Turquoise Energy News #210

Covering

Research & Development Activities & Projects of

November 2025

(Posted December 2nd 2025)

Lawnhill BC Canada - by Craig Carmichael

[Subscribe: email to

CraigXC at Post dot com ; request subscription]

Main URL TurquoiseEnergy.com Also at craigcarmichael.substack.com

Month

In "Brief" (Project Summaries etc.)

* New Cylindrical Battery Design (for organic Cu/Zn cells) - OLAHP

Air Compressor Test - Faraday Cabin Construction

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* Planetary Management: Citizen Appeals Tribunals

* Scattered Thots

- Detailed

Project Reports -

Electric Transport - Electric Hubcap Motor

Systems - no report (will I ever find time to

finish the next motor?)

Other "Green" &

Electric Equipment Projects

* A New Tech ! Resistance Heating Elements made With Power

Diodes (advantages over resistance wire)

* Open Loop Air Heat Pumping (small progress again)

* Faraday Cabin Construction

* Yet More Electrosmog/Tinnitus Culprits

New Battery R & D (back in the

news!) - Organic Copper Crush Experiment - Promising new

cylindrical cell design - Newer New Cell Design

Electricity

Generation

* New Grid Tied System - back on track?

* Old System - The usual Latest Daily/Monthly Solar Production

log et cetera - Monthly/Annual Summaries, Estimates, Notes

November in Brief

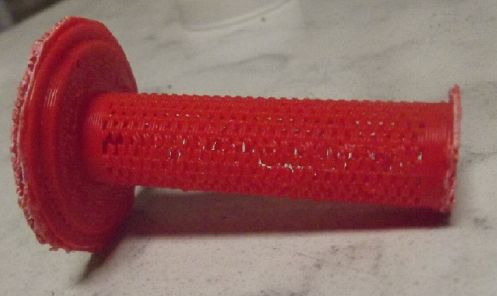

Pivoting Vane Air Compressor,

assembled. It should be super efficient.

Pivoting Vane Air Compressor,

assembled. It should be super efficient.

Sometime near the start

of the month the travesty of the destruction of a BC ostrich farm

got me thinking about citizen appeal boards again. I'm quite

pleased with what I came up with, below in In Passing.

Anyone could start a citizens' tribunal - it doesn't require

government action.

There's really no gardening report this month. I kept

the houseplants, greenhouse and some trees watered. I dug up some

clumps of grass and weeds, and some potatos - some to eat, some

for seed in the spring in case the ground freezes. A cabbage in

the greenhouse has grown a head that I'm about to harvest. A few

cherry tomatos and a couple of peppers are coming in the house,

along with coffee seeds. The avocado is getting quite tall.

There was a warning of some nasty solar storm coming.

Space weather! In a video a CME seemed to disturb about 1/3 of the

whole face of the sun. A space launch was cancelled. On the 12th

there was frost but a beautiful display of northern lights.

(almost actual midnight - "24:30" PST) At first great sheets of

pale light zipped across the whole sky in different directions -

all in a second or less. Mostly the northern half of the sky Then

pillars of light arose from the northern (?)horizon, reaching up

into the sky. But at my place the northern horizon is hidden

behind tall trees. I decided to drive to Jungle Beach where I

could see better to the north. In the 10 minutes that took, clouds

had moved in to the north and east and the lights seemed to have

faded too - a disappointing ending to a great display. Bed time!

[18th] I have been meaning to post all issues of Turquoise Energy

News to craigcarmichael.substack.com . I finally did 2008, #1 to

#12. I backdated all the publication dates to the original posting

date, which is available but requires some manual steps for each

issue, so I was working on it for over an hour. 12 issues per

year, 18 years... I should be done by 2027!

New Chemistry Batteries

I tried pressing the organic material with

copper/monel as a flat plate electrode. It seemed fine but still

had high resistance. I didn't get any farther. Then by the last

third of the month I came up with a new idea for constructing

cylindrical batteries. I picked my smallest ointment jars as a

suitable outer case that wouldn't leak. I started working on it

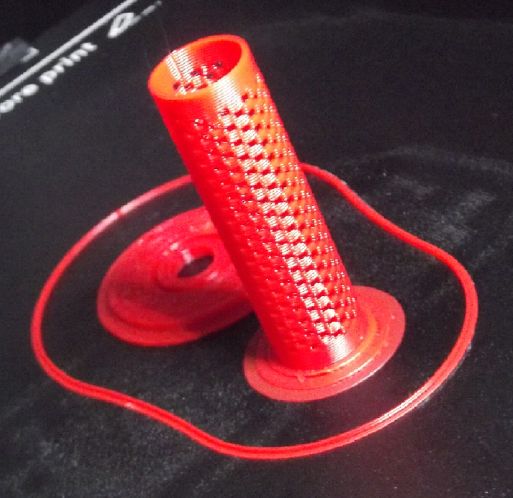

and 3D printed a cylindrical "basket" in ABS to hold the

electrodes separate. Then I realized reversing the position of the

electrodes would solve some construction problems. Without

assembling the first design I revised the basket and other things

and started on the second one, with the "+" electrode on the

outside and the zinc in the middle.

From Outside In:

ABS jar container.

Conductive graphite 'gasket' current collector inside the rim

of the jar.

Crunched positive electrode powder material.

Zinc (negative) basket (separator paper not yet placed inside

the rim).

central wire current collector for the zinc.

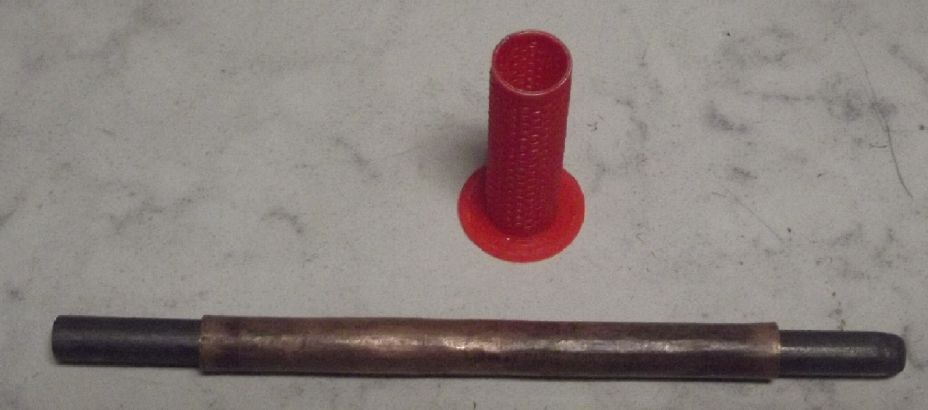

Two pieces of pipe to crunch the positive powder down

into a cohering layer just inside the graphite around rim.

Pressing the 'ears' of the outer pipe compacts the powder.

Withdrawing the inner pipe afterward leaves a space the

same diameter as the inner basket to be inserted.

Separator paper & zinc mix before gluing top on.

Cell being tested

I drilled a hole to hold the cell in a block of wood so

the test

leeds wouldn't tip the cell over or drag it off the

bench.

So far tests with the organic copper/monel mix don't

seem promising.

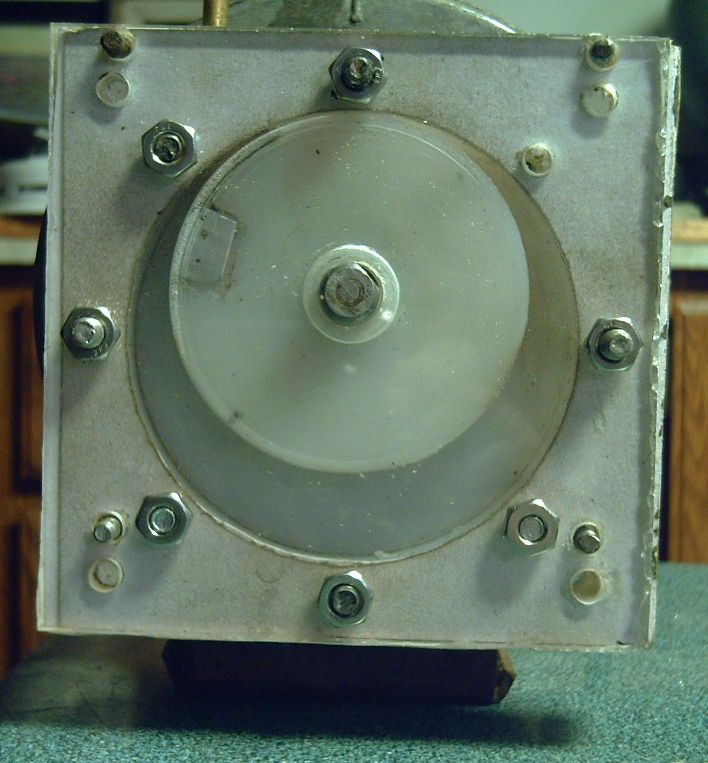

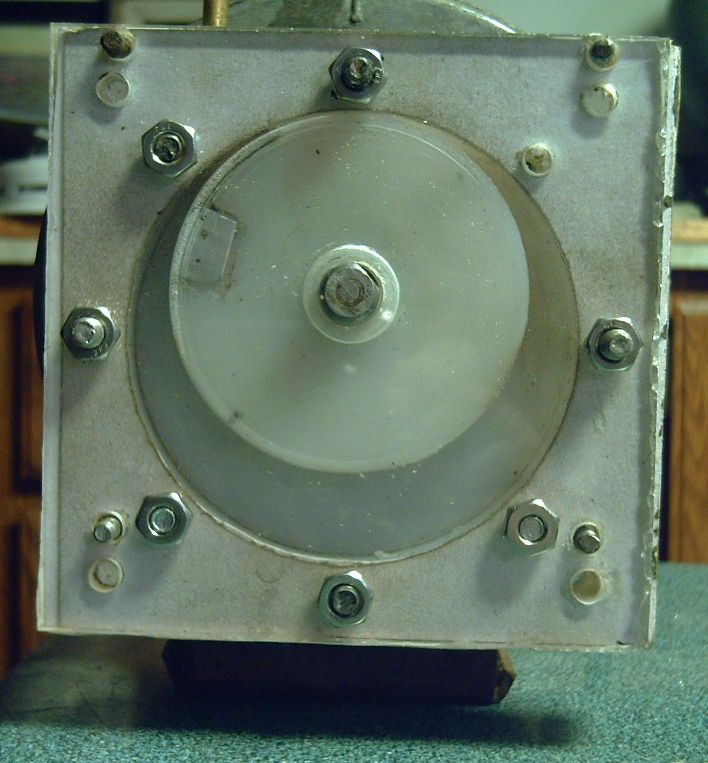

OLAHP Air Compressor Test

Not wanting to leave the project

completely behind, I got the compressor together, mounted it on

the motor and ran it. It didn't seem to push much air and the

rotor seized to the cylinder after it stopped. It seemed a tiny

piece of UHMW, probably scraped off by the pins holding the vane

assembly, had melted and glued them. I didn't get farther than

getting it off and seeing what the problem was.

Not wanting to leave the project

completely behind, I got the compressor together, mounted it on

the motor and ran it. It didn't seem to push much air and the

rotor seized to the cylinder after it stopped. It seemed a tiny

piece of UHMW, probably scraped off by the pins holding the vane

assembly, had melted and glued them. I didn't get farther than

getting it off and seeing what the problem was.

