Turquoise Energy News #211

Covering

Research & Development Activities & Projects of

December 2025

(Posted January 7th 2026)

Lawnhill BC Canada - by Craig Carmichael

[Subscribe: email to

CraigXC at Post dot com ; request subscription]

Main URL TurquoiseEnergy.com Also at craigcarmichael.substack.com

Month

In "Brief" (Project Summaries etc.)

* Solar Power - Solid State Electric Heater - Everlasting

Cheap Battery Developments--Great New Cell Design, working battery

cell - OLAHP: Why It's Better, & Better Indoor-Outdoor Air

Heat Exchanger

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* Supplement for High Blood Pressure - Other Supplements -

Scattered Thots - New: Electrosmog Department - ESD

- Detailed

Project Reports -

Electric Transport - Electric Hubcap Motor

Systems - no report (will I ever find time to

finish the next motor?)

Other "Green" &

Electric Equipment Projects

* A New Tech ! Solid State Resistance Heating Elements

made With Power Diodes (advantages over resistance wire)

* Open Loop Air Heat Pumping - New Indoor-Outdoor Air Heat

Exchanger

* Faraday Cabin Construction

New Battery R & D (back in the

news!)

* Organic Copper/Monel Crush Experiment - Promising new

cylindrical cell design - Newer New Cell Design - Organic monel-Zn

cell - Ni-Zn Cell - Ni-Zn cell #2, many tests run, good

performance - Improvements for next cell

Electricity

Generation

* New Grid Tied System - Now In Operation!

* All Systems - The usual Latest Daily/Monthly Solar Production

log et cetera - Monthly/Annual Summaries, Estimates, Notes

December in Brief

New Battery Cell Design:

New Battery Cell Design:

"+" electrode outside, zinc/zincate "-" in inner basket

If some of my more

recent reports have seemed to lack much meat in the energy

projects direction, here's a change! I spent much of my time

working on things including everlasting batteries, a solid state

diode space heater, a new indoor-outdoor heat exchanger for OLAHP,

and a couple of things for the Faraday cabin.

And somehow at the start of the month I wrote up

about a bunch of supplements that some may find helpful. Mostly

ones I take. These are commonly available dietary supplements for

various purposes, not medications. I'm not a health professional.

(See "In Passing".) Before the month ended I'd forgotten all about

writing about those!

On my 71st birthday, January first, I could see I was

in for a good week of adding and editing before this report would

be ready to post with most of the mistakes and omissions rooted

out!

Solar Power

On the 4th I got an email from BC

Hydro authorizing me to turn on the new grid-tied solar system. I

didn't read emails until the evening of the 5th. So... morning of

the 6th I turned it on. I had an AC power meter/monitor. It turned

on in Chinese. Oh crap, did they send me the wrong one? I looked

at the model number, searched, and found a video in Spanish about

how to change it to English. I changed the video to hear it in

English. Aren't translators wonderful? It turned out the power

monitor was also a "smart" circuit breaker that would shut off the

panels on overvoltage, undervoltage or overcurrent - an extra

level of safety.

On the 4th I got an email from BC

Hydro authorizing me to turn on the new grid-tied solar system. I

didn't read emails until the evening of the 5th. So... morning of

the 6th I turned it on. I had an AC power meter/monitor. It turned

on in Chinese. Oh crap, did they send me the wrong one? I looked

at the model number, searched, and found a video in Spanish about

how to change it to English. I changed the video to hear it in

English. Aren't translators wonderful? It turned out the power

monitor was also a "smart" circuit breaker that would shut off the

panels on overvoltage, undervoltage or overcurrent - an extra

level of safety.

Not much was happening for a bit, then current

started flowing. Then the sun came out for a couple of minutes and

the meter said 480 watts, while the "house" off grid system said

200. (Seemed about right - twenty 350W solar panels versus nine

300W.) Then it went back to raining. In fact, the whole month's

solar energy was pathetic, even for December. On top of rain,

overcast, tree shadows and everything, the panels were covered

with snow for a week.

"Overvoltage" was set to just 250 volts. Voltages in the

house are often up to 126, so 252. After it tripped off a couple

of times, I changed it to 265 volts. With snow covering the panels

and then in clouds and rain, the new system produced exactly zero

for weeks. Apparently it needs some threshold to do anything. My

two DC charge controllers were also pathetic most of the time,

often reading "40" or "80" watts instead of the 1500 they can do

in the summer... but they were more than zero. (I seem to recall

the plug-in grid ties usually being more than zero too.) Total for

December from the new system: 36.62 KWH. Less than I've been using

in a day most days in the freezing weather and heating the

upstairs room in the cabin! But November, December and January are

always pretty much "washouts" for solar around here.

Later I got a bill for November until December 3rd.

Seems I'll be on the "self generation" billing plan from the 4th

on.

---

But when the sun did appear, I had noticed that the

solar power system in the cabin didn't seem to be charging as well

as it should, even for December. Putting the charge controller on

the outside wall made for about a 35 or 40 foot run of #10 AWG

cable from it to the battery. A voltage drop of (say) 1 volt

doesn't mean much most places, but it means the charge controller

is only putting 39.8 volts into the battery instead of 40.8, and

LiFePO4 cells have such flat voltage curves that that means a much

lower charging current is flowing, and solar potential power is

being wasted. (40.8 volts with no load is 100% charge.)

[5th] It was only getting 370 watts and saying 40.0 volts, but I

suspected the charge controller was putting out the set maximum

40.8 volts. I turned on a 250 watt heater. The voltage dropped a

bit but the charging rose to 465 watts. So, there Was more solar

available, but not being used!

[6th] Rather than switch to costly, stiff #6 cable - or move the

36 volt DC electrical service to the wall where the charge

controller was - I decided to turn up the controller by three

notches from 40.8 volts to 41.7. 42.0 volts is the highest

recommended charge voltage. I think lower makes the batteries last

longer, but it'll only get up to 41.7 if the battery is really

well charged and not much current is flowing, ie, in the summer. I

don't expect to see the battery over 41.0 (if that) in the winter

when I'm trying to run electric heat. The sun had come out again

and the result was immediate. Where I hadn't seen over 400 watts

in weeks, it now read 670!

Well, one system at last in service, another

improved. Things are looking up! And the sun will return.

