or so could make a Chevy Sprint

motor-to-wheel variable torque converter much easier to put together.

Seeing that I have had no time to work on it I decided to

just put up a video about it to follow the previous ones on the

subject. I've demonstrated the principle in the Miles truck. At this

point it'll be up to commercial developers and manufacturers to build

the design to their requirements and likings. I explicitly state in the

description of the video that the technology is all free and in the

public domain. I have taken out no patents or restrictions to use.

Somehow I feel this spreading of the idea is a major

achievement. with no more work than a day's video production and

editing.

Perfecting the Magnetic Variable Torque Converter

https://youtu.be/472zxAjCI6Y

(And here are my previous videos on the subject:

Automatic Variable Mechanical/Magnetic Torque

Converter [Theory & 1st tests]

https://youtu.be/9KWASx5C6ZE

- Initial concept & tests

https://youtu.be/aqG2Ol4y9Jw - Just the tests part without the

theory/concept

Magnetic Torque Converter - February 2023 Tests

[Improved but not fabulous]

https://youtu.be/MFbFC5YkvTM

)

Naturally, soon after I thought mine was, in concept, as good as it

gets, I found a video by Robert Murray Smith:

2197 The Infinite CVT And Wind Turbine Control

https://www.youtube.com/watch?v=uyi1Nv7kks8&ab_channel=RobertMurray-Smith

For efficiency this beats mine. But it has no intrinsic

feedback to the "control" motor. It would need electronic sensors and

microcontroller control and has fast-spinning gears and motor that will

have to run at high speeds on the highway. Still, it was the

inspiration for my still better design covered in "Month

in Brief"!

(It is probably a great idea for a wind turbine to achieve a more

constant voltage in low winds, but Smith errs in thinking it could save

trouble in high winds. If the generator isn't loading down the blades

to the point of overheating itself, the blades will spin too fast and

fly apart.

With wind energy being the cube of the wind speed, high

winds are a really serious hazard. I should think the best way is (a)

to have a secure mechanical brake that can stop the blades and (b) I

presume big windplants have a powered aiming ability since I don't see

any aiming vanes... it should turn as much as 90° from the wind if

it's too strong - before it's going too fast or the generator inside

gets too hot. ...or there's too much lateral pressure on the tower. And

then if needed put the brake on. These seem to me like elementary

precautions. But one sees windplants burning up and falling down on

youtube without knowing what precautions and safety systems were in

fact implemented. Were there any? Should they have been adequate? Why

did they fail? How rare or common is it for them to fail over their

service life? BTW how long is their service life? - one also sees them

or their blades being discarded because the blades have deteriorated -

pitted - from running through the air at higher speeds. Are they using

something like PP epoxy, or just cheap fiberglass? What (if anything)

is inside the blade for tensile strength?)

Other

"Green"

&

Electric

Equipment

Projects

Even Better Air

Compressor Design!

for Open Loop Heat Pumping ("OLAHP")

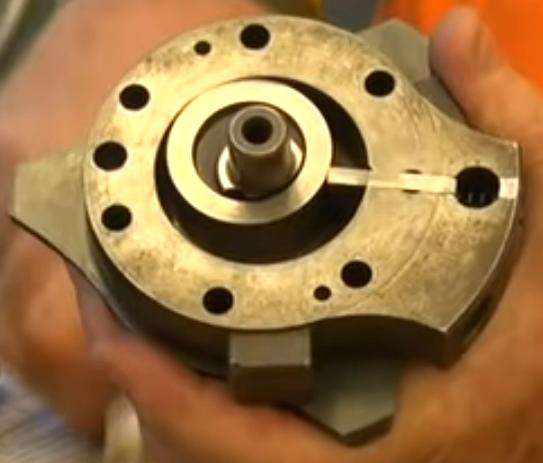

An Even Better Compressor

Start of a

cycle: cam has

passed the vane and air intake, and will

sweep the air around and out the output at the left of the vane.

[11th]

I looked on youtube for interesting videos and it

suggested one with another rotary compressor. It wasn't very

interesting but after the end another was suggested. That one looked

interesting because it showed an actual disassembled unit from a

production heat pump or air conditioner, not just a theoretical

computer animation. It appeared to be a maintenance video explaining

the compressor and all the actual workings and disassembly/assembly. It

was different again from anything I've seen before - and it was Real, a

production unit!

[11th]

I looked on youtube for interesting videos and it

suggested one with another rotary compressor. It wasn't very

interesting but after the end another was suggested. That one looked

interesting because it showed an actual disassembled unit from a

production heat pump or air conditioner, not just a theoretical

computer animation. It appeared to be a maintenance video explaining

the compressor and all the actual workings and disassembly/assembly. It

was different again from anything I've seen before - and it was Real, a

production unit!

The motor shaft had an offset cam instead of the housing

being offset or an elliptical housing. Outside of the offset cam was a

ring "sleeve". There was just One sliding vane. As the motor turned,

the sleeve drew in refrigerant (or air) from one side and sent it

around in almost a full circle to where the cam pushed the sleeve

against the outside, until it reached the vane with a vanishing volume

and sent the compressed refrigerant (or air) out the exit. So for

virtually the whole rotation air is being drawn in on the right side of

the vane and simultaneously compressed on the left.

The "sleeve" could as easily have been a larger cam on the

motor shaft, but instead it slips on the motor cam and doesn't have to

rotate with it, minimizing friction.