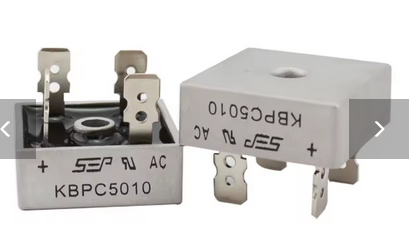

Diodes for Resistance Heating

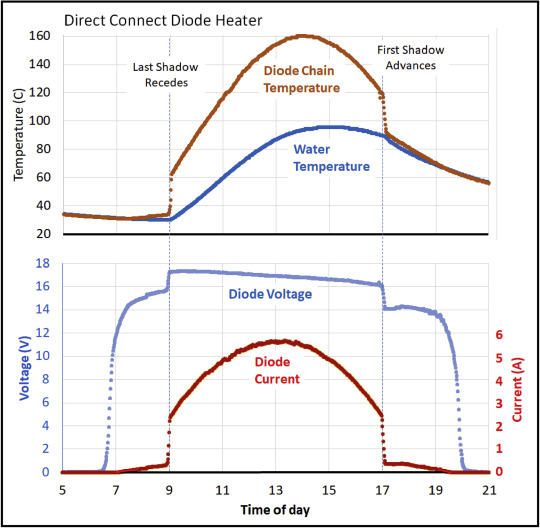

I ran across a new (2019?) idea of using diodes for

resistance heating elements instead of nichrome resistance wire. I

was puzzled why anyone would do that, but it has advantages with

non-exact power sources - solar panels or batteries.

With a solar panel, if the number of diodes is chosen

so that their forward voltage drop equals the MPP voltage of the

panel, it's almost like a solar charge controller. They will

extract the maximum available heating watts from the panel all

day, the voltage always staying near MPP regardless of how much

current the panel can source. With resistance wire, if the panel

can't put out enough current, the voltage is dragged down. Watts =

Volts * Amps, and little heat is produced except at noon on sunny

days.

With a battery, the diodes could be chosen so that

the heaters will put out less and less as the battery gets lower,

pretty much stopping without fully draining the battery. This not

only protects the battery from overdischarge, but can do so while

there's still power left to run lights and other lower power

appliances. It could also be set up as a "dump load" that only

supplies heat when the battery is at full voltage and more power

is coming in. At least, that's the theory. How well the diode

strings can be matched to the 36V LiFePO4 battery will be the

subject of experiments. Diode Vf is unfortunately not

entirely a constant, ranging typicly from .7 to .9 or even 1 volt

depending on current.

As well as space heating, I hope to try making an

alume plate 'stove burner' or 'hot plate' for off-grid cooking

with diodes, and maybe a hot water tank heater. At 36 volts such

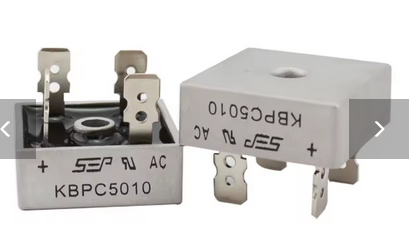

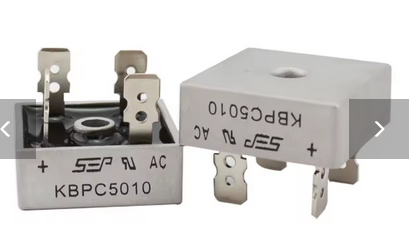

heaters might take about 55 diodes. I've ordered 60 power bridge

rectifiers, which (for this purpose) each have two pairs of

parallel diodes in an alume case that can bolt to a heatsink.

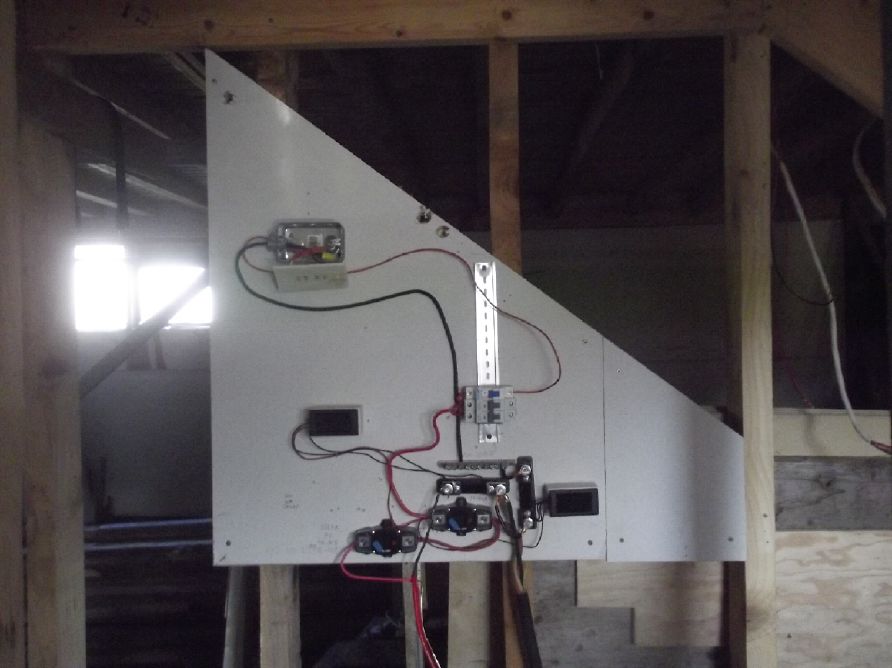

Faraday Cabin Construction

I decided I had put the stairs in a bad place - that

the bottom steps shouldn't stick out into the east side of the

building. Kind of late, but I decided to shift them over by three

feet. First I had to move the 36V DC electrical board/panel under

the stairs by that amount, and of course some wires. Luckily I

don't have a lot of wires yet, and most of them were long enough

for the move. Of course after the move the landing upstairs didn't

quite match the door. (Luckily I had made the landing 5 feet long

with the door at the far end, or moving the stairs wouldn't have

worked at all. I'd have had to change the whole wall to move the

door.) I turned the door around so one wouldn't step right out

onto the top step instead of the landing. I have yet to cut the

landing shorter. It goes way past the door now and needlessly

impinges on the space below. And now the upstairs room light

switch is on the wrong side of the door and needs to be moved.

That should be fun as the wire to the light is inaccessible in the

finished ceiling.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Planetary Management: Citizen Appeals Tribunals

In BC, on a ranch with hundreds of magnificent

ostriches, a few of the birds caught a disease and died in January

2025. The rest remained healthy or recovered. Tests determined

that the disease was infectious avian influenza and the Canadian

Food Inspection Agency (CFIA) wanted to kill all the birds. The

owners fought back and the case went to court in May and again in

August. The courts upheld the law and the CFIA. In November, long

after the outbreak had ended and in spite of much public protest,

the CFIA denied the owners access (even having one arrested for

entering and feeding the hungry birds) and finally shot all the

ostriches.

This was an experimental open ranch, not a "factory

chicken" operation with thousands of hapless birds crammed 24-7

into a closed building in which disease could spread like

wildfire. The sick ostriches were separated from the healthy ones.

The outbreak was closely monitored and studied as part of the

experimental R & D. The birds that recovered would even be

immune. Seemingly the action ten months later was a useless

bureaucratic exercise in futility resulting in senseless

destruction of a fine resource and a severe violation of private

property rights. The ostrich farmers are not even permitted to get

more ostriches in case the influenza virus has infected the soil.

Thus their entire enterprise is ruined. Certainly no good

arguments for doing these things reached us, the BC and Canadian

public. It has been called a serious crime and many feel that way.

Certainly no one will ever dare to try to start an ostrich farm in

Canada again.

What might have been done?

Here's where my idea of citizen appeals tribunals

should have been useful. Courts rule on legality, not on morality

and whether a law or bylaw has been reasonably applied, mercy for

the affected, or the consequences of enforcing it. Had I been in

contact with the affair, I think (admittedly in retrospect) that I

would have liked to strike such a committee even without any

official sanction - perhaps five or seven people to hear the case.

I think I'd have called it:

Canadian

Citizens' Tribunal

hears specific citizen

appeals in individual cases of seeming bureaucratic

overreach or inappropriate application of laws, bylaws or

statutes

After getting the volunteers - who I'm sure would be

forthcoming for such a concern and probably for many others - we

would sit and hear the case. (I would hope for a lawyer and a

veterinarian or two on board. Maybe even a virologist?) We would

invite both the plaintiff (the ostrich farmer family) and the

prosecution (the CFIA wanting to kill the ostriches) to be heard

and or to present written briefs. We would give each party a

chance to respond to the other's submissions. A decision wouldn't

be made in a day without reasonable chances for feedback and for

deliberation within the tribunal. There would doubtless be at

least two or three sittings in most cases. We would invite media

to hear (at least) the final written verdict including the main

reasoning behind it, and send copies to elected representatives.

We would not contest laws, bylaws or statutes as such, only

individual cases. We would adjudge the applicability of the law,

its reasonableness and fairness, only as applied for the present

case, and we could forecast the likely consequences of enforcing

it or not, only in the present case. Thus the tribunal would have

no responsibility to consider or decide on anything except the

case at hand on its own overall merits.

I think we have a pretty good feel for the ostrich

owners' side. Their lifework and livelihood was destroyed by the

federal government civil service by an action that seemed to make

no sense to the public. No moral or physical case for the

reasonableness or necessity of the slaughter after the birds had

long since recovered reached the public ear. On the other side, if

the CFIA presented a good case to the tribunal that would also be

considered. CFIA would be under no legal obligation to respond to

an "unofficial" tribunal, but if it didn't, it would certainly

suggest its only case was "Well, it's the law, and we intend to

uphold it! If we start making exceptions, there would be no limit

to the carnage in bird populations."

The argument that an exception could result in more

exceptions doubtless carries some weight in regular courts of law

and in bureaucratic circles. But since tribunal appeals apply only

to the specific case in question a victory for the ostrich owners

would not set a legal precedent and could not be applied to other

cases. (This aspect of tribunal decisions should be clearly

pointed out in communications including as a footnote in decisions

by the tribunal.)

In spite of having no formal basis for its existence,

a volunteer citizen tribunal would carry moral authority. The more

such tribunals conduct themselves like fair and proper courts, and

the more cases heard and adjudged even handedly - and in

reasonable mercy to the plaintiffs - the more legitimacy and

respect they would acquire. They could become a new institution

assisting with fairness in societal decision making.

It might also make an assessment of the damages that

would result to the plaintiff(s) in the event of enforcement and

suggest a financial compensation amount to be paid if enforced.

Some tribunals might be temporary, addressing a

single issue and then disbanding, or some might find there are

sufficient appeals to warrant continuing existence and regular or

irregular sessions.

What benefits would such moral legitimacy bring?

Almost no one actually wanted to see the ostriches slaughtered,

but no one felt they had the authoritative medical expertise or

bureaucratic or legal justification to say "No!". A well

considered citizen tribunal decision of "No!" would give elected

officials including federal, provincial and local officials -- the

area's MP, MLA and regional district rep, or even the prime

minister and the premier -- a fair basis for instructing the civil

service, here the CFIA, "Desist!" It might even be considered by

the department itself as sufficient cause or excuse to desist with

action, even if not so ordered "from above".