Solid State Electric Heater

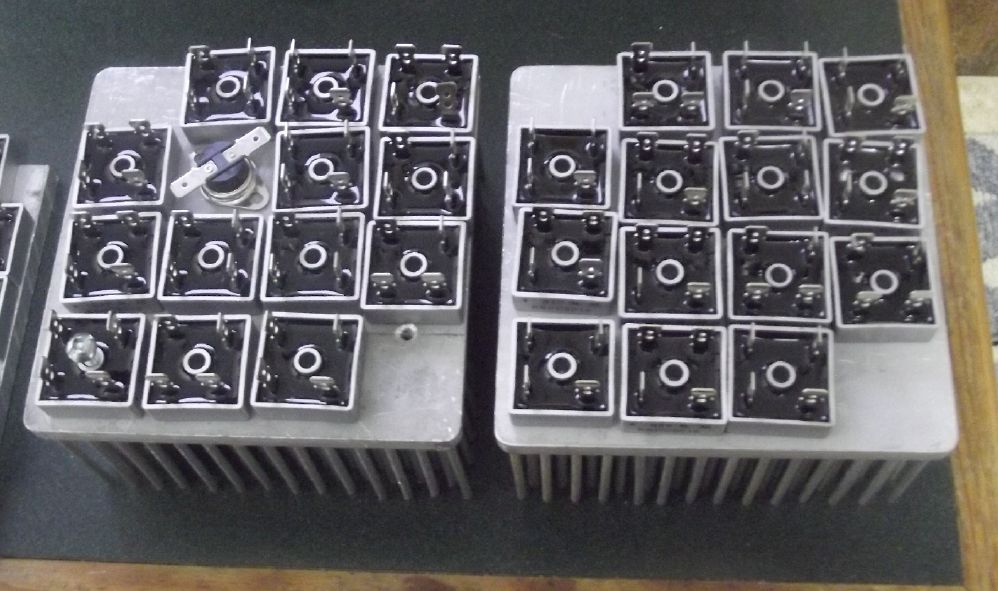

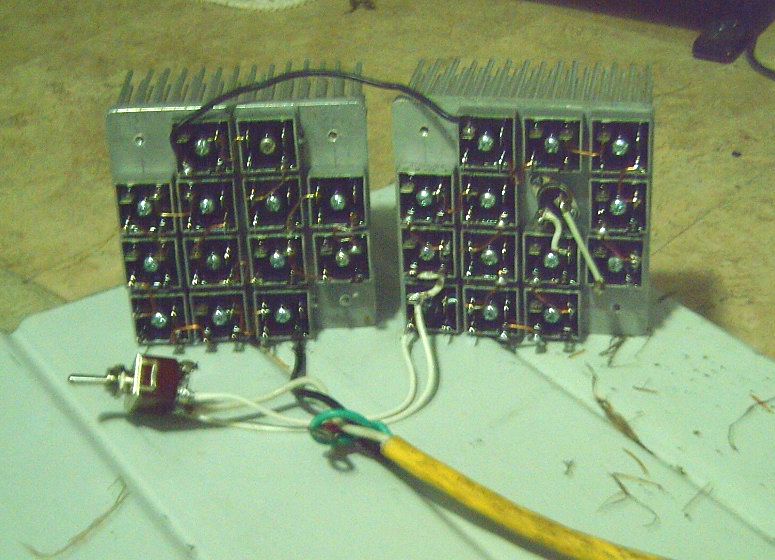

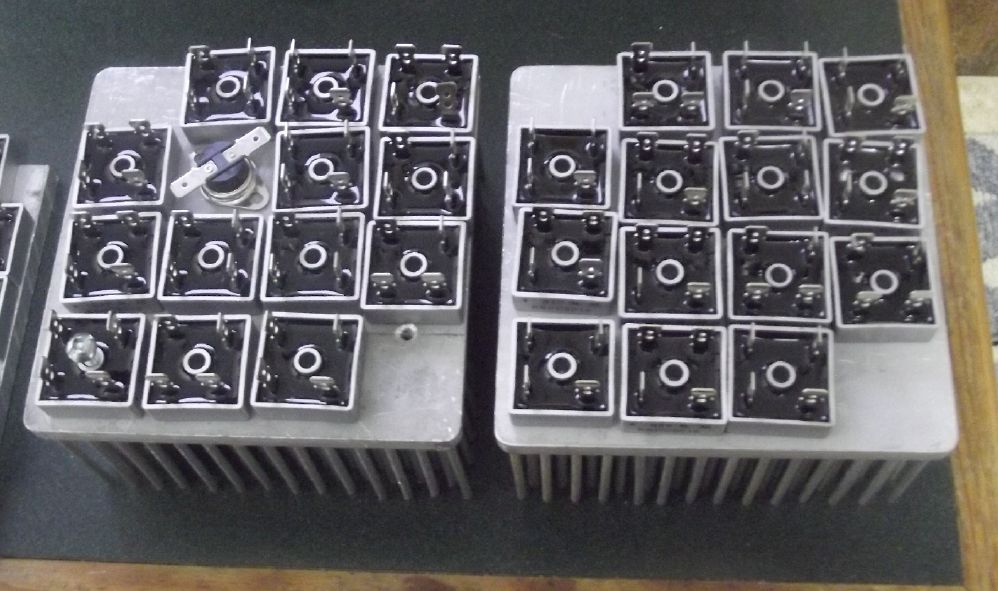

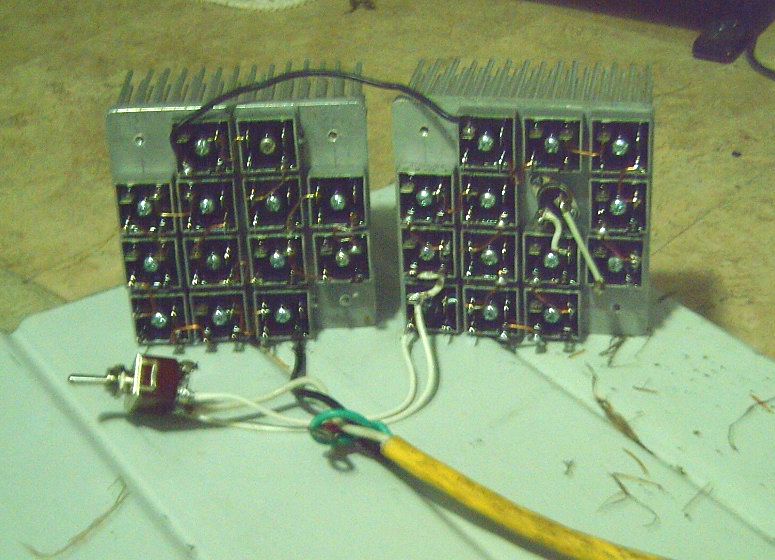

I got 60 power bridge rectifier diodes and laid out

25 on two heatsinks for a 36 volt DC heater, and another 25 on an

alume plate for a 36 V electric 'hotplate' or 'burner'.

First concept, for a burner/hotplate.

Underside view.

First concept, for a burner/hotplate.

Underside view.

Later I got a somewhat bigger plate and dropped to 25 bridges.

I didn't find time to pursue it further. (Yet)

The solid state heater concept, with two 5 by 5 inch heatsinks.

This one I built.

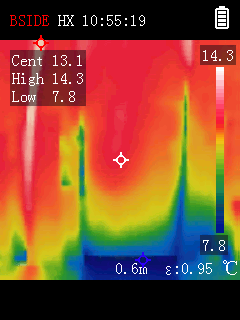

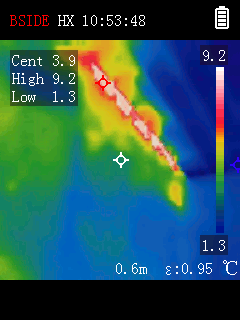

I put together the heater elements

and got it working. I tested it on the kitchen counter using the

36V DC outlet I had wired under the kitchen sink.

I put together the heater elements

and got it working. I tested it on the kitchen counter using the

36V DC outlet I had wired under the kitchen sink.

Per my vague

expectations (but not even mentioned in the bridges' datasheet!),

the forward voltage drops reduce with temperature, so the hotter

it got, the more current flowed - a pronounced positive feedback

loop. It took a while to "ramp up" from around 1 amp (40 watts) to

21 amps (720+ watts) and 120° C, which was about where the

temperature switch cut it off. Then it would cool down for some

minutes and come back on again for another run. I kind of expected

the circuit's 20 amp DC breaker to blow just before it cut out,

but it never did. I added another diode drop with 1/2 of a 26th

bridge. Then it went up much more slowly and only got to under 600

watts before it shut off. So I put in a HI-OFF-LOW switch for

50-[off]-or 51 diode drops.

Per my vague

expectations (but not even mentioned in the bridges' datasheet!),

the forward voltage drops reduce with temperature, so the hotter

it got, the more current flowed - a pronounced positive feedback

loop. It took a while to "ramp up" from around 1 amp (40 watts) to

21 amps (720+ watts) and 120° C, which was about where the

temperature switch cut it off. Then it would cool down for some

minutes and come back on again for another run. I kind of expected

the circuit's 20 amp DC breaker to blow just before it cut out,

but it never did. I added another diode drop with 1/2 of a 26th

bridge. Then it went up much more slowly and only got to under 600

watts before it shut off. So I put in a HI-OFF-LOW switch for

50-[off]-or 51 diode drops.

I didn't experiment with this long enough or through

supply voltage ranges to draw sure conclusions about the heat

turning down if the battery was low. It did seem to "ramp down"

when turned from high to low at whatever voltage was there. (It

doesn't help measuring that the supply voltage drops as the load

increases and vise-versa.)

But later I did find that it had turned itself down

to almost nothing overnight when set on "LOW". Seems the battery

voltage got down a bit in the night. I think it shut down too soon

- there was lots of battery left. On "HIGH" it would have

extracted more before doing the same thing.

Then I mounted them on a scrap piece of alume

siding. It seemed to stand up nicely all by itself, and the siding

became an additional heat radiator. [More in the detailed report.]

Then I mounted them on a scrap piece of alume

siding. It seemed to stand up nicely all by itself, and the siding

became an additional heat radiator. [More in the detailed report.]

It would seem that the solid state diodes heater has these

advantages or features:

* Unlikely to kill the battery if it runs low with the heater left

on (my original attraction to the idea). One night I put it on

"Low" (51 diodes) and in the morning found it virtually cold - the

battery had got a bit low for 51 and the power had "ramped down"

to around 40 watts. Switched to "High" (50 diodes) the power and

heat started ramping up again. If the voltage had been (.7?) volts

lower, "High" would also have turned itself down to "not much".

* Safer: The heat is diffused through the unit. The hottest parts,

the diode bridges, are "inside" and also don't get hotter than

about 125°C. Even without safety shielding no one will get a

sudden nasty burn from an accidental brush.

If the heater gets blocked or covered, it will still

only get up to 120°C before shutting off. I don't think that's hot

enough to start a fire. I set a small piece of tissue paper right

on top of one heatsink and its diodes, partly blocking the

airflow. It didn't do anything. It didn't turn brown or catch fire

in a few hours. (It didn't even keep my coffee hot!)

* The lower temperatures may make for less drying out of the air,

a negative feature of many electric heaters. (...or is that just

from any heat with no air inflow, period?)

* Being solid state except for the thermal cutout switch, it's

likely to last a long time and not burn out.

Of course, being 36 volts, this one isn't going to

shock or electrocute anyone even with bare terminals exposed. Ya,

of course it should have a screen over it anyway. It should also

have better thermal conductivity from the heatsinks to the

chassis/plate so that would get warmer before shutting off. (Then

it would run longer and the average watts would go up. A fan would

of course have similar effect.) But it's just a prototype and I'm

pleased that it works rather nicely for me.

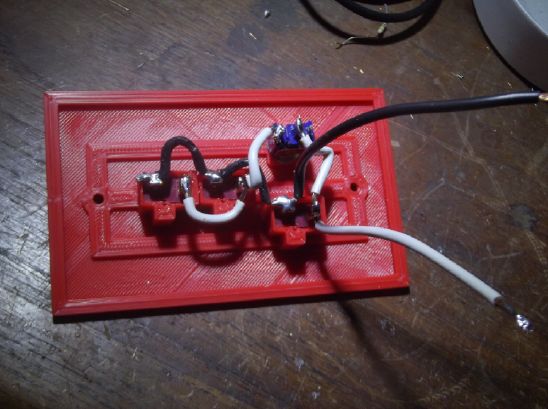

The back of the heater with the

High-Off-Low switch.

The back of the heater with the

High-Off-Low switch.

The last refinement was to cut the shallow bottom arch so that

only the cooler

outside edges touch the floor, and convection can draw air

through under the middle.

(If I had mounted the heatsinks higher up I could have made the

arch taller.)

New Chemistry Batteries - and the New Cell Design

Chemistry is one thing, but the new

battery cell design is the real wonder worker, the "game changer".

There's no stresses on the carefully prepared ion-blocking

separator sheet during assembly. I can compact electrode

substances reasonably well during assembly and they should stay

reasonably well compacted. A big graphite sheet current collector

wraps around the perimeter for making fairly thin electrodes,

valuable with the less conductive positive electrode formulations.

And the solid plastic ointment jars won't leak!

Chemistry is one thing, but the new

battery cell design is the real wonder worker, the "game changer".

