Turquoise Energy News #206

Covering

Research & Development Activities of July 2025

(Posted August 8th 2025)

Lawnhill BC Canada - by Craig Carmichael

[Subscribe: email to

CraigXC

at Post dot com ; request subscription]

Main URL TurquoiseEnergy.com Also at craigcarmichael.substack.com

Month

In

"Brief" (Project Summaries etc.)

* Another 50 Amp T-Socket (+ extra info about the design) - Supercorder

Straight

Flute Making Instructions - Puzzling Power Monitor

Readings - Thinking toward new chemie battery Production - New

Electric

Hubcap type Motor (breaking huge project into three; making coils)

-

Plastic Recycling 2.0

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* Electrosmog - Electrosmog in the Faraday Cabin - Ultrasonic

Audio

"Smog"

* ESD

- Detailed

Project Reports -

Electric Transport - Electric Hubcap Motor

Systems

* Making the Mythical New Electric Hubcap Motor: -

separating

the unmanageable project into three - Coil Winding with ilmenited

epoxy

- motor controllers

Other "Green" &

Electric

Equipment Projects

* Solar Deep Well Pump

* Haida Gwaii Gardening - Fruit & Nut Trees - Corn -

Greenhouse

* The Claw-Hoe: a Better Hoe

for

Weeding - ?

* Plastic Recycling 2.0 (...for Motor Housing parts - see under

Electric Transport)

Electricity

Generation

* The usual Latest Daily/Monthly Solar Production log et

cetera -

Monthly/Annual Summaries, Estimates, Notes

July

in

Brief

Apricots in the greenhouse!

Apricots in the greenhouse!

3 dozen ripe fruits from a spindly little Moorpark Apricot tree

I

bought just last year, bending the whole tree way over.

I had to break off about 70 when they were small so the branches

wouldn't break.

Still it all bent over. A branch touched the ground.

Straightening now

that they're picked.

The gardening report is

in

the "Other

Projects" section.

I went to put up the 36 volt T-Plug house wiring

infrastructure components on line at Thingiverse.com . I had

some

trouble logging into my account after all these years and with a

new

e-mail address, but somehow managed to do it and change my address

without requiring human intervention. By that point I only

uploaded one

design: the three receptacle wall plate. There it sits waiting for

more!

After putting up

scaffolding at the end of June, and having to turn sideways and

sidle

past it going up and down the stairs all this time, I didn't

manage to

do any work on the inside of the cabin. I did however get a helper

for

one sunny day and we took all the metal siding off the East wall,

cut

it all 1/2 inch shorter, put some flashing under it to direct rain

away, and put it all back up. Water had been running down the

siding

and wicking in underneath - even being directed in by sheet

plastic and

tarpaper under the sill plate, rotting the plywood sheathing, and

eventually the wall frame itself. Luckily I hadn't yet drywalled

some

of it. I finally noticed from inside and figured out what was

happening.

The new solar power system also sat idle, waiting for

the

electrician. He's been busy but has been moving it ahead, ordering

lamacoid labels and parts and getting info ready for an electrical

inspector. (On August 5th I got quite the shock: an 811 $ bill

just for

a PERMIT to do the

wiring! (presumably from the BC government since I'm not even in a

municipality.) All to do one connection, from the solar panels

through

an outdoor switch box to the breaker panel.

At the energy symposium in September a BC Hydro rep

told

me there was a 75% rebate for an individual home solar

installation if

it's on a diesel powered utility grid. This seemed really good -

only

believable because BC Hydro spends around 70 cent/KWH for diesel

and

sells us electricity at the BC price of 12-14 cents. I asked him

to

confirm what he had said applied to an individual home. He said it

did

in the presence of a second rep who didn't contradict him (but who

may

perhaps not have been listening). It would be worth it for them,

so it

made sense.

From "a few thousand" then for this solar power

system I'm

up to at least 14000 $ out of pocket when the real terms turned

out to

be "50% rebate, maximum 5000 $" -- a splash in the pan (~25% of

the

cost) to save BC Hydro a lot of pricey diesel oil and me a few

hundred

$ a year! For me it's now something like a 15 year payback. I feel

scammed. If it wasn't for the winter months when the need for

power is

greatest and there's almost no solar to be had, one might consider

just

getting big batteries and going off grid. The equipmentis cheaper

if it

doesn't have to be approved... and the work inspected. In some

climates

it could be worth it.

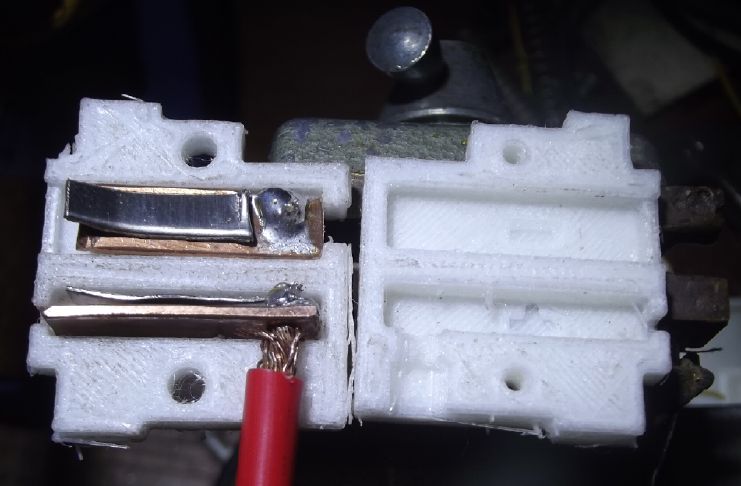

Another 50 Amp T-Socket (+ extra info/thoughts about the

design)

Continuing from June,

near the start

of the month I made another 50 amp T-socket, for a plug-in in the

cabin. I think this is the first illustration where I've shown it

with

the wires. "+" comes out one edge, while "-" comes out one face.

(Here

the "-" wire is being held in a vise helping to keep the pose for

the

picture.)

Continuing from June,

near the start

of the month I made another 50 amp T-socket, for a plug-in in the

cabin. I think this is the first illustration where I've shown it

with

the wires. "+" comes out one edge, while "-" comes out one face.

(Here

the "-" wire is being held in a vise helping to keep the pose for

the

picture.)

With the heavy wire pigtails (AWG #8) the largest,

deepest

"regular face" electrical box is desirable if not vital.

especially when I've added two 20 amp sockets to the same wall

plate

for convenience. (Maybe I should extend the borders of the wall

plate

to make one that can be used with a wholly larger size electrical

box?)

Again, the blades of the socket and the inserted plug

are

pressed together by the spring, to "theoreticly" make

contact all

along one face of each blade. With my design, the spring is a

loose

piece with no electrical connection, held in position by the

assembled

shell. The inspiration for this came from the original T-Plugs,

but

there the springs are external, attached to the plug blades. This

is

easier to make. If I was able to change the original T-Plugs (used

for

20 amp outlets & plugs) to make them more ideal for house

wiring, I

would do them like this and make the blades 10 mm long instead of

8.

Like the "HAT" plugs/sockets I created before I found T-Plugs, and

which are so similar the plugs actually fit into T-sockets. But

without

a manufacturing facility, this is impractical. I did the 50 amp

set

myself because I couldn't find anything suitable available, and

because

it fit with the "T-Plug" philosophy.

Gosh, I ought to 3D print another socket for the

kitchen,

where I put in an inferior draft version where the nylon filament

wasn't extruded hot enough to make the socket solid.

Supercorder Straight Flute Making Instructions

at TurquoiseEnergy.com - URL in image

is gone

From September 2003 and on through 2006, quickly

tapering

off in 2007, I created the Supercorder, a marvelous "21st

century" alto blockflute. Other wind instruments (transverse

flutes,

clarinets, oboes...) had undergone various improvements in the

19th

century and were made louder, but "recorders" were still stuck on

simplistic designs from the 1600-1700's with relatively weak and

uneven

sound, and no way to fine tune while playing. The sound is

beautiful,

but they were inadequate for playing in a modern orchestra,

concert

band or other ensemble.

I modernized the alto recorder, over a century after

most

other woodwinds. I made about 20, of improving characteristics, as

I

went on. I could and did play the new instrument in amateur

orchestras

and concert bands (usually oboe parts, sometimes flute) as well as

in

music jam sessions. The unique sound was often much appreciated.

But of

course I branched off into other endeavors and soon made them no

more.

I still play the one I kept for myself but here on Haida Gwaii

there

are no appropriate ensembles to play it in.

I didn't create it just to let it die there and be

forgotten, but other exciting new things keep taking my attention

away... and now it's been 20 years! I've long meant to "write up

some

instructions" so others could recreate this wonderful instrument

without having to reinvent it. I got earnest about it this month.

I measured up the bore reamers and wrote the exact

dimensions (critical!) for every point along their length, and the

tone

and bolt hole positions from the drilling jig - details vital and

specific to this instrument. Of course, as I worked I started

thinking

of more and more details. Making metal keys and all that

entails...