Scattered Thots

* Why do many people have a lot of "skin tags" (skin polyps)

around their neck area? Why do makers put rough, scratchy collars

on otherwise soft shirts? (Skin tags are "benign tumors" but are

apparently not good for you. Long ago I got rid of a zillion of

them - more around my neck than everywhere else - by rubbing them

about 3 times daily with castor oil and baking soda, for a couple

of days to a week each. I kept jar caps of it by my bed and in the

bathroom - wherever it was handy.)

The tea shirt I have on has a tag/label behind my

neck that feels like it might as well be fiberglass.

* NGO's: Non-accountable Government Opaqueties

* When one innocent person is oppressed, acted against without

absolutely compelling reasons, even in the name of "the greater

good", all innocent people are oppressed, because the greater is

made up of individual persons.

ESD

(Eccentric Silliness Department)

* In trying to create wheels primitive man found that "round" was

a good roll model.

* Gold is said to be really heavy but it has been rising like a

balloon. (Over 5000 $C per 31.1 gram piece at the moment. IIRC I

bought a piece in 2012 for 1350 $.)

"in

depth reports" for each project are below. I hope they may be

useful to anyone who wants to get into a similar project, to glean

ideas for how something might be done, as well as things that

might have been tried, or just thought of and not tried... and

even of how not to do something - why it didn't work or proved

impractical. Sometimes they set out inventive thoughts almost as

they occur - and are the actual organization and elaboration in

writing of those thoughts. They are thus partly a diary and are

not extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before publication. I

hope they may add to the body of wisdom for other researchers and

developers to help them find more productive paths and avoid

potential pitfalls and dead ends.

Electric

Transport (No Reports)

Other

"Green" & Electric Equipment Projects

A New Tech !

Resistance Heating Elements made With Power Diodes

(advantages over resistance wire)

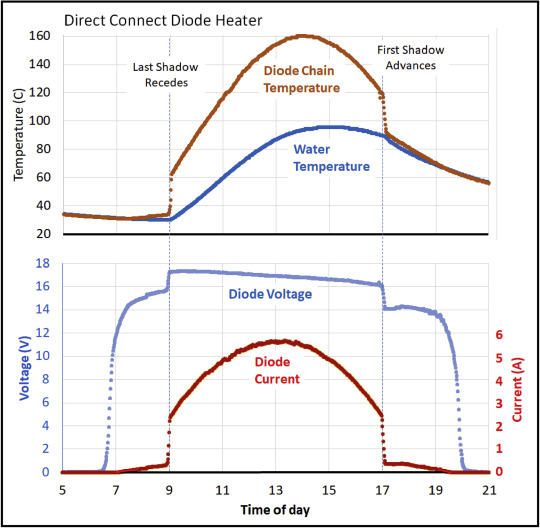

[27th] I watched a couple of videos by Dave, Youtube channel

"Solar Power Edge". Dave has some good and interesting ideas. This

one seemed rather odd at first glance: to make a heater using the

forward voltage drop and heat from diodes instead of resistance

wire. But on inspection it has advantages.

A typical (non-Schottky) diode doesn't conduct

electricity in the forward direction until the voltage reaches its

junction voltage of about .7 volts. Above that, it conducts more

and more current until at around 1.0 volt it may be conducting

tens of amps or even 100's, depending on the specs of the diode.

He was using this with about 25 diodes in series to be 25 unit

heat elements of a heater, running directly off a 17 volt (at

maximum power point, MPP) solar panel.

Solar panels also have diode junction voltages, about

.5 volts per cell. So a 36 cell solar panel is around 18 volts if

light is shining on it, less a little bit if MPP current is being

drawn from it - the MPP voltage.

Now say we have 1200 watts of solar panels. These may put

out 1000 watts at MPP at the equator on a cold day in the dry

season if there are no jet trails. So we connect a 1000 watt

heater of just the right resistance and get 1000 watts of heat.

Perfect! But a jet trail goes by and the afternoon wears on so the

sun angle becomes oblique, and at the MPP voltage it can only put

out, say, 31.6% of maximum current. Our resistance heater is going

to drag the voltage down to 31.6% of MPP voltage. 31.6% amps times

31.6% voltage isn't 316 watts, it's 100. So our heater is only

putting out (purely by coincidence) 31.6% of what it should be

because of overloading the solar panel. The less the light, the

worse it gets. If the panels can only put out 10% of full current,

they will be dragged down to 10% of MPP voltage and the heat

output will be 1% instead of 10%, 10 watts instead of 100 - no

heat to speak of! (All very approximately, I'm sure.)

Now instead we make our heater from a diode bridge.

We make it similarly with just the right number of diodes so that

with 1000 watts MPP from the solar panels, there's 1000 watts of

heat coming out of the diodes. And maybe the diode junction

voltage at this level is, say, .8 volts. So if the panels were 36

volts MPP, that would mean there were 45 diodes, each dissipating

22.2 watts.

Now the sun drops and we're at that 31.6% current

level. The forward voltage drop of the diodes drops to .75 volts.

The solar panels' voltage output drops to (.75/.80*36=) 33.75

volts, (33.75/36 =) 93.75% of MPP voltage. The heat will be

(93.75%*31.6% =) 297 watts - almost the theoretical 316. At the

10% level the diodes might drop .7 volts each, making the figure

(87.5% volts * 10% amps =) 87.5 watts of the 100 watts theoreticly

available.

Or, by time of day according to Dave:

That's quite a difference. In fact, one might call it

a whole exciting new heating technology!

A More Typical Off Grid Heater Design?

Myself, I use the most heat at night and lots of

winter days on the PNW/BC coast aren't sunny, so connecting direct

to a solar panel isn't going to cut it. So I'd plug the heater(s)

into the 36 volt battery system wall outlets like everything else.

I had been trying to make a 'low voltage cutout circuit' mostly

for electric heaters, as dump loads or just to shut them off if

the battery got low. Now my idea instead is that if the battery is

delivering over 40.5 volts (max is 40.8) the heaters should run at

full power, but if it drops to 38.5 volts (~25-30% charge), the

heater(s) should be almost off, delivering just a few watts and

not draining the rest of the power. Maybe total shutoff by 38.0

volts? It would be completely automatic and virtually failure

proof.

Sidetrack on batteries

The exact figures and hence number of diodes do

of course depend on battery type. I am using LiFePO4. 12 cells '36

volts' herein -- generally sitting in the narrow no-load range of

38.4 to 40.8 volts. (Many people charge these at 42 volts, but

they will soon drop back to 40.8 when the charge is removed. I

charge at only 40.8 to make low stress and hopefully have them

last considerably longer. But then they rarely get right to 100%

charge - 90-95% at the end of the day is more usual. Then of

course the voltage will be lower at night depending on loads as

well as charge state. I looked for info on voltage versus battery

temperature, a concern with Li-Ion types, but was unable to find

any info. Dang! How did I get writing on about batteries when the

article is about diode heaters?)

Moving On...

[28th]

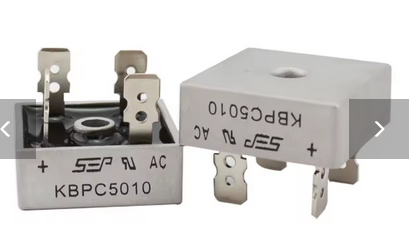

I

ordered sixty 50-amp bridge rectifiers. Each one has four diodes

which can be used in series-parallel between the "+" and "-"

terminals. So two diode drops per unit, and half the increase in

forward voltage with current because there are two sets in

parallel. 38.5 volts with .7 volts forward drop, where the diodes

start turning on, is 55 diodes or 27.5 bridge rectifiers. 40.5

volts over 27.5 bridges would be .736 volts, which will conduct a

lot more current than .70 . How much more remains to be seen. I'm

hoping to be able to tailor the specs to get, say, a 500 watt

heater that will taper off to nothing if the battery gets fairly

low, and never kill it.

[28th]

I

ordered sixty 50-amp bridge rectifiers. Each one has four diodes

which can be used in series-parallel between the "+" and "-"

terminals. So two diode drops per unit, and half the increase in

forward voltage with current because there are two sets in

parallel. 38.5 volts with .7 volts forward drop, where the diodes

start turning on, is 55 diodes or 27.5 bridge rectifiers. 40.5

volts over 27.5 bridges would be .736 volts, which will conduct a

lot more current than .70 . How much more remains to be seen. I'm

hoping to be able to tailor the specs to get, say, a 500 watt

heater that will taper off to nothing if the battery gets fairly

low, and never kill it.

500 watts/27 bridges = 18.5 watts per bridge. (a half

used bridge would be 9.25 W.) Of course they will need to be

mounted on metal - perhaps alume heatsinks. If it's a big enough

plate it can be convective heating. If not there'll have to be a

fan. A nice housing, a power switch, a tipover switch and a

thermostat would be assets. An extra diode bridge or two in the

series and a switch(es) to short them out could provide lower

power settings. Then I might be able to go for a heater capable of

700/400/200 watts, 700 being about the maximum for a 36 volt, 20

amp wall outlet circuit. Exact number of bridge diodes will be

subject to experimentation, of course. There are line voltage

losses, varying diode specs, etc. to consider.

I'd feel a lot better about running DC/solar/battery

electric heat if I knew it couldn't kill the battery if (sooner or

later) I forgot and left it/them turned on. Instead with the right

number of diodes they could make good "dump loads" for times of

excess power.

One might also consider making hot plates for food

and water heater elements made with these components. For the

cooker, the diodes could be heatsinked direct to an alume "burner"

plate. This would transfer the heat to the pot really well and it

might well be more efficient than an induction cooker.

For a water heater the diode elements might be

mounted directly on the side of the tank (especially if it was

copper), again with high efficiency and no need for holes in the

tank.

Sixty bridges is enough to try out two 36 volt heating

elements with a few to spare. The 60 were well under 100 $C.

But wait! There's More!

An interesting associated idea was that the heater

diodes could be used as voltage regulators in place of DC to DC

buck (reducing) converters. One could tap into the diode string at

any desired voltage point in .7 volt steps. As long as the device

being powered used less current than the diode heater was using,

some of the current would flow through the device being powered

instead of the diodes being bypassed, and the voltages would stay

almost the same. One could thus tap off 7 diodes to get (7 * .7 =)

around 5 volts to charge a USB charged device, or about 19 or 20

to charge a 12 volt battery; 17 to 20 to run a 12 volt LED light.

Almost a lab variable power supply, with no smarts or controls at

all! It would however be drawing current and heating the whole

time while in use. That's better in winter than in summer!

Later I looked it up. The diode heater idea wasn't

original with Dave.The earliest reference I found was a 2019

research paper: Hot Diodes!: Dirt cheap cooking and

electricity for the global poor? by six authors. It seemed

others started picking up on the idea about 2024. The original

authors had used cylindrical diodes. Later the improvement of

using power diode bridges with heat transfer cases had arisen.

[29th] Continuing on the theme, what about that 'hot plate' or

'stove burner'? One could bolt the diodes' cases to the bottom of

a round alume plate with flat head bolts. The top would be the

cooking surface. One would definitely need to attach a temperature

sensor or cutoff switch/thermostat and have the 'burner' shut off

below the maximum operating temperature of the diode bridges.

