Turquoise Energy News #202

Covering

Research & Development Activities of March 2025

(Posted April 7th 2025)

Lawnhill BC Canada - by Craig Carmichael

Also at craigcarmichael.substack.com

[Subscribe: email to CraigXC at Post dot com ; request

subscription]

Main URL: TurquoiseEnergy.com

Month In "Brief"

(Project Summaries etc.)

* Low Cost Electricicty Storage - New EV Motor - Open Loop Air

Heat Pumping - Faraday Cabin - 36V DC Solar Energy Improvements -

Dump Load Controller - 36V Electric Heater

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* Tinnitus Report: Purpose of Tinnitus - Canada Election -

Scattered Thots (DST) - ESD

- Detailed

Project Reports -

Electric Transport - Electric Hubcap Motor

Systems

* Unipolar Electric Hubcap Motor: Potential Improvements

Found: Novel Rotor Design! (even more novel)

Other "Green" &

Electric Equipment Projects

* "Faraday Cabin" Construction: Wall boards;

* Open Loop Air Heap Pumping (OLAHP): Compressor/Decompressor;

Tests

* Dump Load Controller

* Resistance Wire Radiant Heater(s)

Electricity Storage:

Batteries ('Everlasting' Zinc-zincate

Chemistry Works. The Research is finished.)

Electricity

Generation

* A little note on the safety & efficacy of 36 volt house

wiring

* Solar Power System Additions: - New Power Monitors for load

& charging

* The usual Latest Daily/Monthly Solar Production log et

cetera - Monthly/Annual Summaries, Estimates, Notes

March

in Brief

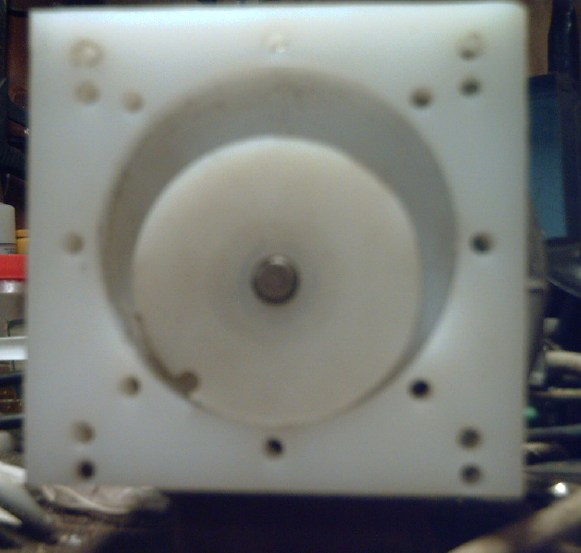

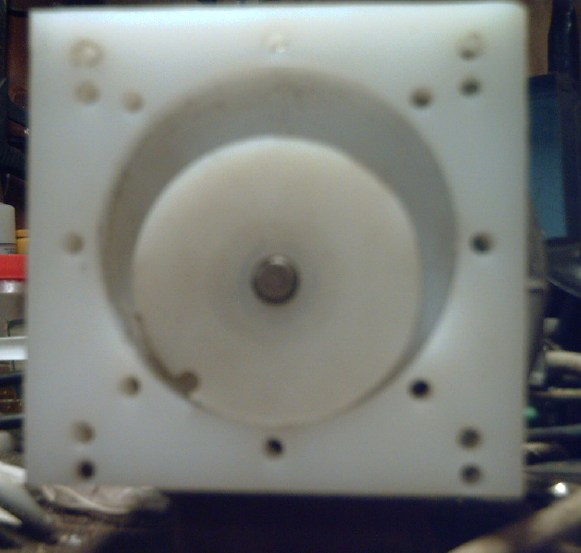

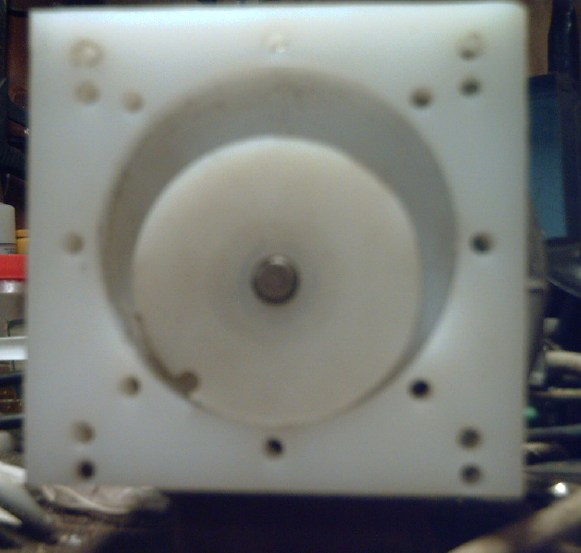

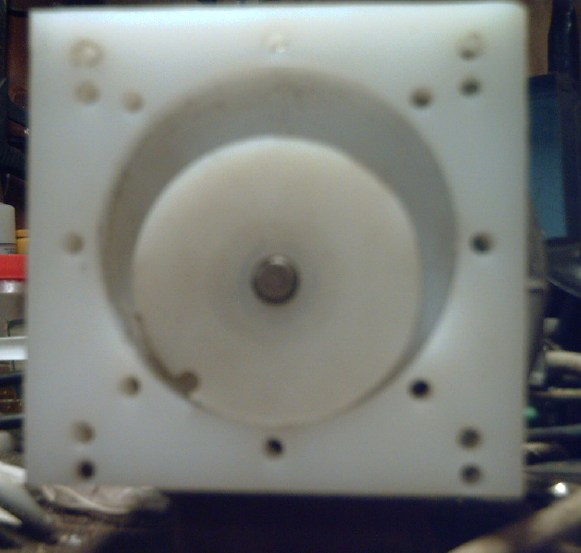

Cylinder for efficient pivoting vane

rotary air compressor

Cylinder for efficient pivoting vane

rotary air compressor

for Open Loop Air Heat Pump, mounted on 1/4 HP motor

New Chemistry Batteries

Being able to store hundreds of kilowatt-hours of

energy at affordable prices instead of lower tens would open new

modes of dealing with energy. Solar power could be stored for

rainy days, not just for overnight, both off-grid, and by

electrical utilities with mega watt-hours. EV's would be lower

cost and have longer ranges. These are immediate promises of the

new battery chemistries where the chief ingredients are abundant,

low cost metallic elements such as zinc and copper.

It occurs to me that the chemistries I've tried or

developed having been proven - Copper hydroxides, nickel-manganese

oxides, nickel hydroxide and especially everlasting

zinc-zincate, all in moderately alkaline solution, that the

project as a research project is over. The next step is production

of practical cells. I was hoping to get there, but realisticly

making batteries has proven very involved and I don't see that I

am going to be able to take it there myself.

[Longer pontification under Electricity

Storage]

New EV Motor

In a piece of highly disturbing info, in a video I

found a new type of motor that appears to be better than the one I

finally started building. I really want to build "the best". In

this new motor, the rotor uses electromagnet coils instead of

permanent magnets, yet it claims 95% efficiency. The advantage is

that the strength of the electromagnets on the rotor can be

reduced as RPM rises, allowing higher RPM's by reducing back EMF.

The tricky part is that it uses electromagnetic induction (like an

induction cookstove) to power the rotor, instead of slip rings and

brushes which are prohibitively troublesome in larger sizes like

transport motors. Well dang! After giving it some thought I

decided the stator could be identical to my present design, but

that I should change the rotor. I might even improve on it with a

hybrid "Hallbach" design having coils and still some permanent

magnets.

Some hype was also had by a lighter weight "yokeless"

motor with no iron laminates behind the stator coils. My design

with individual coils having ilmenite around the wires to complete

the magnetic circuit internally is already "yokeless" and with a

single "Hallbach" type rotor is still lighter, having (in theory -

all else being equal) only 1/4 as much heavy iron as theirs.

Being now unsure of the rotor design and in the press

of other things I didn't do any work on my motor in March. (I'll

probably want to pry off all those powerful magnets I've just

epoxied on and start over!)

[Longer pontifications under Electric

Transport]

Open Loop Air Heat Pumping

In warmer weather I ran a couple more tests with the

existing setup. I figured COP was probably somewhere between 3 and

4. But I have no means of rating it except to compare the 100

watts refrigerator (air) compressor system with a 400 watt radiant

heater and see which heats the space better. There are a lot of

variables over the length of a test.

I have high hopes for the rotary air compressor with a pivoting

vane or flap. It promises to compress much more air with the same

power as a piston compressor. Someone made an "air engine" with

two pivoting flaps that ran 3-1/2 times longer on a pop bottle of

compressed air than any of the sliding vane models he made in the

same video. The air engine and the air compressor are virtually

the same thing with the flap reversed.

I have high hopes for the rotary air compressor with a pivoting

vane or flap. It promises to compress much more air with the same

power as a piston compressor. Someone made an "air engine" with

two pivoting flaps that ran 3-1/2 times longer on a pop bottle of

compressed air than any of the sliding vane models he made in the

same video. The air engine and the air compressor are virtually

the same thing with the flap reversed.

I came up with a good plan to power the one I've

started on and finally fitted it to a 1/4 HP motor with a 1/2 inch

shaft. The rotor spins, but much remains to be done before it's

pumping air.

[More in the detailed report]

