Turquoise Energy News Report #172

Covering

September

2022 (Posted October 9th 2022)

Lawnhill BC Canada - by Craig Carmichael

www.TurquoiseEnergy.com

= www.ElectricCaik.com

= www.ElectricHubcap.com

Feature: Successful Tests:

Magnetic Variable Torque Converter with Planetary Gearset Moves

Miles ZX40 Truck (see in Month in Brief, Electric

Transport;

also see Video of

test prototype working. This design works really well -- will change

the automotive industry!)

Month In "Brief"

(Project Summaries etc.)

- Cabin - Halbach "Array" Magnet Rotor Configurations - Great Variable

Torque Converter at Last! - Power Outage Preparedness

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

- Proactive Approach to Democracy - Asteroid Dimorphos: Ahrrrg,

Monochrome

Again!!! - How Famines Develop Rapidly - Satellites or Armed Drones? -

Smol

Thots (Planetary Carrying Capacity Chart, more...) - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems

* Variable Torque Converter with Planetary Gear: a Magnetic Method -

Assembling the unit - Installing batteries and getting the truck

running again - Halbach Magnet Rotor Configuration: Double the

magnetism (for axial flux BLDC Motors, too!) - Installation -

Tests: Problem; then SUCCESSFUL OPERATION - Video on Youtube -

Improved with Halbach magnet rotor.

* Sprint Car: Tires, TK15 Coulometer to track state of charge,

volts, amps

* Thoughts: Unipolar Electric Hubcap Motor With Halbach Magnet

Configuration

Other "Green"

& Electric Equipment Projects

* Gardening: Some Fall Harvesting - Salal berry Rake

Electricity Storage:

Batteries [no

reports]

Electricity Generation

* My Solar Power System:

- The Usual Latest Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

Solar power generation for the month was 406.02

KWH. That's well over double most previous Septembers, with the sunny

weather and 18 solar panels instead of 12. (If - when - I move the 3

panels from the lawn up onto a 45° frame on the carport roof

(sunniest place), the figures should improve still further!)

On my 'cabin' I almost finished another 1/2 of one

of the outside walls. (In the meantime someone up the road has put up a

whole larger house this summer, and it's ready for the siding, windows

and doors. Mine is taking 'forever'.) Further work awaits Perry

removing his RV... very soon. Hopefully the weather won't be too

miserable to continue with the next section. Then in the spring I'll

pull out the travel trailer too, and finish the last wall. Then there's

the floor, walls & ceiling and the whole interior...

Half a wall with concrete footing, framed,

sheeted and wrapped

Half a wall with concrete footing, framed,

sheeted and wrapped

Some siding done by the end of

the month.

Some siding done by the end of

the month.

(There's no more loose siding: the rest is covering lumber piles!)

The 5 full pieces here had been covering my utility trailer in the

bushes. The spruce needles left

black dots of pitch all over them and they took much longer to clean

with Comet than to install.

I'm going to have almost no 120VAC wiring inside, and what

there is will be shielded. Just a plug or two on the east wall. Instead

for lights and plugs I'll use a 36VDC system with the solar panels and

batteries, and a plug-in adapter to maintain charge when there's no sun

or if I'm using too much power. If indeed AC power fields are what's

keeping my tinnitus going (and if so, doubtless that of many,

many other people), it'll also have grounded alume (AKA aluminum,

aluminium) walls and steel

roofing to shield it from the field of the high voltage power line by

the highway only too close by. (If a cell phone won't work inside

except by a window, I'll

know it's good!) I'll sleep in the cabin, but I suppose I'll still have

to do cooking and most things in the house. So it might not eliminate

the tinnitus, and maybe not even reduce it definitively. If it doesn't

I can make a point of spending some whole days in it to see if that

works. It's worth trying to find out. It's almost impossible to spend

days away from AC electric fields unless one goes camping in the

woods or something - even most campgrounds have power lines these days.