There's no stresses on the carefully prepared ion-blocking

separator sheet during assembly. I can compact electrode

substances reasonably well during assembly and they should stay

reasonably well compacted. A big graphite sheet current collector

wraps around the perimeter for making fairly thin electrodes,

valuable with the less conductive positive electrode formulations.

And the solid plastic ointment jars won't leak!

With these various problems solved I seem to be able

to make batteries that actually work according to plan. Finally I

can concentrate on what goes into the cell, try out different

electrode substances and things, without having various problems

with the mechanical aspects to mess it all up.

With the 'organic chelated copper'-zinc cell

performing but poorly, I got frustrated and decided to try

something that really ought to perform if all my zinc improvements

did: nickel [oxyhydroxide]-zinc, using the nickel substance from

an old Ni-MH "D" dry cell. If somehow offered some opportunity

before getting the organic mix (or else nickel-manganese oxides)

working well, I wanted to be able to say with confidence, "Yes, we

can make great, long lasting batteries! I have proven everything

needed works." But the dry cell mix was designed for pH 14, and it

actually didn't work so well until I raised the pH from the 13

I've been using for some time now to 13.5 with extra KOH. After

that it started holding a charge.

A problem I kind of waved aside now showed

itself as more troublesome than expected. The metallic zinc side

started as metal - fully charged. The nickel, OTOH, had been

sitting for years and was dried out - fully discharged. The Ni-Zn

cell started out 10 times better than the "organic chelated Cu"-Zn

-- but still pathetic. In a few days of charging and discharging,

however, it was much better. Each cycle, running it down to almost

nothing and charging it again, was better than the previous one. I

kept increasing the load, from 100 ohms to 50 to 25, but the

running times got longer faster than I was dropping it. Unlike

most (if not all) of my previous cells over all these years, I

didn't note any sort of deterioration except loss of liquid, which

was to be expected in this process and without good seals. It went

from delivering a few milliamp-hours on the first try to 125 (25

ohms, in 3 hours) by the sixth day. It works, but it's very

tedious.

So I started experimenting. One could either use

zincate solution (discharged) instead of zinc metal, or chemicly

charge up the nickel. IIRC putting the substance in bleach will

charge it. Instead of water, I put in a cc of sodium hydroxide

zincate I had on hand to top up the cell, to speed things up. It

did seem to help.

I got some better tests, but finally I opened "Ni-Zn

cell #2" and re-compacted the nickel material. Then it ran longer

and would drive a 10 ohm load, and short circuit current went up

to 100 mA/sq.cm, which is reasonably good and better than I've

achieved before.

I discovered that while silver would soon oxidize,

gold remained inert and shiny even with the high voltage of a

nickel oxyhydroxide electrode. (Hey! I thought Jungner had tested

ALL the metals around 1900 and found that only nickel would work

in alkaline cells!?! That's what everybody has said ever since -

"only nickel"!)

Pure gold is expensive and of course if there's any

breach in a plating to a susceptible metal underneath, that metal

will eventually disintegrate. Which leaves gold plated graphite.

Graphite won't corrode and it's conductive enough internally, but

surface contact to anything else is generally poor. Plating it

with even an invisibly thin skin of gold should make for excellent

connections and high currents.

Silver plated graphite should work with lower voltage

electrodes.

A silver strip I tried for a positive

electrode terminal.

At the high "+" voltage of NiOOH the surface of the immersed

part oxidized to black Ag2O.

A gold strip however has remained clear and shiny. Wow!

I've never seen that in any literature anywhere! Has no one

ever tried gold before?!?

Next cell plan:

Zinc sheet "-" wrapped around copper wire center,

Silver sheet "+" current collector & terminal at rim,

for Organic-monel "+" electrode substance.

Into January "Ni-Zn Ointment Jar Cell #2" was still

performing very well after over 3 weeks - even improving. Surely

the best cell I've made. Even with only 15 sq.cm. electrode

interface surface it will drive a 5 ohm load, around 280 mA, with

only moderate voltage loss, around .2 volts. The chief remaining

weakness of my cells is that they lose electrolyte: it wicks up

the terminals and evaporates outside. That's why my alligator

clips get all corroded. Along with frequent watering I've now had

to add 2g of KCl salt and 1g of KOH. Modelling clay doesn't seem

to fix it. So far I don't want to really seal them up (beeswax,

heat glue...), as I still want to be able to open them easily to

look inside.

OLAHP - Why It's Better - & Better Indoor-Outdoor Air Heat

Exchanger

First of all, I'm not sure I've successfully conveyed

in the past why open loop air heat pumping (OLAHP) is

fundamentally far superior to today's refrigerant based heat

pumping, so I'm going to take another stab at it. Here's the

essential short version:

* Today's Refrigerant based heat pumping: COP is 1 to 5,

decreasing with outdoor temperature; 100 to 500 watts of heating

for each 100 watts of electricity.

* Open Loop Air heat pumping: COP is around 10, almost independent

of outdoor temperature; 1000 watts of heating for each 100 watts

of electricity.

Here's the more involved description:

"The experts" may say that the coefficient of performance ("COP")

drops with decreasing outdoor temperature, and that attaining a

high COP such as 10 in freezing weather or below is theoreticly

impossible. But they are thinking inside a box.

Let us assume outdoor temperature is -5°C, which is

268°K. In a refrigerant based heat pump, refrigerant is brought in

from the outdoor unit at outdoor temperature. The purpose of the

outdoor radiator-fan unit is in fact to bring the "super cooled"

refrigerant back up to [almost] outdoor temperature. The

compressor heats it from there up to a radiator temperature

where air can be blown through the radiator fins to heat the

indoor space, say 35°C or 308°K. (We assume the indoor space is

about 21 to 23°C.)

The potential COP equation is:

Initial°K / (Final°K - Initial°K), [or (final - initial) in °C -

same thing]

or

Initial°K / (temperature rise or "lift"° [C or K])

So the maximum COP is:

268 / (308-268) = 273/40 = 6.7

An actual system might generously attain around half the

theoretical potential value or COP = 3.4. From my understanding

that would be excellent if not amazing performance at minus five

degrees outside.

In the OLAHP system, the compressor heats air from

[slightly below] room temperature to the same 35° radiator

temperature. Call it 20°C or 293°K. The COP equation then

becomes:

293 / (308-293) = 293/15 = 19.5

The key is that the compressor is heating the "refrigerant" (air)

by only 15° instead of 40°. And the starting temperature is

higher, 293° instead of 268°. Again allowing for about 50%

efficiency, the attainable COP = 9.75 -- 10 rounded off: 1000 W of

space heating for 100 W of electricity. With commercial

development, even higher than 10 might be achievable. Cooling

could of course be done similarly. What would that do to reduce

global and individual energy consumption?

The key to being able to start with 20° air is the

passive indoor-outdoor air heat exchanger. After the

compressed air has gone through the radiator and delivered its

heat to the space, it is down to [just above] room temperature. It

is then fed into the exchanger's piping, still compressed. As it

travels along its length, it gradually gives up its heat to the

incoming uncompressed air from outdoors. At any point along the

length of the exchanger the outgoing air is a little warmer than

the incoming, and is heating it up bit by bit until at the far end

the compressed air is down to [just above] outdoor temperature,

and at the near end, the incoming air has been warmed to [just

below] room temperature - our 20° figure. This is already common

practice in "heat recovery ventilation" except that our outgoing

air is in piping, compressed, which makes efficient heat exchange

easier. This passively warmed air is what is drawn into the air

compressor, not "raw" cold outdoor air.

The still compressed air, now down to [almost]

outdoor temperature, is then fed into a pivoting vane air

engine on the same shaft as the pivoting vane rotary

compressor shaft. Its remaining compressed energy helps turn

the highly efficient compressor, for the ultimate of efficiency.

Finally the air comes out of the air engine decompressed, and is

vented outside. At this point it is well below outdoor

temperature. It is vented away from the intake so it doesn't have

to be reheated to outdoor temperature. The only "outdoor unit" is

the outdoors environment itself. This is the "open loop" part of

the system.

So we have taken 20° room temperature air, compressed

it until it reaches the radiator at 35° where it releases its heat

to the room, then that "spent" air feeds the exchanger and comes

out at outdoor temperature, then the "doubly spent" air helps turn

the compressor before being discharged outdoors uncompressed at

maybe -15°C, "triply spent". So after heating air by only 15° with

the compressor we have extracted 50°, all of which is in some way

used to help heat the space.

As long as the compressor and radiator are adequate,

the space is heated at any outdoor temperature. And as long as the

indoor-outdoor heat exchanger isn't overwhelmed by extreme cold

and too-high flow rate it delivers air from outside at near room

temperature, so there is little theoretical decrease in COP

regardless of the outdoor temperature. It can still be near COP 10

when it is -20° outside - again provided the exchanger is

adequate.

What little COP decrease there will be with dropping

temperature will mainly be attributed to the air engine receiving

less compressed air volume because that air is colder.

Compared to today's systems, this is almost FREE heat in any

weather! Now onto the month's endeavors.

The Better Indoor-Outdoor Air Heat Exchanger

I had considered that the radiator elements from

refrigerant based heat pumps would be good for indoor-outdoor heat

exchangers except that they were set up for a single temperature

difference, whereas the exchanger needs a gradual increase in heat

from outside air up to (almost) room temperature as it travels

inward, driven by a gradual decrease in inside air temperature as

it travels outward heating the air coming in.