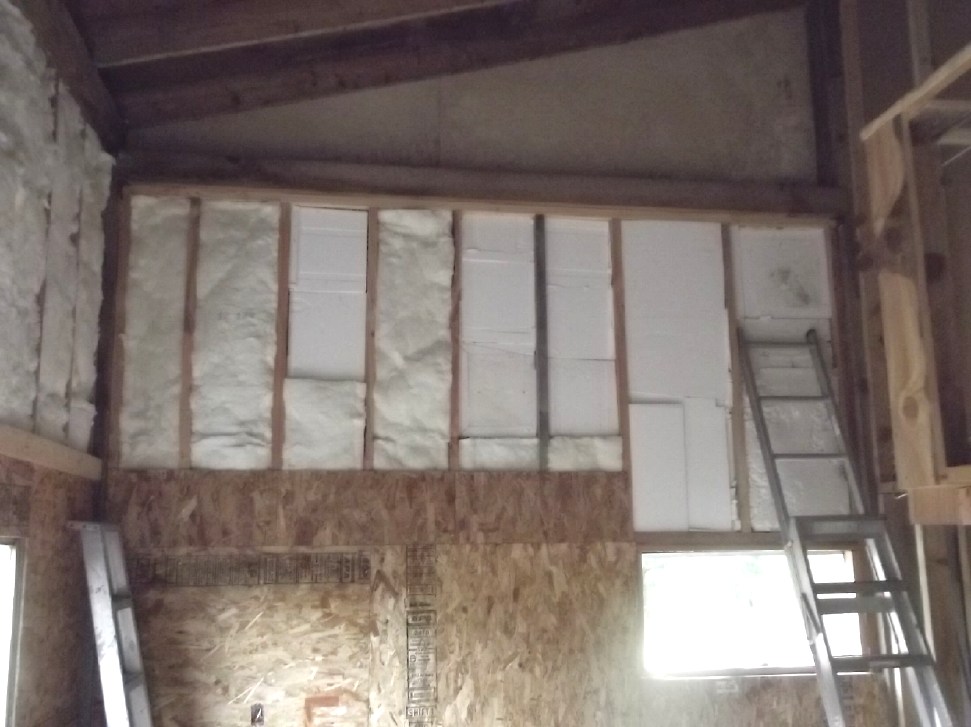

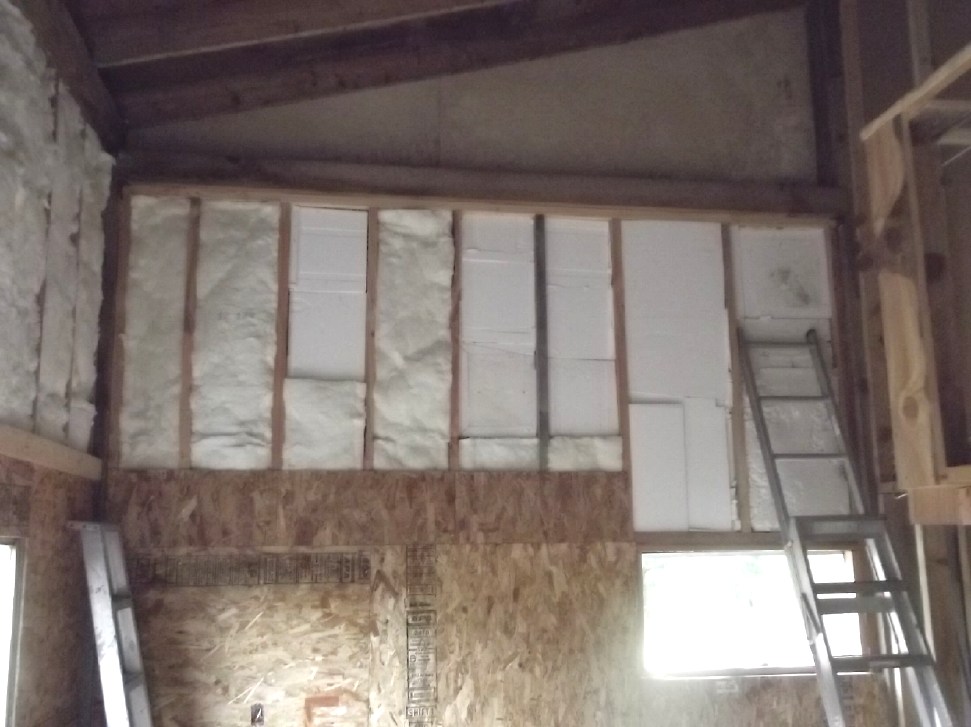

Faraday Cabin

With the improving spring weather I got more work

done on the "Faraday cabin", especially the southwest quarter

including "junk" foam wall insulation, walls, plywood floor,

washroom & closet walls....

With the improving spring weather I got more work

done on the "Faraday cabin", especially the southwest quarter

including "junk" foam wall insulation, walls, plywood floor,

washroom & closet walls....

[More under Other Projects]

