120V Heaters, extra low powered by 36V DC, plugged into a "thermostat box"

(via power bar & adapter plug cable)

While on the

subject of DC power I'm using T-Plugs as the "standard" 36 V DC plugs

in lieu

of there being any practical alternative, but I do have a complaint.

The pins are too short, and they pull out or lose contact with the

socket too easily. They would be much better if they were even 10mm

long instead of 8.

While on the

subject of DC power I'm using T-Plugs as the "standard" 36 V DC plugs

in lieu

of there being any practical alternative, but I do have a complaint.

The pins are too short, and they pull out or lose contact with the

socket too easily. They would be much better if they were even 10mm

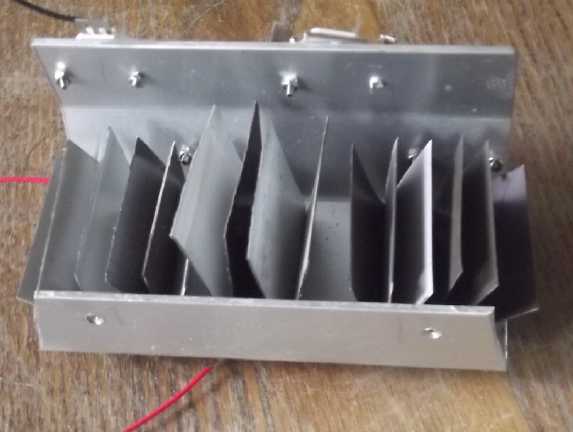

long instead of 8. In thinking of a 36 volt upstairs ceiling light for the

cabin, I went to my long neglected drawer of LED things and found a

rather elaborate heatsink I had made long ago (2013?) to go with a

"mushroom"

light diffuser I had taken a fancy to. (Recall that back then LED

"regular" light "bulbs" were hardly available, much less the wide

variety of LED "bulbs" and light fixtures now on the market.) The

intent had been to bolt four 2.9 volt "Cree" LED emitters to it for a

12 volt light. Then Cree

emitters I had already used started giving me problems. They started

out as 2.9 volts, so four made 11.6 volts, and a resistor would limit

the current for 12 volts. But their characteristics changed - they

gradually started working

at 3 volts, then 3.1 or more, and while they still worked, the supply

voltage had to be raised and

raised to keep the light from becoming quite dim.

In thinking of a 36 volt upstairs ceiling light for the

cabin, I went to my long neglected drawer of LED things and found a

rather elaborate heatsink I had made long ago (2013?) to go with a

"mushroom"

light diffuser I had taken a fancy to. (Recall that back then LED

"regular" light "bulbs" were hardly available, much less the wide

variety of LED "bulbs" and light fixtures now on the market.) The

intent had been to bolt four 2.9 volt "Cree" LED emitters to it for a

12 volt light. Then Cree

emitters I had already used started giving me problems. They started

out as 2.9 volts, so four made 11.6 volts, and a resistor would limit

the current for 12 volts. But their characteristics changed - they

gradually started working

at 3 volts, then 3.1 or more, and while they still worked, the supply

voltage had to be raised and

raised to keep the light from becoming quite dim. In the upshot,

I had all but finished the light, but never

did. Every detail was done except putting the emitters on and wiring

them up. And then

lovely commercial LED flat panel lights (among many other choices)

started becoming available. Now I thought, what emitters do I have left

in that box from those times? I found two sets of three 9-volt

emitters, 'square' and 'oval' in shape. (I think they're about 4000K

color temperature - greenish. Many might have gone lower

3000K(?), more yellow, for a bedroom, but I had these and in general I

do like 4000K. 5000 seems like a lot of blue to me.)

In the upshot,

I had all but finished the light, but never

did. Every detail was done except putting the emitters on and wiring

them up. And then

lovely commercial LED flat panel lights (among many other choices)

started becoming available. Now I thought, what emitters do I have left

in that box from those times? I found two sets of three 9-volt

emitters, 'square' and 'oval' in shape. (I think they're about 4000K

color temperature - greenish. Many might have gone lower

3000K(?), more yellow, for a bedroom, but I had these and in general I

do like 4000K. 5000 seems like a lot of blue to me.)