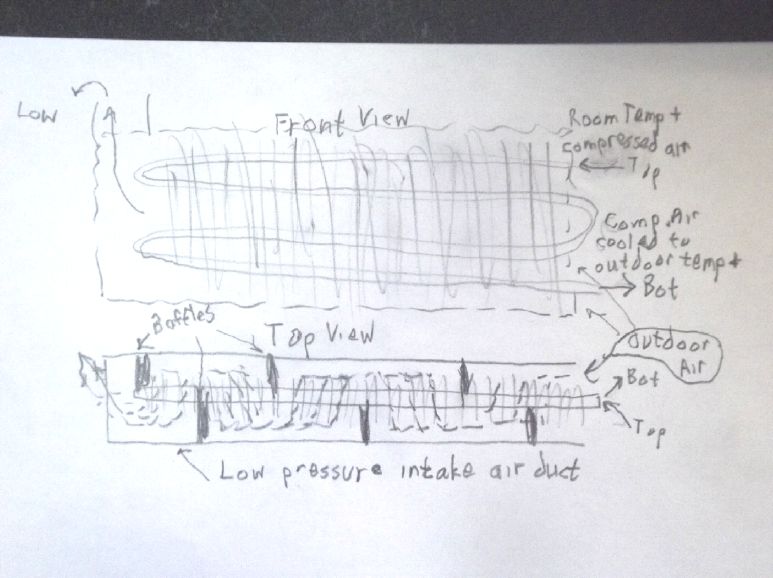

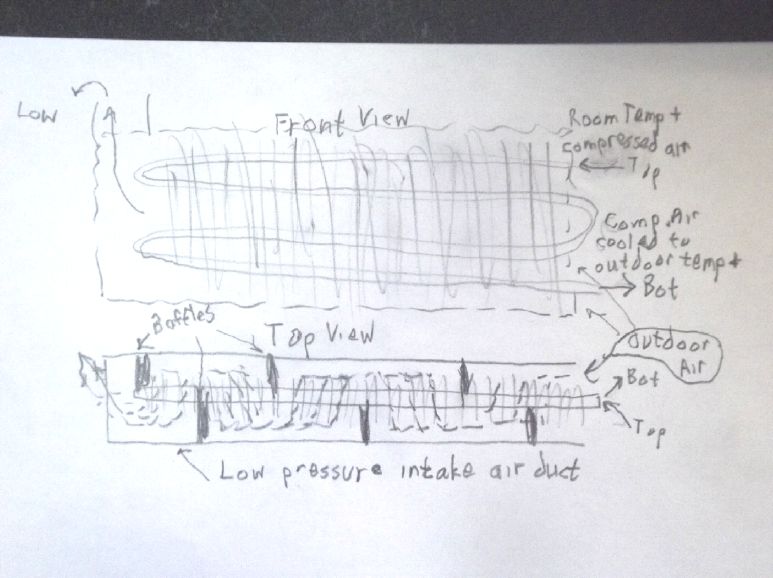

I took a new look at them and realized I could

disassemble them down to the individual radiator elements, which

could then be arranged in a linear progression with baffles to

force the incoming air back and forth across the fins as the air

compressor sucked it in. The outgoing air, having spent its extra

heat to the room, is still compressed and goes out oppositely

through the tubes until it is (almost) at outdoor temperature.

The exchanger is paramount to getting high

coefficient of performance (COP) from the open loop air system,

and this should work much better than what I have been using, so I

decided it's worth making and trying out. Maybe I can get it up to

COP 5, 6 or 7 in freezing weather even without the special air

compressor and "air engine". 600 or 700 watts from a 100 watt

refrigerator compressor - or 900+ watts with a 150 watt compressor

- would go a long way toward making my kitchen warmer in winter!

(COP 10 = 1000 watts from 100 watts with all the components built

and working would be even better of course!)

Idea for baffling in ducts to force

air to flow across radiator fins.

3D printed baffle pieces?

I disassembled a heat pump radiator and extracted the heat

exchangers.

I cut off all the convoluted ends right at the first fins with

the angle grinder,

then started plucking off a bunch of fins to access the pipe

ends.

I got as far as making 14 U-turn pipes to connect the pipes of

the two large heat exchangers.

(I think those two will be sufficient to invoke the law of

diminishing returns without adding more.)

A "linear" arrangement doesn't mean the line can't be folded

over to take up less wall space.

I cleaned the bent pipes in hydrochloric acid. I expect

soldering will nonetheless be a challenge.

In Passing

(Miscellaneous topics, editorial comments & opinionated rants)

HIGH BLOOD PRESSURE - ARTHRITIS & OSTEOPOROSIS - SOME

SUPPLEMENTS

HIGH BLOOD PRESSURE

My friend Ian, who has done various work in health

related fields and who told me 15(?) years ago that boron

deficiency had been discovered to be the common cause of

arthritis, reports finding a herbal treatment for high blood

pressure. [My own blood pressure has been 120 over ~80 for decades

so I have no need or "opportunity" to check this out myself. But I

know many older people have high blood pressure.]

"The treatment for high

blood pressure is stinging nettle root extract. I buy the capsules

because they represent a large amount of herb per capsule. 3 g

actually per capsule.

"The treatment for high

blood pressure is stinging nettle root extract. I buy the capsules

because they represent a large amount of herb per capsule. 3 g

actually per capsule.

I did three to six of those capsules to allow myself

to discontinue the pharmaceutical. In the absence of the

pharmaceutical my blood pressure skyrockets but the herb can

prevent this and allow myself to withdraw. So far I'm down from

three a day to two a day and my energy has gone way up."

(This isn't the stated purpose on the jar. But if it works, it

works.)

I've also just watched a video comparison of grains

wherein the presenter specificly lists khorasan/kamut wheat (and

not any other grain) as very good for lowering blood pressure.

There was however no indication of preparation of the kamut for

food, such as cooking it whole or ground as flour in bread.

Kamut is also the variety of wheat that seemed to

grow best in my garden on Haida Gwaii, and with kernels twice the

size of other wheat kernels.

ARTHRITIS & OSTEOPOROSIS

Again thanks to Ian... I've said this before, but it's worth

repeating... The common cause of arthritis is boron deficiency, so

the usual cure for most cases of arthritis/osteoarthritis, and

osteoporosis, is

(a) boron citrate pills, 3 milligrams daily (Do Not use boron

glyconate! Also beware of pills with only an insufficient amount

of boron citrate, eg, I've seen 800 microgram pills.)

or

(b) common "20 Mule Team Borax". I put a 'heaping' teaspoon of it

(4 to 5 grams) in a pint of water (= 2 tsp/litre), shake it up and

keep it in the fridge. Drink just One or Two Teaspoons of this

liquid per day. (It is only a Trace mineral! Any slight impurities

in the borax are just a trace of a trace. Ian once looked them up

and found there were just minute traces of harmless salts.)

Many people have cured their arthritis with both

these methods. Borax is cheap, but pills are more convenient. It's

said to take 2 or 3 months to take effect, but some people have

noticed more rapid improvement. (One even said relief in her

fingers from the borax was immediate! - surely an anomaly.) There

is a precedent of "borax tea" - it was once popular in England. I

don't know how it was prepared. "Tea" suggests too much borax all

at once, but probably it did relieve arthritis.

It seems the body delivers calcium to the joints to

go into the bones from the more porous ends, but with boron

deficiency the delivery ends or is reduced there. So the calcium

builds up in the joints (arthritis) and doesn't get in to

strengthen the bones (osteoporosis). (We get various deficiencies

because our unsustainable agricultural methods don't replace most

trace minerals and the soil has become depleted. The nutritional

value of many or most of our foods is way down from what it was in

1950. For one thing, our bodily wastes need to get recycled into

the soil rather than "disposed of".)

My mother once fell a couple of times and fractured

the sacrum in her hip. (Age ~80.) After it had healed they decided

to do a "hip replacement", but it was several months before they

got her in. In the meantime I had got her taking the 3 mg boron

citrate pills for two or three months. After the surgeon did the

work he told my mother she had very strong bones. I think the

surgery was completely unnecessary.

I ran this by Ian in an email, and found he had

somewhat different and quite exact ideas about doses and taking of

borax. He's the expert and no doubt there is an optimum. Also he's

using the borax to help clean his teeth! Here is what he said:

"I see two corrections to what you put down. If you're going to

use the boron capsules, you need to take two or three of those

capsules a day, for a total of either six or 9 milligrams daily.

"Mixing your own Borax: The correct formula is 18 g

of (20 mule team) Borax in exactly a liter of water.

"When you work out the molecular weights then each CC of

this liquid contains exactly 2 mg of boron. To use this liquid

you need to dissolve it in hot water, not cold water because

it's a slightly supersaturated solution.

"Once you've got the solution, you use a 5cc syringe which

you can get for free from the drugstore for liquid medicines. I

recommend squirting it in your mouth and swirling it around to

help your teeth. In research with rats, they scratched the rat's

teeth and then washed with the borax solution and the rat

quickly replaced the scratch with fresh enamel. Not sure if this

happens but it does kill tooth decay bacteria."

(FWIW, my 'formula' of "a teaspoon of borax in a pint of water" =

~5 grams in 1/2 a liter or 10 grams per liter - is half as

concentrated and so not supersaturated. A teaspoon holds 5 to 6 cc

of liquid, so two teaspoons is about the same as Ian's dose

recommendation.)

SOME OTHER SUPPLEMENTS

There are other supplements of things that we may not get good

levels of in our food, because of poor soils or regardless. Here

are some I take, probably in decreasing order of importance. (and

the amount I take) This is just my own list, and I'm not a health

professional. On the plus side, people usually think I'm younger

than I am. I told a friend I was 70. He said "You're in good shape

for 70. He*l, you're in good shape for 50!" The supplements surely

help. Read it for what it's worth.

* Vitamin D3 (1000 IU). This cuts the risk of cancer in half, and

cancer is one of the leading causes of death. Tests show that MOST

people don't get enough sun and are seriously vitamin D deficient.

Not to the extent of getting rickets, but by enough to greatly

increase our risk of a number of diseases including cancers,

influenzas and covids.

* Melatonin (5 mg). It is said that we don't make enough of it

after around age 40. The first book I read on supplements listed

2.5 grams after age 40 as #1 on his list. The body makes the most

in the early hours of the morning during sleep, and so I take it

when I get up in the morning. Others take it before bed - it's

supposed to help one get to sleep.

* Borax as per the article above.