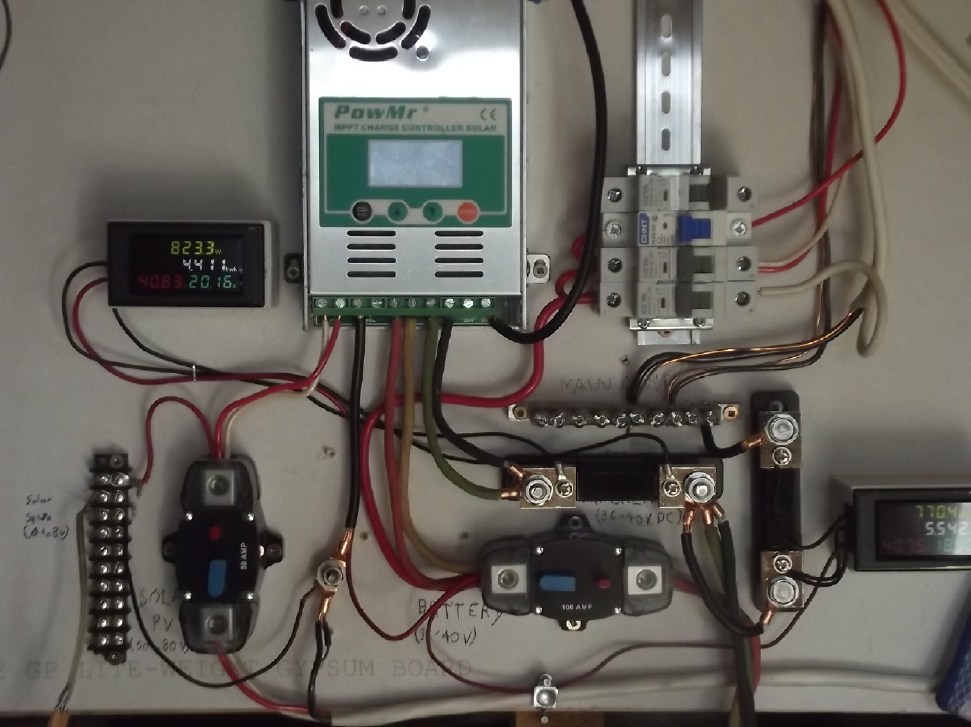

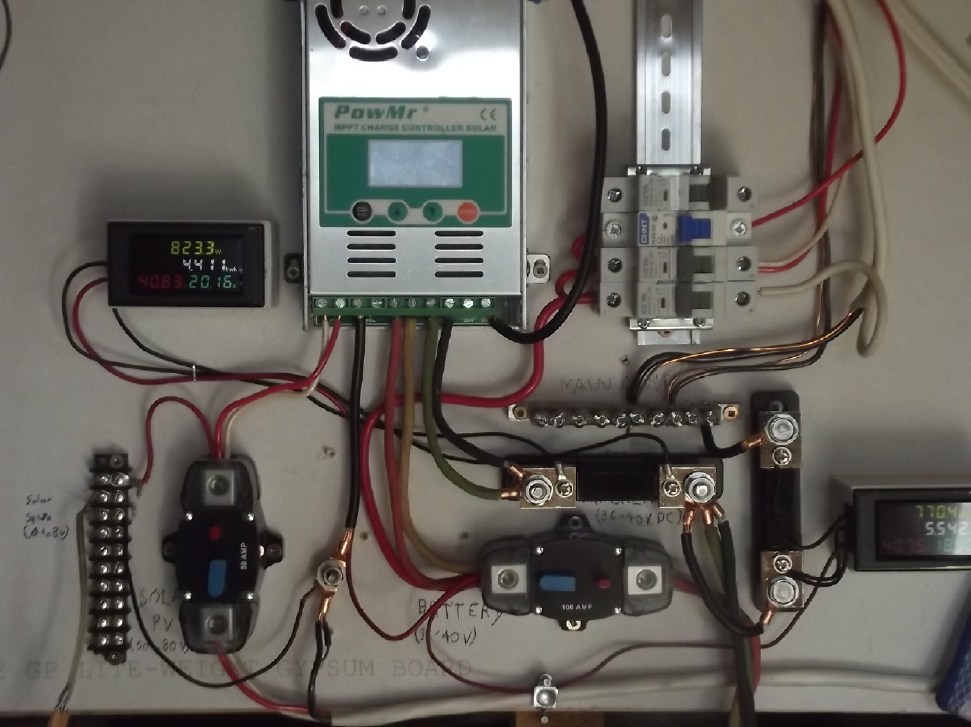

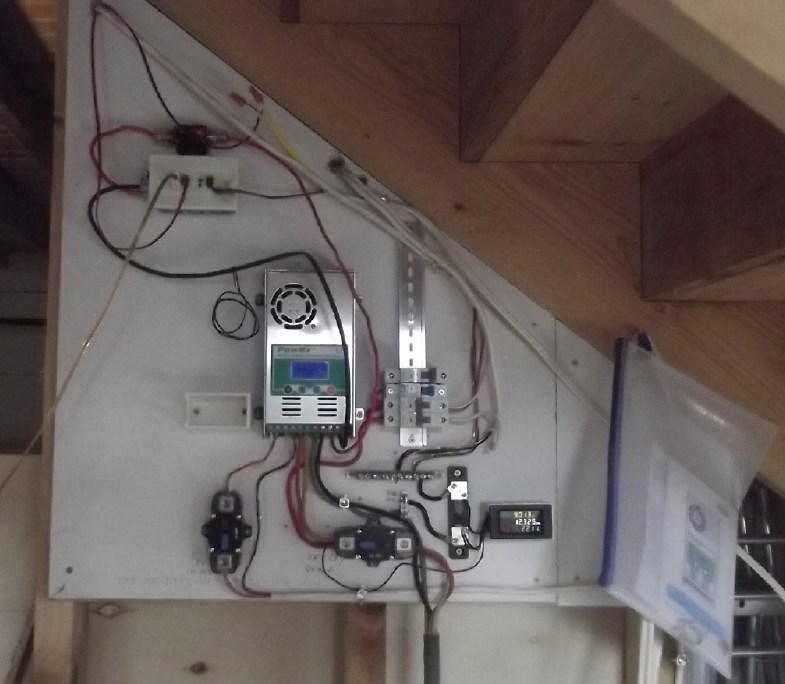

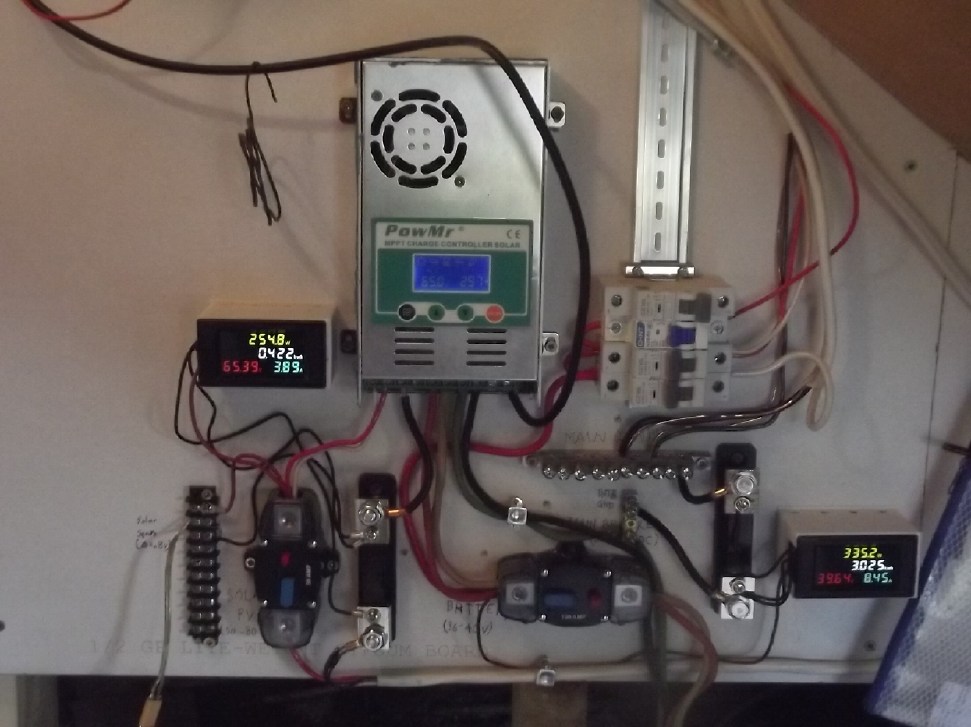

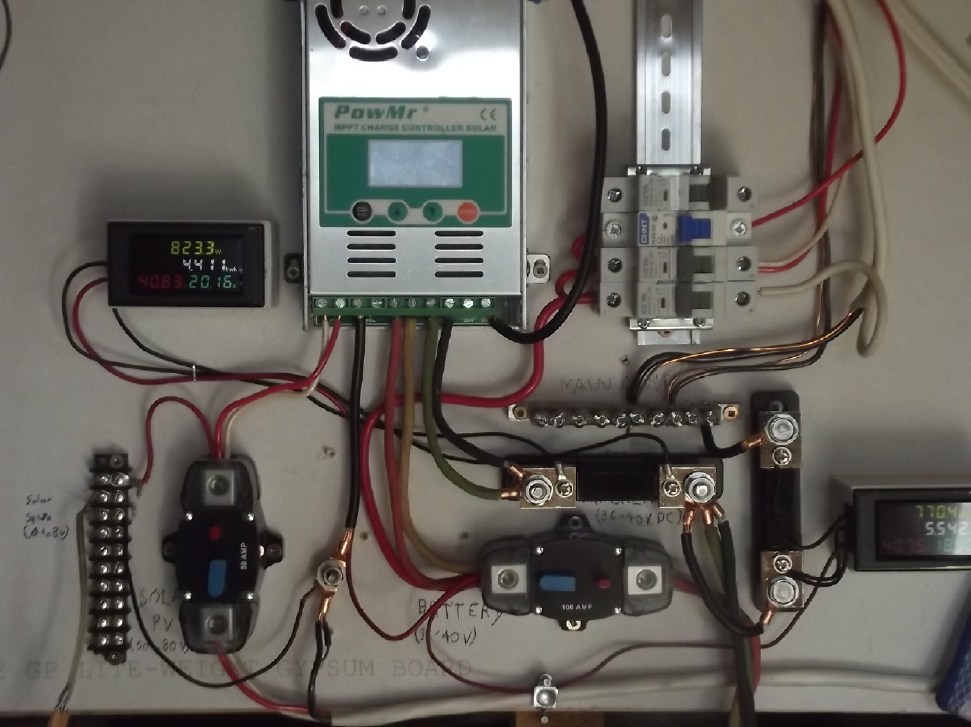

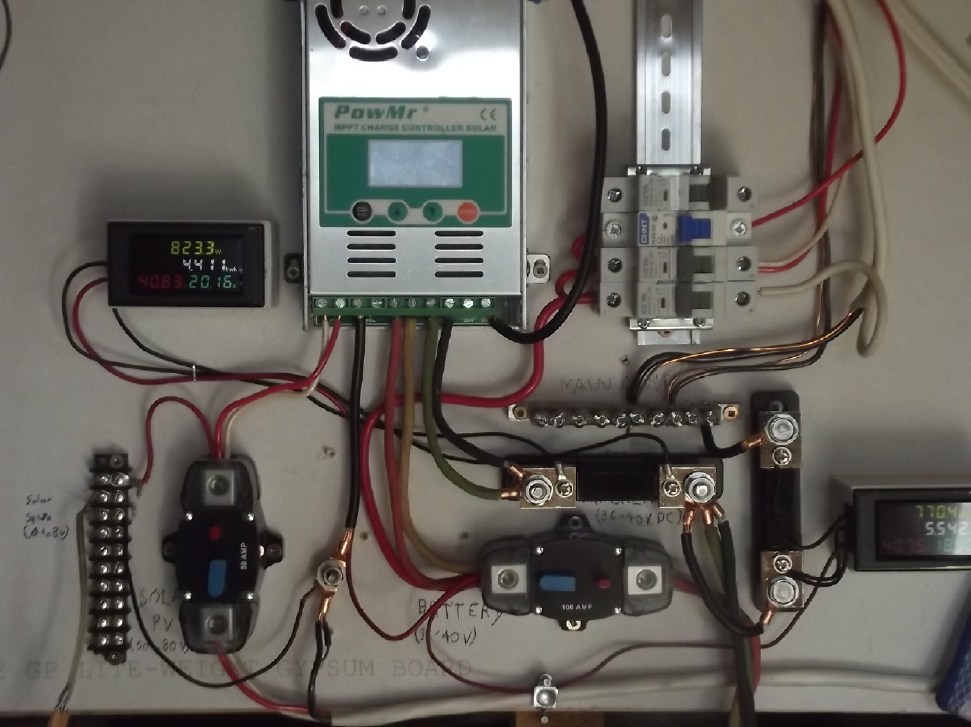

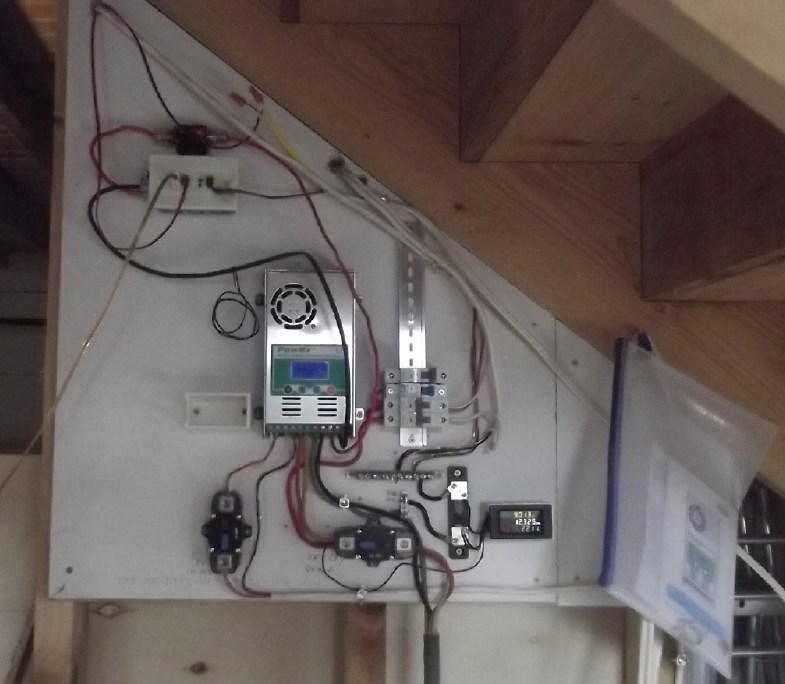

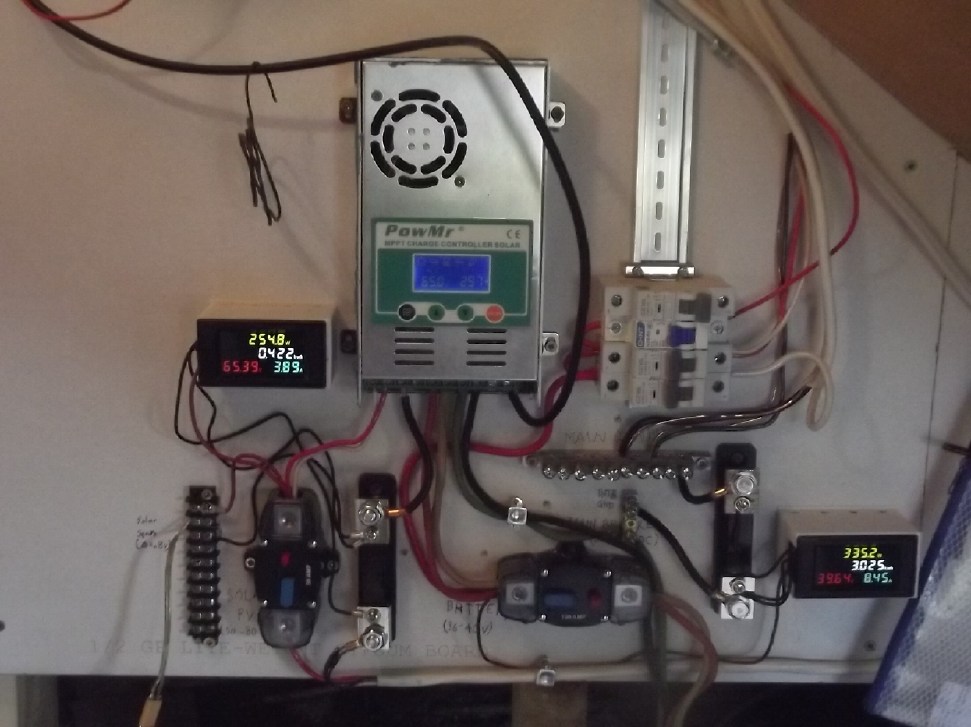

36V DC Solar Energy Improvements

...and some 36V DC electrical board improvements:

DIN rail branch circuit breakers replacing surface mount breakers,

and new load and charge energy monitors.

...and some 36V DC electrical board improvements:

DIN rail branch circuit breakers replacing surface mount breakers,

and new load and charge energy monitors.

[More details under Electricity Generation]