(pretty sure that's well over 100 degrees C. Otherwise you

couldn't boil water.) The pot or pan would of course sit on top of

the plate. Aluminum itself heats (and cools) fast, absorbing very

little of the heat energy itself. Most of the energy would

transfer right into the pot.

The bridges, KBPC5010's, are 28.8 mm square. A square

of 5 by 5 (25) bridges would thus be 144 by 144 mm. That would

require a round alume 'burner' size of at least eight inches (204

mm) diameter. We might need 27 or 28 bridges, but the 2 or 3

center rows could be offset to fit an extra bridge without needing

to increase the diameter.

Even in the absence of a "smart" timer control, if

the burner was left on at night it would put out less and less

heat until it virtually stopped when the battery got down to about

3/4 drained. For solar that's indescribably better than stopping

after the battery is totally dead! whether or not a "balance

charger" prevents critical battery damage. Same thing with space

or water heaters.

[30th] I thought to order a few thermostatic switches of 110, 115,

120, 130 & 135 degrees C for the hotplate. And maybe for a hot

water heater. (They were out of 125 degrees, which would have been

my first choice. But I didn't bother trying another store.) If 135

degrees isn't hot enough, the burner idea may be "out", since the

bridges are only rated to 150 degrees.

Open Loop Air Heat Pumping (OLAHP)

[27th] I (at long last) cut a second

thick paper gasket and put it on. Now the piston was loose instead

of binding. (Art paper was probably not an ideal gasket choice. Oh

well.)

I

fit

it together and did up the bolts. The piston was still loose, but

the clearance front to back was maybe .02 inches.

I

fit

it together and did up the bolts. The piston was still loose, but

the clearance front to back was maybe .02 inches.

I mounted it onto the motor. It ran,

but was stiff. It didn't seem to have enough air pressure at the

little pipe to push my finger aside. After running I found the

piston was seized. Not the motor shaft, the piston itself.

I mounted it onto the motor. It ran,

but was stiff. It didn't seem to have enough air pressure at the

little pipe to push my finger aside. After running I found the

piston was seized. Not the motor shaft, the piston itself.

[30th] I disassembled the

unit. I took it right off the motor with the piston still stuck. I

could pry it up anywhere and flex it a bit. It was stuck at just

one point. It finally popped off. It seemed a tiny bit of UHMW had

melted and glued the rotor to the cylinder. The pin holding the

vane was rubbing (I can see the groove) and must have melted it.

The pinned-in alume piece with a pin holding the vane are the

parts I have the least confidence in. There's no clearance to put

in something more robust. I'd be happy to come up with a better

mechanism.

"Faraday

Cabin" Construction

Wall, Electrical & Stairs

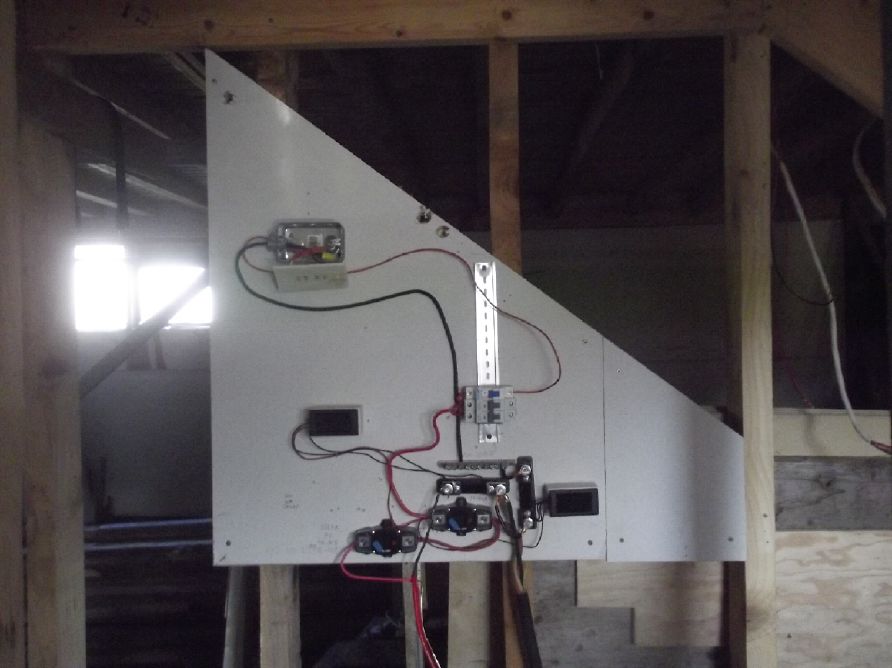

[15th, 16th] I decided I had placed the stairs to the bedroom

badly - that the bottom steps shouldn't stick out into the eastern

half of the building. I finally decided to "bite the bullet" and

move them over. To do that, I would have to "slide" them 3 feet

along the center wall they went up alongside. To do that I would

also have to move the 36V DC main electrical board by the same

amount. Then I would want to reverse the door because one would

almost be stepping on the top step instead of the landing coming

out of the bedroom. If the hinges were on the other side, it would

be safe coming out. It would be a nuisance, but still doable.

Luckily I had made the top landing 5 feet long and put the bedroom

door at the far end. If the door had been any farther east, the

whole idea would have been impractical.

First I slid the battery over 3 feet.

I had to pry the bottom plywood up and slip something under it,

and pull it in stages. Heavy! (135 pounds?) Then moving the wall

panel board involved unscrewing everything from it because I had

screwed the 3/4 inch plywood to the wall studs and then screwed

1/2 inch gyproc onto that for fire safety in case of sparks or hot

spots. The gypoc had to come off to get at the screws holding the

plywood. And of course the components were screwed through the

gyproc into the plywood. But I got it mostly done in a day. The

only thing that was left out was the overhead light and 3-way

switches for it. The wires from the far wall were too short.

[extension wires maretted on & working again, 30th] I set a

standing lamp on the landing at the top of the stairs for now.

Wires to a plug-in in the bedroom were also too short, but I cut

another short length of #12 AWG house wire and added it, again

joining them between studs with marettes. That particular stud is

under the stairs and will have nothing covering it so the join is

in open air and accessible, but I might want to put it into an

electrical box just to be "proper".

First I slid the battery over 3 feet.

I had to pry the bottom plywood up and slip something under it,

and pull it in stages. Heavy! (135 pounds?) Then moving the wall

panel board involved unscrewing everything from it because I had

screwed the 3/4 inch plywood to the wall studs and then screwed

1/2 inch gyproc onto that for fire safety in case of sparks or hot

spots. The gypoc had to come off to get at the screws holding the

plywood. And of course the components were screwed through the

gyproc into the plywood. But I got it mostly done in a day. The

only thing that was left out was the overhead light and 3-way

switches for it. The wires from the far wall were too short.

[extension wires maretted on & working again, 30th] I set a

standing lamp on the landing at the top of the stairs for now.

Wires to a plug-in in the bedroom were also too short, but I cut

another short length of #12 AWG house wire and added it, again

joining them between studs with marettes. That particular stud is

under the stairs and will have nothing covering it so the join is

in open air and accessible, but I might want to put it into an

electrical box just to be "proper".

[16th, 17th] Next I cut and put up two pieces of wallboard below

the upper wallboard (already up and painted) so that when the

stairs moved it would be behind them and I wouldn't have to cut

the paneling out around them. There were a couple of other pieces

I Should have put up but didn't. Oh well!

[18th]

After

a

bit more cutting and fitting of the paneling I took the screws out

and propped up the stairway with some boards. I pushed it along a

few inches at a time with a peevee and then moved the bottoms of

the boards along by lifting and repositioning them so they didn't

lean over more and more.

[18th]

After

a

bit more cutting and fitting of the paneling I took the screws out

and propped up the stairway with some boards. I pushed it along a

few inches at a time with a peevee and then moved the bottoms of

the boards along by lifting and repositioning them so they didn't

lean over more and more.

At some point I reversed the door so one would step

onto the landing away from that too-close first step. Great, now

the light switches were on the wrong side! Also the landing went

way past the door and needed to be cut shorter. (It sort of

intrudes on the space below, so should make it no longer than is

useful.)

[26th] The last 1/3 of November brought freezing weather. The

cabin got too cold to sleep in even with 1550 watts of heat on.

(two AC heaters at the far end of the bedroom 800W+500W plus a

36V, 250W heater running on solar/battery. Also the battery was

too low some nights to use the DC heater. And it was too cold to

work on it too.

More Electrosmog/Tinnitus Culprits

Yet again I feel compelled to write on this

pernicious topic. Electrosmog devices are so ubiquitous! Life was

easier when I just accepted that there was nothing I knew about to

do about the annoying tones perpetually in my ears. On the 14th I

had spent much of the day in the cabin. Presumably my tinnitus

should be less but it wasn't as much less as I had hoped. I went

to bed there expecting it would be much reduced by morning. At

2:30 AM I turned on the light for a moment to make sure I had

unplugged the "cookie tin" computer. I had. By 7:00 AM I started

thinking it seemed like something still had to be aggravating my

hearing. But what? Then I remembered I had brought out a cordless

phone in case I got any calls. It was in the window a few feet

from my bed - one place it would connect to the base in the house.

I thought cordless phones only transmitted to the

base when you pressed "talk"! But of course it is still a radio

receiver and a computer, in an unshielded plastic case. I opened

it and unplugged the battery. By 8:30 when I got up I thought I

felt slight relief, if only because I was listening for it. Half

an hour to make worse, many hours to reduce. I guess if I want a

phone in the cabin, I'll have to run a line from the house and use

a very old "electronics free" phone with a cord. The only one I

have has a pulse dial (and I don't suppose one can buy one any

more), so it'll pretty much be for receiving calls only, since so

many places want you to press a number(s) to get through to

someone.

That AC power lines induce voltages into the body and

cause tinnitus (thousands of AC volts on overhead poles and

120/240 volts in your house walls) is already less than obvious...

Beyond that, if it wasn't for the "Faraday Cabin", I'm sure I

would never have started connecting innocent looking little low

power devices like the DC to DC converters and cordless phones

with my tinnitus. There are just so many of them, all electricly

oscillating at various frequencies from 60 Hz to 100 KHz to 5 GHz.

I would have just "known" that "everlasting" tinnitus was

"incurable", like the lady from the clinic said last year, and as

had been my life-long experience (but for one trip camping in

1990) until I so recently got clued in. I have never got rid of

it, but I have reduced the volume, on rare occasions by quite a

lot. I still have to leave the cabin and do most of my living in

the house, shop and outdoors. If my place was maybe another 100

feet or more farther from the power lines, being out in the yard

wouldn't be such strong exposure. 200 or 300 feet from the power

lines would probably pretty much be quiet. Who lives that far from

power lines? And who doesn't have 120/240V AC running everywhere

through their walls, unshielded?

Something I'm noticing is that if there is no source

of electrosmog, if I'm in an electricly quiet environment, after

an hour or two some of the noise in my ears starts pulsating with

my pulse, stronger as my heart beats and weaker between. That

doesn't seem to happen if there's any notable electrosmog present.