* Creatine (half a scoop - the scoop or spoon comes in the jar.)

This is said to be very helpful for older people to keep up their

strength and muscle mass. I've recommended it to people who have

trouble getting around, and (from age 65) I've been taking it. It

also comes in pill form. On "SciShow" on youtube it was #1 of "Six

Supplements That Are Actually Beneficial" (as best I recall the

title).

* Vitamin C. Apparently Linus Pauling was right - at least half a

gram to a gram daily if you're not getting plenty in your diet.

Vitamin E is said to go along with it, at least 100 mg. Most

vitamin E pills are 400 mg; a few are 200.

* Gingko Biloba (also spelled "ginkgo" but not pronounced that

way. One pill.) The bilobate leaf of the gingko, the oldest living

tree species (dating from the Permian period before the dinosaurs

- not long after the first Glossopteris seed ferns first provided

a good food source for a land based ecology). Evidently helps

build new capillaries. Said to help with memory. Seems to help me

with remembering there was a reason I wandered out to the shop or

whatever, instead of wandering back into the house and then

remembering and having to go again.

* Potassium Bromide powder (KBr, 100 mg - "a pinch of") Reduces my

"familiar tremors". Another thing we probably don't get enough of

in our food any more. As I recall I couldn't write without jitters

in my late 50's. My dad could hardly hold a cup of coffee by the

time he was in his late 70's. I know (knew?) a lady who's similar.

I gave her some and explained, but I haven't seen her since to see

if it's helping.

Some have said that bromine has no biological

function, but this can't be true. Probably its function just

hasn't been identified. We do get a small amount of it in our

food, but ones or low tens of milligrams per day. KBr is used to

prevent convulsions in dogs, and it used to be used (1800's) for

its tranquilizer effect in people. The dosages used for that were

far higher - 2 or 3 grams per day, and that caused mental health

issues, so this use dropped out of favor. I don't get much more

than a gram in two weeks. Apparently it's just enough to help damp

out involuntary twitches and shakes. Not that it's "perfect", just

"a lot better much of the time".

* Ginseng (1 pill - "Organica Siberian Tiger Ginseng") Also helps

with tremors. I found this one before the KBr and I still take it.

Pretty sure they both help. I mention the brand I use because

early on I tried others that didn't help as much. I hope they

don't run out of Siberian tigers!

---

* Sumatriptan (1/3 to 1 whole pill as required). This isn't a

supplement for regular consumption, it's a medication for migraine

headaches when I get one. I'm very prone to getting them from all

but the freshest food - from food that most others have no trouble

with, also from food with particular unhealthy ingredients. MSG is

an example that will give a migraine to most anyone who is

susceptible to them. Sumatriptan usually makes a migraine simply

vanish in a half hour or so as if it had never been. They seem to

last about twelve hours, and by that time the cause of the

migraine is - usually - gone from the system. Life has been much

more worth living since these were invented in the 1990's and my

brother introduced me to them. By prescription (Outrageous -

Why?). Prices vary widely, presently from around 3.50 to 13.00 $

per pill, so shop around. I generally go through 4 to 6 of these

per month. Sometimes I go for weeks without needing one, sometimes

I've got some bad food or something that I don't identify very

quickly and I'm popping them like candy, even a couple a day.

(Last one: one particular type of corn chips was causing me

headaches. I bought and ate 2 or 3 one Kg bags before I figured

out what it was. "Surely it's not the chips! I don't get headaches

from unflavored chips!" "I guess the salsa has gone bad." and I

feed the salsa to the chickens. probably a couple of jars, to no

avail. Now I've accidently bought more the same chips (the bag is

similar to another) and am feeding those to the chickens.)

Scattered Thots

* Chiropractor Harold J. Reilly, author of "The Edgar Cayce

handbook for Health Through Drugless Therapy" (a worthwhile read!)

was asked "Which are the best exercises?" He replied "The ones

that you do!" That's my philosophy on supplements as well.

If our foods were nutritious we'd probably be getting most of what

we need - in considerably varying daily amounts.

* Is exercise a waste of your time? A 100 year old doctor said you

would live three hours longer for every hour of exercise you get.

You could probably argue with doctors about many things, but it

would be hard to argue with a 100 year old one about longevity!

* Specific health problems generally have specific, discernable

causes, but very often they never are discerned and people suffer

and die from remediable but unknown - unrecognized - causes. A

doctor doesn't see patients except in the office, so he doesn't

see what the patient is doing or suspect the cause. He only sees

the effect.

For example, someone I once knew was having severe

problems with his esophagus. It occurred to me later that he loved

to drink scalding hot tea. He was scalding his throat daily,

probably multiple times! He's probably long gone now, from that

cause. Had I been more astute back then I might have connected the

dots. He hadn't. His doctors didn't know why he was having the

problem.

* My butter is so hard even left out on the kitchen counter that

it's frustrating to use. I've often been pulling the soft

margarine out of the fridge in preference. I chalked it up to my

cold kitchen in winter. Apparently that's not it. Across the

country everyone has been noticing it. Someone decided that

Canadian dairy cows should be fed palm oil. Seems that's what's

making the butter so hard even at room temperature. Probably it's

just as healthy. But I bet they never thought it might drive

people to margarine!

* My new AC power monitor (for the new solar power system) started

up in Chinese! I looked at the model number on the box, searched

for that, and found a Spanish (Mexico?) video about how to change

it to English. I turned on 'captions' and they too were in

Spanish. I went into video 'settings' and got that irritating "AI

guy" voice - in English. (Well, probably the "AI guy" is more

palatable than most voices youtube could have picked. It's just

that I hear too much of him! He's probably used for making videos

out of books as well as translations, because suddenly there are

zillions of new youtube channels. Many are of historical subjects

but often with seriously distorted facts.)

But it's English! Previously we could translate text

comments under the video. How fantastic it is now to find a video

made in Spanish or Russian and be able to watch/listen to it in

English! And that on top of the power monitor itself being able to

switch languages. Computers and the internet have provided the

backbone, but the world is still in a process of becoming better

connected. When I was young auto-translations were the stuff of

far out science fiction! (I still go to deepl.com if I want a

second opinion on a youtube comment translation. When things like

"their" versus "our" get scrambled the whole meaning can be

markedly altered.)

* "Whoever would overthrow the liberty of a nation must begin by

subduing the freeness of speech." ~ Benjamin Franklin

Electrosmog Department

(I can't seem to get away from this topic, so here's it's

own place!)

Yet more sources of electrosmog! I'm finding

electrosmog is an onion with more and more layers.

At the start of the month I wasn't getting relief

from tinnitus by sleeping in the Faraday cabin any more. Why?

There didn't seem to be anything it could be. The "Orange Pi zero

3" computer I was now using there wasn't even plugged in unless I

was using it.

I started to suspect the WiFi router in the house,

but it was a good 100 feet away. It seemed so improbable! It was

however located to obliquely hit the bedroom window where the Pi

was located, in order to get internet. It might reflect back

toward the bed from the alume window frame. At 4 AM on the 4th I

dressed, went to the house, and shut its power off, then went back

to bed. By 9 AM I thought I felt a little relief, but I wasn't

sure.

Really? From 100+ feet away, through a grounded

metal wall and barely hitting the window at an extreme angle? "Two

bars" signal strength at the computer in the window (barely enough

to work) and "no connection" away from the window? But this router

had "5G", and a known side effect of 5G is tinnitus. The Pi also

had 5G and kept selecting it in preference to the regular signal.

But it was off at night. I had some other routers and tried them

all, but that was the only one that seemed to get through - and

not on 5G.

Later I found another cause: a 120 V AC extension

cord outside below the window. (more below) It had also seemed too

far away to be affecting things. Then I thought, "Oh, it was the

cord outside the window, not the WiFi router." With the cord

unplugged it didn't seem to need the wire mesh in the window.

Still later, one night my tinnitus got quite loud during the

night. I didn't understand why but in the morning I remembered I

had turned the router in the house on. (I usually keep it off.)

So, it was the router! and the cord. Two layers of

onion! And I wonder why the router is transmitting, apparently

continually, when the computer is off? It must be connecting with

the main house box, with which it is already connected by ethernet

- even with no useful information passing between them! And the

computer in the cabin uses an extra 1/2 a watt when the WiFi is

on, even when there's nothing for it to connect to.

And I think of broader implications: In towns and

cities there might be several WiFi sources in neighboring houses

(as well as in one's own), all within range of causing tinnitus

and health effects. In an apartment building there could be

dozens! There seems to be a lot of irrational behavior in the news

these days. Could it be that people are being driven nuts without

knowing why?

My tinnitus is also aggravated by the Pi computer

despite it being in the metal cookie tin, especially with the WiFi

on, but it's not as bad as my other computers. Maybe some of it

comes from the video display right in front of me - even this

little 5 volt USB powered one? (The whole setup is just 7 watts -

DC to DC converter (36=>5 V), computer, keyboard, mouse, USB

hub with USB memories, and video display -- 7.5 watts if the WiFi

is turned on!)

Friend Dan phoned and we talked about this subject. I

did a search on youtube. I looked at a video by a guy who had used

conductive paint on his walls and taken other steps to block out

UHF signals. One thing he mentioned caught my attention: he said

he had ditched wi-fi inside and used "power line adapters" and

ethernet cables. I looked these up. Sure enough 500 or 1000 MB/S

over an AC electrical cable, input/output to wifi or ethernet.

Just the thing for the cabin?!? I do have an extension cord

running to the far corner - for power tools during construction

and with no woodstove installed yet, I need the electric heat...

at the far end of the bedroom, wires heading directly away.

(Brings body induced EMF in bed to about 15mV. 20mV seems to be

about the threshold level. At least, My threshold level.) Ditch

the wi-fi completely!

I found a power line to ethernet pair on AliExpress

and ordered it. [They arrived and I connected them January 6th.

They work! At last, reliable wired internet in the cabin! Good

riddance to the WiFi routers!]