I mounted it

on the ceiling but

didn't get it wired until early June. I didn't use an electrical box at

the light, but just connected with T-Plugs inside the light itself,

tie-wrapped to the metal heatsink.

I mounted it

on the ceiling but

didn't get it wired until early June. I didn't use an electrical box at

the light, but just connected with T-Plugs inside the light itself,

tie-wrapped to the metal heatsink. I used #18 AWG speaker wire. I

have lots of house wire, but it just seemed like such total overkill

for a light fixture now that lights are LEDs. A 13 watt light is just

.333 amps at 39 volts. Without looking it up, I'm sure #18 wire is

rated for a least 5 amps. I drilled a small hole diagonally through the

center ridge 2 by 10 to get from the wall space into the ceiling space

- not something one would do with heavy wire. Having no "telephone

wire" cable stapler, I used ordinary paper staples at short intervals,

and I poked the wires through the screwdriver holes in the knockouts in

the light switch box, wrapping PVC tape around them to prevent

abrasion/shorts in case the edges were sharp.

I used #18 AWG speaker wire. I

have lots of house wire, but it just seemed like such total overkill

for a light fixture now that lights are LEDs. A 13 watt light is just

.333 amps at 39 volts. Without looking it up, I'm sure #18 wire is

rated for a least 5 amps. I drilled a small hole diagonally through the

center ridge 2 by 10 to get from the wall space into the ceiling space

- not something one would do with heavy wire. Having no "telephone

wire" cable stapler, I used ordinary paper staples at short intervals,

and I poked the wires through the screwdriver holes in the knockouts in

the light switch box, wrapping PVC tape around them to prevent

abrasion/shorts in case the edges were sharp. Over a year ago a wind blew over my insecurely secured 3 PV panel

"A-frame" mounting on the carport roof and one panel had bent and

broken. Then it fell when I tried to lower it off the roof and broke

some more. But testing the wires showed that it still worked so I

didn't discard it.

Over a year ago a wind blew over my insecurely secured 3 PV panel

"A-frame" mounting on the carport roof and one panel had bent and

broken. Then it fell when I tried to lower it off the roof and broke

some more. But testing the wires showed that it still worked so I

didn't discard it. I put 2

by 3 studs from the edge of the floor up to the ridge board for a wall

frame. I only got half the gyproc up.

I put 2

by 3 studs from the edge of the floor up to the ridge board for a wall

frame. I only got half the gyproc up. I put the gyproc on half the wall, then I slid the insulation in above

the ceiling where the light is.

I put the gyproc on half the wall, then I slid the insulation in above

the ceiling where the light is. [16th] Now that it

was spring and

the wood would be drier, I glued down the rest of the

upstairs tongue & groove floor. Three boards per day. I finished

the last bits at the door opening on the 31st.

[16th] Now that it

was spring and

the wood would be drier, I glued down the rest of the

upstairs tongue & groove floor. Three boards per day. I finished

the last bits at the door opening on the 31st. Best "Faraday

cage"? The chicken yard. (The wire is probably grounded here and

there.) There in the front yard so nearly under the power lines my body

voltage measured around a volt, some places closer to two. Inside the

chicken yard with the door closed it was 15 to 20 millivolts, almost a

99 % reduction and surely in the "no tinnitus" range. The chickens

don't know how good they have it!

Best "Faraday

cage"? The chicken yard. (The wire is probably grounded here and

there.) There in the front yard so nearly under the power lines my body

voltage measured around a volt, some places closer to two. Inside the

chicken yard with the door closed it was 15 to 20 millivolts, almost a

99 % reduction and surely in the "no tinnitus" range. The chickens

don't know how good they have it!

The insulation

wouldn't stay up between the 2 foot centers 2 by 8's. At the low wall I

started sliding it in on top of the ceiling sheets. That seemed to

work, but before doing the next sheet up, I decided to make the wall at

the side of the room. I would have to set the short step ladder

uncomfortably close to the edge. If something happened I could see

tumbling out of the upstairs down to the clutter of lumber below, which

would be bound to at least hurt a lot. So at some point I put 2 by 3

studs from the edge of the floor up to the ridge board for a wall

frame. They didn't quite line up with the ridge, so each one was a

custom fit at the top. (I didn't think to take a picture of the open

framework, but I only got half the gyproc up in May.)