Jigs, tools and my unique techniques for various things... The

keyhole

surrounds in the wood... How to set key pads on keys... Porcelain

beaks

(with the special shape for the fine tuning hole)... Windway

dimensions

and how-to... How to tune the instrument...

Was I writing something for experienced woodwind

makers,

or did I have to go over a lot of basics - things it took me two

or

three years to learn, even including tutelage from a lady who

repaired

woodwinds? I decided that experienced makers were probably going

to

stick to making the instruments they already knew and were

marketing.

To get a new enthusiast(s) to venture into making "supercorder

straight

flutes", and perhaps make a business or career out of it, I would

have

to bring beginners up to speed on all the relevant topics. If I

can do

that, someday someone somewhere will get the ball rolling again.

One example of the many

bits of

info

and illustrations someone would need to make this flute:

my angle iron jig for drilling 15 inch long bore holes through

the

instrument body piece and still come out near the center of

the wood at

the far end

Finally I started to realize I wasn't writing a few

simple

pages or a "pamphlet" of instructions but a whole book - even a

considerable tome. There's solid weeks of writing to be done. This

is

inevitably going to take time away from other projects. (No wonder

I've

put it off for 20 years!)

Thinking of new chemie battery Production -- ?

Two chief problems in my experiments were

sufficiently

compacting positive electrode materials, and keeping them

compacted in

the cell. I could solve the first problem for nickel hydroxide

electrodes by using the "+" material from nickel-metal hydride dry

cells. Those cells worked well for a while until the second

problem

raised its head, causing deterioration. (That's why they cram them

into

metal cans!)

When I made cupro-nickel 70:30 sheet metal

electrodes,

they also worked well for a while - really well - but deteriorated

rapidly. But I've had the thought that monel ("nickel-cupro" eg

60:40)

powder might do better, even without compacting it much. All the

insoluble nickel hydroxide would hold the soluble higher-oxide

(valence

+3) copper hydroxides/ions in solid solution? And then there's the

SDBS* to stop dissolved cuprate ions from escaping the electrode,

just

like with the zincate ions. Only 1.2 or volts or so, but it should

make

an everlasting cell with Great energy density. Meanwhile large

lithium

batteries are doing a lot of damage worldwide, even burning

dwellings

and sinking ships. An alternative or replacement is surely needed.

This

is probably worth an experiment or two.

(In the news I saw an older Nissan Leaf like mine that caught fire

at a

fast charger. First time I've heard of a Leaf burning. I think I

won't

ever try fast charging mine!)

* SDBS: sodium dodecylbenzenesulfonate

Puzzling Power Monitor Readings

In the cabin power system two identical DC Power

monitors

read charge and discharge from the battery. The one on the load

side

says "0.0" if nothing is turned on. The one on the charge side

says

"11.2 W" (or so) at night when no solar energy is coming in. This

"zeroing error" adds up to around 8 fictitious "KWH generated"

over a

month.

I decided to swap them. But when I did, it was still

the

one in the charging that wasn't zero, this time the other monitor.

I

tried shorting both sense wires to the same side of the shunt but

it

didn't help - still 11.2 W. To be sure I had actually swapped

them, I

swapped them again. Still whichever one is on the "charge" side

doesn't

zero. even with the solar panels and charge controller breakers

Off.

I'm mystified.

(The monitor in the house system's charging circuit also

reads

not zero: "2.1 W" - not so bad, still a mystery.)

The Mythical New Electric Hubcap Motor

Having some years ago conceived of a better

"unipolar"

axial flux BLDC motor and motor controller plus a few improved

ideas in

the meantime, I finally decided to break the project into three

separate projects, each of which would be a valuable

accomplishment in

itself and not dependent on the next one. The first was to make

the

BLDC motor. I conceived it could be run as a regular BLDC motor

wired

as "delta" instead of "wye" and rewired for unipolar operation

later

with the same coils. Then I could buy and wire up a "regular",

"off the

shelf", BLDC motor controller.

The other two pieces of the "total" project, the

unipolar

motor controller and the "induction powered" brushless

electromagnet

rotor, can be put off until later or even indefinitely.

Then in thinking of the regular BLDC motor

controller, I

then got the idea that by tying one leed of each coil to B+ and

the

other ends to the the three motor controller drive outputs, one

could

get unipolar operation from the bipolar motor controller. Just one

phase of each three would be on at a time, and all would have the

same

polarity. (I thought for a bit one could wire 'north' coils to B+

and

'south' to B- and have a finer torque ripple curve, but then I

realized

that trying to do this with three outputs in place of six would

tie

coil ends together so they would be two in series from B+ to B-

when

the output was unpowered.)

It seemed that there was insufficient reason to make

my

long-planned six phase unipolar motor controller if the job could

be

done - at least adequately - with a commercially made three phase

one.

That eliminates project two entirely. Project three can stay on

the

"wish list" for a long time too if the car runs well with the

original

motor.

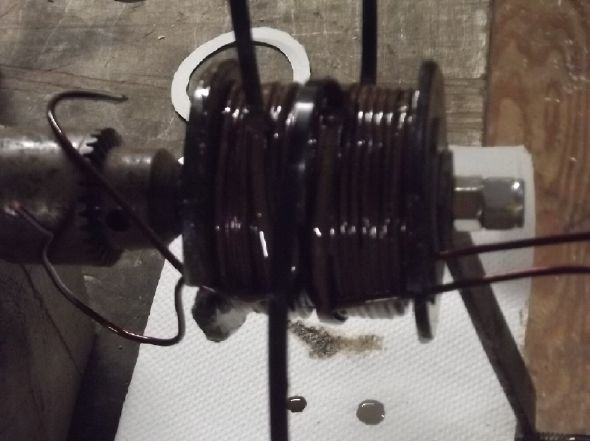

I (at last) continued

work on the motor by

winding the 12 coils, each 27 winds of #11 wire.

I (at last) continued

work on the motor by

winding the 12 coils, each 27 winds of #11 wire.

Each coil will take the full 36 volts rather than

being

effectively two in series (18 volts each) as in "Y" configuration.

I added the ilmenite [nano powder] to the epoxy. I

don't

know why I never thought of that before, when I was always having

so

much trouble with it flaking off the outside.

It seemed to me the next thing was the plastic plate "end bell" to

hold

the coils. And it seemed I would have to make the plate myself -

from

recycled plastic.

Plastic Recycling 2.0

So on the 23rd I finally finished the large oven for

melting plastic, begun so long ago and sitting outdoors under a

metal

roofing sheet. (2022; TE News #164-169,171) I thought I would have

to

remove the ex-freezer's inner 'tub' and replace the melting foam

insulation with something that would take the heat. Then I decided

to

put some mineral wool insulation right inside all around, so that

the

foam insulation wouldn't get too hot. That's what I had done on

the

lid. I bent up the oven element to make it narrower and put a

small

piece of metal roof under it so it wasn't right on the mineral

wool.

The lid fit really badly. The mineral wool

sticking up

helped. Then some boards stuck in around the edges.

The lid fit really badly. The mineral wool

sticking up

helped. Then some boards stuck in around the edges.

Then I took a metal

frame that I scrounged

for this very purpose in 2022, and cut it up to make supports

inside

the oven. With several tens of pounds of weights on the mold lid,

the

mold needs to be well supported!

Then I took a metal

frame that I scrounged

for this very purpose in 2022, and cut it up to make supports

inside

the oven. With several tens of pounds of weights on the mold lid,

the

mold needs to be well supported!

Plastic melting oven put off for 3

years,

operational in a day!

Plastic melting oven put off for 3

years,

operational in a day!

Oven with first mold inside, ready to

melt.

Oven with first mold inside, ready to

melt.

After that I went through a few iterations of trying

to

make a nice plate of polypropylene. I set the oven to 205°C

(400°F). It

seemed to be too hot! The plastic stuck really hard to the mold

plates.

The next one popped off nicely, but the third one stuck fast

again.

Both times it stuck I had to scrape and re-polish the mold plates.

Yuk!

Here is a whole "not very brief" gallery of plastic pictures for

anyone

interested to end "July in Brief".

Otherwise, here we run into August and the Tlell "Fall" Fair.