(Another strong tone mostly in my left ear doesn't change so

easily. It only reduces in volume after many hours mostly in

electrical quiet. My left ear has more hearing damage, which seems

to be a key factor in susceptibility.) The pulsating is allowing

me to determine more quickly and certainly than before if the

environment is electricly quiet or not.

But wait, there's more!

When I moved the 36V electrical board, I went up a

ladder on the outside and shut off the solar charge controller.

Somehow there seemed to be electrosmog in the building again the

next night. What? Electricly I hadn't changed anything at all! It

was all wired just the same, mostly without undoing the

connections!

[18th] What it might be was that I had moved the cable from the

charger to the battery on the outside wall. It had never been

clamped down owing to a lack of suitable wire clamps. Now it was

hanging a bit away from the wall. This was the East side of the

building, the power lines side. Perhaps it was acting as an

antenna, picking up the field form the 14,400 volt AC power line

and bringing it into the long section of the cable inside the

building going to the electrical board and the battery?

I got the idea to shield the cable. I found a long

scrap of shaped alume flashing just right for the job for this

wall. I screwed it to the wall with the wires inside/behind. The

field from the power lines was so strong I could (since I was

listening for it) hear my tinnitus getting louder as I worked. I

hate going out that side of the building, and I'm glad for the

grounded metal roof, walls and doors, and the 2 inch mesh chicken

wire over the windows.

[18th] In the night the work proved to have had no discernible

effect. It was good to enclose the cables, but I had to look

elsewhere for the noise source. It occurred to me that one thing

had changed... a little. The electrical board was just that much

closer to my bed, so any noise from there would have just that

much more effect. Could the power monitors possibly be emitting

noise?!? I disconnected their "+" power wires and went back to

bed, but in a couple of hours I wasn't convinced. The only thing

that really made the cabin (electricly) quiet again was shutting

off both main breakers to the battery - charge and load, 50 and

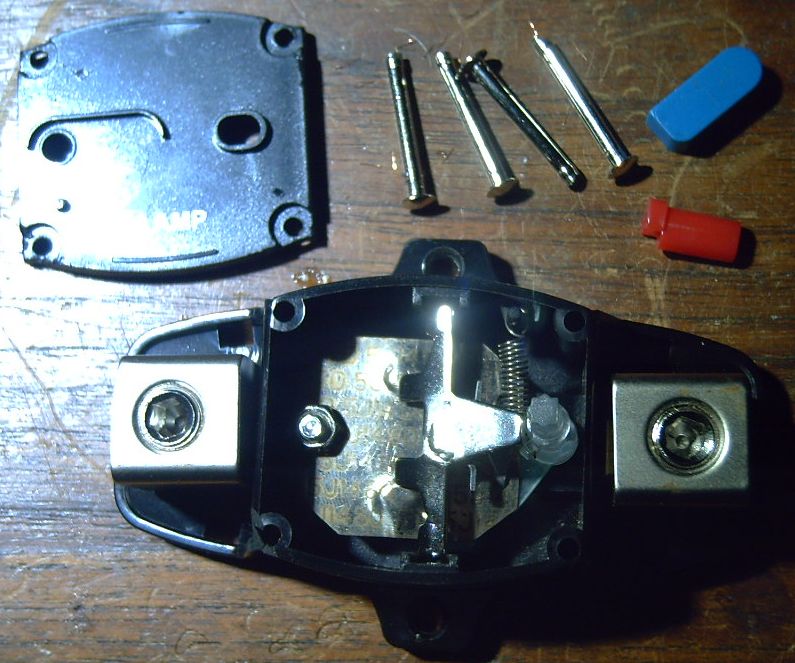

100 amps.

What

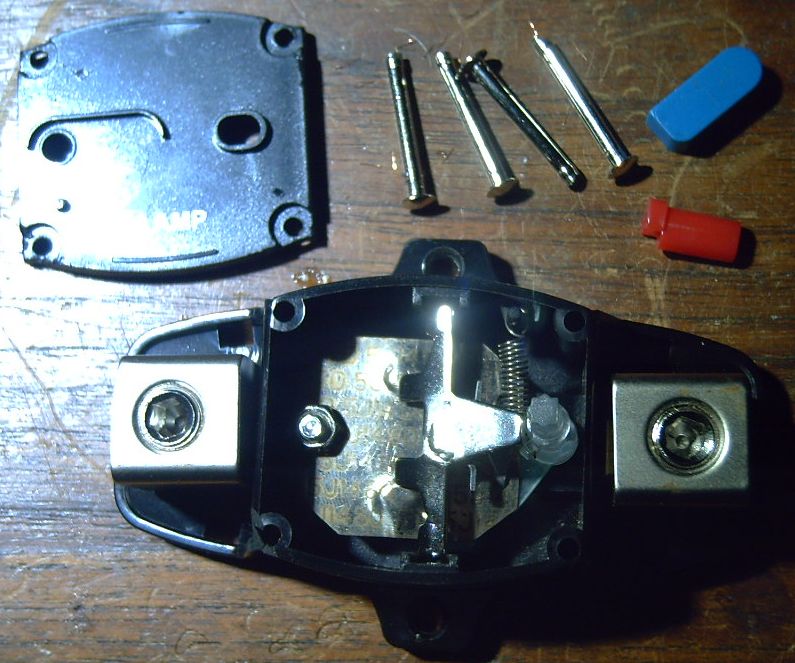

about

the breakers themselves? They were the "industrial", seemingly

high quality DC surface mount breakers I had found and bought not

so long before I heard of DIN rail breakers. In the morning [19th]

I changed them both for two of the older "audio system" DC surface

mount breakers. (I'm so glad for working with electricly safe 36

volts instead of a higher voltage where all sorts of additional

precautions are required! No shocks from touching the power

wires.) I drilled out the rivets and took one of the suspect

breakers apart. In spite of the strong "snap" and solid feel when

opening or closing, and in spite of the high current ratings, the

contacts appeared to be just part of the metal switch, chrome or

stainless or something, rather than the usual welded-on nickel or

gold plated contact points. Perhaps they really did make noisy

electrical contact? The "audio" breakers had gold plated contacts.

(at least for the wires - I've never opened one to see

inside.) Overnight with new breakers might tell. Unless it's

the power monitors. Beyond that, my imagination really runs out of

ideas, however seemingly unlikely. [Yes, it did seem to be those

breakers! My tinnitus was again quieter overnights.]

What

about

the breakers themselves? They were the "industrial", seemingly

high quality DC surface mount breakers I had found and bought not

so long before I heard of DIN rail breakers. In the morning [19th]

I changed them both for two of the older "audio system" DC surface

mount breakers. (I'm so glad for working with electricly safe 36

volts instead of a higher voltage where all sorts of additional

precautions are required! No shocks from touching the power

wires.) I drilled out the rivets and took one of the suspect

breakers apart. In spite of the strong "snap" and solid feel when

opening or closing, and in spite of the high current ratings, the

contacts appeared to be just part of the metal switch, chrome or

stainless or something, rather than the usual welded-on nickel or

gold plated contact points. Perhaps they really did make noisy

electrical contact? The "audio" breakers had gold plated contacts.

(at least for the wires - I've never opened one to see

inside.) Overnight with new breakers might tell. Unless it's

the power monitors. Beyond that, my imagination really runs out of

ideas, however seemingly unlikely. [Yes, it did seem to be those

breakers! My tinnitus was again quieter overnights.]

I should note that all this is much less noise than

there is outside the cabin. But tinnitus causing noise

nonetheless.

Since I moved here, the bedroom always seemed to be

the worst place. Indeed it's where I was first looking around for

ultrasonic irritants that might be plugged in even before I

realized the main culprit was the AC electricity itself. Now when

it's too cold I have slept in the house. And I've been shutting

off the breakers to the bedroom and to shop. Once I left the shop

on. In a couple of hours my ears were ringing much worse - just

like "old times"! That definitely was a big source. Why? I'm

pretty sure it's not just wires, but the controls for the well

pump, which are in the crawlspace right underneath the bedroom and

fed from the shop subpanel. I don't know why they should be noisy,

but it has some suspect contact points between the lid and the

box. I should go down and have a look at it. Or just put in the

"24 volt" well pump I bought.

Haida Gwaii Gardening

(No Report)

Having thought about the

organic "+"trode mix, I wondered if it would cohere or swell if

placed in a cell and used. If it swelled, it would need a tight

electrode container to hold it compacted. If it stayed crunched

down, and since the zinc electrode had no pressure, flat plate

cells could easily be assembled. It needed an experiment to find

out.

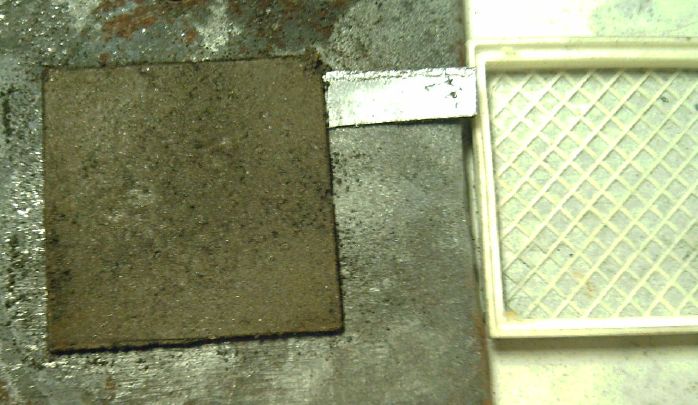

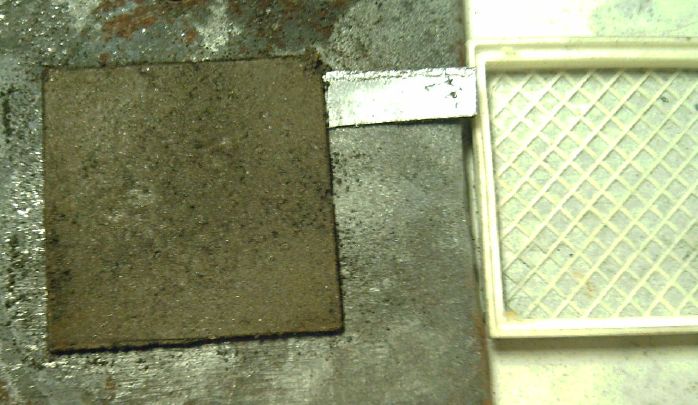

[18th] I put a graphite foil 'plate' with a tab

and some of the grit into the 50x50mm flat electrode compactor and

just used a hammer to crunch it down. I didn't weigh it or

anything. It looked great. Maybe a bit thin. The resistance was

still megohms. Still worth trying.

[18th] I put a graphite foil 'plate' with a tab

and some of the grit into the 50x50mm flat electrode compactor and

just used a hammer to crunch it down. I didn't weigh it or

anything. It looked great. Maybe a bit thin. The resistance was

still megohms. Still worth trying.

I sized it up against one of the flat stacking trays

I had made some time ago. For some reason it was a bit smaller

than 50x50mm inside. That would munch the piece all up. Maybe they

shrank? I would have to print some new ones, a little bigger.. I

had noted the 3D printed PVB seemed to gradually deteriorate in

cells, so I would try printing new ones in ABS. So the next job

was 3D printing. But new thoughts entered my mind.