The insulation

wouldn't stay up between the 2 foot centers 2 by 8's. At the low wall I

started sliding it in on top of the ceiling sheets. That seemed to

work, but before doing the next sheet up, I decided to make the wall at

the side of the room. I would have to set the short step ladder

uncomfortably close to the edge. If something happened I could see

tumbling out of the upstairs down to the clutter of lumber below, which

would be bound to at least hurt a lot. So at some point I put 2 by 3

studs from the edge of the floor up to the ridge board for a wall

frame. They didn't quite line up with the ridge, so each one was a

custom fit at the top. (I didn't think to take a picture of the open

framework, but I only got half the gyproc up in May.) I put the

gyproc on half the wall, then I slid the insulation in above the

ceiling where the light is. (I did in fact stumble against the wall

once coming off the short stepladder. I like to think that if I had

done it without the wall up yet, I'd have positioned the ladder another

way. But the wall certainly made it much safer.)

I put the

gyproc on half the wall, then I slid the insulation in above the

ceiling where the light is. (I did in fact stumble against the wall

once coming off the short stepladder. I like to think that if I had

done it without the wall up yet, I'd have positioned the ladder another

way. But the wall certainly made it much safer.) [16th] Now that it

was spring and

the wood would be drier, I started gluing gluing down the rest of the

upstairs tongue & groove floor. Three boards per day. I finished

the last bits at the door opening on the 31st.

[16th] Now that it

was spring and

the wood would be drier, I started gluing gluing down the rest of the

upstairs tongue & groove floor. Three boards per day. I finished

the last bits at the door opening on the 31st.

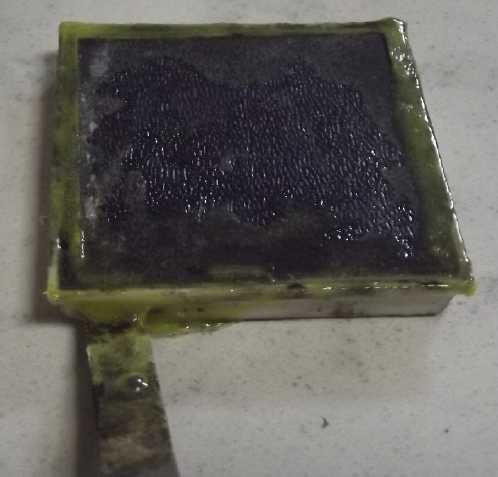

Then I gooped

up the edges of the back cover with ABS

cement and stuck it on. I added some more along the seam on all four

sides with a small screwdriver. I gave it a while to dry and was about

to put it in the cell when I remembered that I hadn't gooped up the

terminal slit. So I did that. If the zinc in the electrode is going to

dissolve into "supersaturated" zincate liquid as it discharges and stay

that way until it is recharged, it is obviously vital that there be no

leaks - no way in and out of the zinc box or compartment except through

the treated separator sheet.

Then I gooped

up the edges of the back cover with ABS

cement and stuck it on. I added some more along the seam on all four

sides with a small screwdriver. I gave it a while to dry and was about

to put it in the cell when I remembered that I hadn't gooped up the

terminal slit. So I did that. If the zinc in the electrode is going to

dissolve into "supersaturated" zincate liquid as it discharges and stay

that way until it is recharged, it is obviously vital that there be no

leaks - no way in and out of the zinc box or compartment except through

the treated separator sheet. I

started by picking out a 3D printed tray. It seemed to

me that the zinc side had an advantage with the copper screen running

through it in three layers. The copper only had a solid (and rather too

thick) sheet of CuNi metal. What if I cut the sheet back and forth and

then expanded it out in the jewelers rolling mill? I found a piece that

with a long terminal tab and the right width, but it was only about 3/4

tall. If I stretched it it could be about right. I cut it into

connected strips with tinsnips, about 3-4mm wide. I ran it through the

rolling mile a few times until it was actually too tall for the space,

then I bent it at the joins to make 45° angles, so it went pretty

much front to back within the electrode space as well as covering the

50x50mm area.