Midway. Air to left of vane is

being pushed

into the outlet.

Midway. Air to left of vane is

being pushed

into the outlet.

Air to right is coming in the inlet to the right of the vane.

Air on left of the vane is well

compressed and

being pushed out.

Air on left of the vane is well

compressed and

being pushed out.

Still more air is coming in the inlet to the right of the vane.

The sleeve on the offset shaft

doesn't actually

have to spin, so it

The sleeve on the offset shaft

doesn't actually

have to spin, so it

slides on the spinning offset shaft, a smaller diameter with less

friction.

This is better than anything I've seen yet, and the fact

that it's in production probably says it's the best of the ideas. Now

we take that and replace the sprung sliding vane with a pivoting vane

(in the same place, maybe with a small spring) to further reduce

friction, use slippery UHMW in the housing, add the decompression

assist section ["Pelton Wheel"]

to

help

turn

the

same shaft, and I think it should be "the best"

...unless something even better that I've missed until now turns up.

But at this point it's hard to imagine anything simpler or more

effective.

I don't suppose I could find one to use it instead of

making one (it might be "Carrier" brand) , but there's nowhere

to attach a decompressor anyway. But it's well I haven't gone any

farther on last month's design!

Hmm... The cam on the motor shaft might be replaced with a

vane or just a leaf spring that pushes the UHMW ring "sleeve" against

the outside edge? Oh, wait... the air pressure would push it open. It

would have to be a solid vane. Or there might be an offset bearing race

on the motor shaft to hold the ring - definitely lowest friction?

It occurs to me that only a "lobe" sweeping around is

actually needed to move the air. But it has to press the vane out to

the edge and let it back. The ring is probably the smoothest way. I

could also see the ring sleeve and outside edge having gear teeth that

mesh, virtually eliminating air leaks from that edge. (That still

leaves top and bottom leaks.)

[14th] It occurs to me that driving an off-center lobe is probably

going to cause a lot of needless vibration. I think I'll return to the

centered rotor with offset outer housing. So the pivoting vane will

have to be on the rotor. But the video was by no means a waste: now I

realize that only one vane is needed, sweeping around the full circle.

That will have the least friction. (and be the easiest to write the

G-code for routing out one slot!) And to leak out top and bottom

(except across

the vane), air has to leak across the big plastic rotor instead of just

a narrow ring.

A Better Decompressor

The same morning I had another inspiration about making a

decompressor. Instead of feeding air in at the center of a "rotating

hose sprinkler" that shot air out the ends backward, one could have a

fixed nozzle driving a "pelton wheel" on the compressor shaft. The

decompressed air could also be removed at a fixed point (almost

anywhere?) on the side of the housing. No rotating air connections! (It

would still be in an enclosed housing because the decompressed air

coming out will be cold, maybe colder than outdoors, and has to be

piped outside.)

Hmm, I wonder if I can just buy an appropriate pelton

wheel in a housing? Even if I had to change the nozzle and perhaps the

output opening, it would probably be much easier than making my own.

[15th] I tried to order a

260mm diameter pelton wheel with 25 somewhat

cheap looking plastic fins. It said it couldn't be shipped to my

address. I sent a message asking if the seller could mail it, but he

didn't understand that the web page literally wouldn't let me order it

because of his one limited shipping option.

[15th] I tried to order a

260mm diameter pelton wheel with 25 somewhat

cheap looking plastic fins. It said it couldn't be shipped to my

address. I sent a message asking if the seller could mail it, but he

didn't understand that the web page literally wouldn't let me order it

because of his one limited shipping option.

Then I started thinking that

"airfoil" blades would probably be better for air. Pelton wheels are

for water.

Indoor-Outdoor Air Heat Exchanger

I gathered together the radiator pipes Mike gave me when I

was

first working on this project in 2020. The six pieces (counting one I

made myself, not shown) made 246

inches length of fins.

Since this is a crucial component for getting a very high

COP I decided to put them all together in a single length, folded into

four rows with a shallow vertical descent angle from top to bottom so

condensation would accumulate in one place, where I intend to place a

jar (or something with a valve?) so one can see when it's getting full

and empty it. The housing with 2" styrene foam insulation (R 10) on all

sides and between the rows will be 60" x 24" x 8". That's 5/8 of a

sheet of thin plywood and some 2" by 8"s, and a lot of foam.

The outgoing compressed air (being cooled by the incoming

outdoor air) flows through the pipes. The incoming outdoor air flows

outside them, all around the fins, picking up heat. The warm air output

may

or may not be directly connected to the input of the air compressor. If

not directly connected, the compressor nevertheless draws in air,

which will flow into the heated space through the heat exchanger. The

advantage of this is almost free fresh air. The disadvantage is that

air will also be drawn in through air leaks in the structure.

Electricity

Storage

Everlasting Copper-Zinc Cells with Plastic Pocket Electrodes

[1st - large clamped flat cell.] Trying a long discharge with 50 Ω

after charging overnight at 1.4

V. (just 17 mA by AM) It started out low at only 1.006 V, but it

dropped in voltage very slowly. I had tried this a year ago with cobalt

oxide (at a slightly lower voltage) but found it wouldn't recharge

[TENews176]. If the copper oxide was pure it probably wouldn't either,

but alloyed/in solid solution with nickel it seems to work. I'll know

for sure when I try to recharge it and run a second test. [February

note: Copper alone, with some graphite, works fine. Some of the

presumptions weren't quite right.]