[21st] As I see it there are two main mechanical problems: (a)

holding electrodes compacted and (b) ensuring there are NO leaks

bypassing the separator sheet. Any tiny gap anywhere will mean

dissolved ions crossing electrodes and the rapid deterioration of

the cell. Traditional metal cylindrical cells, or my cylindrical

separate 'porous' plastic electrodes, are great to hold materials

compacted. (So much for my new flat electrode!) But here Any

separator leaks will eventually destroy the cell, even with there

being two separators between "+" and "-" with my porous cylinders.

This is much more exacting than simply preventing solid,

non-soluble plates from touching each other with any suitable

porous separator sheet, as is common in most traditional battery

constructions.

If copper, with its similar soluble states to the

zinc (zincate... cuprate), is the "+" active material (whether in

an organic matrix or not) it seems evident that it must need the

same separator sheet treatments: soaking with toluene, saturation

with SDBS* and the osmium doped surface 'film'. So why have two

separator sheets? Probably just one sheet with both surfaces

'filmed' should be simplest and best. After all, the hardest thing

to make is the thrice treated separator paper. That says that

pairs of individual separated electrodes with two papers should be

"out".

But... what about One porous cylinder, with the

'trodes being inside and outside? There's a similar early cell

configuration that used a porous clay pot. A plastic cylinder is

lightweight and takes up relatively little space.

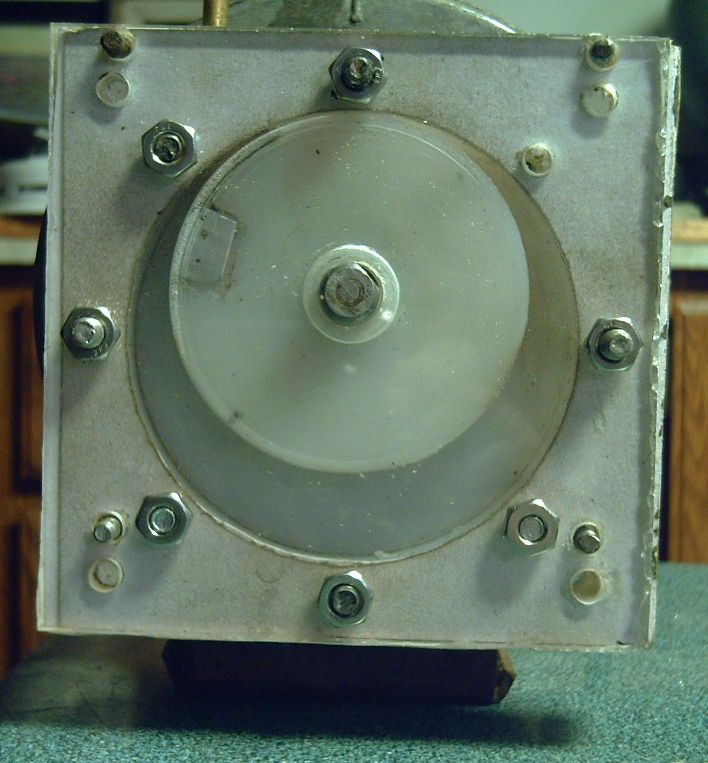

New Cell Design

A construction now suggests itself to me: just One

carbon rod center, the organic copper substance, and an outer

paper sleeve treated on both sides, all held inside a 3D printed

ABS 'porous' cylinder 'basket', as the center of a cylindrical

battery. ...the same as just one electrode of my separate

electrode cells. It could work whether or not the "+" substance

has to be held tightly compacted, although as I've discovered, it

will certainly be easier to assemble the electrode if it doesn't.

It's the surest form in which to ensure the paper will have no

gaps, with the porous plastic cylinder having a solid bottom and a

solid segment going a bit up the side from the bottom, and similar

at the top, so there could be no gap at the top and bottom edges

of the simple cylinder sleeve of paper inside that. (Of course the

paper overlaps itself at the seam, and is held to the outside by

the electrode substance.) Of course there's a hole in the top

center for the carbon/graphite rod to make external connections.

If the "porous" cylinder should have to hold the

material strongly compacted to keep it from swelling, it seems to

me now that it would be better to beef up the 3D printed design as

far as required, rather than to be drilling holes in thick walled

PVC pipes with the CNC router table.

Then the cell would have a solid plastic outer tube

(PVC?), with end caps glued top and bottom. (or might I hope to

find tall, thin ABS or PVC jars ready made? Ha ha!) The outer

section is the zinc side. The material in the zinc side is always

loose - no compaction.

Then, one could simply wind a copper wire in a coarse

helix ("spring" shape) fitting around the outside of the tube, and

a tiny top hole for that to connect to the outside. On discharge,

the zinc dissolves from the wire to form dissolved zincate ions,

becoming a "supersaturated" solution, which apparently can stay in

that form forever, with the osmium catalyst preventing it from

ever turning into zinc oxide at the separator sheet. On

recharging, the zinc electroplates onto the wire and then onto

itself as the wire is coated, and we don't care whether it forms

dendrites or clumps or loose, fuzzy plating because all is fully

contained within the electrode.

One could use a nickel oxyhydroxide, or

nickel-manganese oxides, plus side, but neither of those forms

move a lot of electrons per molecule compared to the promise of

copper with valences ranging from 0 to +3, plus whatever more

oxidation-reduction the organic materials might be capable of.

(Nickel hydroxide/oxyhydroxide has been tweaked to move about 1.5

electrons per nickel atom, and nickel-manganese oxides might give

2. Copper would be 3 and with a dissolved ion state, it is likely

to be more fully utilized.)

The zinc has most of the energy. The least plus

'trode material mass that balances the most zinc mass provides the

highest energy density.

Volta's original "electric pile" battery was copper-zinc.

Attempts to make copper-zinc or either one rechargeable foundered

on the soluble ions, which migrated between electrodes, messing

everything up. (Strangely, I guess no one ever tried soaking a

thick watercolor paper in toluene and then impregnating it with

Sunlight dishsoap and then painting the surfaces with a film of

osmium doped acetaldehyde for a separator paper.)

[23rd] In OpenSCAD I designed a porous 'trode shell with more open

hole coverage around the outside, on the assumption that it

wouldn't have to take a lot of pressure. I sized the height to fit

inside a small ABS ointment jar. And I did a lid to glue to and

close off the top of the trode once filled, and then to also cover

the whole jar. It had a central hole for a 5/16" (8mm) carbon rod

and one for a #14 solid copper wire (overkill for the zinc side)

near the rim. The jar is about the size of a "D" cell.

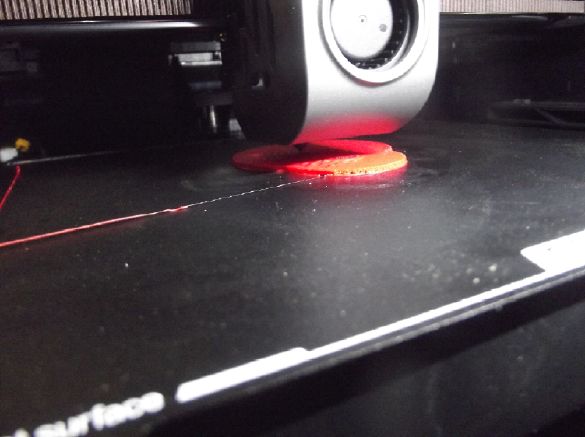

I set the "slicer" to make "fat" .4mm layers, which

seemed to be the key to make ABS printing work without a heated

enclosure - it worked on my old "RepRapPro" and it's the only way

I've ever successfully printed ABS.

I tried to print it in ABS in the Creality K1C

printer with the passively heated enclosure, but the filament just

wouldn't stick to the bed at all. I think this is the first time

I've tried ABS in that printer. I had high hopes but was

disappointed to not even get it started. After a couple of tries I

thought, wait, I've been here before! 3D printer filament just

doesn't work unless it's completely dry. The little alcove where

it was stored was pretty cool - it had probably absorbed some

moisture. I set a couple of pieces of wood on a grill on the

woodstove and the filament spool on that.

Suddenly "into" 3D printing but stalled for a day on

printing the trode, I've been meaning for some time to print a

couple more nylon T50 high current 36V socket shells for wall

plates. The nylon filament was still loaded into the AnyCubic I3

Mega printer. So I started the print. It got over 80% finished but

a corner had curled up a bit and when the extruder touched that it

knocked the print loose. I tried again and it didn't get half as

far. Oh, wait. That printer with the nylon filament was in the

same rather cold alcove. I pulled the nylon filament out of the

printer and set the spool on top of the other one on the

woodstove. Maybe tomorrow! I also brought in from the shipping

container about ten remaining spools I had bought in when I was in

Victoria, and left out there in the cold and damp all this time.

"Tomorrow" I decided it hadn't been long enough, and left the

spools on the stove another day.

[25th]

I told the slicer to print a "raft" rather than my usual "skirt",

hoping to make sure the edges didn't lift. That seemed to work,

but the printer spent almost 20 minutes printing a huge four layer

"raft" - about half of the total print time. And it didn't print

the bottom of the actual print on the glass as I had expected,

with the "raft" around it. Instead it put my print on top

of the "raft".

[25th]

I told the slicer to print a "raft" rather than my usual "skirt",

hoping to make sure the edges didn't lift. That seemed to work,

but the printer spent almost 20 minutes printing a huge four layer

"raft" - about half of the total print time. And it didn't print

the bottom of the actual print on the glass as I had expected,

with the "raft" around it. Instead it put my print on top

of the "raft".

Then I had to extract the print from this substantial base with

tinsnips and a diagonal cutter. The cylinder didn't fit in the jar

by the 1.6 mm extra height. Most of the holes in it were good, but

at the left and right were so many gaps I was sure it would just

burst open when I tried to fill it. And the holes for the

terminals didn't go through the "raft" - apparently I was expected

to drill them out. I didn't think that was the idea of 3D

printing! Apparently I could also have selected "brim". Maybe I'll

try that sometime.

Then I had to extract the print from this substantial base with

tinsnips and a diagonal cutter. The cylinder didn't fit in the jar

by the 1.6 mm extra height. Most of the holes in it were good, but

at the left and right were so many gaps I was sure it would just

burst open when I tried to fill it. And the holes for the

terminals didn't go through the "raft" - apparently I was expected

to drill them out. I didn't think that was the idea of 3D

printing! Apparently I could also have selected "brim". Maybe I'll

try that sometime.

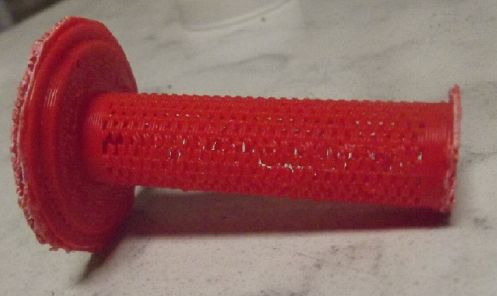

Anyway, success printing with ABS for the first time

in years!

So:

modified

design. I made the perforations 1.2 x .8 mm instead of .8 x 1.2 mm

to have more (at least, some!) plastic between holes. That's 3

layers tall instead of 2, and narrower. And I decided to manually

do my own version of a "raft" - smaller and thinner - that

wouldn't make a mess of everything and double the printing time.