I

started by picking out a 3D printed tray. It seemed to

me that the zinc side had an advantage with the copper screen running

through it in three layers. The copper only had a solid (and rather too

thick) sheet of CuNi metal. What if I cut the sheet back and forth and

then expanded it out in the jewelers rolling mill? I found a piece that

with a long terminal tab and the right width, but it was only about 3/4

tall. If I stretched it it could be about right. I cut it into

connected strips with tinsnips, about 3-4mm wide. I ran it through the

rolling mile a few times until it was actually too tall for the space,

then I bent it at the joins to make 45° angles, so it went pretty

much front to back within the electrode space as well as covering the

50x50mm area.

[25th] I

soaked a separator paper in SDBS solution, then cut a piece of

1/16" ABS sheet for a back to the tray. I put the paper in behind the

plastic grill. When it's wet is the best time to fit it properly. Then

I looked for my previous instructions so I wouldn't forget any steps.

Which issue was that in again? I'm probably about ready to do a

"battery making manual" and keep it updated with whatever new is

learned.

[25th] I

soaked a separator paper in SDBS solution, then cut a piece of

1/16" ABS sheet for a back to the tray. I put the paper in behind the

plastic grill. When it's wet is the best time to fit it properly. Then

I looked for my previous instructions so I wouldn't forget any steps.

Which issue was that in again? I'm probably about ready to do a

"battery making manual" and keep it updated with whatever new is

learned.

Now what? A whole new electrode, again, to try a different

powder mix on spec? It's well glued shut. But I had made the tray type

with no lip around the "basket weave" face. Perhaps I could snip it off

round the edges, pull off the separator paper, and thus access it from

the front, losing some interface surface to glue when putting it

together again?

Now what? A whole new electrode, again, to try a different

powder mix on spec? It's well glued shut. But I had made the tray type

with no lip around the "basket weave" face. Perhaps I could snip it off

round the edges, pull off the separator paper, and thus access it from

the front, losing some interface surface to glue when putting it

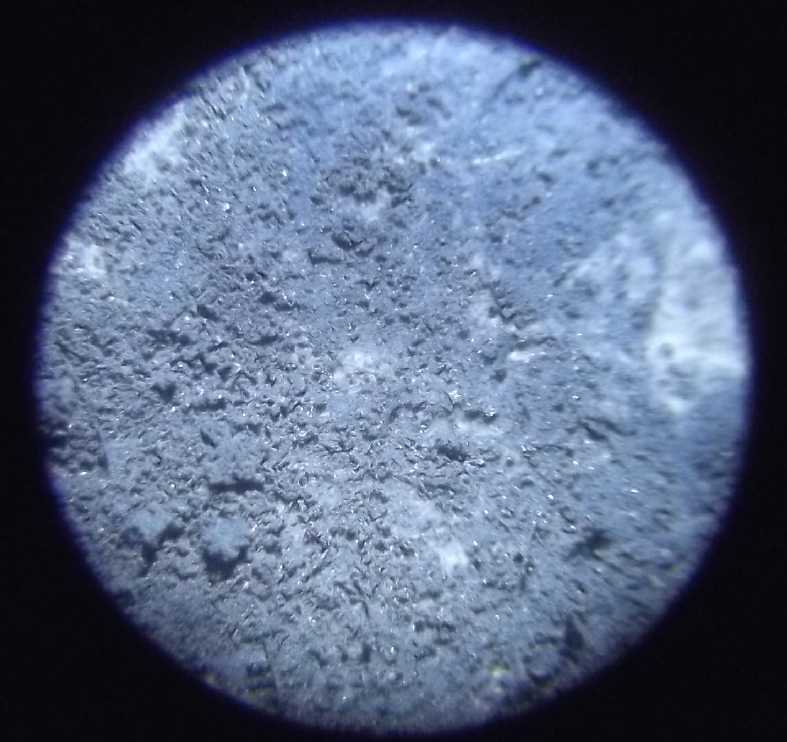

together again? [27th] I say!

The monel powder seems to have shaped it up marvelously. Charge

currents (at 1.6V) seem higher, and in a few minutes of charging the

voltage started drifting down from over 1.5V(!) instead of 1.3V. It

momentarily put out over 1.2V (over 110mA) into the 10 ohm load - the

highest ever. Hmm, and over 1.4V into 50 ohms! This suggests a copper

oxyhydroxide voltage of at least +.2V, which is about what I had

previously surmised. So far it's looking like the best battery I've

done. Once again, the question is how long it can do that once charged,

and will the discharge voltages keep gradually decreasing?