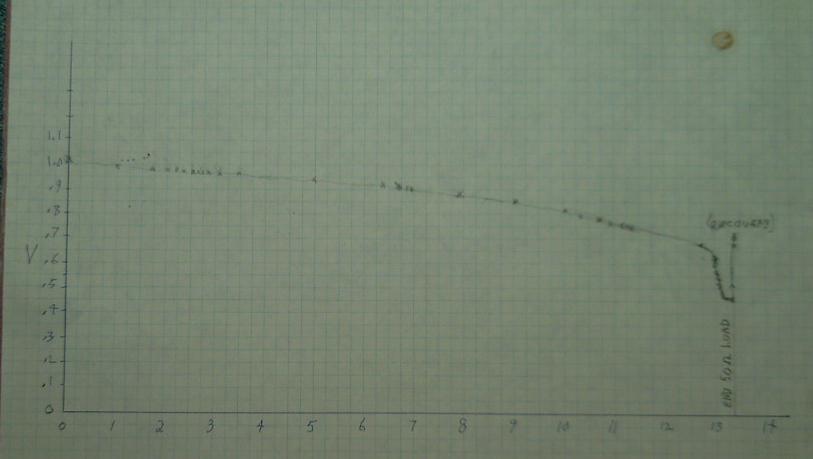

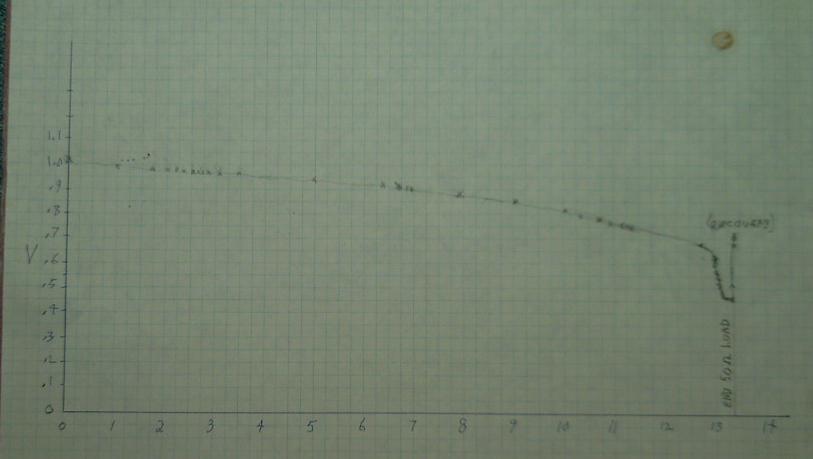

The first long test ran for just over 13 hours and produced this graph:

One can see the "cliff" at about .65 volts at about the 13 hour mark

where the copper oxide [Cu(OH)2, CuOH] has all been reduced to copper

and voltage falls

quickly. Then at about .45 volts it levels out again. This would be

where the nickel hydroxide component starts getting reduced back to

nickel metal. Not only is this a pretty low voltage, it was dropping by

3 mV/minute, probably indicating that there wasn't a whole lot of it

available at the surface to react. I declined to push it further. It

just might be undoing the conditioning from all the previous charging.

In considering that 50 ohms is a very small load (20 mA at

1 volt) and yet there was considerable voltage drop below the open

circuit voltage (perhaps 100 mV initially), and that 13 hours of that

is only about 1/4 of an amp-hour, it must be remembered that in this

test cell the active cupro-nickel (a) is solid .51mm (#24 gauge) sheets

rather than powder with a high surface area to volume, (b) is at 70:30

somewhat short of nickel in ratio to the copper and (c) that as of the

last opening, mostly only one side of one sheet had the coppery color

indicating it was being employed. (Why that is I'm not sure but will

run experiments charging sheets in a vat with the platinum negative.) A

well compacted 60:40 cupro-nickel or a 50:50 monel would doubtless

supply much higher currents with much lower voltage drops for much

longer times.

In fact, now that I understand the voltage is only around

1.0 volts rather than 1.2 or 1.3, I think I should try the monel powder

filled perforated tube electrode again.