It printed fine and seemed stronger. I adjusted some dimensions in

the lid. I fitted the terminals/current collectors.

So:

modified

design. I made the perforations 1.2 x .8 mm instead of .8 x 1.2 mm

to have more (at least, some!) plastic between holes. That's 3

layers tall instead of 2, and narrower. And I decided to manually

do my own version of a "raft" - smaller and thinner - that

wouldn't make a mess of everything and double the printing time.

It printed fine and seemed stronger. I adjusted some dimensions in

the lid. I fitted the terminals/current collectors.

The

8

mm O.D. carbon rod took up much of the space in the 12 mm I.D.

'porous' cylinder. With the separator paper, the thickness of the

electrode would be less than 2 mm. Thinner electrodes are better

for conductivity.

The

8

mm O.D. carbon rod took up much of the space in the 12 mm I.D.

'porous' cylinder. With the separator paper, the thickness of the

electrode would be less than 2 mm. Thinner electrodes are better

for conductivity.

It hardly mattered where the copper wire ran.

Wherever it was the zinc would plate onto it (providing it made

initial connection), and there was oodles of room in the jar. In

fact, I could have fit in three of these "+" cylinders - with

three carbon rods - and just added more zinc around them to triple

the capacity without increasing the cell size. But I just wanted

it to hopefully work, without making extra parts.

I got out a small already toluene treated watercolor

paper and cut it down further to fit. Then I soaked it in SDBS*

solution for ten+ minutes and set it to dry. Then I hit a slight

snag. I couldn't find the new osmium powder I bought a couple of

years ago. And I couldn't remember what the vial looked like.

Finally I looked at an unopened shipping box that I thought was

something else, but I saw that I had scratched "Os" on it. No

wonder I couldn't remember the vial!

Still waiting for the paper to dry... I thought, as

usual, the way to crunch down or compact powder in the tube was to

have a pipe that fit over the carbon rod, without being big enough

on the outside to touch the fragile paper. I could press it, pound

it on top, or twist it back and forth. Also the bottom needed to

stay centered in the tube to prevent damaging the paper. I thought

to 3D print an indent in the bottom to hold the rod centered. (So

much for tapering the rod.) As usual, as I've tried so many times,

I couldn't find a pipe that would fit nicely. Those that fit over

the rod were too big on the outside. This time I was determined. A

so-called 1/4 inch copper pipe almost fit over the 5/16" rod, and

was if anything too small on the outside - good for staying clear

of the paper. I got out a 5/16" drill bit and worked it through.

The carbon rod still wouldn't go in. I found a nail slightly

larger. I inserted it a little way and started pounding the

outside of the pipe against the nail with the nail on a flat

anvil. This starts expanding the pipe. Then the nail will go in a

bit farther. I worked on it I'm sure for over half an hour before

the nail went all the way through. When it finally did, so did the

rod.

Later I printed the revised version. It came out

well. (Simultaneously printing the T50 socket in nylon

("Novamide") on the other 3D printer didn't - it would print a few

layers and then the corners would lift off the glass bed. I can't

seem to get the glass bed even looking clean. I think the nylon

filament doesn't dissolve or weaken in acetone. [Later I got it to

work using the "glue stick" for the other printer on the glass.])

In the first versions the lid had clicked solidly

onto the cylinder - even with some difficulty to get all the way

on, straight. Too solidly - when I tried to separate the second

one, the lid ripped the top two layers off the cylinder. So I had

left the slot a little wider on the last one. I discovered looser

wasn't necessarily better. On the first ones, the top and cylinder

wouldn't even need to be glued together. That would certainly be

simpler. So I put it back just .1 mm radius looser than the

original instead of .4 mm. Hopefully that will be perfect. If not

I'll put even the .1 mm back and hope I don't have to pull the top

& cylinder apart. Certainly if one is making cells, one

doesn't want to have to anyway!

I also looked at the design, with it's "platform" on

the bottom to prevent it from coming off the bed. I had the

thought that I could make that base solid and then print an

outside wall for the cell. It would be about the size of a "C"

cell with the same capacity as before, since it's the inside

electrode that limits it. If only 3D prints weren't so prone to

leaking! I don't think I'll bother trying.

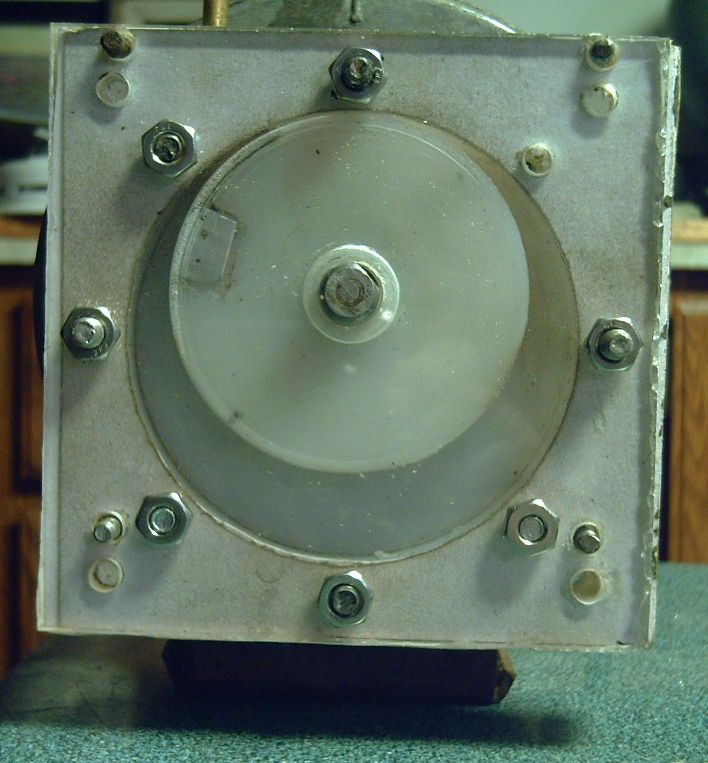

Newer New Cell Design

[26th] It occurred to me there was another

possible cell configuration: with the zinc mix on the inside and

the organic copper substance outside. One could put the thin

coppery layer outside by wrapping a thin sheet of graphite gasket

material just inside the outer cell wall for it to connect to.

Some fatter, stiffer piece of graphite would have to be placed

touching that for a terminal post. Having the zinc on the inside

would be similar to typical alkaline dry cells. I think it would

have the advantage: the outside diameter outside the porous wall

would be somewhat greater, allowing more copper in a thinner sheet

to surround the zinc.

[26th] It occurred to me there was another

possible cell configuration: with the zinc mix on the inside and

the organic copper substance outside. One could put the thin

coppery layer outside by wrapping a thin sheet of graphite gasket

material just inside the outer cell wall for it to connect to.

Some fatter, stiffer piece of graphite would have to be placed

touching that for a terminal post. Having the zinc on the inside

would be similar to typical alkaline dry cells. I think it would

have the advantage: the outside diameter outside the porous wall

would be somewhat greater, allowing more copper in a thinner sheet

to surround the zinc.

The zinc 'trode doesn't have to be thin. In fact, the

porous wall could be made even a large diameter to allow more

copper, placing just enough zinc inside to balance it with the

center otherwise empty - just filled with water or with a hollow

or other lightweight center filler.

With the copper inside, only making the cell taller

increases its capacity. The carbon rod determines the inner

electrode cross section, since the copper substance needs to be

only a thin layer around it. Having it outside would allow "any"

diameter cells, since the copper substance could still be thin a

thin layer for good conductivity, but now around the whole outside

edge. Energy storage and current capacity of a cell could be much

greater.

Making the cell might be facilitated by

(a) putting the conductive graphite gasket inside the outer rim.

(Hmm, a gold plated metal outside case might work too!)

(b) inserting a cylindrical metal spacer into the cell, smaller

than the rim by the thickness of organic copper substance desired

(c) putting in the substance and crunching it down with a "pipe"

between the graphite and the cylinder.

(d) extract the cylinder (with the pipe held in place to help hold

the copper stuff "wall" in?)

(e) insert the porous basket (same size as the metal cylinder)

with the paper and the zinc on the inside.

The carefully treated separator paper is never

subjected to the stress of having the copper crunched down in

contact with it. The graphite gasket is, but hopefully it's

stronger and anyway it can survive some scratching. Neither is the

basket stressed very much - only at the outside when inserting it.

Even in the little ointment jar it would have a lot more substance

for energy storage. Its chief drawback would seem to be wasted

volume in the middle, probably to be filled with

water/electrolyte. But for cheap stationary storage where weight

and volume aren't critical the above "copper outside" layout seems

like a good bet for production.

Suddenly I like this even more -- even for the

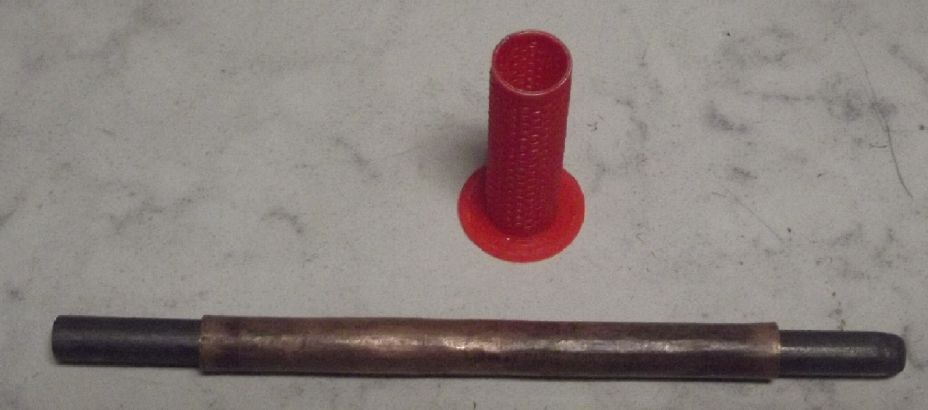

prototype! What have I got for a cylinder and a pipe to fit the

ointment jar? I found a stainless steel pipe that seemed about

right for a cylinder. (It doesn't have to be solid.) Then I

discovered that a 1 inch copper pipe was pretty much a perfect

telescoping tube around that.

Amazing! With that piece of "luck" I was convinced to

start over.

I

cut

the pipes to what I hoped were suitable lengths. I cut a piece of

graphite and put it around the rim of the jar. I put the stainless

pipe in. Then I fed in some bits of powder around the edge with a

tiny spoon. Then I tamped it with the copper pipe. I couldn't get

much pressure with the copper pipe, since I could only touch it

around the edges and it went most of the way into the jar. I took

it out and soldered a couple of "handles" onto the copper to press

down on. That seemed much better. The stainless pipe should have

been an inch longer. The copper pipe came right to the top of it

when pulling it out so it was hard to hold it in place in the cell

when taking the copper pipe off to add more powder. (The leftover

piece was shorter and bent on the end. Finding more the same would

probably be hard.)