Under the video were over 3000 comments mostly about

the deleterious effects people were experiencing from UHF and

power line electrical fields. A few mentioned very serious health

effects. Some noted the relief they felt and the good nights

sleeps they got during power failures when everything all around

was off. No one noted tinnitus in the ones I read, but there was

one reference to "hearing it" when the wi-fi was on.

[10th] Something still didn't seem quite right.

Finally I got up from my nap and unplugged the 120 VAC heaters. In

an hour it *seemed* a little better. (And cold.) Notwithstanding

that my induced body voltage in bed from the heaters was under 17

mVAC and I have been considering my tinnitus causing threshold to

be "about 20 mV", they seemed to be aggravating it. I hung a piece

of conductive fabric across the room between the heaters and the

half of the room I usually occupy, and grounded it at a 36 VDC

outlet. I used a single wire with a T-Plug (minus, ground pin) on

one end and an alligator clip on the other to connect to the

fabric. I took out my original piece of stucco wire from directly

in front of the heaters. Within two hours of going to bed, I found

that removing the wire had been a big mistake! I put it back so it

had two shields. I did some induced body voltage tests and found

it was under 15 mV.

[10th] Something still didn't seem quite right.

Finally I got up from my nap and unplugged the 120 VAC heaters. In

an hour it *seemed* a little better. (And cold.) Notwithstanding

that my induced body voltage in bed from the heaters was under 17

mVAC and I have been considering my tinnitus causing threshold to

be "about 20 mV", they seemed to be aggravating it. I hung a piece

of conductive fabric across the room between the heaters and the

half of the room I usually occupy, and grounded it at a 36 VDC

outlet. I used a single wire with a T-Plug (minus, ground pin) on

one end and an alligator clip on the other to connect to the

fabric. I took out my original piece of stucco wire from directly

in front of the heaters. Within two hours of going to bed, I found

that removing the wire had been a big mistake! I put it back so it

had two shields. I did some induced body voltage tests and found

it was under 15 mV.

I think that the effect must not only be from the AC

voltage field, but also from the oscillating magnetic field. The

heaters are running a lot of current, so they're a strong source

of magnetic fields. That's probably why they need two layers of

shielding even from across the room. This could also explain why

things seem so much worse now, in the winter, than they did in the

summer. And there's not only my own heaters, but the amount of

power people (including me) are using in the winter is much

higher, so the too-close power lines also have a much greater

magnetic field. This would be hitting me whenever I'm outside.

Another problem was that the cloth

blocked the heat. So I took it down and threw up a piece of

'hardware cloth' mesh. Should be just as good for 60 Hz.

Another problem was that the cloth

blocked the heat. So I took it down and threw up a piece of

'hardware cloth' mesh. Should be just as good for 60 Hz.

(BTW: The heater at the bottom of the picture is the one I

converted to 100/250 W, 36 V DC. If the batteries are charged I

use it and may turn off one or both of the others if it's not too

cold. But this winter has had a lot of freezing temperatures.)

But it seemed that there was electrosmog of some sort

still getting at me inside the cabin. There was that one

loud tone in my ear that didn't seem to diminish overnight. I was

sure tinnitus takes days to fade, but shouldn't it at least be

down a bit overnight? And again it's been worse in the winter.

Finally on Christmas eve I thought of the two windows

on the West wall - the bedroom window and one on the ground floor

not very far away. These were on the opposite side from the power

line, out of sight of it, so I had thought no voltage gradient

fields could come through them. And I couldn't imagine that there

were any sort of radio transmissions coming from that direction.

Starlink, all the way from space? Seems ludicrous. But I'm

probably wrong about the power line electric field, and the

magnetic field was probably another matter too. I stapled up an

alume window screen over the bedroom window and grounded it. It

seemed to help some overnight. So in the morning I put up 2 inch

mesh chicken wire on the downstairs window, and then the upstairs

because the window screen was too narrow for full coverage. Now

there's 2" chicken wire on ALL the windows. If it's the 60 Hz

power lines, that should work, but if some RF or UHF is coming

from God knows where, a much finer screen would be needed. [It was

an extension cord outside the windows - read on!]

There's still other electrosmog in the onion layers!

When it's quiet, at low volume, I have heard what sound for all

the world like CW transmissions (Morse Code) in my ears since

probably my early teens (late 1960's). Not high pitched - maybe

500 Hz to 2 or 3 KHz. Sometimes I there are two or three stations

at once. I hadn't noticed them for quite some time. But I think

it's just because they were drowned out by other, more powerful

tones. Now that I have been blocking so many sources of those,

peeling away layers of onion, I hear them again. I don't think

these ones are just irritation that builds up: I think they are

the actual CW transmissions, in real time, hitting my hearing

mechanism somewhere, somehow. And somehow they seem to penetrate

the grounded metal roof and walls of the "Faraday" cabin. (When AM

radio stations used to broadcast at very high powers, some people

are known to have heard them "in their fillings", including what

was being said and the music playing.)

I know most of the Morse code letters, but I've never

trained on reading it. They're low volume and by the time I've

figured out what one letter is, three or four more letters have

passed. Unfortunately I can't take them from my head and record

them or feed them into a computer. My best guess is LF (~500 KHz)

marine radio weather forecasts. I sailed on weathership Vancouver

once and in the radio room all the sounds coming in over the

radios were "deja vu" (well, deja ecoute.) When I was in the coast

guard in the later 1970's the forecasts were sent by hand on a

schedule, but last I remember seeing, they were typed in and sent

automaticly. (And they're mostly read by computers and turned into

text automaticly, too.) They may be always on. I only hear them

when all else is very quiet. I heard them as a kid in Edmonton far

from the coast, so I think the skip carries them far and wide. In

fact, that's why they're broadcast at such low frequencies - to

reach to ships far out at sea. Dang! Now I'm hearing two! There's

the one in my right ear that prompted me to write this section,

and now another lower pitched one in my left ear. Naturally these

can be even more annoying than the continuous tones. If they were

at the higher volume of those, they might be unbearable. ([26th] -

OMG, I think I just caught a "CQ CQ" (-.-. --.-

-.-. --.-) going by in my left ear while I was typing

the paragraph below this one. That means "broadcasting to all

stations", typicly starting a marine weather report. Then a "V"

(...-) after, probably starting "VAK" or VAG" or whatever -

Canadian coast guard radio station identifiers. But I can't follow

the rest. A few minutes later: Now the higher pitched one has

started up again in my right ear.)

Surely this whole system is redundant now with the

ubiquitous, planet-wide satellite communications?

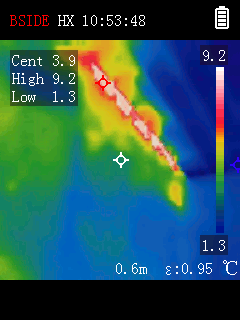

[26th] At last I seem to have finally figured out the biggest

cause. From the entry is a 150 foot extension cord (120 V

AC) to the travel trailer that for some reason I still have. It

has a heater with a timer and in cool to cold weather I go out

daily and put it on for an hour so it doesn't get damp and mouldy

inside. The cord goes outside right at the door, but it runs along

the base of the wall of the cabin. Some signal might be getting in

under the metal wall. And then it goes across the lawn, passing

outside the bedroom window. Hmm, that must explain what's been

coming in the window, since there's nothing else on that side but

forest. I thought the cord was too far away to matter. Apparently

not! [But it was one of two things, along with the WiFi hub.]

I didn't expect that it would have much effect

inside, but I unplugged it Christmas evening and finally felt like

I wasn't being "hit" with something very notable during the night.

Perhaps I had the cord unplugged over the summer and so it was

better then. I have been reluctant to unplug it because about

every second time I plug it back in, the ground fault breaker

trips and I have to go to the house and reset it.

[30th] I still feel there's some irritation - probably lesser but

still there - preventing the ringing from subsiding more

overnight. Another layer in the onion. I think it's still the

heaters, even at the far end of the room and with two grounded

shields between them and the bed. There just doesn't seem to be

anything else. But I couldn't be in the cabin without the heaters.

I thought "How can I reduce their AC magnetic field?"

If they were DC it wouldn't matter, and the heaters could run on

DC as well as AC. But if one converts 120 V AC to DC, after

filtering (with really big capacitors) it would be near 171 volts,

which would burn out the heaters. So one would have to transform

the voltage down by the square root of two first. For heaters that

would be a big ugly transformer or a x10's KHz PWM converter,

either of which would doubtless make plenty of its own noise.

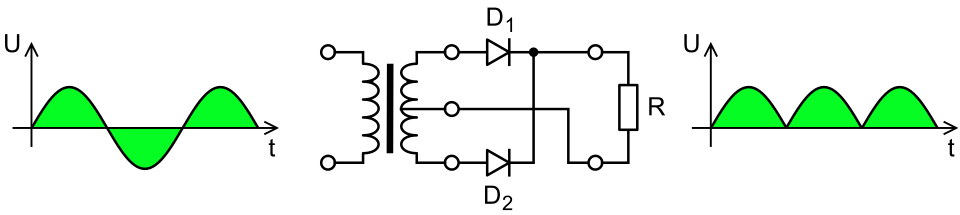

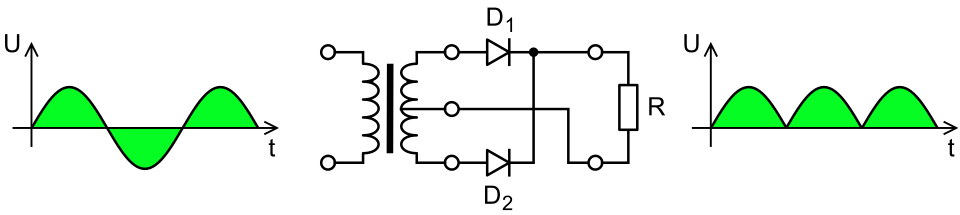

+171 V to -171 V = 342

V peak to peak = 120 V RMS. The rectified waveform is +171 V

peak to 0 V, still 120 V RMS

But I could rectify it

and not filter it. (No transformer, 4 diode rectifier

bridge.) That would reduce the peak-to-peak travel of the AC waves

from 342 volts to 171. That should make some reduction in

the oscillation of the magnetic fields.