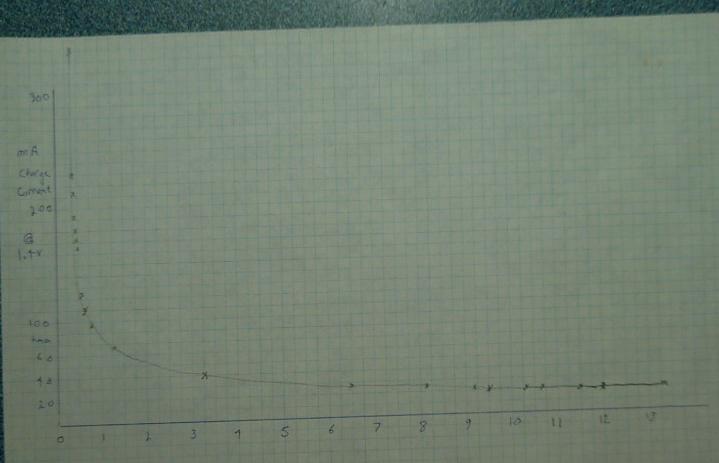

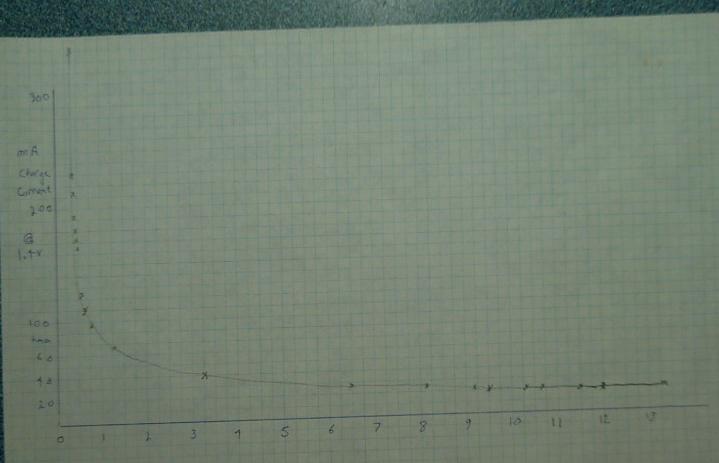

Recharging after that (at 1.4 volts) of course also took hours, mostly

at not much higher current than the discharge:

With the charge still at 22 mA, I turned the charge voltage down to 1.3

V. After a short period of adjustment, the current dropped to about 16

mA.

At 1.2 V, it dropped to 10 mA and at 1.1 V, to 4 mA. At 1.0 V setting,

current reversed and -1 mA was flowing from the battery to the power

supply, whose meter continued to read 1.1 V. Again the currents would

be much higher at lower voltage (eg, 1.2 instead of 1.4 V) if there was

more active substance in the cell.

[2nd] When I briefly changed from 'charge' to 50 ohm 'load' the voltage

dropped a lot. I changed it to 1.6V charge for 3(?) hours. At 10:00 PM

after it sat a few minutes I started the second long load test. It

still started low, .938 volts. But it rose in a couple of minutes to

over .95, and over the first 1/2 hour to .964V. There it stayed for

about 15 minutes before losing a couple of millivolts. To me anything

under 1 volt sounds so low... yet .96 is only 40mV below where it

started on the first test. What counts more is how long it runs. I

started it in the evening presuming it will run all night and finish

sometime in the morning when I'm back to see the last phase.

Somewhere in the first days of January I ran some tests on

the flat cell and found that lower voltages that were disappointing me

were owed to poor connections between the CuNi sheets inside the cell.

(The inner sheet did most of the chemistry, but the terminal tab was on

the outer sheet, and the surfaces naturally oxidized.) The chemistry

was working fine. Tightening the clamp screws brought the voltages back

up.

Nickel Manganates: Manganese, not Nickel?

[5th] I thought once again about how one might get manganese to

recharge. It suddenly occurred to me that the nickel manganates

electrode (or nickel-manganese oxides) mix I had created in several

variants and tried to make work just might be exactly that. I had been

trying to charge it to nickel oxide reaction levels, but why might it

not just as easily charge only to the lower manganese oxide levels,

just as the cupro-nickel charged to the copper oxide level rather than

the nickel oxyhydroxide level? Why had I never, ever tried doing that?

Why

was I so sure that the previously untried mix should do one over the

other? That might explain the rapid voltage drops under load to around

1.3V(?) or so when I was expecting 1.8+. I might have been

deteriorating the whole thing trying to charge it at too high a voltage

(2.1V) as if it was nickel-zinc instead of manganese-zinc (~1.6V).

That level had oxidized the cupro-nickel sheets. Perhaps what I had

done should instead

have been a way to make a rechargeable manganese electrode? To be fair

to myself,

for many years I was unaware that a manganese oxides electrode in fact

wouldn't recharge, so I wasn't looking for a way to make it do so.

I want to try it out some time to make "rechargeable

Mn-Zn" cells

at some point. Copper has more energy, but Mn-Zn would be useful

especially for dry cells since they

would be the expected 1.5 volts and (with all the techniques I've

developed) indefinitely rechargeable. (at

least until the dry cell actually dries out with charging as they

eventually do.)

New Cell Idea

[6th] I had also been

toying with "How are multiple electrodes stacked

end to end in 'prismatic' cells?", when they seem to need to be held in

compression so they don't swell and lose connectivity. The answer

(without it being mentioned or readily apparent in diagrams) is

probably that such cells are constructed so that there was no space at

either end for them to expand into. I had been trying to make "flat

cells" with a single electrode pair and thin plastic on their faces.

The thin plastic bulged, but I couldn't conceive of using thick plastic

to hold such a thin cell - the cell walls would be thicker than the two

electrodes they enclosed. The next morning these things came together:

why not multiple smaller electrodes stacked in a cell with thick

plastic at each end? Even thin cell sides would hold the ends together.

Although the length would be fixed and the thickness of one-off "DIY"

electrodes would vary, shims could be inserted into one end to occupy

excess space. Having a bit of excess space would ensure that the

electrodes wouldn't break up by trying to scrunch them in sliding them

sideways into place.

[6th] I had also been

toying with "How are multiple electrodes stacked

end to end in 'prismatic' cells?", when they seem to need to be held in

compression so they don't swell and lose connectivity. The answer

(without it being mentioned or readily apparent in diagrams) is

probably that such cells are constructed so that there was no space at

either end for them to expand into. I had been trying to make "flat

cells" with a single electrode pair and thin plastic on their faces.