[27th] I say!

The monel powder seems to have shaped it up marvelously. Charge

currents (at 1.6V) seem higher, and in a few minutes of charging the

voltage started drifting down from over 1.5V(!) instead of 1.3V. It

momentarily put out over 1.2V (over 110mA) into the 10 ohm load - the

highest ever. Hmm, and over 1.4V into 50 ohms! This suggests a copper

oxyhydroxide voltage of at least +.2V, which is about what I had

previously surmised. So far it's looking like the best battery I've

done. Once again, the question is how long it can do that once charged,

and will the discharge voltages keep gradually decreasing? I grabbed a

piece of cupro-nickel. I wasn't just

sure what I might do. I squeezed it in the rolling mill, thinking to

make it long and fold it in half, and crimp the edges. Like the old

1890s designs. Then I annealed it and rolled again. It seemed thinner,

but it was just a bit short for a 50x50mm electrode box without

folding. Hmm... I

could use the other 3D printed tray with a solid bottom and the CuNi on

the front? Okay. Then I punched it full of holes with a hammer and

nail, one at a time. (Ug!)

I grabbed a

piece of cupro-nickel. I wasn't just

sure what I might do. I squeezed it in the rolling mill, thinking to

make it long and fold it in half, and crimp the edges. Like the old

1890s designs. Then I annealed it and rolled again. It seemed thinner,

but it was just a bit short for a 50x50mm electrode box without

folding. Hmm... I

could use the other 3D printed tray with a solid bottom and the CuNi on

the front? Okay. Then I punched it full of holes with a hammer and

nail, one at a time. (Ug!) The thin plastic tray back

would bulge, so I

cut a piece of 1/16"

ABS and put it inside to stiffen it. I added 20 wt% monel (but only a

tiny amount by

volume) to the Cu(OH)2 mix and used 5 grams.

The thin plastic tray back

would bulge, so I

cut a piece of 1/16"

ABS and put it inside to stiffen it. I added 20 wt% monel (but only a

tiny amount by

volume) to the Cu(OH)2 mix and used 5 grams. I

pressed it in and gooped

it shut with plenty of ABS cement, even tho the front was metal, not

ABS, I pressed it a bit in the hydraulic press then found some metal

pieces to fit and held it pressed with a C-clamp while the glue

hardened. A little powder puffed out the front through the nail holes.

That wouldn't do.

I

pressed it in and gooped

it shut with plenty of ABS cement, even tho the front was metal, not

ABS, I pressed it a bit in the hydraulic press then found some metal

pieces to fit and held it pressed with a C-clamp while the glue

hardened. A little powder puffed out the front through the nail holes.

That wouldn't do.

I

pressed it in in front of the

perfed metal. I left it to dry on the woodstove warmer. Then I found a

piece of 3D printed "basketweave" and glued it on around the edges. I

still wasn't satisfied that the copper would stay compacted inside.

I

pressed it in in front of the

perfed metal. I left it to dry on the woodstove warmer. Then I found a

piece of 3D printed "basketweave" and glued it on around the edges. I

still wasn't satisfied that the copper would stay compacted inside. I thought

about this arrangement, which was so likely to

prove unsatisfactory if a lot of pressure needed to be kept on the Cu

materials. And then again about my earlier 3D printed "perforated"

plastic tubes. But they weren't very strong either - some had broken.

Then SUDDENLY I [thought I] knew how to perforate smooth plastic! Heat

a pin frog

(or similar metal perforator with pins), perhaps with an iron, and melt

the holes through! Why, in 16 years, have I never thought of this

before? With a strong perfed tube lined with a treated separator and

glued-on end plugs, one could hold the copper substance strongly in

compaction, with a simple monel wire or rod in the middle for a current

collector and terminal. (Say: for the terminal/current collector, a

screw shape. The 'trode would be made solid-filled, then the terminal

screwed into the middle. That would only improve compaction. Copper

& monel screws? Hah! Good luck!)

I thought

about this arrangement, which was so likely to

prove unsatisfactory if a lot of pressure needed to be kept on the Cu

materials. And then again about my earlier 3D printed "perforated"

plastic tubes. But they weren't very strong either - some had broken.