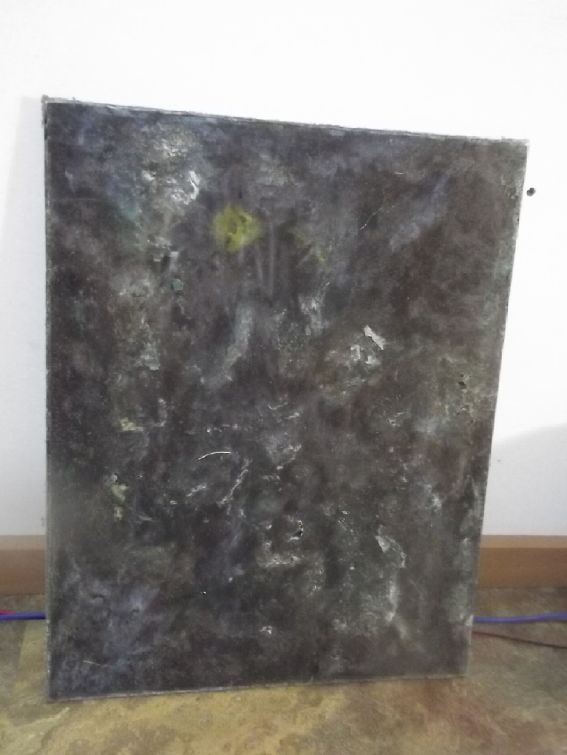

"Contour map" - insufficient

material to fill the

space

"Contour map" - insufficient

material to fill the

space

The back side was nicer

Really glued on! I had to

heat it

up to 75°C

again to get it starting

to come off at all - and even then I had to chisel some of it

off.

Still a mediocre result

Then I decided to try

180°, and oiling the mold plates with canola oil, and a different

plastic: polyethylene from a large fishing float. I cut it up

pretty

small as it was all curved and big pieces stuck up a lot. 3 Kg of

it

fit in the mold better than 1 Kg of ropes.

At 180°, plates buttered

with

canola oil, and

with 40 pounds of weight on top, the polyethylene didn't flow

very well.

At 180°, plates buttered

with

canola oil, and

with 40 pounds of weight on top, the polyethylene didn't flow

very well.

It did however pop right out of the mold.

This time, 80 pounds of

weights

This time, 80 pounds of

weights

It came out better, but still not a solid, square plate.

I think I can get it there. Solid, dense material for the motor

end

plate!

The second try with

more

weight was better but still didn't flow sufficiently. I'll have to

try

a higher temperature - maybe 186°. But I'm going up slowly. I

really

really don't want pieces stuck hard to the mold plates again!

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Electrosmog

in

the

Faraday

Cabin

[15th] I didn't seem to be

getting the sort of tinnitus relief in the cabin that I was

getting a

year ago when I started sleeping there in the summer. This was

especially puzzling when I thought that only the 60 Hz power lines

were

the cause. Now that I understand every frequency through to at

least

UHF (WiFi, cell phones, centimetric and perhaps even millimetric

waves)

contributes, and as I brought computer equipment into the cabin, I

started being affected by new and previously unsuspected sources.

Most especially, I have been feeling like my tinnitus

starts getting worse and worse in the morning while I'm still in

bed.

How could that be? Was I imagining it? After an hour nap in the

afternoon it seemed worse instead of better. I had turned the

laptop

OFF and unplugged the DC to DC power adapter. What on earth else

was

there?

Suddenly it dawned on me that the main solar charge

controller, notwithstanding that it's "MPPT" with a "steady" DC

voltage

output to the batteries, must nevertheless regulate the voltage by

some

form of PWM in the DC to DC conversion. The fluctuating readings

when I

tried to make a "dump load" device that measured the solar panels'

voltage demonstrated that. That would be On-Off voltage switching

at

probably 16 to 100 KHz - supersonic. (15 KHz, maybe even 10 KHz,

is now

supersonic to me.)

It starts charging when it gets light out. In the

summer

that's 5 AM or whatever. By the time I'm getting up it's switching

several hundred watts, charging to make up for the electric heat

I've

been running all night. Likely there's the aggravation. Whether

it's

supersonic audio (actual vibration, humming) or supersonic

electrical

field I don't know, but it explains the timing really well.

Last summer, 2024, the charge controller was

"temporarily"

mounted on the far wall. Then it had been moved to the center of

the

cabin, much closer to the bedroom.

But the charge controller is in a metal housing! I

checked

with a meter. The DC voltage on the housing was jumping all over

the

place. It wasn't grounded. The perfect electrical noise shield

already

surrounding the unit was left unconnected! I connected a ground

wire to

the distribution ground and to one of the controller's mounting

bracket

screws.

I decided I wasn't satisfied with that. I flipped off

the

solar panels' breaker and disconnected the charge controller. I

also

shut off the AC source power supply that I had set to 38 volts in

the

event the batteries became too discharged. (It has never been

needed

since the earliest times of setting up the 36V DC system.) Let's

see if

a couple of mornings without it at all are better, and then try it

with

the shield and see if whether it gets bad again or not. It's

finally

warm enough that no heat is needed at night. The batteries could

probably run lights and computers for weeks.

[Aug 3rd: It's better. I'll be moving it outside entirely, into an

equipment box high up on the far wall!]

[17th] It seems better with the charge controller off. If, as

seems

only too likely, the charge controller hums audibly at whatever

supersonic frequency it switches at, grounding the case won't

help. The

conclusion I reluctantly came to was that it will have to go on

the

outside of the wall in a box. ...the east wall at the north

corner,

where I had it "temporarily" just inside with the batteries, and

where

all the solar panel wiring comes to. ...up by the eaves.

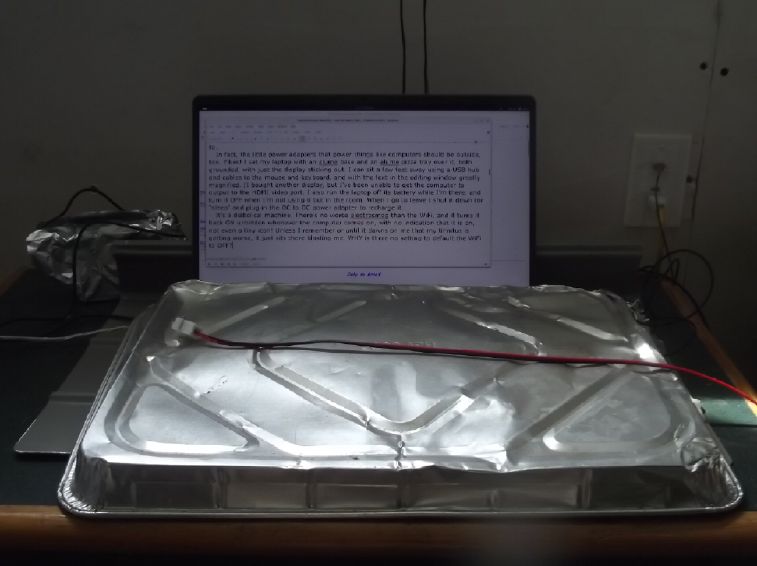

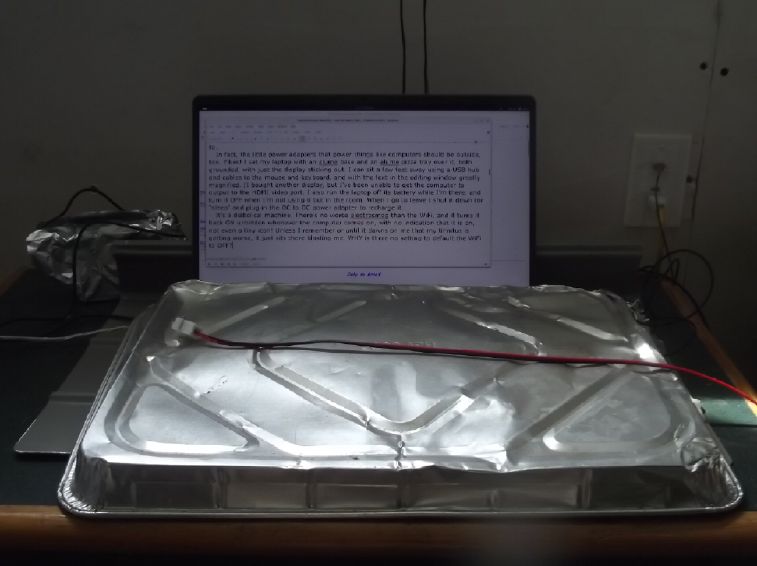

In fact, the little power adapters that power things

like

computers should be outside, too. Yikes! I set my laptop with an

alume

base and an alume pizza tray over it, both grounded, with just the

display sticking out. I can sit a few feet away using a USB hub

and

cables to the mouse and keyboard, and with the text in the editing

window greatly magnified. (I bought another display, but I've been

unable to get the computer to output to the HDMI video port. I

also run

the laptop off its battery while I'm there, and turn it OFF when

I'm

not using it but in the room. When I go to leave I shut it down

(or

"sleep" and plug in the DC to DC power adapter to recharge it.

Laptop sitting on metal

plate,

covered by

baking tin except display.

It's all grounded.

It's a diabolical machine. There's no worse

electrosmog

than the intentionally broadcast WiFi, and it turns it back ON

unbidden

whenever the computer powers on, with no indication that it is on,

not

even a tiny icon! Unless I remember to turn it off (after it has

finally booted up, told me to enter my password then showered me

with

distractions bringing up menu bar, icons and windows), or until it

dawns on me that my tinnitus is getting worse, it just sits there

blasting me. WHY is there no setting to default the WiFi to OFF?!?