The thin plastic bulged, but I couldn't conceive of using thick plastic

to hold such a thin cell - the cell walls would be thicker than the two

electrodes they enclosed. The next morning these things came together:

why not multiple smaller electrodes stacked in a cell with thick

plastic at each end? Even thin cell sides would hold the ends together.

Although the length would be fixed and the thickness of one-off "DIY"

electrodes would vary, shims could be inserted into one end to occupy

excess space. Having a bit of excess space would ensure that the

electrodes wouldn't break up by trying to scrunch them in sliding them

sideways into place.

Matt gave me some copper

powder to try out a copper

electrode with. What were the chances that someone local who I knew

would have a substance that almost no one uses? Only one store on all

AliExpress sells it.

I decided to try both things at once: a copper zinc cell

with copper powder & graphite, and the new cell case idea with just

three electrodes - two 6mm thick on the ends and one 12mm thick in the

middle. I went right out to the freezing shop, fired up the scary table

saw I got at the refuse station a couple of years ago and left out in

the rain since, and cut a few bits of my dwindling stock of thick ABS

plastic pieces. It cut it without melting the edges like my radial arm

saw does. In the evening I glued it together, an open top box for four

24mm thick of electrodes that should be strong enough to not allow them

to bulge. (The top comes later.) I sized it 53mm wide to hold

electrodes made with my 50x50mm compactor, and 25mm long, leaving room

for the papers.

[7th] Luckily I tried filling it with water before making the

cell. In spite of using apparently lots of ABS cement, and in spite of

no light showing through the seams anywhere, it had a pinhole leak.

Good grief! I smeared on more glue. Perhaps what I need is a really

fine saw blade to make really smooth cuts. (And a special push stick to

hold down the little, thin, light pieces as I cut. Yikes!) That might

just

solve my forever making cells that leak? (The poor carpenter blames his

tools, but the good carpenter gets better tools?)

The next change was to make the current collectors a

little smaller to leave a couple of mm so they wouldn't press on and

maybe cut the papers. The final thing I wanted was paper envelopes to

slide the electrode briquettes and current collectors into, open only

on the tops. Was there a way to glue papers into envelopes? Heat glue

might work. Just wetting watercolor paper, forming it and letting it

dry might work for it. Or maybe just cutting it 55mm wide and putting

it in as "U" shaped pieces blocking the entire cell width between

'trodes

would work? I'm not so sure about parchment paper. Same thing? How sure

would that be to not allow shorts? Since it would be much simpler I

decided to try it.

Ideas got modified as I went. Like the monel powder, the

copper + graphite powder (100g + 15g) wouldn't form a 'briquette' but

merely crumbled back into powder at any touch. Finally I compacted it

directly onto a CuNi flat sheet current collector and put it into the

tipped-up cell like something on a spatula going into an oven. I put a

sheet of parchment paper over that for a separator.

Ideas got modified as I went. Like the monel powder, the

copper + graphite powder (100g + 15g) wouldn't form a 'briquette' but

merely crumbled back into powder at any touch. Finally I compacted it

directly onto a CuNi flat sheet current collector and put it into the

tipped-up cell like something on a spatula going into an oven. I put a

sheet of parchment paper over that for a separator.

I could see that this would make an ideal battery... if

done with great precision by a machine. A man with tremors was

something else. Three electrodes. Could I put it together without

everything crumbling into a mess, and with the separators actually

preventing shorts between them?

I decided to scrap the

clamped flat cell and use the zincs from

inside it. Uncovering the zinc side I found it had swelled up from 4 or

5 mm to 7 or more. Much of the zinc was now oxide (ZnO, discharged)

especially around the edges. Deeper in and especially against the

copper current collector was metallic zinc, and it was actually hard to

crunch through it with a thin knife. The copper foil underneath was

still bright and shiny.

But I cut another current collector and then a piece

simply to protect the papers and put them in. I pried them apart with

two screwdrivers and made a space. I measured out 21 grams of

copper/graphite powder and started filling with a spoon. Then I stuffed

it down with a couple of thin, flat pieces of ABS. I wondered how

little of the 21 grams would go in. When it was all in and the space

not anywhere near filled, I wondered if I would ever finish filling it.

The first 'trode had 21 grams of copper powder and the second one about

27. 40 amp-hours or so?

There was

copper powder everywhere and I wondered if there

was any chance it wasn't all shorted out. But I filled it with

electrolyte and the voltage between negative and the two positive

terminals read .83 V and .84 V. They would only drive a few milliamps

if shorted since the copper was totally discharged. When I started the

charge to my surprise it was only 26mA. But where the zinc briquettes

measured in the lower 10's of ohms, the copper powder was megohms, or

even tens of megohms, so maybe I shouldn't have been surprised. It

seemed very strange since copper is the second best conducting element

on the whole periodic table and I had added graphite to ensure good

conductivity. Surely the copper powder particles weren't in good

contact with each other? Pressing down on the open top of powder in the

electrode with the plastic piece didn't help. (That was

conductive graphite I added, wasn't it? Yup, 1's of ohms. In fact, the

copper powder sufficiently pressed between two sheets of metal was even

lower 1's of ohms.)