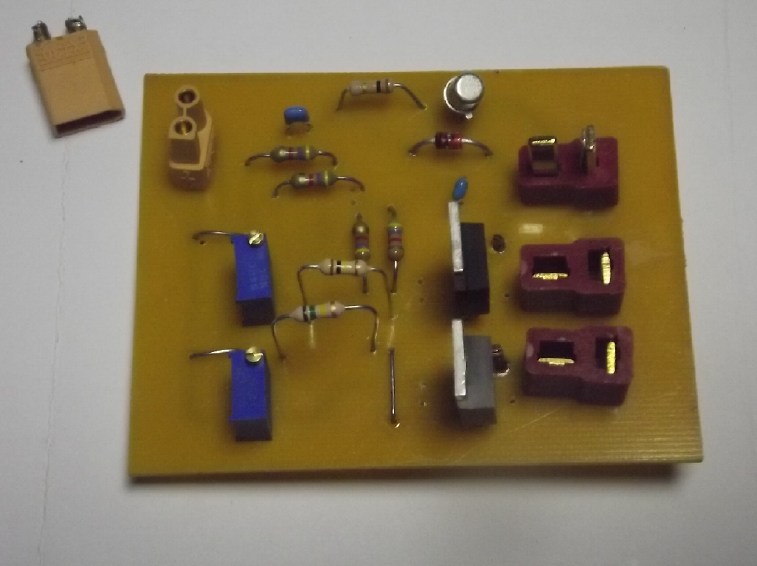

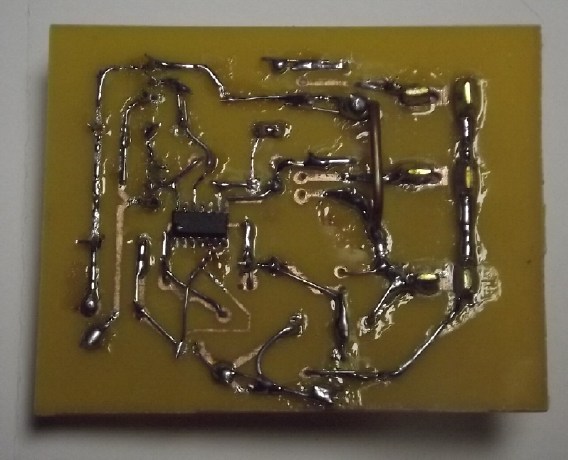

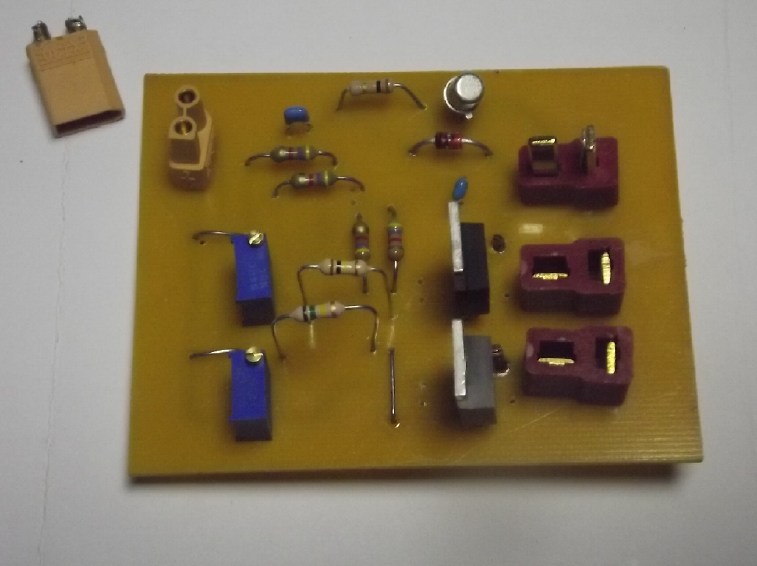

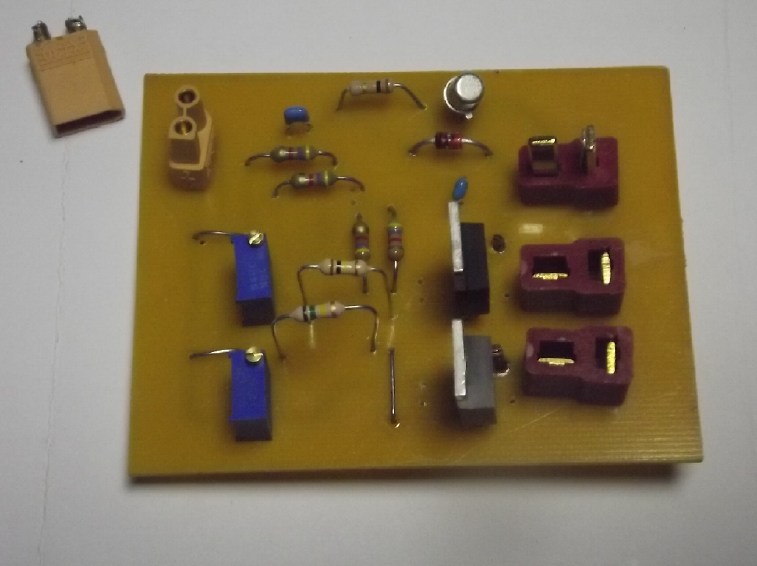

Dump Load Controller

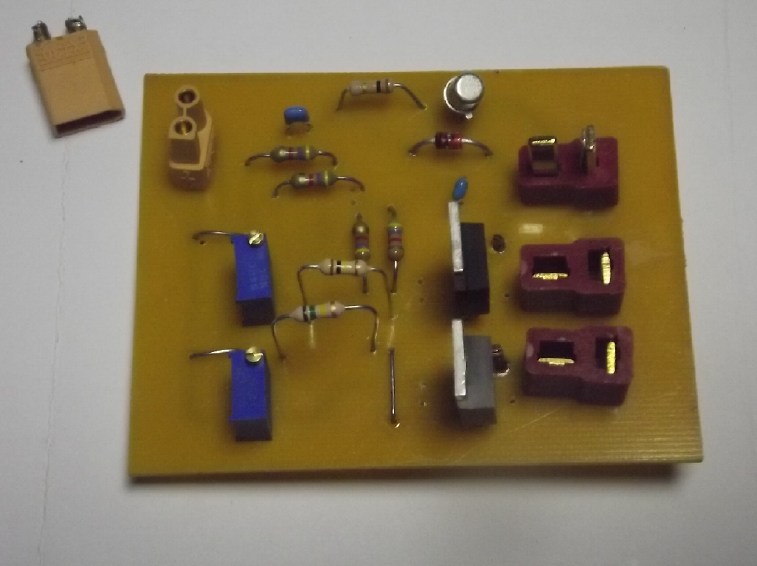

As another solar energy addition, I

tried to make a "dump load controller" to turn on heaters during

the day if there was excess solar power. I used (half of) an LM339

quad voltage comparitor to sense the switching points.

As another solar energy addition, I

tried to make a "dump load controller" to turn on heaters during

the day if there was excess solar power. I used (half of) an LM339

quad voltage comparitor to sense the switching points.

I utilized the usual 36V T-Plug system to plug the

controller into an extension cord and to have one or two

independent loads plug into the board. In order that the board

have no long wire dangling off it I used an XT30 plug for the

solar voltage sense. The solar voltage sense is 1/10th of the

actual 50-75 volts DC. The terminal strip at the electrical board

(in the above image) holds the voltage divider resistors.

But my crappy laser printer resulted in spotty PCB

traces that caused much grief in wiring and troubleshooting, and I

hadn't thought everything through very well.

Among other things there's an obvious feature I

missed: the loads should have OFF-DUMP-ON switches, since one

might want to run heaters at night or keep one load off in favor

of another.

And it didn't work as expected. Apparently the solar

charge controller uses PWM or something and the solar panels are

alternately loaded and open, so the expected steady DC voltage

actually fluctuates. As the trim pot was turned to the switching

point the load (a lamp with a DC light 'bulb') flickered instead

of being only on or off. I fixed that with a large capacitor to

smooth out the sense line. But also when it's supposed to be off

it isn't quite off - the bulb glows dimly. I haven't figured that

one out yet. (Obviously I need to get out the oscilloscope to look

for AC waveforms instead of of just a meter for DC levels.)

Finally, I made a 36 volt heater, or

at least, the framework of one. So far it just has an alligator

clip cord, which can be clipped onto any of the screws that hold

the doubled zig-zag wires, giving various wattages. With the

screws going into plywood, I keep it below where the wires might

start to glow, about 220 watts. It has been useful in the bedroom

in the house.

Finally, I made a 36 volt heater, or

at least, the framework of one. So far it just has an alligator

clip cord, which can be clipped onto any of the screws that hold

the doubled zig-zag wires, giving various wattages. With the

screws going into plywood, I keep it below where the wires might

start to glow, about 220 watts. It has been useful in the bedroom

in the house.

I could put alume flashing behind the wires for

radiance, but they should be thermally isolated from the

wood. Perhaps I should make some ceramic pieces? Maybe with a

screw hole and a wire hole? Now it doesn't sound like a two hour

project any more!

[More on these somewhere under Other Projects]

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Tinnitus

Report: Purpose of Tinnitus

[23rd] I had a logging friend come over and cut down three trees.

I was afraid of hitting my travel trailer if I cut the large one

myself. He had them down in minutes but insisted on bucking the

biggest one into firewood since he had a full tank of gas in the

saw. I had my new Stihl battery electric chainsaw so I cut off

branches ahead of him so he had only the main trunk to cut. But I

was working too close to him with no hearing protection. (He had

earplugs.) I finally went off and got my "earmuffs", but by then I

had been too exposed for too long.

For the rest of the day and the next my tinnitus was

really bad. I'm sure I did my hearing no good at all.

Probably it is "self evident" that this is what

tinnitus is supposed to be for: to warn us when we're exposing

ourselves to too much noise and damaging our hearing. If it wasn't

for the fact that electric fields also make "forever" tinnitus in

the absence of audible noise, we'd probably become more averse to

being in loud situations and preserve our hearing better. That's

just my opinion - that tinnitus has a purpose and that that's how

it's supposed to work.

It's said that 10% of the population has the

"forever" tinnitus - surely from electric power fields - and it's

probably a much higher percentage of older people. I look forward

to finishing and spending several quiet days in my "Faraday cabin"

to verify for certain that it does eventually fade to nothing in

the absence of power line EMF fields. And to see how many days it

does take.

[April 2nd] Latest report: I spent as much time as I could Sunday,

Monday and Tuesday in and working in the cabin, and I slept in it

at night. The intensity of the ringing was much reduced Monday and

especially Tuesday and the loud tone faded to a diffuse high

frequency noise. I didn't drive anywhere so I didn't get that

"right under the 14,400 volt power poles for an hour"

amplification. But I still spent too much time in the shop, the

house and in the yard too near the power lines, where I started to

notice it gradually increasing again, and it wasn't going to

vanish entirely with the repeated aggravations. Tuesday night I

slept in the house again and the tone was back in force on

Wednesday morning.

Of course I was listening carefully for these

effects. If I had been trying to ignore it to stay sane instead of

paying specific attention, probably nothing would have surfaced

from the subconscious into my conscious mind. The big change is

when it's gone entirely or virtually.

[April 3rd] Egad, more to report! Then on Wednesday (2nd) I

started doing some work in the front yard - about as close to the

power lines as I could be since my yard rapidly rises 10 feet from

the highway - so the line was as close as if I had climbed part

way up a pole. The ringing in my ears increased so rapidly that

after about 20 minutes I stopped and dragged the object of my

attention behind the lawn tractor all the way around to behind the

house and shop. Then I had to drive into town - another hour under

the power lines in the car. For the rest of the day and on into

Thursday it was really bad (despite sleeping in the cabin). The

contrast from Monday and Tuesday was so pronounced it probably

would have forced itself into my consciousness, especially if I

had worked out front for a couple of hours. And I Have had days

and nights of blaring tinnitus that I've noticed before, asking

myself "Why why why? I didn't do anything very loud!" -- surely

after days when I was working similarly close to the power lines

for extended periods.

The next week the pattern may more or less repeat.

Waiting for "don't have to drive anywhere" days and working in the

cabin. I find myself avoiding things I want or need to do just

because I know they're in zones of higher fields. Maybe I should

just hide in my Faraday cabin and become a hermit? (Have to finish

it and get internet & fone first!)

Canada

Election

I had the experience of watching one Mark Carney, a

first time candidate for any political office, pontificate for

maybe 20 minutes, sitting in a cafe that had the TV on. For the

last decade he has been governor of the Bank of England, where ex

prime minister Liz Truss said he was a disaster and that some of

the problems he caused were blamed on her. He was apparently

popularly known as "Mark Carnage". It sounds like he had to "get

out of Dodge" before the B of E collapsed under him.

Now somehow he has been magicly parachuted back into

Canada as instant prime minister, in highly suspicious

circumstances. (Remember the usual leadership race coverage? No?)

Somehow large numbers of liberals were "disqualified" from running

or even voting, and it seemed to be over almost before it began. I

heard his first speech and it sounded like all his policies were

identical to those of corrupt Justin Trudeau's and I asked myself,

"Why did we bother getting rid of Trudeau? It sounds like

absolutely nothing will change!" Then I discovered that Carney was

Trudeau's consulant all along. He and Trudeau have been associates

and friends for years and both are in Klaus Schuab's ("You'll own

nothing and be happy") World Economic Forum, espousing the same

philosophies and aims. (Hmm... I seem to recall a couple of

earlier Carneys in Liberal party political circles from the 1970s,

too. Art? Pat?) Now he has called an early snap election before we

might get to see what sort of a leader he might turn out to be.

And rather than equal opportunities, I bet the other party leaders

don't get two minutes of uninterrupted TV air time in which to say

what they want, between them. (not without the viewer being told

by the commentator sentence by sentence what's wrong with their

plans.)

I have the impression "big money" is trying to

railroad us into another four years where they call all the shots

and tell our "elected" "leader" what he is to do. Well, at least

they haven't arrested Pollievre on some trumped up charges and

told him he's disqualified from running for office, as is

happening to the leading potential future leaders in Europe right

now. (Romania, France, Turkey... Ukraine... Germany? Britain?)

Scattered

Thots

* Trump said that if elected he would

get rid of daylight savings time. "Nobody likes it." said Trump.

And yet today the computers turned their clocks ahead as usual for

the next 2/3 of the year. Has he broken his most important

political promise? Is it like Justin Trudeau promising before his

very first term, "This will be the last 'first past the post'

election."?

Or are the computers rong? Or does Trump have no say

in this? After all, the present twice extended dates were voted on

by congress. (at the behest of some deluded but persistent

congressman who thought doing so would somehow save energy, and

that that was a good enough reason everyone should get up before

the crack of dawn. Apparently if he or any of the other 500-odd

people in congress had troubled to investigate before voting, the

few statistics available indicate that using DST causes marginally

higher energy usage. Also, why did it apply in Canada with no

public discussion and AFAIK no vote?)

I'm not changing my schedule nor my clocks that

haven't changed themselves. Maybe next year, this piece of

craziness will finally end?

ESD

(Eccentric Silliness Department)

* Officer: "Why did you try to shoot Polish president Donald

Tusk?"

Suspect: "Hunting elephants is banned. I was after ivory."

(Am I actually going to leave this here?)

* What caliber was King Arthur's weapon? . . . .

.. . . .. 'X' caliber.

* I hear there's a plan afoot to make the USA into Canada's 11th

province.