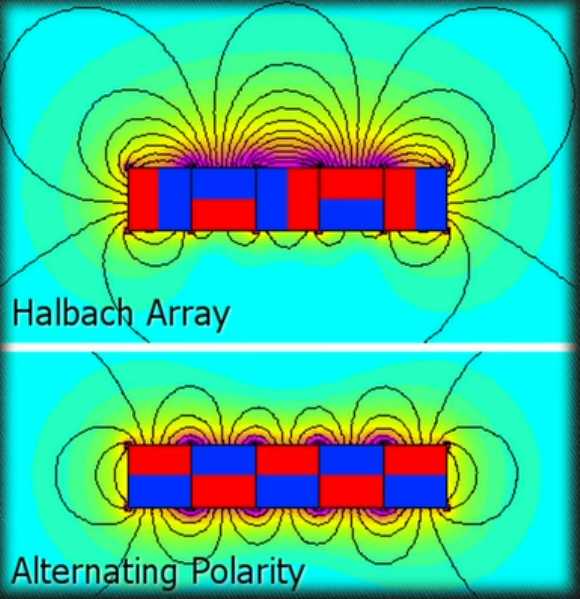

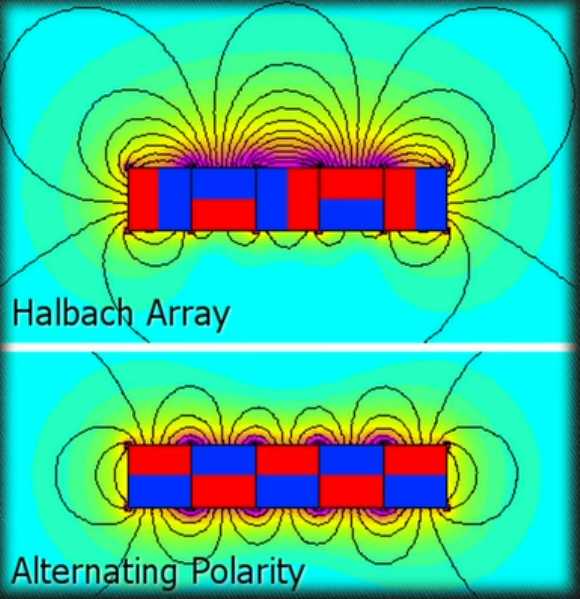

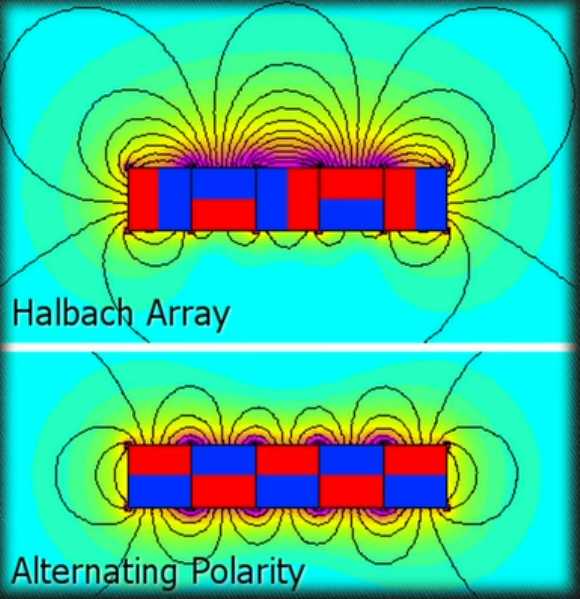

Halbach Magnet Rotor Configurations

[12th] I ran

across the Halbach concept, again, this time in a youtube video, where

it was

shown for a homemade axial flux BLDC motor in a way that finally got my

brain in gear. In everything I've seen before all the magnets in the

"array" were clumped together inline in a row. Somehow the term "array"

confused me, I didn't understand the concept and I lost interest. In

this video a flux diagram was shown with the usual sort of 5 magnet

cluster, but this one shows the idea clearly. (If the top figure is a

Halbach "Array", why is the bottom one not an Alternating "Array"?)