There was

copper powder everywhere and I wondered if there

was any chance it wasn't all shorted out. But I filled it with

electrolyte and the voltage between negative and the two positive

terminals read .83 V and .84 V. They would only drive a few milliamps

if shorted since the copper was totally discharged. When I started the

charge to my surprise it was only 26mA. But where the zinc briquettes

measured in the lower 10's of ohms, the copper powder was megohms, or

even tens of megohms, so maybe I shouldn't have been surprised. It

seemed very strange since copper is the second best conducting element

on the whole periodic table and I had added graphite to ensure good

conductivity. Surely the copper powder particles weren't in good

contact with each other? Pressing down on the open top of powder in the

electrode with the plastic piece didn't help. (That was

conductive graphite I added, wasn't it? Yup, 1's of ohms. In fact, the

copper powder sufficiently pressed between two sheets of metal was even

lower 1's of ohms.)

Then again, when the copper charged and formed hydroxide,

it was going to need more room than the metal. Part of the theory is

that as it charged and discharges, the particles will link up and form

low resistance paths. That this happens is shown in that once the cell

has charged at a patheticly low rate and is then discharged, it

recharges at much higher currents up to the point it was charged to

previously. Presumably it will eventually be fully charged and far more

conductive. I may be having a problem with that because of too much

copper in the cupro-nickel current collector sheets? It gets involved

in the reactions (which is of course how I first noticed copper).

(Should I try a graphite foil current collector?)

Then the first copper 'trode shorted to the zinc. I had to

disconnect it. I couldn't see the top of its separator parchment paper.

I thought I had been careful to make sure it didn't get sucked down in

when I put in the zinc 'trode, but it was completely vanished. As I

feared, I hadn't managed to do everything perfectly enough to make it

work. Hmm... If I had made and used the metal insert sooner, the

separator couldn't have got pushed down when I put in the zinc section.

Maybe what I need is perfect my techniques rather than give up on this

form of cell assembly so soon? But it took my whole day and was pretty

disappointing.

The second side was charging at just 10mA. It was going to

take a while to get up over 20 amp-hours that way! I raised the charge

from 1.4V to 1.6. Maybe some changes to the CuNi sheet would cause

better connections to form? Current rose to 29mA.

After a while there seemed to be a lower resistance path

between '-' and the remaining '+'. Had some powder got around the

separator sheets? Zinc dendrites getting by the dopant and the SDBS

papers? With everything stuffed together there was no way to fix

anything: the cell had to come apart and start over. I'm sure I've

played this broken record over and over.

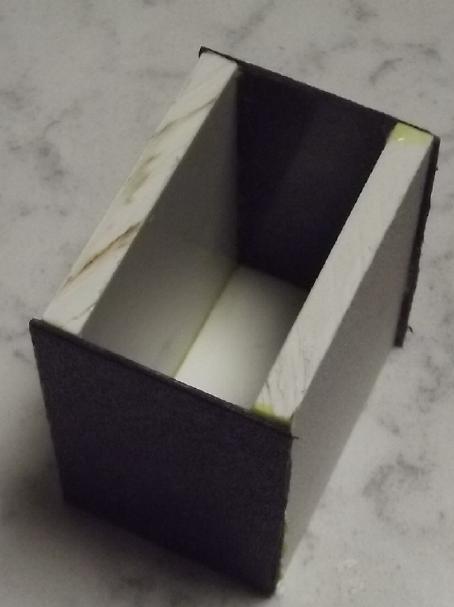

I need to be able to handle

individual electrodes. The

round tube "perforated plastic pocket electrodes" had some poor

characteristics, but they were makeable, individually serviceable, and

they worked. What about doing similar but rectangular envelopes, which

could be stacked completely filling the rectangular cell so they had

nowhere to bulge? If each electrode was to be 6mm thick and doubles

were stacked with the current collector between making 12mm, an awful

lot of 'trodes could still be stuffed into a small space, almost

completely filling it.

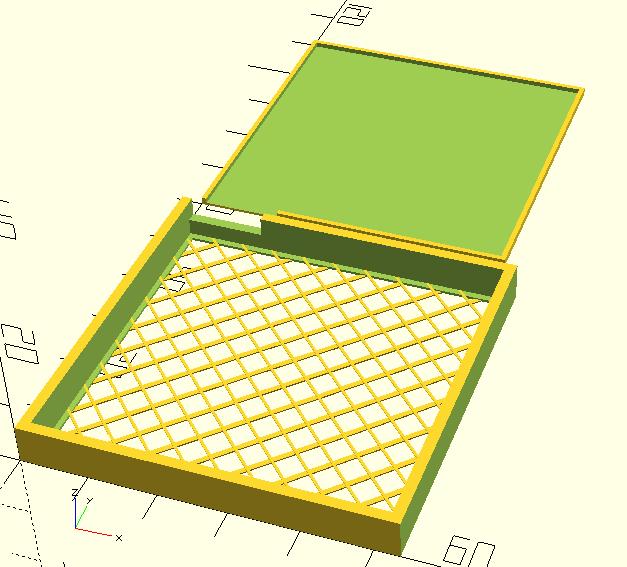

Before bed I designed the "fat" and "thin" 50-50 (mm)

pockets, sliced them to G-code and took them to the printer. Prints?

Mañana.

[8th] I pulled the electrodes out of the open box. I had compacted the

last copper 'trode as I added more and more powder, and they were well

jammed in. It was hard prying the outer current collectors out and

there was certainly no room for anything to swell without breaking the

box. On the bright side, the copper with graphite was fragile solids

rather than loose powder and the resistance through a clump of it to

the sheet metal was mid 1000's of ohms instead of upper 1,000,000's.