"in depth

reports" for each project are below. I hope they may be useful to

anyone who wants to get into a similar project, to glean ideas for

how something might be done, as well as things that might have

been tried, or just thought of and not tried... and even of how

not to do something - why it didn't work or proved impractical.

Sometimes they set out inventive thoughts almost as they occur -

and are the actual organization and elaboration in writing of

those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before publication. I

hope they may add to the body of wisdom for other researchers and

developers to help them find more productive paths and avoid

potential pitfalls and dead ends.

Electric

Transport

Unipolar

"Electric Hubcap" Motor... Revised Yet Again: Novel Rotor

Design

I chanced across a video showing a "new" type of

motor - at least, new as far as electric transport motors.

A DC motor with electromagnets in the rotor, and

brushes on slip rings to carry the magnetizing current to the

rotor, does have its advantages but, particularly in higher power

motors and at higher RPM's, the brushes and rings will arc, make

electrical noise and rapidly wear out both the brushes and the

slip rings.

The advantage is in running high RPM's. Permanent

magnets provide lots of torque, but the high, fixed back EMF

limits RPM. Torque drops with RPM as the generated voltage

approaches the supply voltage. With electromagnets on the rotor,

the rotor magnet strength can be turned down as RPM increases,

reducing back EMF. And the advantage of low and high RPM

capability is that it eliminates the need for the variable torque

converter on which I have lavished so much time and effort.

Now a company has made a transport motor that uses

electromagnetic induction to transfer power to the rotor coils

instead of slip rings. It is said to be 95% efficient in spite of

the induction losses and powering rotor electromagnets, which is

as good as any permanent magnet motor. And of course a motor with

no permanent magnets eliminates the inherent safety hazard they

present.

Oh, No! I am suddenly confronted with the idea or

truth that the motors I've been making or developing all these

years probably aren't the best possible. Then, why bother with

them? And just as I was finally building the most advanced

version! What can be salvaged if anything, and what needs to be

redone? Or should I just do other projects and forget motors?

Well, the rotor is different, but the stator can be

the same - probably exactly the same. And the unipolar motor idea

still eliminates iron magnetic hysteresis losses.

In studying electromagnetic induction, I ran across a

small DIY induction cooker that used a "U" shaped (ferrite?) core.

The heat to the pan was concentrated on the two spots at the ends

of the core. That suggests that the spinning rotor could have two

concentric rings, at the ends of the stationary "U", to receive

the energy from the primary coil.

It seems to me that on the rotor I could use the same

arrangement as on the stator: separate unit coils, wound around

iron powder toroidal cores with epoxy/ilmenite to to glue the

wires and carry the magnetic circuit. There would still be 12

coils on the stator. There would be 8 coils so 8 magnet poles on

the rotor - the usual 3 to 2 ratio.

A possible variant would be to have a cylinder

permanent magnet in the "donut hole" of each rotor coil. This

would set a minimum magnetism of the rotor and it would require

less power to energize the coils less strongly, but it wouldn't be

enough to limit the RPM to an undesirable figure. Again I would

have to figure out a good configuration for such a system, but I

got the cylinder magnets and determined mountings within the coils

for them when I was considering the "permanent magnet assist"

stator coils idea.

I could also add 8 sideways permanent magnets between the

coils to constitute it a Hallbach configuration rotor,

strengthening the field toward the stator with little field going

into the rotor disk. With the permanent magnets taking some of the

load, the rotor would require the least induced energy - perhaps

none at higher RPM's.

[14th] I didn't like all the extra variables this would throw into

an already experimental mix. I came up with another plan: the

rotor with the permanent magnets was 7/8 of an inch thick: disk

1/8 + two layers of magnets 3/8 + 3/8 = 7/8. The coils for the

electromagnet design would be one inch, plus no more than 1/4 inch

for a steel or other disk. That's just a possible 3/8 inch

difference. And insulated copper rings? Probably they would be

recessed toward the center and make no extra height.

I decided to make the permanent magnet rotor and

motor, but make the housing 3/4 of an inch longer than it needed,

to accommodate a fatter rotor when and if I get that far. First I

would get the permanent magnet version working and mounted in the

car, and tested in actual use. Later I could remove the first

rotor and try out the new one on a motor whose stator and motor

controller was already known to work.

---

I also discover that there's a name for my design

with individual coils whose magnetic circuit is completed by the

ilmenite around the windings: any such stator with no laminate

backing needed to carry the magnetic field between coils is called

"yokeless", and the idea as applied in one new motor appears to be

causing some excitement recently, largely because of the reduced

weight. But the motor in question is able to be "yokeless" by

virtue of having a magnet rotor on each side of the stator: the

"yokes" are on the outside of the rotors. With only one rotor and

it being Hallbach, my motor uses just one thin "yoke", on the

rotor, instead of two fat ones - 1/4 the iron weight. And my

unipolar motor idea still eliminates iron's magnetic hysteresis

losses. (There are probably some bad yokes about rotten eggs in

here somewhere!)

Other

"Green" & Electric Equipment Projects

"Faraday

Cabin" Construction (long continued)

At some point I finished insulating

the southwest quarter walls with foam. (Except that gable end

way up there)

[14th] I put up the rest of the birch

wall paneling in the southwest quarter.

That's so much better than looking at ugly fiberglass (and

foam) insulation.

(I don't understand why some sheets are much darker and more

patterned than others,

except that they were probably bought at different times. I

was expecting a more homogenous appearance.)

I intend to put wallpaper on the lower "chipboard" parts.

BTW: Birch slivers are nasty!

[16th] I put insulation between the floor joists at the outside

walls in the southwest quarter [what, no picture?], did a little

caulking at the drain pipe so mice couldn't potentially squeeze in

there, and screwed down the first three sheets of plywood floor.

The walls might be a little ramshackle (and the interior walls not

done at all), but basicly it's starting to look almost civilized!

In one corner. Instead of buying more 3/4 inch fir plywood I used

up some birch plywood I already had.

The cabin's interior walls will be pretty minimal.

Four areas will be separated: the garage, the bedroom above the

garage (together filling the northwest quarter), the washroom plus

storage closet and the electrical closet under the stairs (both in

the southwest quarter). The other half I plan as "open space": the

sunny livingroom with a view (southeast quarter), and in the

northeast the woodstove area (and probably an OLAHP installation;

maybe a big water piped "sand battery" under the floor with a warm

water radiator somewhere) and probably a food prep area of sorts.

But presently I intend that my main cooking area and the bath will

continue to be those in the main house.

[19th] There was just a little piece of the southwest floor to go.

I was doing other things, but I finally said "I can't go back to

the house without cutting that last piece of plywood and finishing

the floor! So I did.

[21st] I thought if I was making the washroom walls from 2 by 3's,

that there were some used ones in the lumber piles. No one will

see them once the wall is covered, so why not use those rather

than slit more 2 by 6's in half?

I opened up the pile and discovered that they were

soaking wet. Two pieces of the metal roofing covers formed a

shallow "V" instead of both running the same way, draining all the

rain right into the wood. So I found all the 2 by 3's and took

them inside the cabin, and put a fan blowing on them to dry them

out some before using them.

At some point I reflected that I had made a mistake

in placing the stairs: I should have put the bottom end flush with

the cabin's center post instead of having the lowest three steps

sticking into the other half. The whole east half of the cabin

would have been completely clear, with the stairs, landing and

bedroom entrance themselves unchanged, just a bit farther over.

Much too late now! How little real thought went into the

placement!

[26th?] The boards looked much dryer. I cut the

better ones to length. [27th] I screwed the wall frames together

and put them up. Then I cut and put up 2 by 4's for the ceiling

frame. With just a 4 foot span it was convenient to lay them on

their sides. [28th] I pushed up a sheet of 3/4 inch plywood for

(most of) the ceiling cover. I have the idea to store seldom used

things on this ledge above the washroom (ladder access), as well

as storage in the large closet space I made as the end section of

the washroom frame.

[26th?] The boards looked much dryer. I cut the

better ones to length. [27th] I screwed the wall frames together

and put them up. Then I cut and put up 2 by 4's for the ceiling

frame. With just a 4 foot span it was convenient to lay them on

their sides. [28th] I pushed up a sheet of 3/4 inch plywood for

(most of) the ceiling cover. I have the idea to store seldom used

things on this ledge above the washroom (ladder access), as well

as storage in the large closet space I made as the end section of

the washroom frame.

I got a ladder and climbed up. From here I could

reach the cabin roof. I'll have to put up scaffolding and insulate

that "cathedral" ceiling way up there - hopefully all of it before

next fall. I may have enough fiberglass and styrene foam already.

Later I decided to use rainwater instead of my iron

and sulfur rich well water. I could put a barrel on top of the

washroom where it wouldn't freeze in winter, and plumb it to the

eaves trough. That should suffice for hand washing.

[29th] I cut and put up 1/4 inch birch plywood for

the washroom & closet wall paneling. I used a piece that had

once been out in the lumber piles collecting rain for the back of

the closet. (At last, there's just one sheet of that left now.

It's the worst one - too ugly and degraded to use for anything

except maybe in little bits of the better parts. or firewood.)

[29th] I cut and put up 1/4 inch birch plywood for

the washroom & closet wall paneling. I used a piece that had

once been out in the lumber piles collecting rain for the back of

the closet. (At last, there's just one sheet of that left now.

It's the worst one - too ugly and degraded to use for anything

except maybe in little bits of the better parts. or firewood.)

More Foam for Wall Insulation, and the Danger of Waste Plastic

& Plastic Foam

This piece of foam stranded on a beach

was visible from the highway

This piece of foam stranded on a beach

was visible from the highway

way out on a point of land. One day I went off on an expedition

and

retrieved it, dragging it through jungle and swamp to the

highway.

Amazingly I got it into the open tailgate of the car!

There was a problem: the inside seems to be a barrel, not solid

foam.

Now I don't know what to do with it. But at least it's off the

beach.

[12th] I continued to accumulate styrene foam for insulation. The

recycling centre phoned and said "you've hit the mother lode", and

sure enough I filled my trailer with 1/2 and 1 inch flat sheets.

Being out of room inside, I left most of them in the trailer for

now.

[15th] In the distance I saw what looked like a

big piece of foam washed up on a neighbor's rocky beach. I phoned.

[16th] She returned my call. It was. After my call she had tied it

so it wouldn't float away.

[15th] In the distance I saw what looked like a

big piece of foam washed up on a neighbor's rocky beach. I phoned.

[16th] She returned my call. It was. After my call she had tied it

so it wouldn't float away.

She wanted it gone ASAP. She said once she had a

chicken that stopped eating, and she had to kill it. It turned out

it had found some styrene foam on the beach and eaten the little

beads. Its belly was full of foam beads and it was starving. This

is why it's worth getting this stuff out of the environment. I

can't always tell plastic and rubber bits from clam shells and

seaweed without close examination. How are sea birds and sea

creatures with small brains and monochrome vision supposed to?

[17th] I cut it in half, there being a thin spot

part way along. I put the smaller end on the hot wire "table saw"

and cut it up. It didn't go very well. First it was wet, which

didn't help then it had a pocket of sand, and the wire didn't like

cutting through big burrowing toredo worms. One of them was almost

an inch in diameter and several inches long. That was actually

rather gory. Finally, the wire at the sides, not in the foam,

started glowing bright red with just 3-1/2 amps. Before it took

3-3/4 amps before it would faintly glow. What's changed? All I can

think is that this is the second spool of resistance wire and

maybe it's different from the first? It doesn't look any

different. The glowing wire would snap after a bit. Several times

I had to pull out the snapped wire and put a new piece on.