[12th] I ran

across the Halbach concept, again, this time in a youtube video, where

it was

shown for a homemade axial flux BLDC motor in a way that finally got my

brain in gear. In everything I've seen before all the magnets in the

"array" were clumped together inline in a row. Somehow the term "array"

confused me, I didn't understand the concept and I lost interest. In

this video a flux diagram was shown with the usual sort of 5 magnet

cluster, but this one shows the idea clearly. (If the top figure is a

Halbach "Array", why is the bottom one not an Alternating "Array"?)

On his actual

axial flux rotor the magnets only touched (if at all) at the inner

corners. Wait! A Halbach "array" will still work, with gaps between the

magnets? on a rotor? This was never mentioned. Then I could actually

use it in my own axial flux rotors - Awesome!

On his actual

axial flux rotor the magnets only touched (if at all) at the inner

corners. Wait! A Halbach "array" will still work, with gaps between the

magnets? on a rotor? This was never mentioned. Then I could actually

use it in my own axial flux rotors - Awesome!

Basicly by adding "sideways" magnets between norths and

souths, most of the flux

comes out one ("front") face, while very little comes out the opposite

("rear") face. This might virtually double the strength of the

permanent magnet rotor's field facing the stator, and hence increase

the torque per amp of motor current.

In addition, with little flux through the rear, a steel

rotor to carry that flux between magnets is evidently not needed. A

steel magnet

rotor need only be thick enough for mechanical strength, not magnetic

flux capacity, so the motor can be a little lighter.

In another

application, such a rotor should also obviate the need for the Piggott

type type axial flux alternator with a magnet rotor on each side of a

thin iron-free stator. One rotor with a greater field should be

sufficient, which would simplify the one shown here (from TE News #124). Or, two rotors

could match a stator an inch thick and more instead of 1/2 inch. That

would hold a lot of copper windings! Or such a higher powered unit

could more simply be two rotors and two 1/2 inch stators. (Or one rotor

with Halbach configured magnets on both sides between two stators.)

Thinner

stators should make for better cooling of the coils.

In another

application, such a rotor should also obviate the need for the Piggott

type type axial flux alternator with a magnet rotor on each side of a

thin iron-free stator. One rotor with a greater field should be

sufficient, which would simplify the one shown here (from TE News #124). Or, two rotors

could match a stator an inch thick and more instead of 1/2 inch. That

would hold a lot of copper windings! Or such a higher powered unit

could more simply be two rotors and two 1/2 inch stators. (Or one rotor

with Halbach configured magnets on both sides between two stators.)

Thinner

stators should make for better cooling of the coils.

And a Halbach

configured rotor in the torque converter I was making would have much

more flux too. After initial tests of my new torque converter I added

six thin magnets (3/8" x 1/2" x 2") on their sides to my existing

rotor between other magnets. It definitely increased the flux - see

next.

And a Halbach

configured rotor in the torque converter I was making would have much

more flux too. After initial tests of my new torque converter I added

six thin magnets (3/8" x 1/2" x 2") on their sides to my existing

rotor between other magnets. It definitely increased the flux - see

next.

Great Variable Torque Converter at Last: prototype made and tested!

Well, this is a major "ultra efficient EV" component I've

been trying to create since June 2009, with various half-baked ideas

and various results but none really satisfactory. Finally last month I

conceived the best pieces, put together in the right configuration to

make it all work: a planetary gearset, with magnetic coupling between

two

of

its

elements. I described it in theory in last month's

issue, and built one for the Miles ZX40 EV truck this month. Some short

"jury rigged" tests proved it works well, smooth and effective, and

making the magnet rotor "Halbach" tweaked the magnetic-mechanical

proportions into what appears to be a good balance. Charts (see

detailed report under Electric Transport) show the theoretical

efficiencies, even under various magnetic coupling strength scenarios,

to be well over 90% when crusing at typical vehicle speeds, which is

better then the 80+ percent of today's "improved" automatic

transmissions.