I bought a VGA to HDMI adapter and got the new

display

working from the old laptop. The larger display makes it

good

enough for writing with.

Here's a taste of some of the "electrosmog" stuff at researcher

Magda

Havas' website (MagdaHavas.com) on electrosmog. If I'm noticing

tinnitus and it's only the least hidden of many effects from EMF

fields

and radiation, the whole area is potentially of more than academic

interest to a lot of people. Someone I talked to thinks a lot of

people

(in Victoria BC) are going around in a "brain fog" since they put

in

all the "5G" cellphone towers, and he says his car radio

completely

breaks up into static when he passes by places where they are

known to

be.

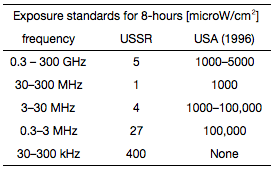

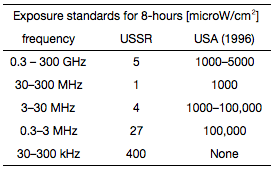

<<

This "allowable exposure standards"

table shows the

nonchalant treatment of the whole subject area by the West

compared to

what researchers who were probably more biased toward "playing it

safe"

came up with. Havas says the American standards were based only on

occasional exposure by telecomm workers, not for men, women and

children to be subjected to them "24-7" at home, work, school and

everywhere - even by multiple sources and frequencies at once.

This "allowable exposure standards"

table shows the

nonchalant treatment of the whole subject area by the West

compared to

what researchers who were probably more biased toward "playing it

safe"

came up with. Havas says the American standards were based only on

occasional exposure by telecomm workers, not for men, women and

children to be subjected to them "24-7" at home, work, school and

everywhere - even by multiple sources and frequencies at once.

The table is from: Influence of High-frequency Electromagnetic

Radiation at Non-thermal Intensities on the Human Body

(2001) - A

review of work by Russian and Ukrainian researchers)

No Place To Hide – Newsletter of the Cellular Phone Taskforce

Inc.,

Volume 3, Number 1 – Supplement, 33 pp.

1. Introduction

2. Natural Electromagnetic Background

3. History of Research in the USSR

4. Physical Approach to Resonant Absorption of Low intensity HF

EMR

5. Reception of EHF EMR at the Cellular Level

6. Experiments on Animals

7. HF EMR in Medicine

8. Mechanisms of Action of EHF EMR on Biological Objects

9. Standards and Normalization of HF EMR

10. Effects of High-frequency Communications Media on Human Health

11. Discussion

12. Conclusions

13. Appendix

14. References

>>

Ultrasonic Smog

[28th] A month or so ago I had discovered that DC to DC power

adapters

evidently 'humming' at maybe 50-100 KHz were a big tinnitus

problem,

and probably from actual ultrasonic sound waves rather than from

their

electric field. (AC power adapters are probably little better

except

for generally being lower power capacity and housed in a sealed

plastic

case blocking much of the sound.) I had moved it to the floor

downstairs and made a long cord to bring the power upstairs to my

old

19 volt laptop. [It's slower, quieter and WiFi & networking

can be

turned OFF until manually turned ON again.]

One morning I thought, after it being On a while,

that it

was still aggravating my ears even from 10(?) feet away through

the gap

under the door - and maybe through the floor and wall too!

I took one very long cord and made a second one, and

threw

the converter outside the far door of the cabin. Surely that will

afford relief! At least until it rains, the unit shorts out, and

my

laptop blows up. Hmm. I put a bucket over top of it. (As if on cue

-

drizzle!)

If I wasn't sitting in a "Faraday Cabin" with very

low

electrical noise, in the morning after my tinnitus having been

somewhat

quieted down from sleeping there overnight with everything

(especially

including the adapter) unplugged or off, I probably wouldn't have

noticed. It would have been just one more unsuspected ear/tinnitus

aggravation of many, an innocent looking little box.

The solar charge controller also seems to be a source

of

ultrasonic smog. I've found an large electrical box and plan to

move it

outside on an outside wall far from where I usually am - the side

where

the power lines are anyway. In fact, probably up by the eves well

above

where people are (outside or in). In the meantime, if I'm in the

cabin

it's turned off.

I tried online to find some meter to measure

ultrasonic

audio, or all audio up to (at least) 100 KHz, but I drew a blank.

Most

audio level meters it seems crap out somewhere below 10 KHz.

Scattered

Thots

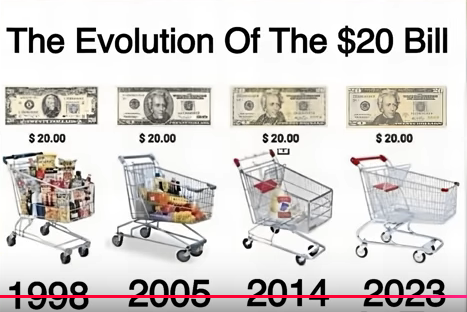

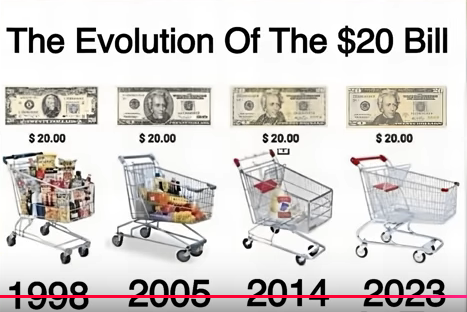

* This seems exaggerated. I once heard that sometime in the 1950's

10$

would buy a week's groceries -- probably that was for a family. I

remember bread at about 25 cents a loaf around 1967. In the early

to

mid 1970's 20$ might have got a full cart.

But if the time scale is off, it's still

illustrative! In

July 2025 I just paid 37.59 $ for one nice big carrot cake. (I was

in

shock when the price came up on the cash register. I almost put it

back.)

* The "private central banks" system makes currency into a pyramid

scheme. Money from thin air is "loaned" to the government. The

government

then "owes" the money back with interest. The money to pay

the

interest

can only, in the final analysis, come from borrowing more money.

Governments will spend what they will. Wherever the

money

comes from, it is incumbent on them to be prudent and spend wisely

on

the public's behalf. Wouldn't it be better to have the public

treasury

simply print the needed money itself? Then nations wouldn't be "in

debt". The money wouldn't be "owed back" to make bankers rich, men

who

have done little of productive value to create the wealth they

assume

possession of. The end of government interest payments alone would

cause a lowering of taxes. Of course, greedy bankers have always

found

some misinformed person with a grudge to murder national leaders

who

try to eliminate private central banks. Andrew Jackson was the

only one

on whom the guns misfired, and the US was rid of private central

banks

for 80 years until Christmas 1913.

Reckless, unproductive spending (by governments...

and

citizens themselves) and private banks able to conjure money into

existence (central and otherwise) have both contributed to

impoverishing the citizens of nations round the world.

* The Nazis conquered Germany by force before they went on to

attack

other nations. At the Nuremberg trials someone asked Hermann

Goering

something like "Weren't there people in Germany who objected to

this?"

Goering's chilling reply: "Not above ground."

I had an uncle (my mother's sister's husband) who was

in

the Canadian military. Shortly before he died, he confessed to his

family that in World War Two he had been an assassin for the

Canadian

government, killing people the government didn't want around.

It was wartime, but is the parallel not disturbing?

ESD

(Eccentric Silliness Department)

* The schizophrenic went on a relaxing vacation hoping to find

some

peaces of mind.

* Pi = 3.14159 ; 1/2 Pi = 6.495

"in depth

reports"

for each project are below. I hope they may be useful to anyone

who

wants to get into a similar project, to glean ideas for how

something

might be done, as well as things that might have been tried, or

just

thought of and not tried... and even of how not to do something -

why

it didn't work or proved impractical. Sometimes they set out

inventive

thoughts almost as they occur - and are the actual organization

and

elaboration in writing of those thoughts. They are thus partly a

diary

and are not extensively proof-read for literary perfection,

consistency, completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths

and

avoid potential pitfalls and dead ends.

Electric Transport

Making the Mythical New Electric Hubcap Motor

Breaking Daunting Project Into

Three

Smaller Ones

[18th] I couldn't seem to get on with this motor plan - for years

now.

Now I think to break it down into three separate projects, each of

which would be "complete" in itself without doing the next one(s):

1. A 12 coil, 8 permanent magnet poles "Electric Hubcap" type

motor

along the lines of my previous versions with improvements I've

thought

of over the years including for more robust construction and

mixing the

ilmenite into the epoxy for the coils.