[17th] I cut it in half, there being a thin spot

part way along. I put the smaller end on the hot wire "table saw"

and cut it up. It didn't go very well. First it was wet, which

didn't help then it had a pocket of sand, and the wire didn't like

cutting through big burrowing toredo worms. One of them was almost

an inch in diameter and several inches long. That was actually

rather gory. Finally, the wire at the sides, not in the foam,

started glowing bright red with just 3-1/2 amps. Before it took

3-3/4 amps before it would faintly glow. What's changed? All I can

think is that this is the second spool of resistance wire and

maybe it's different from the first? It doesn't look any

different. The glowing wire would snap after a bit. Several times

I had to pull out the snapped wire and put a new piece on.

I finally put a fan on, but with the big chunk of

foam there, it could only cool one side. Finally, two fans! I had

been warm enough, but with the fans blowing I got pretty chilly.

(I could see my breath and just after I finished there was a brief

deluge of hail.) I had had more than enough for the day by the

time I finished the small end. But I wasn't able to just quit

working yet.

It was well my neighbor related to me the story about

the chicken. A lot of styro beads had rubbed off the deteriorating

float, and the barrel float too. I let my chickens out to forage

and have dust baths in the late afternoons (after the hawks seem

to have left for the day). They came around that side of the house

and started pecking away at the beads. They weren't to be

dissuaded except by throwing a handful of bird seed to distract

them. I spent the better part of an hour vacuuming up all the

little beads off the lawn. (Vacuuming. The Lawn.) Then they

started pecking at the floats themselves and breaking beads off

them. I had to roll the floats into the garage and close the door.

And then vacuum up more bits from the lawn. I am also always

picking up bits & beads of styrene foam whenever I go for a

walk on the beach; sometimes larger pieces. Along with other

plastic. No wonder sea birds and turtles are dying en-masse all

over the world!

[19th] I cut up the larger end. It was almost as much of a pain as

the first side. Several times the wire broke, and it didn't come

out very smooth. I could see not only my breath, but moisture

coming off the foam where it was being cut. And if I Stopped

pushing to be sure I wasn't about to break the wire, the stretched

wire sagged and melted downward, making far less than flat

surfaces.

I now know that I don't want any more foam floats

that have been washing around in the ocean if they are encrusted

with sea life (which takes on quite a stench after a couple of

days as it decays). Putting them in a landfill doesn't get them

out of the environment. Better to burn them if they're too

deteriorated.

Open Loop Air Heat Pumping (OLAHP)

I did two rather separate things on this: a bit of

work on the rotary compressor, and a couple more tests in warmer

weather on the present setup with the fridge compressor.

Rotary Compressor

From a theoretical design to a practical working

prototype is not necessarily a straightforward, transparent

process. Luckily starting with the rather complex "ROVACS" rotary

compressor-decompressor I didn't have confidence or time to try

making something similar, and in five years the plan has evolved

into something much simpler and far more efficient: the single

rotary pivoting vane design plus a similar but separate

decompressor or "air engine" on the same shaft, without me having

built any more complex and less efficient intermediate models.

Now that I've done some CNC on it, for starters I

thought that the pivoting vane or "flap" should have a pin for a

hinge. Maybe I should cut into the UHMW rotor and make some tiny

assembly holding the pin? But how? I finally thought of the mini

milling machine for machining it to remove small amounts

accurately, without making it a real hack job. I haven't used it

in so long it didn't come readily to mind. I didn't get any actual

work done on making it, preferring to have the rotor and cylinder

going first.

Then, I had been wondering since I made it, a few

things about how the unit was going to connect to a motor and be

turned.

[20th] I used the milling machine to make a depression in the

rotor for the bearing. I should have used a boring bar on the

lathe, because I couldn't seem to coordinate the two levers by

hand and gouged out too much, in an irregular shape. The rotor was

jamming against the innermost point of the housing. I put it on

the lathe and turned down the outside. This made it much smoother.

Just for that it was worth it. I see turning the housing to smooth

the inside of the cylinder - both rim and bottom - is also a

"must". It'll need some way to center on the lathe while the round

inner parts are turned, so it needs bolt holes for the lathe

plate. (Hmm... Actually the outer corner mounting holes as-is are

perfect.)

As to powering the compressor, I

thought of a stepper motor and how it might attach by its face to

the compressor body piece, with the rotor simply being on the

motor's shaft and not needing any bearings of its own. But a

stepper motor was (among other things) too small.

As to powering the compressor, I

thought of a stepper motor and how it might attach by its face to

the compressor body piece, with the rotor simply being on the

motor's shaft and not needing any bearings of its own. But a

stepper motor was (among other things) too small.

Then in the shop I dragged out an old

1/4 HP (~185 watts) washing machine motor that I had acquired from

some scrapped unit long, long ago and far, far away. If I used its

four assembly bolts and extended them out with threaded rod and

standoffs it could "face mount" to the compressor housing like the

stepper motor. All while mounted on its cushion stand, meaning the

compressor would be mounted "in the air" on the end of the motor.

Then in the shop I dragged out an old

1/4 HP (~185 watts) washing machine motor that I had acquired from

some scrapped unit long, long ago and far, far away. If I used its

four assembly bolts and extended them out with threaded rod and

standoffs it could "face mount" to the compressor housing like the

stepper motor. All while mounted on its cushion stand, meaning the

compressor would be mounted "in the air" on the end of the motor.

This made for a lot of clarification of what had to

be done. I would have to re-make the compressor housing with a

larger surround and the bolt holes spaced to line up with the

motor bolts. [Actually the housing proved jut large enough as it

was.] The rotor center would match the 1/2 inch motor shaft with

its flat side, and have set screw(s) to hold it on.

Somehow I didn't manage to get any

more done on it until April 3rd, when I drilled the holes to fit

the cylinder body to the motor. I managed to get the piece pretty

exactly aligned and screwed down on the CNC table so that the new

holes aligned closely with the previous routing.

Somehow I didn't manage to get any

more done on it until April 3rd, when I drilled the holes to fit

the cylinder body to the motor. I managed to get the piece pretty

exactly aligned and screwed down on the CNC table so that the new

holes aligned closely with the previous routing.

[April 4th] I continued by turning the piece on the

lathe with a boring bar, to smooth and true the inside faces of

the cylinder. Part of the bottom was a bit too deep. If I dug down

that far, the cylinder would have been thicker than the rotating

disk. As long as the disk is the fatter piece, I can put a gasket

between the lid and the outer parts. Hopefully not much air will

get by.

[April 4th] I continued by turning the piece on the

lathe with a boring bar, to smooth and true the inside faces of

the cylinder. Part of the bottom was a bit too deep. If I dug down

that far, the cylinder would have been thicker than the rotating

disk. As long as the disk is the fatter piece, I can put a gasket

between the lid and the outer parts. Hopefully not much air will

get by.

Apparently the CNC should be set not to go down quite

to the full 1/2 inch depth or the full diameter, and also to make

the rotor disk slightly oversize, so these critical faces can be

trimmed to exact dimensions on the lathe after.

I thought of expanding the center hole

of the rotor to 1/2 inch for the motor shaft, and how a twist

drill was likely to drift off center. Then I remembered I had some

step drills, and I used one with a 1/2 inch maximum step to ream

it out. That seemed to work pretty well. It was a tight fit on the

motor shaft.

I thought of expanding the center hole

of the rotor to 1/2 inch for the motor shaft, and how a twist

drill was likely to drift off center. Then I remembered I had some

step drills, and I used one with a 1/2 inch maximum step to ream

it out. That seemed to work pretty well. It was a tight fit on the

motor shaft.

I set the parts to the motor and spun it. without the

wooden pivot, which might have flown out. Seems to fit well.

Further Tests of Present (Fridge Compressor) System

[25th] It was much warmer on this morning - about 10° instead of

frost. I decided to try the existing OLAHP setup in this milder

weather. I took many readings over some hours, but the sun came

out and probably did more heating than anything else. I couldn't

swear there was any heating from the system at all. But outdoors

it was still 10°. It didn't rise above 11 all day. (or was it 12?

- shoulda wrote it down!) As with the previous tests the

temperature differences were pretty tiny. A couple of things were

notably different: First, the pipe from the compressor was warmer,

around 35° instead of upper 20's. I had to change the clamping of

the temperature probe to the pipe (the tape had gotten oily and

came loose) and I suspect it was right this time rather than

previously as it was more in line with expectations. Second, the

air coming in from the indoor-outdoor air heat exchanger was

warmer, around 20° instead of 15. This makes sense since it was

10° outside instead of 0°. I could feel the slightly cooler air

wafting out of the duct as the compressor drew air from the room -

just as it should.

Analysis

Let's look at the individual components -

The compressor was drawing room temperature air (23°), or slightly

less because it was just a short distance from the heat

exchanger's outdoor air intake duct (20.5°) to the compressor box.

So, perhaps somewhere around 22°. I measured the compressor output

pipe and hence the initially compressed air at about 34°, at 40

PSI. Probably inside the fridge compressor's sealed housing it

would be a little warmer yet, maybe around 37°. So the air was

being heated by 37-22=15°. [Hmm, that may be an underestimate?] If

it was a 100% efficient compressor the potential COP would be

296°K/15°=~20. Because we're not feeding the cold compressed air

back into a "compressed air engine" or "decompressor" to help the

compressor turn, 1/root2=29.3% of the energy the compressor uses

is wasted (as compressed air hissing to the outdoors) leaving

potential COP=14, and of course the fridge compressor surely isn't

very efficient itself. When I see the astonishing performance

difference between the (more typical) sliding vane and the (new

invention) swiveling vane or "flaps" "air engines" in the video

(TE News #201 or #200), I suspect it isn't even 50%, reducing it

to maybe COP=7. Even this doesn't seem to explain the seemingly

poor performance of the unit.

Then, the air going into the radiator was only around 28°. This is

just three feet farther down the same copper pipe from the air

compressor that was 34°, a perplexing loss of 6°. How is all that

heat being radiated off such a short copper pipe with no fins? Now

that I think about it, this is probably the most puzzling question

of all. There is air blowing out the hole in the box around the

pipe and cooling the first few inches, and the air probably isn't

traveling down the pipe very fast... but still! Is there a leak in

the pipe somewhere? (Hmm... a leak doesn't seem likely because the

pressure can build up if the output is closed off. And I'd hear it

hissing.)

The (28° going in) compressed air coming out the other side of the

room heat radiator was down to 24°, just a little above room

temperature (23°). The air blowing from the radiator into the room

was also measured as about 24°. This is how it's supposed to be,

except why isn't the air going in warmer to start with - closer to

the 34° coming from the compressor?

When I turned the radiator fan off for a while, the

compressed air out measured over 25° instead of 24°, so the heat

was still radiating off the fins to the room by convection, not

quite as effectively as with the fan on.

Finally, the compressed air (from the room radiator, 24°) going

into indoor-outdoor air heat exchanger (how about "IOHX" herein)

was coming out the other end at about 20 to 21°, having passively

warmed the outdoor air coming into the house. That air presumably

started at the outdoor temperature (~10-11°) and was coming into

the room at around 20.5°. The air was only wafting in from

outdoors, as mentioned this slight breeze could be felt at the

duct from the IOHX into the room.

On the one hand, one might think the IOHX performance

was very good because the air was so warm coming in, passively

heated by 10° out of a potential 12 or 13°. On the other, why was

the compressed air not cooled more if it was heating 10° air at

the bottom of the unit? There seems to be much wasted heating

capacity there. (Too bad it seems I didn't measure the compressed

air out in the earlier tests with 0° outdoor temperature.)

Yet More Further Tests

[27th] I ran a few more tests. It was 10° out again, but with

heavy overcast, so the sun wasn't coming in the windows to make

extra heat and mess up readings even more than usual. All other

heat in the house was turned off. There was a fair breeze that

probably caused a bit of extra air to come through the IOHX from

outside. I closed a sliding door that somewhat reduced the space

being heated. If it wasn't COP of 7, it was at least more

encouraging because at one point the room temperature was going up

instead of down.