I printed two of each 50 x 50 mm pockets, but the thin one

looked too skinny to work with. By the time the current collector and

papers were in, I didn't see how I could manage to put in the actual

powder. The thick one I could fit in one side instead of two. The

reason was that 2mm of each was lost in plastic thickness. I needed to

make them 6mm and 12mm I.D. instead of O.D.

I only managed to fill one 'fat' 'pocket' with one zinc

briquette on one side of the copper sheet, with an old piece of doped

parchment paper and a new toluened watercolor paper.

[9th] I soaked the zincode

in SDBS for an hour while I filled the

other 'fat' pocket with a copper powder trode. I thought of how

performance kept deteriorating as the CuNi sheets oxidized (and how I

really wanted monel with more nickel than copper), and at the last

minute I removed it and put in a graphite foil current collector

instead. The empty cell had weighed 19 grams and after filling it was

43 (46 with the heat glue applied), but the CuNi had been 11g and the

graphite foil would have been about 3g, so 11 for the cell leaves 32

grams of copper powder - a theoretical 23.6 amp-hours for 23mAH/g / 46g

= 500 amp-hours/Kg. The zinc side is probably similar. With a

lightweight case and not a lot of water needed, even at 1 volt that

would be maybe 400 WH/Kg. Theoretical. That would be pretty impressive

if even half attained. Now, might it for once actually get any

substantial fraction of those amp-hours without zinc dendriting, the

"+" current collector or other component deteriorating or the cell

springing a leak first?

[9th] I soaked the zincode

in SDBS for an hour while I filled the

other 'fat' pocket with a copper powder trode. I thought of how

performance kept deteriorating as the CuNi sheets oxidized (and how I

really wanted monel with more nickel than copper), and at the last

minute I removed it and put in a graphite foil current collector

instead. The empty cell had weighed 19 grams and after filling it was

43 (46 with the heat glue applied), but the CuNi had been 11g and the

graphite foil would have been about 3g, so 11 for the cell leaves 32

grams of copper powder - a theoretical 23.6 amp-hours for 23mAH/g / 46g

= 500 amp-hours/Kg. The zinc side is probably similar. With a

lightweight case and not a lot of water needed, even at 1 volt that

would be maybe 400 WH/Kg. Theoretical. That would be pretty impressive

if even half attained. Now, might it for once actually get any

substantial fraction of those amp-hours without zinc dendriting, the

"+" current collector or other component deteriorating or the cell

springing a leak first?

But when I pulled it out, there was a suspicious amount of

zinc in the dripping liquid. I became sure there was a gap somewhere. I

decided to try a little origami and wrapped a piece of watercolor paper

around the entire electrode box, folded around the bottom and open only

at the top (hopefully) above the water line.

The cell charged at a

whopping 1mA. At that rate it would

take 40 days and 40 nights just to get to one amp-hour! I blame using a

graphite instead of monel current collector... but I really don't know

why it was so slow. But it did slowly take on some charge over the day.

Over the day, with no apparent leaks, I added electrolyte

several times. Presumably the copper was charging to Cu(OH)2 and using

up the water.

[10th]

Overnight it occurred to me that if the electrolyte water was

being consumed and I kept adding more, the salt concentration must be

getting really high. In the morning it would drive a 50Ω load near .5V

instead of .6V - ug! There should be virtually NO voltage drop with a

50Ω load! I filled it (the small voids not occupied by electrodes) with

distilled water and then drained it out three times to dilute the salt

concentration hopefully to something reasonable. There was nothing like

enough fluid to check with a hygrometer. There seemed to be a lot of

bubbles trapped in the zinc. They seemed to be having trouble escaping

through the heat glue top except where there were a couple of gaps

around the edges. I rather doubt they could penetrate the stiff SDBS

soaked papers. I'll have to remember to make top openings in the zinc

next time.

[10th]

Overnight it occurred to me that if the electrolyte water was

being consumed and I kept adding more, the salt concentration must be

getting really high. In the morning it would drive a 50Ω load near .5V

instead of .6V - ug! There should be virtually NO voltage drop with a

50Ω load! I filled it (the small voids not occupied by electrodes) with

distilled water and then drained it out three times to dilute the salt

concentration hopefully to something reasonable. There was nothing like

enough fluid to check with a hygrometer. There seemed to be a lot of

bubbles trapped in the zinc. They seemed to be having trouble escaping

through the heat glue top except where there were a couple of gaps

around the edges. I rather doubt they could penetrate the stiff SDBS

soaked papers. I'll have to remember to make top openings in the zinc

next time.

Perhaps that explained the lower current drive? Charging

was again down to 1mA. Oh... that and the electrodes being 10mm thick

instead of 6mm. More likely I should have made a new sheet of osmium

doped parchment paper or cellophane instead of re-using a piece from

the flat cell. Bad mistake? Perhaps I should try making a new zincode

for this cell with these mistakes corrected? I set the 3D printer to

work on a new 'porous' box.

It also, when the charge was disconnected, now drifted

down slowly to 1.1V instead of plunging to 1.0. So it did seem to be

charging. And obviously there were no zinc dendrites creating low

resistance paths between the 'trodes.