But I could rectify it

and not filter it. (No transformer, 4 diode rectifier

bridge.) That would reduce the peak-to-peak travel of the AC waves

from 342 volts to 171. That should make some reduction in

the oscillation of the magnetic fields.

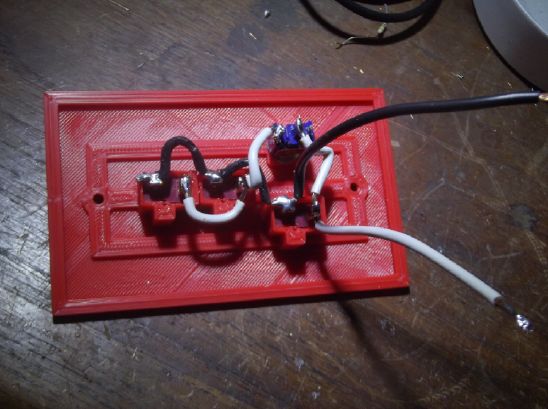

So I took one of my new bridge rectifiers and a

scrap outlet box and made a box to do that. Hopefully it will

help. (The rectifier can barely be seen through the spare holes.)

So I took one of my new bridge rectifiers and a

scrap outlet box and made a box to do that. Hopefully it will

help. (The rectifier can barely be seen through the spare holes.)

At first I plugged the two heaters into this box.

Then I realized the field still was in the extension cord. So I

put the box at the far end of the cabin, so the entire extension

cord, heaters and all were unfiltered DC instead of AC.

Then, in addition to the two layers of wire screen

between the heaters and the bed, I put a conductive fitted sheet

under the mattress liner and grounded it. (3 of the 6 DC outlets

in the bedroom - in the already shielded cabin - are now occupied

just for shield grounding wires!) Since the heaters are on the

floor and the power cords run below bedroom floor level, that too

should block out much of their magnetic and electric field from

lying in bed. I think I've finally reduced and blocked out most of

the AC power noise and getting more relief by morning. But then I

have to get up and walk across the unshielded yard to the

electricly noisy house, and start my day. And maybe drive into

town on the highway right under the power lines. Can I ever get

away from it long enough for the ringing to fade away entirely,

even once?

-----

Dr. Gerard Hyland, Biophysics, University of Warwick, 2

times Nobel Prize contender Medicine, says:

“A major contemporary threat to the health of Society is

man-made ‘electrosmog’. This non-ionising electromagnetic

pollution of technological origin is particularly insidious, in

that it escapes detection by the senses – a circumstance that,

in general, tends to promote a rather cavalier attitude,

particularly with respect to the necessity of ensuring an

adequate degree of personal protection. Yet the nature of the

pollution is such that there is literally nowhere to hide.”

At the serious risk of being repetitious I think electrosmog

of all sorts is going to be one of the major health preoccupations

of this century. So far we are just making it worse and worse,

adding layer upon layer to the onion. AC power lines were the

start 100 years ago. Then radio. Now UHF - "microwaves". Some are

saying putting WiFi in schools is a crime because of the radiation

it exposes developing children to. Warnings by those in the field

about health problems that 5G would bring were disregarded and it

was rolled out everywhere anyway without a pause. ("Follow the

Science!" - unless it's not convenient.) Some vandalism of 5G cell

towers may be because of people being driven nuts by them being

too close to their dwelling place and finding no way to get

relief. I'm glad I moved to the country but sorry my place is so

close to the highway power line. So far my [known] adverse

reactions to all this have mostly been tinnitus. (That is, since I

got the cell phone out of my pocket. After a year or two it was

making my leg 'pulsate', a 'muscle tic' under the pocket where I

kept it. At first I would think it was the phone vibrating, but it

almost never was. What would have been next, cancer?) Others have

trouble sleeping, more serious health problems or even die of

cancer, especially brain cancer from cell phones too often and too

long held up to the ear - or even kept under the pillow. As Hyland

says, our senses don't detect anything - until it has manifested

itself as some health problem whose cause is usually 'unknown'.

ESD

(Eccentric Silliness Department - No electrostatic

discharge)

* I wanted to sit in the dark. So when I turned off the last

light, I was delighted.

* 'sno boots like snow boots when there's snow. (Where did all

that snow come from, anyway? It's like winter when it's

actually... oh ya!)

"in

depth reports" for each project are below. I hope they may be

useful to anyone who wants to get into a similar project, to glean

ideas for how something might be done, as well as things that

might have been tried, or just thought of and not tried... and

even of how not to do something - why it didn't work or proved

impractical. Sometimes they set out inventive thoughts almost as

they occur - and are the actual organization and elaboration in

writing of those thoughts. They are thus partly a diary and are

not extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before publication. I

hope they may add to the body of wisdom for other researchers and

developers to help them find more productive paths and avoid

potential pitfalls and dead ends.

Electric

Transport (No

Reports)

Other

"Green" & Electric Equipment Projects

A New Tech !

Resistance Heater made With Power Diodes

(advantages over resistance wire)

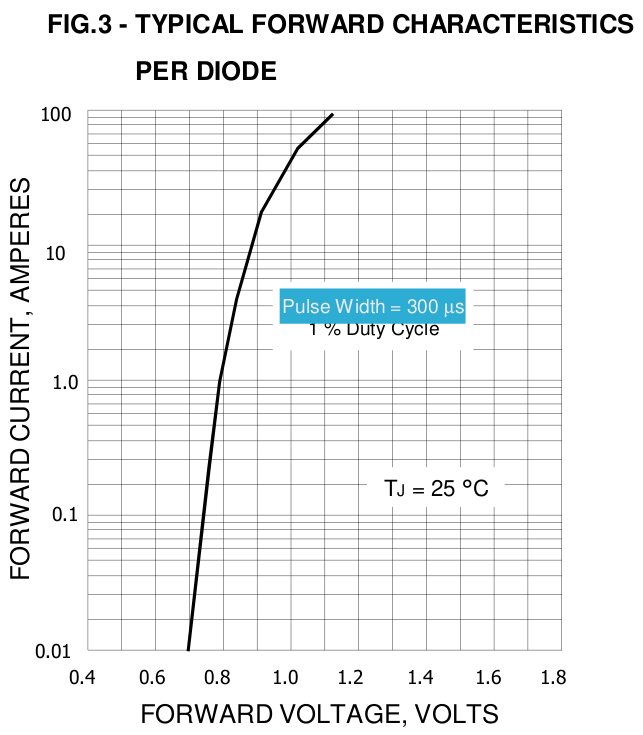

[16th] The 60 power diode bridges arrived. With 26 of them (two

diode drops each), they will start turning on at Vf 0.7

* 52 = 36.4 volts. Below that voltage they should draw no current

from the supply, protecting the batteries from overdischarge.

Another possible advantage is that electric

resistance heaters tend to dry out the air. Possibly the solid

state heater with no red-hot element won't have that effect? But

I'm guessing.

36.4 volts is only about 11 or 12% battery remaining.

But they only pass about 200 mA per diode at .75 volts, which is

only: 2 diodes * .2 A * 39 V = 16 W. And that is just under

50% charge. It will take a very long time to deplete even one KWH

at 16 watts, and the depletion will drop as the voltage does.

Presumably during the day much more than that will be made by the

solar panels, even in December fairly far north.

However, the highest diode drop we will see is about

.8 volts, which is only about 1.3 amps. 2 * 1.3 A * 41.6 V = 108

watts. That's a pretty small heater, and only at 100% charge with

very low line drop to the heater. We'd need several banks of such

heaters. Instead, we will probably choose instead to have a few

fewer diodes and assume the small energy loss as the voltage drops

will be made up by solar power within a day.

I got two 5" x 5" heatsinks for a diode based heater,

and a 6" x 7" x .375" slab of alume for a hotplate 'burner' from

my stashes. I arranged the bridges on them. These are thick enough

to thread a #10-24 bolt mounting hole for each bridge without

putting a bolt plus nut on each one.

Later I decided to spread the diodes on the hotplate

out a little, so I found a little bigger burner plate, 7" x 7.5" x

.375". (Both pieces scraps from AGO courtesy of Jim Harrington

some years ago.) I thought of setting up a little g-code program

and having the drill router drill the mounting holes in 'perfect'

rows. But I'm not sure about having a high speed router drill the

alume, so I decided to do it by hand. Mark. centerpunch. drill.

tap. 'Tap' (cut bolt threads) is by hand anyway. with the threader

tap in the battery electric drill, loose enough to slip rather

than snap. It's much faster for smaller threadings.

[17th] We can make tables:

Heater characteristics with 26 Rectifiers

Diode

Drop (V)

|

Battery Voltage

(drop *52)

|

Current (A*2)

|

Power (W)

|

Battery %

|

.70 or less

|

36.4 or less

|

0

|

0

|

12

|

.75

|

39.0

|

0.400

|

15.6

|

50

|

.80

|

41.6

|

2.600

|

108 - The voltage will

rarely be this high

|

100

|

.85

|

44.2

|

10.40

|

The voltage will never

be this high!

|

|

.90

|

|

20.80

|

|

|

While it would be nice to have all

current stop at 26.4 volts, it looks like the heater power

available would be too low.

We could have 25-1/2 rectifiers using only one pair of diodes in

the 26th one, but I'll skip that table.