The first test was just to run the compressor with no

fans blowing. The compressed air pipe coming out from it hit

60.2°, a foot or so out from there at the PSI meter it was 42.4°

and farther along at the input to the radiator it was down to 31°.

No sign of an air leak. At the output of the radiator the

compressed air pipe felt cool. (didn't measure)

I suspect the air flow must be fairly slow for such a

temperature drop in a few feet of pipe with no radiator fins. But

one takeaway was that I really should have some way to measure the

air flow. After all, power is proportional to volts times amps or

mass times speed or torque times RPM... or pressure times flow.

Not knowing the flow rate is a serious handicap.

With the room being 20.0°, turning the fans on got

some very warm air blowing out of the box and reduced the

compressor out pipe to 35.8°, down to 30.0° at the PSI meter and

27.0 at the rad input. After the rad it was 22.9°. The air wafting

into the room from outside through the IOHX was 18.7° - a pretty

good rise from 10° towards 20. The compressed air coming out,

having warmed that outdoor air, was down to 16.9°. From there it

is allowed to decompress and hisses out outside through a tube. If

room air is entering the compressor at 20° and leaving the house

at 16.9° (before decompression), that indicates that at least some

heat is being extracted from the outdoors into the house.

That was when I noticed the kitchen window was open

about 1-1/2 inches. Rats! Air would be drawn through that more

easily than through the IOHX. Half an hour after closing it the

room was up from 19.9° to 20.7, which said the unit was at least

putting out a little heat, but it didn't rise any further - in

fact the reading dropped by .1°.

After an hour I turned off the heat pump and plugged

in a 400 watt radiant heater. The room warmed further over the

next hour, to 21.3°.

So the heat pump brought the temperature up by .8° in

1/2 an hour but no further in the next 1/2 hour, and and the 400W

heater raised it by a further .6° in an hour. So perhaps they were

about equally effective? That would give the heat pump with the

100W fridge compressor a COP of around 4. That would seem

reasonably consistent with my 2020 results where COP with a small

fridge compressor was around 3 in zero degree weather.

I turned all heat off and the temperature

dropped in over an hour to 20.1° - a 1.0° drop. Then I left the

heap pumping on for about 3 hours. The temperature dropped from

20.1° to 19.2°, but the outdoor temperature had dropped from 10 to

8°, so it might actually have been a bit of a gain, depending when

it got colder and on the thermal inertia of the room.

But there's still another wild card in getting exact

readings: the refrigerator. I couldn't turn it off safely. (I'd

forget!) It uses 120 watts and itself has a COP probably of around

3 or better, so whenever it comes on (frequently) it adds 360+

watts of heat to the room. That's almost as much as the heater and

seemingly similar to the heat pumping. The rest of the time, cold

is leaking out of the fridge. That's why I don't feel any of the

readings, however accurate the temperature sensor, are totally

definitive. Of course it should average out, but not always in a

one hour test.

[30th] On line I found something like a short piece of pipe with

inside threaded ends and an LED display for 45$. It said it was

for measuring liquid flow, but one reviewer said he found them

great for 'various liquids and gasses'. So I'll hope it works for

air.

A "dump load" is

something for an off grid solar or wind power system to power when

there is an excess of energy. In the case of wind power, it is

necessary to use excess power to prevent the propeller from

over-revving in high winds. For solar it's just a way to use

available excess energy rather than letting it go to waste. One

could for example heat a "sand battery" or hot water for later, or

just run an electric heater for free.

[14th] Before designing a circuit to control dump loads, I checked

on line. Some people suggested using a microcontroller. I found an

opamp circuit and it worked as I had envisioned, by measuring the

voltage on the solar panels to see if it was above MPP, which

would mean the charge controller wasn't drawing all the available

power because the battery didn't need it. But it seemed needlessly

complex, so I designed my own anyway using an LM339 quad voltage

comparitor. It could run up two "dump loads" independently so one

could have one load for a little excess power and another, perhaps

larger, if the voltage still got higher indicating the solar

panels had still more power available.

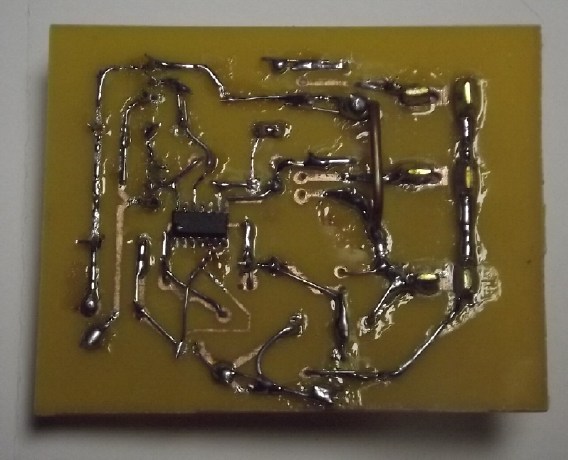

[18th] In the evening I started laying out a circuit board. [19th]

I spent most of the day on it. I ended by printing out the board,

finally trying out the fingernail polish remover method I had seen

on Youtube of transfering the the print from glossy magazine paper

to the copper board. It sort of worked but it looked too faint,

and there was still toner on the paper. I didn't give it much hope

for good etching. Either my technique wasn't good or the remover I

had was a different formula.

It's been a long time since I made a board. Even a

"simple" single sided PCB seems to take just as long as ever and I

wondered at the wisdom of the undertaking, "wasting away" the day

sitting at a computer and then still having to make the board and

install it. But, "in for a penny, in for a pound", I might as well

complete it and have it working.

[22nd] So after searching three times through my

stationary supplies and even throwing a bunch out, I finally found

my "fab in a box" heat ransfer paper and did it that way. Even

there, it wasn't much of a board.

[22nd] So after searching three times through my

stationary supplies and even throwing a bunch out, I finally found

my "fab in a box" heat ransfer paper and did it that way. Even

there, it wasn't much of a board.

I'm sure my laser printer, in spite of being set

to "darkest, maximum contrast and high quality", just doesn't put

down half enough toner on the paper. And it's obviously getting

worse. The traces, and then the copper on the etched board, looked

fairly solid but there were minute gaps with disconnects here,

there and everywhere. When putting the components on, I didn't

clip off the leeds. Instead I bent them over to reinforce the

copper run on the board and soldered them to the trace.

I'm sure my laser printer, in spite of being set

to "darkest, maximum contrast and high quality", just doesn't put

down half enough toner on the paper. And it's obviously getting

worse. The traces, and then the copper on the etched board, looked

fairly solid but there were minute gaps with disconnects here,

there and everywhere. When putting the components on, I didn't

clip off the leeds. Instead I bent them over to reinforce the

copper run on the board and soldered them to the trace.

[23rd]

I drilled the holes in the board with a "dremmel". [24th] I put

the components on the board. As I was finishing this up and

thinking about using it, a couple of things occurred to me. If I

was to connect the same heater(s) that I usually used for heat at

night to turn on as "dump loads" in the sunshine, then each load

should have an "ON-DumpLoad-OFF" switch. Otherwise they would have

to be unplugged from the controller and into an "always on"

receptacle at night. (Or whenever they were to be used.)

[23rd]

I drilled the holes in the board with a "dremmel". [24th] I put

the components on the board. As I was finishing this up and

thinking about using it, a couple of things occurred to me. If I

was to connect the same heater(s) that I usually used for heat at

night to turn on as "dump loads" in the sunshine, then each load

should have an "ON-DumpLoad-OFF" switch. Otherwise they would have

to be unplugged from the controller and into an "always on"

receptacle at night. (Or whenever they were to be used.)

The other thing was that since it was an automatic

control with mosfet switching anyway, it should shut the loads off

if the battery was low. There are two spare voltage comparitors on

the LM339 anyway. The first feature would be simple. The second

might require a logic AND gate. OTOH one might get away with using

the fourth comparitor and a couple more resistors?)

[30th] While it was light out

I also added the solar PV voltage sensor for the dump load

controller, and plugged in the controller. I found a couple of

things not right and changed them. But then a mystery... The lamp

("dump load") I plugged in was On, but the voltages to the LM339

gate indicated it should be Off, the "-" input being higher

voltage than the "+" input. The gate's output was High (turning On

the mosfet and the lamp) instead of Low. It turned out there were

multiple problems. I printed out the schematic and the board for

troubleshooting. By then I had other things to do.

[31st] I worked troubleshooting the dump load controller most of

the day. I would have just thrown in the towel, except each

problem looked like it would be the last one, so best not to quit

just short of success. The majority were owed directly or

indirectly to bad connections, which were from the printer not

printing dark enough and making a PCB with dotty traces.

Once I had solved a bunch of them I thought I'd be

there, but then I just sat there looking at it. The lamp test load

would flicker instead of just suddenly coming on, and then it

wouldn't quite go out. I tried a 200 watt heater, and the mosfet

started smoking. I managed to unplug the heater before something

blew. I'm sure it got so hot because of being not quite off, same

as the lamp. Then the 400W heater upstairs came on (I could hear

its fan) and the solar voltage reading went UP in instead of DOWN,

from about 70V to 74V, and the test lamp came ON with the heater

instead of OFF! That seemed bizarre, and I had the thought that

the charge controller was drawing current with some sort of PWM

and while its meter showed stable, so it was probably putting

spikes into the solar voltage. This is the voltage I'm sensing to

decide when optional loads turn on and off? I put a 220uF

capacitor on the solar sense input at the PCB. That fixed the

flickering as the lamp came on, but it still wasn't turning right

off. Instead, the LM339 output read about 3VDC instead of 0V or

12V (Vcc). Also only one of the two seemingly identical dump

controllers worked. The other wouldn't turn the lamp off. What was

with that one when the voltages all seemed good, same as the other

one? I guess I need to drag out the oscilloscope to better see

what more bizarness is actually going on.

I hadn't expected this to be any sort of significant

project. A "couple of days" stretches out and I'm not getting my

spring seedlings potted. or anything else - and in nice weather

before the biting bugs start coming out, too.

[April 1st] The thought "ground loop" had occurred to me, but it

seemed insufficient as a possible explanation. After working on

the cabin and other things, I sat in the cabin with a glass of

wine across from the electrical board. Then it occurred to me that

the sense lines had the solar panel ground, solar "+" and "-".

(This is actual ground via a ground rod.) The board plugged into

power, "B+" and load ground, which was two current sensing

shunts away from solar ground. There could easily be 30 or 50 mV

difference, but they were shorted together in and by the circuit

board. This probably explains some of the craziness. The sense "-"

needs to go to the same "-" that's powering the board.

Resistance Wire Radiant Heater

[9th?] I thought it should be simple enough. Use

a 2 foot long piece of plywood and put lots of screws at each

end, then zig-zag it all with resistance wire. But I wanted to

use lots of length so the wire didn't glow red and sag and the

screws didn't get too hot. The wires sagged enough anyway when

heated that I moved the screws farther apart, from 1-1/4 inches

to 1-2/3 so they wouldn't touch adjacent wires. (I also wrapped

the wires 1-1/2 turns at each screw instead of 1/2 a turn to

give them more resilience.) I ended up doubling up the wire and

still it was lower power than I had planned - 68 watts across

the length. I could however attach the power to any of the

screws, and the shorter the wires, the higher the power. If I

put one power connection to the middle screw, putting the other

on one end made 100 watts and the other end made 120. So with an

alligator clip between the two end screws it was 220 watts. Then

with the middle power connection moved to the other end... ouch,

a big spark! Oh ya, the cross connection between ends. I burned

out a couple of the heater wires. Rats! I got them together

again and continued. I could connect across less than half the

length and get 220 watts, or 440 by doubling - and quite hot

wires.