I've recently realized that it can be the same

motor

for either bipolar or unipolar operation. I was already going to

make

it so the coil wire ends poke out and are connected externally, so

it

can be easily reconfigured. If I wire it up "Delta" instead of

"Wye",

then the coils will have the same voltage and so the same number

of

windings for either bipolar or unipolar operation. At 36 volts

that's

about 27 or 28 windings instead of the 20 or 21 of my previous "Y"

wired motors. 27 winds of #11 wire is exactly three full layers of

wire.

I will also just complete the Hallbach configured

permanent "supermagnet" rotor that I started making some months

back.

Forget the improved but more complex rotor with electromagnet

poles to

be powered via induction instead of troublesome brushes & slip

rings.

That means I can build Just the motor similar to the

way

I've built them before (with all the latest of course), and simply

buy

a BLDC motor controller instead of having to make the unipolar one

before I can make it run. Curtis, known for reliable motor

controllers,

seems to make several variants, a couple of which should work fine

and

hopefully still use the old Curtis handheld programmer that I

already

have.

[Aug. 3rd - Hmmpf: On line I've contacted 3 Canadian Curtis

distributors and none have bothered to reply.]

2. Once the car is on the road via "1.", and if I then decide I

have

time to spend on it, I can build the unipolar motor controller. I

suppose unipolar isn't a vast improvement in reliability given

that I

finally decided it would actually have to have both high and low

side

mosfets for best efficiency (the high sides being used only for

synchronous rectification). So "shoot through" currents are still

possible. (What are the chances of any controller I make even

being As

reliable as a commercially made motor controller of a quality

brand?)

Still I think it should have the efficiency "edge" by

not

reversing the magnetic polarity of the iron particles in the coils

and

so it avoids that bit of hysteresis inefficiency and heat.

[Unipolar

motor controller ideas are scattered in various issues of TE News

from

2016 on, where I made and used one on the "ARM", a feeble attempt

at an

"Axial flux Reluctance Motor". It got unexpectedly hot largely

owing to

use of simple diodes instead of synchronous rectification.]

3. Finally if I still want to I can delve into the further

intricacy of

making a new electromagnetic coils rotor, with the new "induction"

technique for powering the rotor coils (rather than slip rings).

[An

appropriate configuration with a "U" shaped inductor primary and

two

rings on the rotor to match was shown some TE News issues back.] I

could change the rotor without significantly changing the rest of

the

motor. This rotor would be able to turn down its magnetism as RPM

increases. This would give the motor more torque (and hence power)

when

running at higher RPM's, ie with the car at highway speeds. This

will

or would mean adding complexity and induction transfer components

as

well as the coils rotor itself.

Time moves on and I'll probably be happy just to

FINALLY

make the motor, put the Sprint car on the road to demo a great

"ultra

efficient" axial flux BLDC motor, and leave the (formerly

futuristic)

refinements to someone else.

I started getting out stuff to make coils. It took me

a

while to locate my ilmenite, which don't think I've used since I

moved

from Victoria. (It was near my other "pottery" chemicals, but in

another box hidden under some clutter.)

[19th] I set up the coil winder, having somehow managed to keep

all its

parts together, and got everything ready. Then I mixed 10 grams of

ilmenite, 10 grams of epoxy 'hardener' and 50 grams of epoxy resin

("West System" epoxy) to make just 70 grams of ilmenite infused

epoxy.

After mixing it I poured 1/3 of it into one little plastic cup and

kept

2/3 in the other. I put the 2/3 in a freezer so it wouldn't set

(for a

couple of days, anyway).

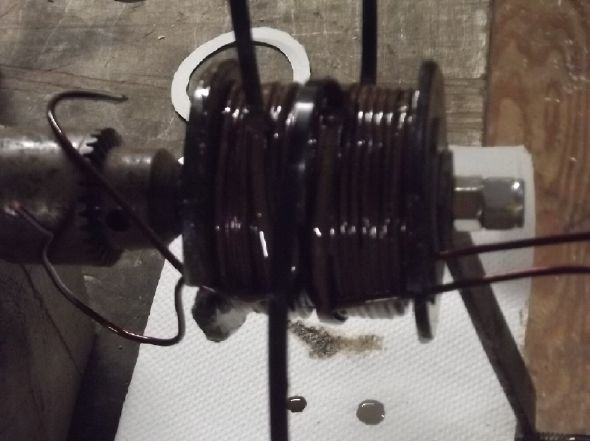

I wound the first two

coils, painting

illmenited epoxy onto the iron powder core before the first layer

and

then onto each new layer of windings. When each coil was wound I

used a

cable tie to prevent it from unwinding. But I also remembered a

trick

of pulling the wire across the winding handle so it wouldn't

unwrap if

I had to pause and let go during the winding.

I wound the first two

coils, painting

illmenited epoxy onto the iron powder core before the first layer

and

then onto each new layer of windings. When each coil was wound I

used a

cable tie to prevent it from unwinding. But I also remembered a

trick

of pulling the wire across the winding handle so it wouldn't

unwrap if

I had to pause and let go during the winding.

It was still tacky at bedtime. I can't put the coils

in

the oven to cure them faster the way I used to in Victoria because

this

cursed oven has no "warm" setting below "much too hot", at no

particular stated temperature. (That makes it no good for raising

bread

dough in, either.)

[20th] I gave the coils (now set) another coat of ilmenite/epoxy

from

the cup in the freezer and set them in the sun in the morning,

then

wound two more in the afternoon. The direct sunlight got the epoxy

to

set pretty rapidly. When they were ready I gave them their outer

coat.

In the evening I wound a 5th coil, but had to stop there as the

mix was

nearly gone and I didn't want to mix another batch so late.

I wonder that I never thought in past times, with all

the

troubles I had getting the ilemnite not to flake off, to mix it

into

the epoxy. I guess I was thinking that it was just supposed to be

on

the outside where the epoxy was inside the windings. Even then it

would

have been easy to mix it with epoxy and paint it on the outside.

(And

why shouldn't it go within the winds as well as around

them?

Probably better! In fact, why wouldn't one want magnet wire makers

to

add ilmenite to the insulation? Probably even better!)

[22nd] I finished winding the coils, giving them a second coat of

ilmenited epoxy, then (when set) filing off excess epoxy and

touching

them up.

Council of Motor Coils in

session. All those FOR

making a motor raise your tentacles!

Council of Motor Coils in

session. All those FOR

making a motor raise your tentacles!

Unipolar Motor Controllers Are Commercially Available!?!?!

(Then, this boy is DONE with making motor controllers!)

I started thinking about motor controllers again. The

original reason for wanting a unipolar motor controller was so

that it

could use low-side mosfets only, eliminating the possibility of a

short

circuit from having top and bottom transistors both transiently

come on

at once. That would probably drasticly improve the reliability of

my

home-made motor controllers. Then too, it was to eliminate the

iron

hysteresis losses associated with repeatedly reversing the

magnetic

polarity. (Of course, with the ilmenited iron powder coil cores,

those

losses are already much reduced over typical motors.)

But if one is to have high-side mosfets anyway for

synchronous rectification, where is the reliability gain? And if

commercial car motor controller makers are making them essentially

100%

reliable now, it's the law of already diminished returns. The

Kelly

controller worked great in the car until two phases of the motor

shorted. (Which said I should change the motor wiring techniques,

not

the controller.)

Then I started thinking about wiring the motor in

Delta

instead of Y. Delta is fine for sine wave AC... but if A and B are

on,

aren't the two legs going between A and B through C "half on",

backwards? Is Delta even a legit configuration for a BLDC motor?

Would

"C" have to be switched high or low instead of the usual choice of

leaving it unpowered?

But one could gain a three-phase unipolar operation

by

tying one side of each coil to "B+" instead of going either Delta

or Y.

Then it would get the full battery voltage when the coil's other

wire

is driven low.

Furthermore, the magnetic polarity of the

coil can

be set as desired by reversing the ends of the wire regardless of

the

electrical polarity.

Furthermore [wait... this doesn't work! But read

on.],

that's only using the low side drivers and getting three phases.

One

could tie the other half of the coils to ground instead of B+.

Then

they would be driven ON by the high side mosfets, at the

phase

angles right between the low side driven coils. Again, the unpolar

magnetic

polarity is independent of the electrical polarity.

Thus it seems we can make a six-phase unipolar motor

controller out of a three-phase bipolar controller. It's all in

the

configuration. Well, DUH! Here I finally have a simple answer to

something that looked really complicated. ...like adding the

ilmenite

to the epoxy and other great simplifications occasionally and

finally

found for vexing problems.

From this moment I'm going to drop any and all ideas

about

making my own motor controllers. I haven't been very successful at

it

in past efforts, and if I can't improve on an available commercial

product, there's little point to it.

[23rd] Oops: Wired in delta, if each output of three is taking one

coil

low and one high, the two coils are going to be in series from B+

to

ground when the output isn't driven. It can be made to work but by

only

using the low side drivers, so no coil is ever driven "south",

only

"north", in a three phase manner. More torque ripple, but it's

simpler.