With 25 rectifiers

Diode

Drop (V)

|

Battery Voltage

(drop *50)

|

Current (A)

|

Power (W)

|

Battery %

Charge

|

.70

|

35 or less

|

0

|

0

|

0

|

.75

|

37.5

|

0.400

|

15

|

~12

|

.80

|

40

|

2.600

|

104

|

88

|

.85

|

42.5

|

10.40

|

416 - The voltage will

never be this high! |

>100

|

.90

|

|

20.80

|

|

|

Well Dang, that still looks kind of low powered. Drop one more

rectifier?

With 24 rectifiers

Diode Drop (V)

|

Battery Voltage

(drop *50)

|

Current (A)

|

Power (W)

|

Battery %

Charge

|

.70

|

33.6 or less

|

0

|

0

|

0 - cells

minimum

allowed

voltage

|

.75

|

36.0

|

0.400

|

14.4

|

~10

|

.80

|

38.4

|

2.600

|

100

|

20

|

.85

|

40.8

|

10.40

|

424

|

100

|

.90

|

43.2

|

20.80

|

The voltage will never

be this high!

|

|

Now the voltage minimums are looking pretty low. 38.4 V is only

20% charge. I don't think I want it still running 100 watts there

- the idea is to stop making heat before the battery is too low

while (LED) lights and other light loads can still run until the

sun comes back.

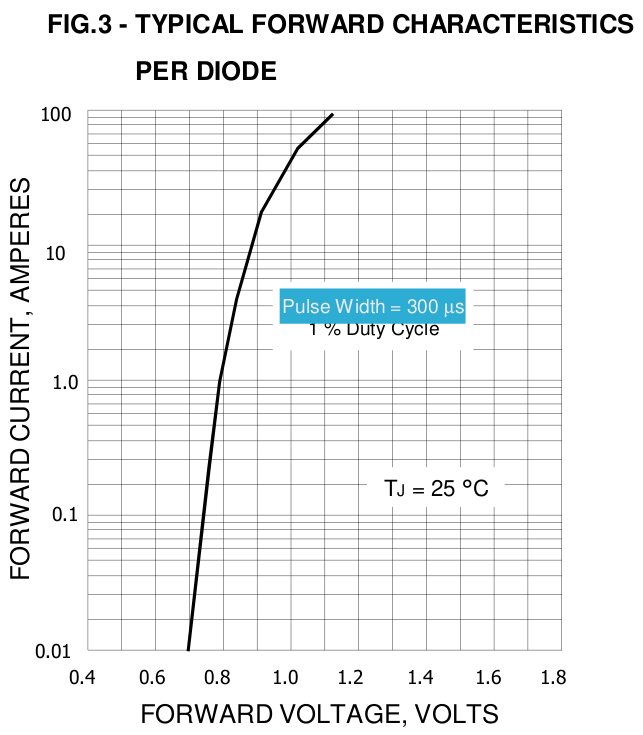

[Later, replacing the original speculative

paragraph... When I actually made the heater and tested it, there

was a major factor not even mentioned in the datasheet. That is

that the forward voltage drops are given only for 25° C. Nothing

was said about temperature factors, leaving one to assume they

worked the same regardless of temperature. In fact, the forward

voltage drop of the rectifiers is much lower at 100° than at 25,

so the power consumption goes up drasticly with temperature!

Current listed for .9 volts is reached at .6 volts when the heater

is somewhere around 100° and continues to rise with temperature.]

[Later, replacing the original speculative

paragraph... When I actually made the heater and tested it, there

was a major factor not even mentioned in the datasheet. That is

that the forward voltage drops are given only for 25° C. Nothing

was said about temperature factors, leaving one to assume they

worked the same regardless of temperature. In fact, the forward

voltage drop of the rectifiers is much lower at 100° than at 25,

so the power consumption goes up drasticly with temperature!

Current listed for .9 volts is reached at .6 volts when the heater

is somewhere around 100° and continues to rise with temperature.]

I think I want to try 25 bridges (50 pairs of diodes)

and see what happens. Also of note: 400 W / 25 bridges = 16 watts

per bridge. They can certainly handle that!

I drilled & tapped the holes in one of the

heatsinks, then mounted the components, which were 12 diode

bridges (13 on the other one) and a high temperature cutout

switch, 120° C. The vacant diagonally opposite corner spaces with

holes will be for mounting the heatsinks on some frame to be the

body of the heater. That took the evening and made for a somewhat

late bedtime.

It does occur to me that the voltage/power gradients

could be achieved, and be more carefully tuned, using a

microcontroller and ordinary resistance wire. But that would

require pulse width modulation to turn down the heat, and

switching that heavy load would make substantial electrosmog. I

doubt I'd want it in my Faraday Cabin.

Another approach could be multiple resistance wire

elements of differing wattages, again preferably with an

'intelligent' control. (eg, 40, 80, 160 & 320 watts, providing

40 to 560 watts in 40 watt steps.) That wouldn't use PWM.

But I want to try the "dumb" diode approach and see

how it works. There may be more advantages than are apparent in

advance, and it's an easy experiment (no programming to do) that

shouldn't take long. (unless of course it is a success. That would

warrant further development!)

I connected the diode bridges together with bare #14

solid wire. That avoided a lot of wire stripping and pushing

stranded wire through little holes. Only the overtemperature

switch got insulated wire, the wires being longer and running past

other terminals. I put it on the power supply. What, nothing? Oh,

wait... the terminal marked "+" is the cathode... that's "-" if

it's a load rather than a power supply, not "+". The other way

around it worked. It started drawing current somewhere around

17-18 volts, but the 12 bridges needed 22.5 volts to draw 2 amps

of current. I'm not so sure 25 bridges - 50 diodes - will make

much heat with "only" 40 or so volts. But I didn't test it long

enough to get very warm.

Later I wired up the other heatsink with 13 bridges,

allowing 50 or 51 diode drops.

[21st?] I connected them and put in a

switch. (High-OFF-Low, 50-OFF-51) I tried it out at the 36V outlet

in the kitchen.

[21st?] I connected them and put in a

switch. (High-OFF-Low, 50-OFF-51) I tried it out at the 36V outlet

in the kitchen.

Both house and cabin batteries were rather low owing to the little

solar power available in December (and still trying to run what

little heat it could in the cabin). On "high" it took a long time

to ramp up to a high power. Then I switched it to "low" and it

began ramping down again - presumably it was saving the battery,

and had the voltage been much lower, "high" wouldn't have ramped

up to higher powers either.

[23rd] I remembered that I had a

backup power supply in the cabin system to keep the battery from

getting overly depleted. It had been unused and unplugged but was

still installed. I plugged it in and turned it up so it would

charge the battery. Then I could use the battery at night to run a

36 volt heater for extra heat (besides the 1300 watts from two 120

VAC heaters at the far end of the room).

[23rd] I remembered that I had a

backup power supply in the cabin system to keep the battery from

getting overly depleted. It had been unused and unplugged but was

still installed. I plugged it in and turned it up so it would

charge the battery. Then I could use the battery at night to run a

36 volt heater for extra heat (besides the 1300 watts from two 120

VAC heaters at the far end of the room).

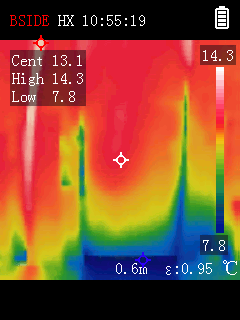

So the battery voltage was a volt or more higher, and

the heater was much stronger. In a relatively short time it ramped

up to 21 amps, 720 watts. Just when I thought the 20 amp breaker

would blow, the thermal switch shut it off. A few minutes later it

came on and did the same thing again. It was probably averaging

400-500 watts. [Later estimate: 300-350 W] Not huge but definitely

a heater. In an hour the room was up from 13° to 16 and rising.

With a laser temperature sensor the highest temperature I measured

was 113°C, directly on a rectifier metal package.

I flipped the switch to add in the 51st diode, 25-1/2

rectifier bridges, into the circuit. It got less dicey, starting

near 7 amps, 315 watts and running up to just under 16 amps, 590

watts, and then shutting off. But it didn't stay off very long. (A

couple of minutes? I didn't time it.) It was probably putting out

about the same amount of heat overall - on longer, off shorter. I

suppose if the heat switch didn't open, on the higher setting the

breaker would blow before the diodes got too hot. I'm not so sure

on the "lower power" setting.

[24th] I ran the heater overnight in the bedroom in the cabin. It

raised the temperature from what would have been around 14 or 15°

to 19 or 20. Much nicer! (-2 to -4 outside. +1 in the uninsulated

part of the building.) It used something over 3 KWH. By spring

that energy will probably be available from the sun, but in

December it just adds to the huge electrical consumption from the

power grid, much of which this winter is for the cabin bedroom

heat. If I had any financial sense I'd abandon the cabin until the

weather improves. I'm still burning lots of firewood in the house

anyway. I certainly hope to finish the cabin insulation next

summer! And maybe get the woodstove in.

I used a piece of alume siding as a

mounting for the heater. I cut some "Z clips" (meant for mounting

solar panels) in half. I attached the heatsinks by the open corner

positions to the siding. The switch handle is on the back. I was

hoping for heat transfer through the "Z" clips to the big piece. I

used some heatsink paste on the "Z" clips (only at the plate, not

at the heatsinks - oops), but it didn't seem to transfer very

well. I got the idea to put more clips under all the corners by

inserting them under the bridges in the occupied corners. That

would strengthen the mountings, but mainly it should help transfer

more heat to the "back" piece.

I used a piece of alume siding as a

mounting for the heater. I cut some "Z clips" (meant for mounting

solar panels) in half. I attached the heatsinks by the open corner

positions to the siding. The switch handle is on the back. I was

hoping for heat transfer through the "Z" clips to the big piece. I

used some heatsink paste on the "Z" clips (only at the plate, not

at the heatsinks - oops), but it didn't seem to transfer very

well. I got the idea to put more clips under all the corners by

inserting them under the bridges in the occupied corners. That

would strengthen the mountings, but mainly it should help transfer

more heat to the "back" piece.

It's certainly easier to carry put together into one