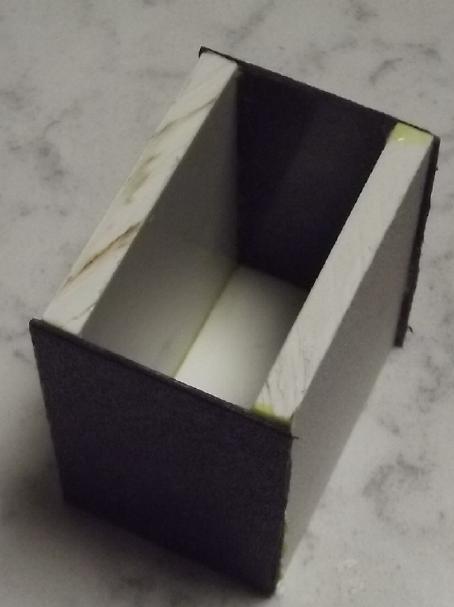

With

lid

I got an idea that I might

make at least the zincodes in a

smooth box instead of perforated; one with a removable bottom so one

can push the 'trode out the top. After all thick, watercolor paper

stiffened with SDBS made a "box" all around the outside. And the zinc

formed into briquettes that could be placed inside. I would get the

electrode all ready, then push it out of the box and use it with just

the bare paper covering, no plastic box. If a box was still wanted

between, the copper side still had one.

Well, I tried making a zinc with just folded paper and

even with some 'magic transparent' tape, which let go when wetted, made

a mess with zinc powder leaking out after soaping it. I did get it into

the cell, and there didn't seem to be any problems. Maybe keep the

plastic enclosure, but with bigger "perforations"?

I used this

zinc "envelope"

for a month.

No zinc Dendrites.

[11th] The cell seemed to

work a little better than with the

previous

zinc. It was by now holding over 1.1 volts open circuit. But the

voltage still dropped a lot under load, and it picked up more charge

almost as slowly. This time all the zinc was metallic powder with no

ZnO. It occurred to me there was now a space. I put in the platinum

piece and put the negative leads on that. I set the voltage to 1.8V to

let it bubble hydrogen while more of the copper charged to oxide. It

started charging at 9mA instead of 1. That helped a lot even in 1/2 an

hour.

[11th] The cell seemed to

work a little better than with the

previous

zinc. It was by now holding over 1.1 volts open circuit. But the

voltage still dropped a lot under load, and it picked up more charge

almost as slowly. This time all the zinc was metallic powder with no

ZnO. It occurred to me there was now a space. I put in the platinum

piece and put the negative leads on that. I set the voltage to 1.8V to

let it bubble hydrogen while more of the copper charged to oxide. It

started charging at 9mA instead of 1. That helped a lot even in 1/2 an

hour.

I tried another 50Ω discharge and someone came over. I

forgot and left it running about 1-3/4 hours. It was down to .43 volts.

After 3 hours of Pt charging the voltage was still down a bit from

previous, but it was working well.

[12th] Voltage is still a bit lower, but

run time still gradually

increasing. With a 50Ω load it starts around (only) .7 volts and I run

it down to .650. 15 minutes yesterday evening, 22 minutes this AM. I

confess I don't understand why the drive is so feeble. That has to go

up!

Higher Currents

To drive 50Ω and only have under .7V instead of over 1.0V

meant it was hardly driving 14mA instead of, a minimum of, say, 25mA

per square centimeter of interface area. 25mA * 25 sqcm = 625mA --

about 2% of what was wanted.

First, there were actually 5 sheets of separators plus the

wall thickness of the porous plastic box between the two actual

electrodes:

- The osmium doped cellophane (needed)

- Two sheets of toluene treated, SDBS soaked watercolor paper (making

sure the zinc was well contained)

- The "porous" box wall

- One more sheet of toluene treated watercolor paper in the "+" box

- A sheet of parchment paper in the "+" box next to the copper

Surely something could be eliminated without the

electrodes touching or zinc dendrites escaping? I pulled it open and

removed one of the SDBS soaked sheets. I put it back together. So far

no shorts or low resistance paths; it held its charge nicely. I tried a

50Ω load test. The voltage started about 20mV higher. Better, but

hardly enough improvement to notice.

What if I just filled a porous box with copper+graphite

(with a CuNi current collector behind it) - no papers? I tried it. Lots

of copper powder came out the "pores". I got it 1/4 full and put it

into the cell. Not much. I was getting much better currents with the

CuNi sheets!

Speaking of which, they had started performing after setting the

charge to 1.8 volts. I assumed that had to do with the nickel in the

cupro-nickel sheets. What if that wasn't the reason? What if I turned

the first nickel powder box with the graphite foil to 1.8 volts charge

instead of 1.4? So I set it back in place and tried that. Charging

currents were substantially higher. After 1/2 hour of charging the load

voltage was up another 30mV. Was something different happening, or was

it just the same thing happening faster? Did it matter? Apparently I

should continue.

After another 3 hours, the cell had gained another 25mV

and was now discharging into 50Ω at .775V instead of the original .700V.

But all this was two-bit improvements instead of two

orders of magnitude! The cupro-nickel sheets had worked much better.

Let's see.... what else is working against better

performance? For one thing, the copper electrode is 10mm thick instead

of 5 or 6. For another, I used the graphite foil current collector

instead of monel or the cupro-nickel. Again, pretty small peanuts?

Hmm... were the "perforations" in the plastic box letting enough ions

pass?

But is the copper powder I got from Matt really very good?