Moving on... The next task is the housing. Metal is out for

electromagnetic reasons. I want to make it of polypropylene, but I

was

unable to buy a sheet of it a while back. The obvious thing would

be to

make it out of old PP ropes washed up on the beach. That meant

getting

back to the plastic recycling project I had started 2? 3? 4? years

ago.

So that occupied the next days.

Oven, not

pretty but ready in a day! added rock wool

insulation,

bent-up oven element (on gray metal), shelving for

molds

[23rd and on] I

finished

up the large size plastic oven I started making from a discarded

freezer about 3 years ago. It went faster and more easily than I

expected. Then I scraped and polished the mold plates, still with

baked

on crud from its last use so long ago. Finally in three bakings in

the

now temperature controlled oven, I cast a thicker plate of PP than

any

before. But there were still a lot of air bubbles causing voids

under

the top mold plate. By early August things were looking more

promising.

I cover this in more detail under Plastic

Recycling

[23rd and on] I

finished

up the large size plastic oven I started making from a discarded

freezer about 3 years ago. It went faster and more easily than I

expected. Then I scraped and polished the mold plates, still with

baked

on crud from its last use so long ago. Finally in three bakings in

the

now temperature controlled oven, I cast a thicker plate of PP than

any

before. But there were still a lot of air bubbles causing voids

under

the top mold plate. By early August things were looking more

promising.

I cover this in more detail under Plastic

Recycling

Of course, that was it for progress on the motor

itself.

[August 7th] Last night it occurred to me that while the low side

drivers of one phase of my own KBL36301 Kelly controller were

burned

out, I could use just the high side drivers for unipolar

operation.

What? I don't even need to buy a motor controller? What about the

synchronous rectification at turn-off? Or does that go through the

other two phases? Did I damage the board too much for the rest of

the

controller to work when I was futilely trying to repair it?

Okay, it might, or might not, work.

Other "Green" & Electric Equipment Projects

Solar Deep Well Pump

[15th] 3 or 4 years ago I

bought a "solar deep well pump": "24 volts, 300 watts". It had a

solid

state control box with BLDC motor controller and that type of very

efficient motor. According to the web page info, it sounded good

enough

for my 67 foot deep well. Now my 36 volt DC systems are running

great

and could surely supply the well pump even in winter, since it

usually

doesn't run very long. On top of everything else, if the well pump

was

DC, I could turn off the 240V AC going under my bedroom to the

shop at

night and eliminate it's strong electric field.

(Electrosmog/Tinnitus

reduction)

[15th] 3 or 4 years ago I

bought a "solar deep well pump": "24 volts, 300 watts". It had a

solid

state control box with BLDC motor controller and that type of very

efficient motor. According to the web page info, it sounded good

enough

for my 67 foot deep well. Now my 36 volt DC systems are running

great

and could surely supply the well pump even in winter, since it

usually

doesn't run very long. On top of everything else, if the well pump

was

DC, I could turn off the 240V AC going under my bedroom to the

shop at

night and eliminate it's strong electric field.

(Electrosmog/Tinnitus

reduction)

A while back I also bought two 25 amp DC to DC

converters

to reduce the 36 volts supply to 24 for the pump. I finally got

the

pump out of storage and read the instructions. Great zot! It would

run

on 36 volts! As a bona fide solar pump, it would run on pretty

much

whatever solar panels would put out, up to 48 volts abs. max.

That's

simpler, with no DC to DC needed. Too bad I didn't read the

booklet

earlier. In fact, the supply voltage specs were identical to those

for

the 36 volt pump... which the web page hadn't offered me. There

the

choice was 24 volts or 48. Hmpf!

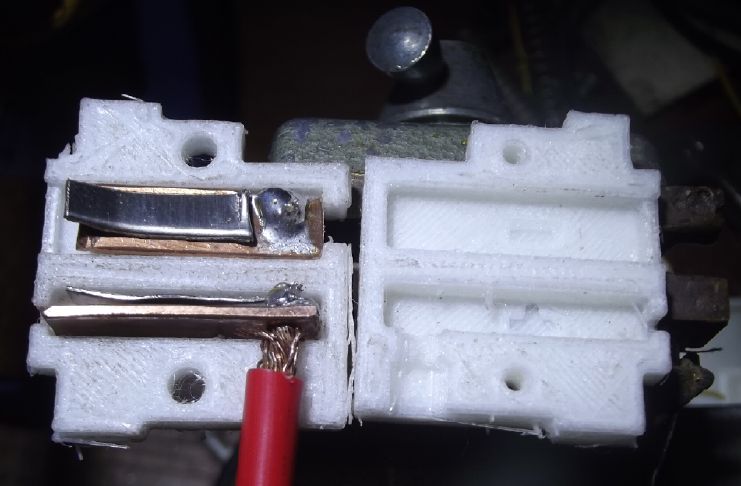

Pump Controller

Pump Controller

Pump Controller Opened

I connected the pump wires to the controller and made

a

long #16 AWG cord with a 36V plug on the end. I took it outside to

a

rainwater barrel. Then I thought to put in a switch so I could

turn it

on right at the pump, and quickly off again if needed, instead of

it

coming on as soon as I plugged it in in the kitchen without me

seeing

it start up.

I plugged it in and went out and flipped the switch.

Water

gushed out of the pump. It didn't seem very strong and didn't

spray out

of the barrel, but it sprayed and I couldn't slow it down trying

to put

my hand over the outlet. The pump was running at 3400 RPM and

drawing

310, 334 or 350 watts depending which meter you believed. A bit

under 9

amps at 35 volts. (The actual battery voltage was still over 40 -

too

long of too thin wires!) The voltage will be higher when installed

and

plugged in nearby the power box in the garage. The power to the

actual

motor deep in the deep well will however go through around 130

feet of

wire. (AWG #12)

I wired my test switch from "COM" to "TH" - "tank

high".

In this case, it'll be "tank up to pressure". When I flipped the

switch

On the pump stopped. It didn't seem to resume when I turned it

off.

Perhaps it has a time delay. I wasn't into waiting around for what

might be 30 minutes.

[17th] I picked (after rinsing, de-stemming and cutting off

occasional

bad bits) 300 grams of strawberries, adding to the 100 I picked

from

the earliest crop. I ate a few and froze the rest in a ziplock

bag. I

should have picked a larger bag - it's already full.

Then suddenly no more. They're "everbearing" through

summer but with the crappy weather there seems to be a pause after

the

first crop. Now there's lots of runners going every direction.

What to expect from a 4 by 5 foot berry plot?

Outdoor Fruit & Nut Trees

Originally I had a circle of fence wire (of some

sort)

around each fruit tree. Then I planted a "pollinator" pear inside

with

an apple tree. Sometime I ended up with the walnut and an apple

together. This was murder to maintain. Grass, weeds, ferns and

even

woody plants would grow inside the fence circles and through the

wires,

making them hard even to remove to get in.

This month I ripped out most of these. I cut some

stakes/posts and did one large fence around all except the

farthest

pear over.

I came back and found the chickens inside. Great,

they

could root out some weeds and bugs! But I wondered how they had

got in.

Crawled under somewhere? I opened the "gate" - just a piece

between two

posts that hooked on one end - for them to get out easily. An

opportunist missed no opportunity. I came back about three hours

later

and found that a deer had gone in and eaten all the leaves up to

about

a meter+ on all the trees except the walnut, which had no leaves.

Why

waste time with individual trees each in their own little fence

circle

when you can go in and eat five trees at once? It ate half the

little

green apples, and the leaves on my apple graft - the one and only

successful graft I've ever made in my life out of innumerable

tries

over the years. (I was sorry I had pruned away the branches around

it

to give it lots of room to grow.)

On the plus side, it looks like there were enough

leaf

bits left on my graft that it has survived. It's budding a new

leaf.

I've used branches with flowers from this particular tree to

pollinate

my own trees before and I'm expecting much better pollination when

this

branch starts producing its flowers.

From a circle of wire

around each

tree,

It turned out the chickens were (are) getting in behind the

remainder of the spool of wire, which I hadn't cut off and

stapled yet.

There are just a few apples on each of the large

trees,

"liberty" and "empire". The "pollinator" "northern spy" produced

on

flowers this spring. I don't think much of the "empire" apples.

And

they don't keep long. The "liberty" are nicer, but neither one

gets

very big. I think the trees are too near the ocean, with

southeasters

blowing right up the driveway towards the fruit trees.

This year is slightly exciting because one of the

pear

trees set fruit and is growing just three little pears, all in one

clump. In eight years neither tree has had any pears. (Two years

ago

they set a few but some squirrel came along and nipped them all

off

almost before they started growing - Grrr!) Three pears is nothing

but

at least I get to see what "Clapps Favorite" pears look like.

(Longer

and thinner than bartlett, already reddish.)