Then SUDDENLY I [thought I] knew how to perforate smooth plastic! Heat

a pin frog

(or similar metal perforator with pins), perhaps with an iron, and melt

the holes through! Why, in 16 years, have I never thought of this

before? With a strong perfed tube lined with a treated separator and

glued-on end plugs, one could hold the copper substance strongly in

compaction, with a simple monel wire or rod in the middle for a current

collector and terminal. (Say: for the terminal/current collector, a

screw shape. The 'trode would be made solid-filled, then the terminal

screwed into the middle. That would only improve compaction. Copper

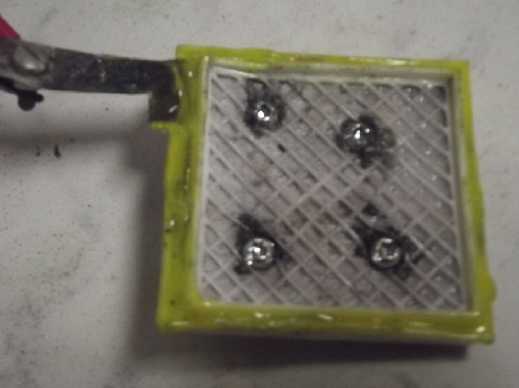

& monel screws? Hah! Good luck!) I

got out 4 small nylon machine screws, drilled holes

right through the thickness, and tightened them on with stainless nuts.

(insofar as one can tighten nylon screws... I only used my fingers on

the nuts for fear of stripping them if I used a wrench. But metal

except monel in contact with the electrode would corrode away.)

I

got out 4 small nylon machine screws, drilled holes

right through the thickness, and tightened them on with stainless nuts.

(insofar as one can tighten nylon screws... I only used my fingers on

the nuts for fear of stripping them if I used a wrench. But metal

except monel in contact with the electrode would corrode away.) I took out the

plastic nuts and put in metal

ones. Then metal screws. They

wouldn't last, but at least I could torque them down! This time, 87mA.

Again not the huge improvement I had hoped for. But it stayed over 30mA

for a while, and the open circuit voltage didn't jump up over 1.2V but

instead was only about 1.0, probably meaning the charge was dispersing

into at least some of the powder better. I opened it again and torqued

down the screws pretty hard. Again there seemed to be slight

improvement. Compaction certainly seems to be what it needs. Now, time

to let it charge for a while and see what happens!

I took out the

plastic nuts and put in metal

ones. Then metal screws. They

wouldn't last, but at least I could torque them down! This time, 87mA.

Again not the huge improvement I had hoped for. But it stayed over 30mA

for a while, and the open circuit voltage didn't jump up over 1.2V but

instead was only about 1.0, probably meaning the charge was dispersing

into at least some of the powder better. I opened it again and torqued

down the screws pretty hard. Again there seemed to be slight

improvement. Compaction certainly seems to be what it needs. Now, time

to let it charge for a while and see what happens!

I re-designed

the cylindrical electrode "pocket" (from

December) for 3D printing with .4mm layer height, which I hope should

work okay with ABS filament. Just 32mm tall for the first try, and to

fit in the same cell with the latest zinc.

I re-designed

the cylindrical electrode "pocket" (from

December) for 3D printing with .4mm layer height, which I hope should

work okay with ABS filament. Just 32mm tall for the first try, and to

fit in the same cell with the latest zinc. [31st] The print didn't

work on the first two tries, but after I

sprayed hair spray on the Kaptan tape, the third one stuck and printed.

I flexed it a bit and it snapped. Ug! I held it together and smeared

methylene chloride all over it. Hopefully that will hold, but I didn't

dare stress it very hard. (Maybe I should actually immerse them

in methylene chloride after they're printed? That would probably

strengthen them, but I'm almost out of it and I'm sure I'll have a hard

time getting more on this island.)

[31st] The print didn't

work on the first two tries, but after I

sprayed hair spray on the Kaptan tape, the third one stuck and printed.