[9th?] I thought it should be simple enough. Use

a 2 foot long piece of plywood and put lots of screws at each

end, then zig-zag it all with resistance wire. But I wanted to

use lots of length so the wire didn't glow red and sag and the

screws didn't get too hot. The wires sagged enough anyway when

heated that I moved the screws farther apart, from 1-1/4 inches

to 1-2/3 so they wouldn't touch adjacent wires. (I also wrapped

the wires 1-1/2 turns at each screw instead of 1/2 a turn to

give them more resilience.) I ended up doubling up the wire and

still it was lower power than I had planned - 68 watts across

the length. I could however attach the power to any of the

screws, and the shorter the wires, the higher the power. If I

put one power connection to the middle screw, putting the other

on one end made 100 watts and the other end made 120. So with an

alligator clip between the two end screws it was 220 watts. Then

with the middle power connection moved to the other end... ouch,

a big spark! Oh ya, the cross connection between ends. I burned

out a couple of the heater wires. Rats! I got them together

again and continued. I could connect across less than half the

length and get 220 watts, or 440 by doubling - and quite hot

wires.

I should probably try tripling the wires. The

plastic foam "hot knife" saws hadn't used much of the resistance

wire. The doubled heater wire had used up a whole spool, so

tripling it would be another half spool.

Bedroom Heat

With the workings of a 100/120/220 watt DC heater.

(hardly a finished product!), on the 10th I set it in my bedroom

on top of the "sand battery" box near the 36V triple outlet.

With the days now recharging the battery even when partly cloudy

I continued to run the 200 watt heaters from the 36V DC

(150+50+50 as ~1/10th their 120V AC rating). I had been using

them to supplement the baseboard heat. Now and on subsequent

nights I also plugged in the new heater. With 350 or 470 watts

of heat from the batteries the bedroom stayed up at 18 to 20C

without using the baseboard heater at all. I was a bit surprised

it kept up that well as the nights were still cold - around

freezing with frost in the mornings. They were using about 3.5

to 4.5 KWH per night, with the solar recharging the battery the

next day. 470W is pressing the 15 amp breaker on that outlet.

Redoing it I would put in a 20 amp breaker, preferably in a DIN

Rail breaker system.

Assuming the battery lasts many years and that it's

sufficient heat, this is actually better than a typical

grid-tied solar system as there is no solar power during the

night so bedroom/nighttime heat would always come from the power

grid. But I should add a thermostat and either auxiliary power

to the DC or a low voltage cutout in case the battery gets low

unnoticed. At the last gasp the balance charger should

disconnect the battery if any cell falls below 2.5 volts, but

that's awfully low. I'd rather have it cut out around 3 volts on

any cell.

Of course if one incorporates a battery one can

have a more sophisticated grid tied system with an

inverter/charge-controller where power comes from a hierarchy.

In its simplest form:

1) Solar if available

2) Battery if charged & there's no/insufficient solar

3) Power grid if there's nothing else

and available solar power goes to:

1) Charging the battery if it isn't charged

2) The power grid if the battery is charged

This assumes the battery is only or mainly charged from solar

rather than from the grid. Other arrangements are possible, such

as using batteries at times of day when grid power costs more

and charging them from the grid when it's cheaper regardless of

solar, in jurisdictions where such variable rates are used.

[14th] I had to get used to the voltage levels. Before, under 38

volts meant the battery was quite low. But the voltage drops

more under higher load. When I turned on the 250W of heaters,

the voltage would drop from (eg) 39.6 to 39.0V or under 39. By

morning it might be around 38.5. When I also connected the new

heater with a further 100 or 220 watts, the meter in line with

that heater would drop to 37.X, and I had to 'reorient' my

thinking, that it wasn't suddenly at a low charge, just under a

heavier load than "usual". (And a somewhat skinny wire to the

heater.) Unless the battery started out low, it would stay above

37V all night, and jump back to over 39V when the heater was

turned off.

But after 3 nights I decided that 470W for the

night was a bit much, draining the battery as much as half way.

So I stuck to 350 watts, which made for about 3-1/2 KWH used per

night and didn't drop it below 38. The bedroom seemed to stay

around 18.5°.

There was solar power to burn most days for a

couple of weeks. Now I thought to plug in the sand "battery". It

stores the better part of 1 KWH, which could be added at night

to the 3.5 KWH from the battery battery to make it a bit warmer.

A bigger pail holding more sand would of course be more useful.

Sand is cheap. Or a bigger actual battery - really 10 KWH

doesn't go very far. I could see them being cheap enough to want

double or triple that or more if battery prices keep dropping

while the price of grid power rises.

And of course, this is another plug for really

cheap copper-zinc or nickel-zinc moderately alkaline cells if a

manufacturer will adopt my chemistry(s). Then one might

economicly want 50 or 100 KWH of storage. After all this time I

don't see how to manufacture them myself - I'm having trouble

even getting the forces and forms needed to compact nickel

electrodes sufficiently to make them work properly. But surely

the time will come.

Electricity Storage

Copper Oxyhydroxide

or Nickel Oxyhydroxide

or Nickel-Manganese Oxides

& Zincate Cells

Low Cost Electricicty Storage

With the advent of low cost solar panels, it is now

possible to capture plenty of energy from the sun in lower

latitudes, and for much of the year in higher latitudes too. It is

well known that storage of electricity is now the biggest handicap

to "going off grid".

I've purchased two sets of 10 KWH batteries for under

about 2000 $C each. (12 * 286 AH * 3.2V = 9627.2 KWH). This is

sufficient for lighting and limited power applications. Except in

winter I can run 3 or 4 KWH of bedroom heat at night, and more

during the day when the sun is shining. It would be somewhat

better at a lower latitude. But even for that bit, two cloudy

winter days with little recharge would tax the battery and three

would kill it. and there's lots of things I wouldn't even try.

For example, my Nissan Leaf electric car has a 24 KWH

battery pack, and that's not half of what any new EV has. I

wouldn't normally try and recharge it from my solar/battery

systems because unless watched "like a hawk" it might drain the 10

KWH battery entirely and cause problems as well as turn off the

electricity. I might say I would charge the car if I had a well

charged 30 KWH storage battery, considering the car isn't likely

to need more than 20 KWH on any particular occasion. For a new car

the figure well might be 70 to 100 KWH. Likewise, I might run

sufficient electric heat for a house for the whole day instead of

just a bit in one room. And heat hot water and use a clothes dryer

- power intensive functions. Heating hot water is a wild card

because it can come on any time day or night, whether the battery

is well charged or not. The more storage there is, the easier

things get. With just 10 KWH one must be very careful not to drain

the system overnight. With 100 KWH one would have a margin of days

instead of hours and could say (eg) "I shouldn't do laundry today"

or "We should light the woodstove today instead of using electric

heat." if capacity is down, without worrying that the refrigerator

or the hot water tank will drain the system in regular operation.

But if 10 KWH of lithium-iron phosphate cells is 2000

$, 100 KWH is pretty unaffordable. This is why we need low coast

batteries like copper-zinc. A safe 2000 $ battery needs to be 100

KWH instead of 10. Like everlasting copper-zinc (or

nickel-manganese oxide-zinc or even nickel-zinc). Then we will

start seeing lots of people going off grid, and we will see the

grid itself storing huge amounts of energy to have many hours or

even days of storage for whole communities. I've made the

zinc/supersaturated zincate "forever" cycling chemistry, but I

don't see how to manufacture actual practical cells. That needs a

big investment in a real factory.

(Think of hundreds and thousands of kilowatt-hours of cheap, safe,

"forever" energy storage instead of tens and hundreds of costly,

unsafe cells with a few years of service life. I've proven the

everlasting zinc-zincate chemistry, with a choice of at least

three positive electrodes. Really the project needs to go to some

sort of production processes. I can't take it there myself.)

My Solar Power System(s)

(My solar panels images - TE News #200)

A little note on the safety & efficacy of 36 volt house

wiring

May I once again suggest "36" volts is the optimum

wiring voltage for living spaces? For all my sloppy carelessness,

especially plugging in soldered plugs with no shells and with my

fingers directly touching both terminals, I've had sparks but I've

never had the slightest shock from the 36-41 volts of DC power.

The one caveat is that this has generally been indoors in a dry

environment.

A 48 volt system, which might actually measure up to

57 volts or so fully charged, is said to be somewhat hazardous.

Various national standards put "hazardous" voltage as starting at

42 or 50 volts. "36" volts with a well charged battery comes just

about up to the start of the lower figure. At 36 volts, running 20

amp circuit breakers and common #12 AWG wire with typical small

electrical boxes to T-plug wall sockets allows running plug-in

appliances up to almost 700 watts, nearly one horsepower.

So on the one hand, why have hazardous voltage

running all over the house and in every cord and every appliance,

and on the other, why use a needlessly low voltage that requires

higher currents and very heavy wiring for power loads? 36 volts is

the upper limit of non-hazardous, but it Is non-hazardous in any

normal conditions. (Gripping a part being welded with 36 volts

while standing in salty water in a cramped boat hold doesn't count

as "normal"! Even then the guy lived to tell me the story.) And

why use AC when the 60 Hz oscillating electric fields somehow

trigger continuous tinnitus in so many people, and other health

concerns whose cause is (usually?) not understood according to

GreenHomeInstitute.org ?

Today there are reliable devices and circuits for

converting between voltages and between AC and DC, so why should

we accept anything that is hazardous or deleterious for our health

in and around our living spaces?

Solar Power System Additions

[14th] I had got two new power monitors, and I

went to put the second one in the cabin, where the present one was

monitoring the load rather than the charging. Functioning on some

sort of autopilot, I simply replaced that one with the new

external shunt one that could measure higher currents. Wait... I

thought this one was to measure the charging!?!

[14th] I had got two new power monitors, and I

went to put the second one in the cabin, where the present one was

monitoring the load rather than the charging. Functioning on some

sort of autopilot, I simply replaced that one with the new

external shunt one that could measure higher currents. Wait... I

thought this one was to measure the charging!?!

Oh well, the currents were exceeding the 20 amp limit

of the first monitor and I'll probably add more loads, so it did

need replacing. So I left it like that. I went into the house and

ordered a third monitor and shunt, and a couple more things from

the same store while I was at it. When the new one comes, it can

measure the charging.

[30th] The new power monitor and two 100 amp shunts having

arrived in my post box, I put one shunt onto the cabin power

monitor where I had been using a 50 amp shunt and dividing the

readings by two.

I mounted the other one

by the 3D printed case already mounted for the power monitor for

the solar charging circuit. I thought this time I would directly

monitor the solar panels where they fed into the charge

controller. I wired up as much as I could without cutting into the

75 volts from the solar panels for the shunt. That I did after

dark when there was 0 volts from the panels.

I mounted the other one

by the 3D printed case already mounted for the power monitor for

the solar charging circuit. I thought this time I would directly

monitor the solar panels where they fed into the charge

controller. I wired up as much as I could without cutting into the

75 volts from the solar panels for the shunt. That I did after

dark when there was 0 volts from the panels.

Only when I turned the breaker back on and the

monitor remained blank did I realize there was a fly in the

ointment: the voltage sense wire was also the power for the

monitor. In the evening when I came to read the day's accumulated

solar intake, the display would be off! Oops; duh! And if I

powered it from the battery, the voltage wouldn't match the

current and the watt-hours would be wrong. I would have to redo it

- cut the ground wire from the charge controller to the battery

and put the shunt there, with meter power coming from the battery.

And splice the ground wire from the solar panels back together

where I removed the shunt. Ug! Clearly I'm not giving enough

thought to what I think of as "trivial" projects. My mind glosses

over the details (where the devil is said to lie) and I keep

making mistakes.

[April 1st] I moved the current shunt from solar panel ground to

"B-" battery ground and rewired the power monitor.

The 36V DC electrical board as finally

wired.

The 36V DC electrical board as finally

wired.

Note the new DIN rail breakers replacing the previous surface

mounted branch circuit breakers.