Walnuts On the 7th(?) I noticed tiny

buds on

the bark of my seemingly dead large walnut. It was such a cold

spring

that the buds that came out in May died on both trees. And it was

still

cold. I decided to put plastic bags over both to try and at least

keep

the wind off them. On about the 15th it finally warmed up but it

was

quite breezy. The wind carried off both bags. I tried to do a

better

job of anchoring them, using bungee cords around the trunk of the

large

tree.

Walnuts On the 7th(?) I noticed tiny

buds on

the bark of my seemingly dead large walnut. It was such a cold

spring

that the buds that came out in May died on both trees. And it was

still

cold. I decided to put plastic bags over both to try and at least

keep

the wind off them. On about the 15th it finally warmed up but it

was

quite breezy. The wind carried off both bags. I tried to do a

better

job of anchoring them, using bungee cords around the trunk of the

large

tree.

I've been watering them daily in the hopes they would

spring back to life. I wasn't really expecting anything until I

saw the

buds. I hope the small black walnut will commence too. My place is

just

too close to the ocean and the place I've planted them gets the

breeze

off the beach. (You'd think with 2 cleared acres I could find some

better spot for my fruit and nut trees. I haven't.) Combine that

with

an unseasonably cold, cloudy spring and early summer... Walnuts in

Port

Clements away from the open ocean seem to be doing fine.

[August 4th] Wow... Just a couple of leaves barely starting to

open on

the big tree and what might be the beginning of buds on the small

one,

and the weather has turned cold and miserable again! [August 7th]

A

couple more now, and leaves are starting to open in three clumps.

Might

be some tiny buds on the little black walnut too. (or it's

starting to

grow lichens.)

The cover on the small

walnut.

The cover on the small

walnut.

Yes that's the beach and ocean just across

the highway and past a row of spruce trees.

Greenhouse

Greenhouse (Aug 7th) It

kind of

grew

in pieces, neither half being the original.

I've just finished replacing plastic that let little light

through with

scrapped window glass

on the big door at the right hand side of the left half.

(There's a 2 by 4 behind the door because the roof support

board chose

right in the middle

of the door, the widest span, to have a big knot that let it

sag down

to hit the door.)

Squashes want to grow out under the door and grow onto the

lawn.

I got some lovely big orange squashes on the lawn that way 2

or 3 years

ago so I'm encouraging it.

Many things grow better in a greenhouse this far

north, or

outside the south wall of the house. Here the winter is often

about as

mild as Victoria about 5 degrees farther south. It contrasts with

Edmonton at the same latitude where it is often way below freezing

for

the whole winter. Instead the summer is usually quite cool and

many

common crops struggle. I've said before it's almost a unique

climate.

In addition I'm very close to the shore - Hecate Strait. Other

gardeners do better a bit farther from the sea.

The Apricots, just before I

picked

them on the 30th

The Apricots, just before I

picked

them on the 30th

The avocado pit from the compost pile that I planted

in the house last fall is growing leaps and bounds.

...What do I do with it?

South side of West end of greenhouse.

The Strawberry Tree (Arbutus Unido) I got this spring is also

growing

leaps and bounds,

tho presently hard to see in the tomatos. (Its main stem is just

right

of the

closest tall stake.) These are delicious, juicy fruits.

I should get a lot of tomatos.

Note the yellow edges of the zucchini leaves (front). Potassium

deficiency.

I've sprinkled some woodstove ashes under it.

.

With the sudden heat from mid July the corn suddenly

started taking off, along with other things that hadn't been

growing

very well.

Outside Gardens

Josta berries are apparently a cross between

currents and

gooseberries. They are similar in size to gooseberries rather than

the

small size of currents, and the bushes aren't full of thorns like

gooseberries. Mine are black but I've seen red ones too. I might

call

them "grape size black currents." Less seedy.

Josta berries are apparently a cross between

currents and

gooseberries. They are similar in size to gooseberries rather than

the

small size of currents, and the bushes aren't full of thorns like

gooseberries. Mine are black but I've seen red ones too. I might

call

them "grape size black currents." Less seedy.

Somebody gave me two plants about five years ago. I

planted them on the west end of the garden on the south side. They

had

nothing until last year, when there were a few. This year I picked

a

cup or more off one bush and made a "josta upside down cake" type

dish.

Mmm.

At

the

opposite

corner

the

new

yamhill

hazelnut

doesn't seem to be

doing too well. I think of various things it could be, but I'm

probably

not watering it enough. (It's rather "out of sight" and too many

other

things to remember!)

At

the

opposite

corner

the

new

yamhill

hazelnut

doesn't seem to be

doing too well. I think of various things it could be, but I'm

probably

not watering it enough. (It's rather "out of sight" and too many

other

things to remember!)

Peas mid month

...and chickweed. Oodles of chickweed.

I revived a bit of this little patch with the rototiller and

some

sprouting

"Russian Blue" or "Violet Queen" potatos with purple skin and

flesh,

and a few

prolific "Huckleberry Gold" with yellow flesh, all left over

from last

year.

Potato tops are poisonous.

That doesn't stop the deer from eating the tender tops.

I suddenly got the inspiration to simply throw pieces of

chicken wire

over

the top of the whole patch. It's spotty coverage but it seems

to be

working

A large volunteer poppy in the garlic patch.

Should be a lot of poppy seeds in those globes!

(I'd better harvest them all or poppies may be my new worst

weed!)

Black Locust and Birch trees grown from seed this year.

Next spring I'll plant some by the front fence with wire

stapled to the fence to keep the deer from eating them.

Again a few sunflowers by the south wall.

When the weather Finally turned nice and sunny in mid July I

brought out

the coffee trees from inside the patio door. Oops. Many leaves

got

badly

sunburned.

They have been dying and new leaves are growing to replace

them.

Strawberries in the south wall garden. The berries are good at

hiding.

Corn in the greenhouse, 21st. Only the ones from Dragonfly

Garden look

like

they might make cobs. The ones I planted just aren't growing.

Why?

Also 21st: The corn I planted in a the big "cold frame" box

are

doing about as well as the Dragonfly ones in the greenhouse.

By August 7th they were a bit ahead, forming husks with

"silks" to catch the pollen.

Hidden fishpond with water lily. It hasn't grown a flower

since the

first year, when a deer ate it.

Unfortunately if it isn't well covered over raccoons will be

fishing

and someday

some otter will find it and clean out all the goldfish in a

brief time

on one day.

(That happened to my pond in Victoria twice.)

Instead it is occasionally visited by frogs or toads

that just stay a day or two and don't eat goldfish.

House Garden at the end of the month (July 31st):

garlic, corn growing tassels, seeded trees in pots, the coffee

trees in

pots.

Far right, back: small blueberry bushes.

House Wall Garden outside section at end of month:

Carrots that not many grew, now reseeded; board; carrots that

grew;

strawberries; onions (some from an onion bulb "set", some from

seed.)

(Where did that poppy come from?)

The Claw-Hoe: a Better Hoe

for

Weeding?

[23rd] I once bought the most useless hoe imaginable. The cutting

end

was formed of two overlapping circles. Either I was in an

experimental

mood or it was the only one in the store. (Who can remember from

about

1980? and why did I still have it?)

Of course no cutter dragging along the ground is or

stays

"razor" sharp, so the effect of the circular shape was to push the

weeds sideways into line with the crop plants, making them harder

even

to pluck by hand.

Last week I thought to buy a "normal" hoe for the

copious

weeds choking out my crops, but didn't. Instead I got the idea to

make

this one the opposite shape: straight and not sharp at the left

and

right sides, so as to go by the crop and not cut it, and concave

on the

end to form a point at the left and right edges. Then sharpen the

rear

face so as to cut the weeds as I drag the hoe backward through the

weeds, including right next to but not quite in line with, the

crop

plants.) I tried it out. Not bad. Actually it had a better working

angle on the handle than most hoes. When I went to do the right

side I

had an inspiration: cut it into triangles and points - almost

"tines".

Then dragging it through the weeds they would catch in the inner

slots

instead of escaping by slipping by underneath.

I can see my beets!

I can see my beets!

With this I was plucking up great gobs of chickweed

and

other weeds as I went. I had to keep dumping them aside, and for

the

first time ever I actually cut some good swaths through the thick

weeds

choking out my beets, beans, spinach and lettuce. and near the

peas and

potatos. The working end is pretty narrow left to right, but that

might

be good if you can get between "double rows" planted close

together.

And the cutting edge isn't very far to the back, so it has less

tendency to twist than most hoes.

I checked on line to see if there were any better

hoes

than those I've seen before. There was just one new type, with

tines -

sharper tines than mine. Like mine it worked at a more slanted

angle,

and it also had a horizontal slicer on the front that could

potentially

be useful. But it also had a couple more cutters on the sides

which

IMHO just would make it hard to get next to the crop plants for

close-in weeds without endangering them. I think the designer just

got

a little too fancy, to the detriment of the tines idea. Also in

the

video the user kept having to pull the weeds off the tines by hand

instead of dumping them off, so they may have been a bit too

pointed

and the slots too narrow, gripping the weeds too strongly.