I flexed it a bit and it snapped. Ug! I held it together and smeared

methylene chloride all over it. Hopefully that will hold, but I didn't

dare stress it very hard. (Maybe I should actually immerse them

in methylene chloride after they're printed? That would probably

strengthen them, but I'm almost out of it and I'm sure I'll have a hard

time getting more on this island.) [9th] The broken panel from

the carport roof winds of March, 14 months ago,

was still sitting on the lawn leaning against my porch. I had noted

that it still

worked, so I hadn't thrown it out. Now with the DC system seeming to

lose out against a grid tie

if it wasn't sunny, I checked. I couldn't remember about a cable that

ran from the porch into the garage at the solar equipment. It was once

the cable for the windplant. What after that? I had forgotten.

[9th] The broken panel from

the carport roof winds of March, 14 months ago,

was still sitting on the lawn leaning against my porch. I had noted

that it still

worked, so I hadn't thrown it out. Now with the DC system seeming to

lose out against a grid tie

if it wasn't sunny, I checked. I couldn't remember about a cable that

ran from the porch into the garage at the solar equipment. It was once

the cable for the windplant. What after that? I had forgotten.| Days of __ KWH |

May 2024 (18 Collectors) |

April 2024 (18 C's) |

May 2023 (18 C's) |

| 0.xx |

|||

| 1.xx |

|||

| 2.xx |

|||

| 3.xx |

|

||

| 4.xx |

|||

| 5.xx |

|

2 |

|

| 6.xx |

|

|

|

| 7.xx |

2 |

|

|

| 8.xx |

1 |

2 |

|

| 9.xx |

3 |

1 |

|

| 10.xx |

4 |

1 |

1 |

| 11.xx |

3 |

2 |

|

| 12.xx |

1 |

4 |

1 |

| 13.xx |

2 |

3 |

|

| 14.xx |

4 |

2 |

1 |

| 15.xx |

3 |

1 |

|

| 16.xx |

1 |

4 |

2 |

| 17.xx |

2 |

3 |

1 |

| 18.xx |

2 |

||

| 19.xx |

1 |

||

| 20.xx |

1 |

1 |

2 |

| 21.xx |

1 |

1 |

1 |

| 22.xx |

2 |

3 |

1 |

| 23.xx |

2 |

3 |

|

| 24.xx |

1 |

3 |

|

| 25.xx |

|

1 |

|

| 26.xx |

3 |

||

| 27.xx |

3 |

||

| 28.xx |

2 |

||

| 29.xx |

1 |

||

| Total KWH for month |

432.53 |

483.68 | 642.52 (all- time record!) |

| Km Driven on Electricity |

1091.9 (ODO 108799) (~~145KWH) |

1066.8 (~~140KWH) |

1207.4 Km (175 KWH?) |

| Date |

Used (watt-hours) from Battery |

Recharged (W-H) from solar |

| April 29th |

2650 |

2440 |

| 30 |

2647 |

2890 |

| May 1st |

2749 |

2990 |

| 2nd |

3059 (w. daytime heat) |

2790 |

| 3rd |

2080 |

1749 |

| 4th |

3606 (.w daytime heat) |

3136 |

| 5th |

1876 |

1702 (rain) |

| 6th |

1433 |

2227 |

| 7th |

2532 |

2601 |

| 8th |

1839 |

2228 |

| 9th |

2720 |

2377 |

| 10th |

2328 |

2301 |

| 11th |

1663 |

2484 |

| 12th |

2916 |

2020 (cloudy) |

| 13th |

2181 |

1903 (cloudy) |

| 14th |

1969 |

2183 (cloudy) |

| 15th Subtotals, May 1-15 |

1597 34,548 |

1606 (rain - still just 39.6V) 34,297 |

| 16th |

1491 |

2231 (catch-up) |

| 17th |

2642 all heaters, 280W |

2655 |

| 18th |

1801 |

2126 |

| 19th |

2526 all htrs - warmer! |

2045 |

| 20th |

2568 |

2684 |

| 21th |

1725 |

2317 (1 KWH |

| 22th |

1863 |

2276 catch-up!) |

| 23th |

1858 |

2045 |

| 24th |

1858 |

2045 |

| 25th |

1773 |

1616 |

| 26th |

2371 |

2478 |

| 27th |

2385 |

2492 |

| 28th |

2394 |

2100 |

| 29th |

2030 |

2251 |

| 30th |

2389 |

2449 |

| 31st |

2189 |

1525 |

| subtotals May 16-31 |

32,005 |

33,084 |

| May WH Totals |

66,553 |

67,381 |