I

cut

the pipes to what I hoped were suitable lengths. I cut a piece of

graphite and put it around the rim of the jar. I put the stainless

pipe in. Then I fed in some bits of powder around the edge with a

tiny spoon. Then I tamped it with the copper pipe. I couldn't get

much pressure with the copper pipe, since I could only touch it

around the edges and it went most of the way into the jar. I took

it out and soldered a couple of "handles" onto the copper to press

down on. That seemed much better. The stainless pipe should have

been an inch longer. The copper pipe came right to the top of it

when pulling it out so it was hard to hold it in place in the cell

when taking the copper pipe off to add more powder. (The leftover

piece was shorter and bent on the end. Finding more the same would

probably be hard.)

Jar + graphite sheet: 10.5 grams

add organic mix: 21.6 grams (so 11.1 g of electrode mix)

While

I

was waiting for the propane to warm up for that, I changed the 3D

print design. The changes were mostly to dimensions - a fatter tub

- so it was pretty simple. I printed one. The top fit about right.

The "skirt" around the outside at the bottom that I put on to make

sure the print didn't come loose while printing had to be cut off

and made flush. The scissor blade rode up and cut into the side.

Then when I was filing around the bottom it broke off. Ug! I glued

it together again with methylene chloride and a couple of the

scrap pieces.

While

I

was waiting for the propane to warm up for that, I changed the 3D

print design. The changes were mostly to dimensions - a fatter tub

- so it was pretty simple. I printed one. The top fit about right.

The "skirt" around the outside at the bottom that I put on to make

sure the print didn't come loose while printing had to be cut off

and made flush. The scissor blade rode up and cut into the side.

Then when I was filing around the bottom it broke off. Ug! I glued

it together again with methylene chloride and a couple of the

scrap pieces.

The

basket

seemed to go into the filled jar just about right - I was feeling

just a little resistance shoving it down. When I pulled it out it

broke up the mix crunched into the outer rim beside the graphite

sheet. If it hadn't, the basket might be said to have been too

loose a fit. Normally of course the zinc basket will never be

pulled out again. I just put it in for the 'fit' test.

The

basket

seemed to go into the filled jar just about right - I was feeling

just a little resistance shoving it down. When I pulled it out it

broke up the mix crunched into the outer rim beside the graphite

sheet. If it hadn't, the basket might be said to have been too

loose a fit. Normally of course the zinc basket will never be

pulled out again. I just put it in for the 'fit' test.

A major redesign - some great improvements and

several things proven to work nicely. A good day!

---

* SDBS: again, sigh... sodium

dodecylbenzenesulfonate. Soapy stuff. Zincate and cuprate ions

won't penetrate this.

[27th] I cut some pieces of watercolor paper to size (46 x 70 mm),

then soaked them in toluene and dried them, twice.

My bottle of SDBS had finally run out. It took quite

a few flushings to rinse out the suds from the bottle. I looked in

back issues of TE News to see what proportions I had used.

Evidently I hadn't recorded it. If memory serves it was about a

rounded teaspoon of SDBS in a drink bottle. This time I measured

the teaspoon, 5.5 grams, and the pure water to fill the bottle,

200 cc. Then I painted the watercolor papers, thoroughly soaked,

both sides, and set them above the woodstove again. (Previously I

had poured the bottle into a shallow container and left papers in

that to soak it up for ten minutes. This time somehow I hadn't

thought of that. Hmm... is there a difference?

When they were dry, I got out the new vial of osmium

powder. The old one from Alfa Aser (2008?) was narrow enough to

pour straight into a small test tube. The new one was too fat. I

didn't want to loose a bit of powder in a funnel each time - that

gram of powder was 2 or 3 hundred dollars. So I used a funnel to

pour it into the old vial. Then I poured some acetaldehyde from

its bottle into the new vial, put the lid on and shook it to get

the remnant. I poured that through the funnel into the test tube,

picking up remnant from the funnel. The slightly dark color in the

tube said that was enough osmium. I painted a paper with this,

both sides. This is supposed to be a surface layer, a film, but

certainly a lot of it soaked into the paper. This time I didn't

want to heat it, so I left it on the counter to dry.

Then I curled it around a tube and

put it into the electrode cylinder. I added 5 grams of zinc and a

trace of zircon. I pushed a #14 solid wire in through the cap into

the recess in the bottom. Then I glued the cap on.

Then I curled it around a tube and

put it into the electrode cylinder. I added 5 grams of zinc and a

trace of zircon. I pushed a #14 solid wire in through the cap into

the recess in the bottom. Then I glued the cap on.

(Something that has been bothering me... I can add the

zirconium silicate powder to the zinc powder as a hydrogen

overvoltage raising additive, but I don't know how it'll stay

mixed in as the zinc dissolves and replates. ...I won't worry

about it for now.)

I

inserted

the cylinder into the cell. Again it seemed to be just rubbing on

the organic copper mix all around it a bit. In the lid I had

printed a 12 mm wide slot for the "plus" terminal. I stuck a piece

of metal into the slot to push some mix away, then a piece of

graphite foil. It seemed loose. I added a second and a third

piece, making it thicker. That seemed good enough. Then I squirted

in 10 cc of electrolyte.

I

inserted

the cylinder into the cell. Again it seemed to be just rubbing on

the organic copper mix all around it a bit. In the lid I had

printed a 12 mm wide slot for the "plus" terminal. I stuck a piece

of metal into the slot to push some mix away, then a piece of

graphite foil. It seemed loose. I added a second and a third

piece, making it thicker. That seemed good enough. Then I squirted

in 10 cc of electrolyte.

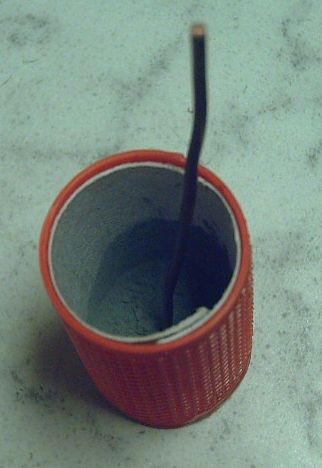

The cell started off saying ~.5 V, but it dropped

gradually. I considered that the loose zinc powder probably wasn't

making a very good connection with the wire. It needed some of it

to be discharged to Zn(OH)4-- and recharged

to plate onto the wire and gradually connect all the pieces

together. (In this cell, for this purpose, lumpy plating and

dendrites become advantages instead of problems!) But if it was

already fully charged to metallic state, and the plus was

(obviously) fully discharged, how was any to be discharged to

begin the process?

I shorted out the cell through the 300 mA current

plug on the multimeter (which is really around 5 ohms, not a

short). It started out at 1.2 mA and soon was down to .6 . Then

the meter complained that its battery was low. So I took

it off and put in a charged battery (9V NiMH). When I came back,

it read .00 or .01 mA. But it gradually came back to over 1 mA. By

bedtime it was .9 mA and in the morning it was still .7 mA.

Nothing fast here, but it should be making at least a few

zincate ions to use for starting to properly charge the zinc into

solid connections.

In a way I was sorry to have glued the top on the

electrode cylinder. That meant I couldn't take the top off the

cell without pulling out the zinc'trode, which would rip up the

'plus' substance. I could possibly stick a pH paper into the slot

with the graphite foil electrode. I couldn't check the electrolyte

level. OTOH, presumably no zinc ions could seep over the rim and

get out of the cylinder!

[28th] 'Short circuit' current went for .7 mA to .4 . I decided to

keep it going.

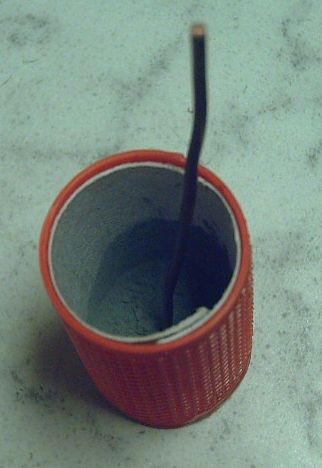

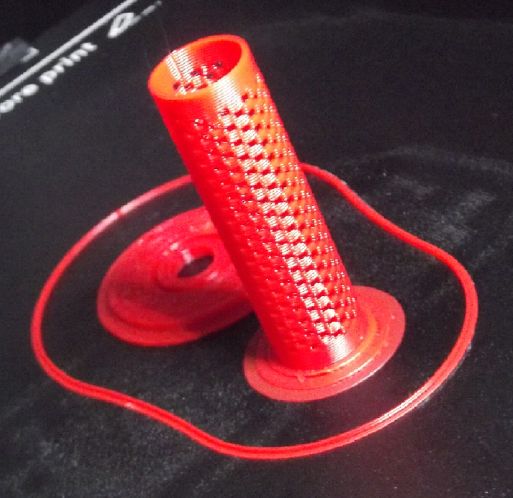

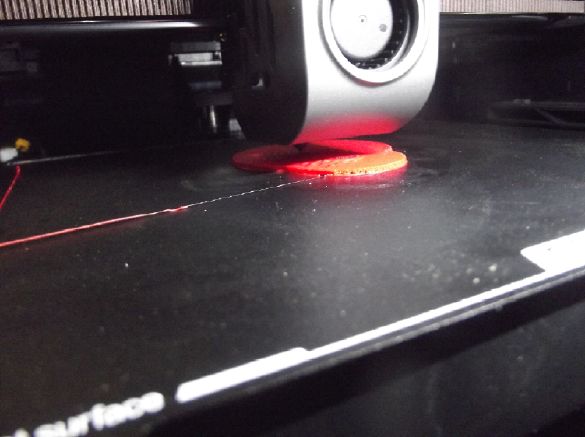

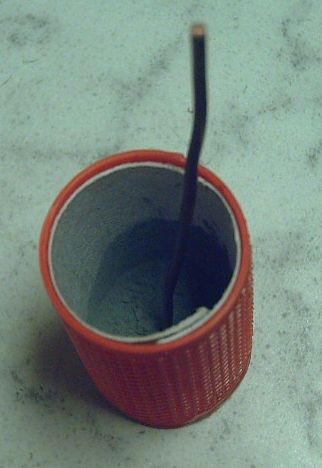

[29th]

Current

was down to .10 mA in the morning, but later rose to .22 mA and

stayed there until evening. I disconnected it in the evening. The

test leed wires almost dragged the cell off the counter. This has

happened before and I'd had enough of it. I took an ugly block of

wood and drilled a hole in it to fit the cell into.

[29th]

Current

was down to .10 mA in the morning, but later rose to .22 mA and

stayed there until evening. I disconnected it in the evening. The

test leed wires almost dragged the cell off the counter. This has

happened before and I'd had enough of it. I took an ugly block of

wood and drilled a hole in it to fit the cell into.

Soon I moved it more safely toward the back of the

counter. At least it's a lot heavier than the wires and they'd

have to drag it a fair ways.

[30th] Voltage rose by itself to almost 1/2 a volt. I put a very

slow charge on around 9 AM, which soon tapered to about 1.0 mA

with a voltage reading of 1.146. Why push it?

I couldn't pull the cell open without destroying it

anyway, so I glued the top onto the jar. I printed another

electrode cylinder basket to have an unfilled cell that I could

show.

[Dec 1st] I raised the voltage to ~1.5V. It stayed up there

drawing half a milliamp. It would drive a 100 ohm load at over 1.2

volts momentarily, but it faded fast. Next time I'll time its drop

to 1.00V. So far it doesn't seem like much of a battery.

Electricity

Generation

New Grid-Tied Solar Power System

Well, mea culpa. By the time the solar panels