So if I may be so bold as to claim another very tiny

"world's best", I think I've just made the most effective hoe. In

fact,

other than the above one I just looked at on line I've never seen

a hoe

that even was very effective before. I've always considered them

an

almost useless implement. Only my desperation to somehow pluck up

chickweed without plucking my crops led me to think of trying one

again

- and then to experiment.

Plastic Recycling 2.0 (to Make the

Motor

Housing)

(Note: The gallery of plastic images is in July in

Brief

- not many pictures in this text.)

[23rd] I was unable to buy a sheet of polypropylene (PP) a while

back.

So to make a PP housing for the motor, the next most obvious thing

would be to mold the plates out of old PP ropes washed up on the

beach.

That meant getting back to the long neglected plastic recycling

project

and finishing the plastic melting oven I started 2? 3? 4? years

ago.

Since that's outside work and it was a nice day, I

began.

When I left off, I had found that heating the oven - the shell of

a

freezer - not unexpectedly melted the foam insulation. I had

thought to

heat it up and melt it, then yank out the entire inside surface

assembly. Then I could replace the foam with higher temperature

insulation. I heated it to 120°C for a while, and then started

slashing

at the foam just inside the inner walls with a long, thin knife.

But it

didn't look like it would be an easy or clean job, and as I worked

I

thought up another idea. There was plenty of space. What if I put

higher temperature insulation inside of the inner walls so that

the

foam just didn't get all that hot?

So next I took a "cube" of steel racking (1 x 1 inch

square tubes) that I had got at the refuse station when I was

working

on it before to use as shelving to hold plastic molds up off the

bottom. I cut it to fit inside and make a single shelf near the

top of

the space. I also bent the oven element that heats it up to a

shape to

my liking that fit under the shelf unit.

Just two pieces of 22 x 27 x 3.5 inch insulation

covered

the inside walls. (The floor took one full piece. With the width

of the

shelf I had to split a piece down the middle twice, to 11 x 1.75

inches

to line the front and rear walls, so the other half was left over

to do

the ends and misc.)

So what I expected might take a couple of days I got

done

in one.

Later I cleaned and polished the large rectangle mold

(17

x 22 inches). On the last piece I had done (so long ago) I had

overheated some horrid black plastic in the previous oven with no

temperature control and it was solidly stuck to the alume. I did a

lot

of scraping with a chisel, and the then polishing took a long

time. It

did more smearing the plastic around thinly than getting rid of

it. But

eventually it was done.

Finally I took some crappy old rope and cut pieces to

the

length of the mold. 1030 grams of it. I looked forward to doing

the

melt in the temperature controlled oven, where I could leave it in

for

hours for the plastic to flow into the corners and voids, and hope

for

generally better results than I had been achieving before. But it

was

getting late so I left it. "Monyana (is good enough for me)", as

the

song goes.

[24th] I put the mold in the oven, put weights on it, and turned

it on.

I set the control to the temperature mentioned TE News #197

(400°F)

205°C. In 90 minutes or somewhat more it was only at 199. But the

plastic was oozing out and seemed a bit charred around the edges,

so I

shut it off and opened it. I was afraid the plastic would be baked

solidly onto the mold surface again, but it wasn't too bad.

Then I realized what the problem was: A

piece

of the insulation was covering the temperature sensor! So the oven

was

considerably hotter than the sensor indicated. It surely would

have

been up to temperature and beyond. The oven's outer foam

insulation

seemed to have weathered that pretty well. I peeled the insulation

away

to expose the sensor. I tried to pull it farther into the oven

space,

but it didn't seem to want to go. Good enough I hope.

The 1030 gram plate seemed pretty thin and one corner

wasn't filled. I decided to add another 600 grams of ropes on top

and

try the same piece over again. There was also a jute or hemp rope

within it. That one didn't melt at all.

In the evening I added 600 grams more plastic, with

the

original plate under and the new ropes over. This time the

temperature

reading rose much faster and the oven was at the setting (205) in

about

45 minutes. I left the mold in for a further 45 minutes at full

temperature, then turned it off and opened the lid. With the oven

not

overheating, the smell, which was awful and strong the first time,

was

barely objectionable. In addition it didn't seem like the plastic

material was deteriorating or sticking much to the mold - I could

probably re-melt it several times if need be.

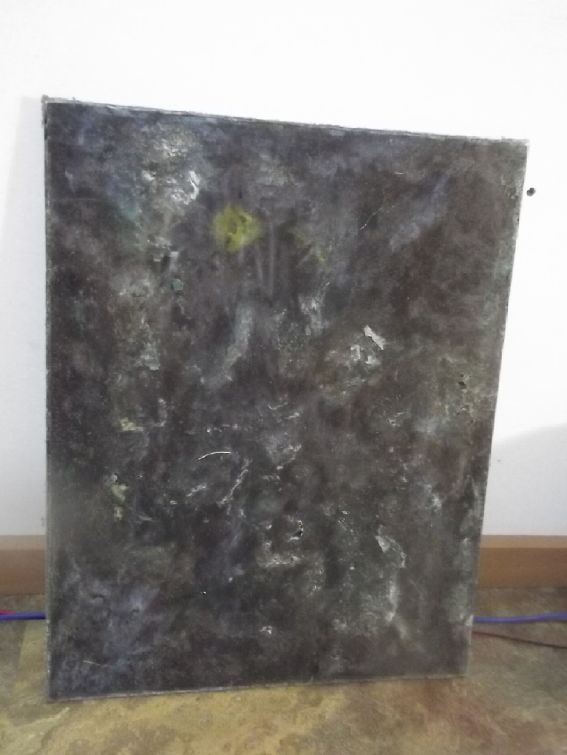

The resulting slab however was pretty poor. It looked

more

like a routed contour map than a flat piece. I thought of three

possible reasons for the spotty filling and poor flow:

1. insufficient weight (~40 pounds) on the lid of the mold.

2. oven temperature too low.

3. insufficient melt time

Then the real reason occurred to me: there was simply

insufficient material to fill the space. The first time I had put

in

stand-off screws in the corners holding the top 1/2 inch above the

base. It seemed awfully thin and I had changed to 1/2 inch

stand-offs.

But it already had left a void corner with 1030 grams of rope

bits. I

had only added another 600 grams (=1630) and doubled the volume to

fill. Probably it should have had a total of maybe 2200 to 2500

grams.

Manyana!

[25th] I re-assembled the mold and put the piece back in, and

added

another 600 grams of old beach ropes material on top, making it

theoreticly 2230 grams. I cut and slipped two very thin slivers of

sheet metal into the cracks along two edges of the mold, about

3-1/2

inches tall, to help keep the lid from shifting when the material

placed in the mold caused it to be sit above the 2 inch edges

before it

started melting, which is most of the time, especially if you want

to

make a thick tile.

If it works well I may sand the top piece a little

and add

thin sheet to all sides. Four inch tall sides for the molds would

be

wonderful. (1 x 4 inch rectangular tubes? 'n' x 4 angle iron"? Do

they

even make such sizes? What's at the refuse station?)

I heated it for three hours this time, hoping it would

become

more uniform and air pockets would fill with plastic instead of

air.

The whole process, while still needing to be done outdoors for PP,

is

much more pleasant with an oven that holds the desired temperature

instead of overheating, scorching and vaporizing plastic and

warping

the alume alloy mold plates.

Ever since I originally started the project, I've

wanted

to make longer plates for dug-in garden surrounds to keep grass

roots

from spreading into the garden, but it suddenly occurred to me

that one

could melt tiles together with a heat gun to make a double size.

Or

even string several together to make a whole impermeable wall.

Well,

duh, so why did I make a larger plastic melting oven? But there

are

other pieces that would be nice to make larger or longer. (Eg,

plastic

fence posts?)

I have also realized that in the one "sample" garden

border I dug in before, I should have put the plastic Outside the

wire

deer fence instead of Inside. Then one could weed-whack the grass

right

up to the plastic without hitting the wire fence. With it on the

inside, there's a troublesome line of grass between the wire and

the

plastic that the weedeater can't get at.

The 2100 gram piece is by far the thickest I've done.

Putting it in the oven for 3 hours helped - it popped out of the

mold

easily. The lower surface was smoother. The upper surface was

still

full of sharp edged voids here and there, probably from trapped

air

bubbles.

I think I'll try making a few very small holes in the

top

piece for air to escape. I hope plastic doesn't fill the holes,

leaving

sprues and making it hard to separate from the plate.

[27th] I put 6 tiny holes in the top plate, about 5-1/2 inches

from the

edges and from each other. I tried to make a new plate with 1200

grams

of old ropes. It was a disaster! The plastic stuck to the mold

plates

like krazy glue, especially the bottom plate. When I finally

managed to

chisel the piece off it, there was all this horrid black plastic

here