Operation

Consider at low vehicle speed the motor turning at 50 RPM

and the

planetary gear body virtually stationary, balanced between moving the

truck wanting to push it backward and the magnetic drag pulling it

forward.

The gear reduction ratio is then the 5 to 1 of the planetary gear.

Now consider driving at 50 KmPH using the same torque. The

drive shaft is then turning about 1100 RPM (for the test truck). The

difference of turning

between the motor and the planetary gear body for the same torque is

still 50 RPM. But they

are both spinning. For 1100 RPM output, the motor is turning at 1140

RPM and the body

1090 RPM in the same direction.

So the gear effective ratio is 1140/1100 or 1.036 to 1.

At higher motor torque for acceleration, the RPM of the

slip increases, making higher effective gear ratios at the same speeds

for more torque and power to the wheels. The higher the vehicle speed,

and the lower the power required, the lower the percentage losses and

the nearer the gear reduction approaches 1 to 1 with everything

spinning in unison.

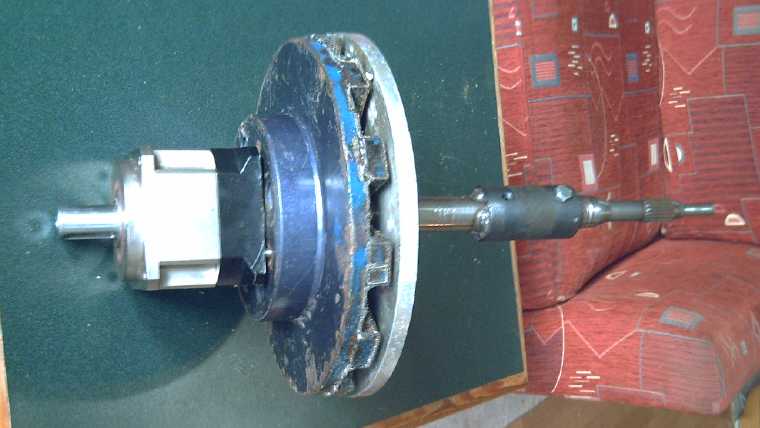

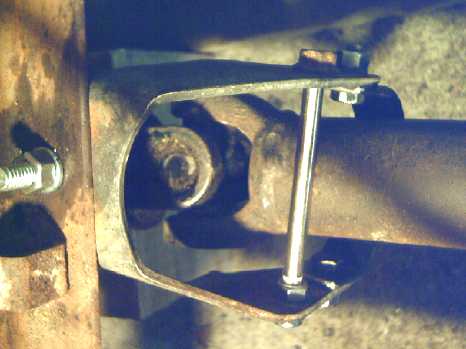

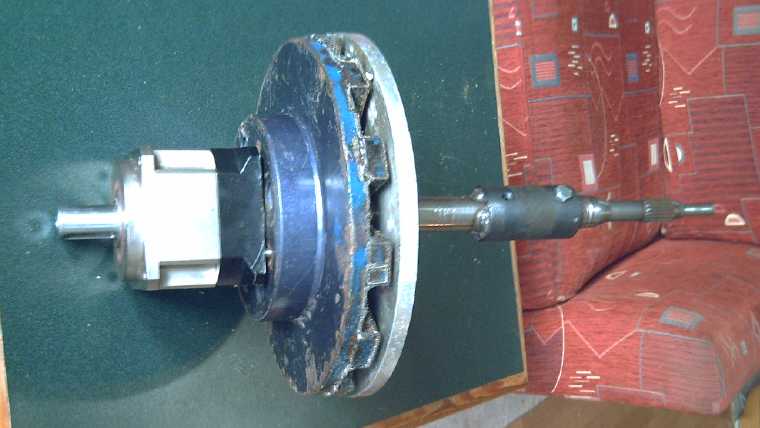

Jury-rigged prototype under truck

Jury-rigged prototype under truck

RIGHT to LEFT:

* EV Truck's Drive Motor * Kludged Motor Shaft

* Alume Disk (turns with motor shaft) * Magnet Rotor (turns with

planetary body)

* Planetary Gearset (5 to 1 reduction)

* Truck's Drive Shaft to rear wheels, with "U" Joint

* Improvised Hanger/Bracket to Hold front end of Drive Shaft for Tests

Remaining to be measured are the levels of magnetic drag

of these particular coupling rotors, and how warm or hot the alume

disk gets owing to the magnetic slip. But it looks like losses will be

only a very few percent

when underway. What is still needed is an RPM meter on the motor shaft

so the

slip can be measured. (The output shaft RPM can be determined from the

vehicle speed.) The theoretical charts indicate that

it would probably be almost superfluous to lock the two disks together

at higher speeds with any reasonable configuration.

Torque Converter Videos

I made a video and uploaded it to Youtube. But it seemed

people got lost in my long theoretical explanations first part, which I

actually made before I had the truck running, and never got to the

actual tests in the truck. So I did a second video, which was just the

first one without those parts. The viewer will probably "catch on" to

the operation just from

seeing it work.

This torque converter can replace an entire vehicle

transmission.

Its exact operation (to match a given vehicle) depends on the planetary

gearset's design ratio and

the strength of the magnetic coupling.

For the truck I picked a 5 to 1 reduction gearset. With

the 2.2 to 1 reduction in the truck's rear differential, that would

give 11 to 1 - plenty for the motor to start the truck moving. Then as

speed increases and torque drops, the variable torque converter gets

near 1 to 1, so in the truck overall it might be 2.3 to 1, and at 100

KmPH on the highway the motor would be turning just 2300 RPM. Its 10 KW

motor is rated for 10000 RPM peak or 5000 RPM steady, so it's in a good

range with higher efficiency.

Before thinking of the truck, for the Sprint car I ordered

a heavy 7 to 1 gearset, to be connected from the motor straight to the

CV shaft to the right front wheel with no further reduction. 7 to 1

ratio with the 3.6 KW forklift motor should allow the lightweight car

to start moving uphill or from in a pothole and accelerate well. (And

if that's not enough, the ratio can actually increase to up to maybe 10

to 1 with the planetary body turning backward at low speeds.) But as

the speed increases and the reduction ratio drops toward 1 to 1, the

motor is turning the same speed as the wheel (or not much more, say

1050 or 1100 RPM at 100 KmPH, depending on torque required). This suits

this motor which tops out at around 2000 RPM. (Whether a 3.6 KW motor

can actually keep the car, light as it is, moving at 100 KmPH is

another question, but if any drive train arrangement will make it work,

this is the one!

Fabrication & Tests

Having pulled it off the Miles ZX40 cargo truck at the

end of August, I disassembled the planetary drive assembly. I enlarged

some holes on the gearset and rethreaded them for 1/4"-20 bolts.

(#10-32 screws to take the whole torque of the body? Good grief!) Four

holes in the magnet rotor made long ago fortuitously lined up with

those and I bolted then together. Well, that was simple!

I drilled a hole in the side of the "hat" shaped magnet

rotor to stick an allen key through. Otherwise there was no way to both

mount it on the planetary and tighten the clamp that holds the motor

shaft. Both had to be done "first".

I contrived to put together the alume disk assembly on the

motor shaft using an SDS "taper lock shaft hub" and drilling some holes

in a huge, heavy washer that fit onto its taper, as well as in the

alume disk. I got the disk well centered when I

drilled the bolt holes.

I put the assembly back together with the disks on it and

tightened the motor shaft via the side hole with an allen key and a

flashlight.

Then I had to

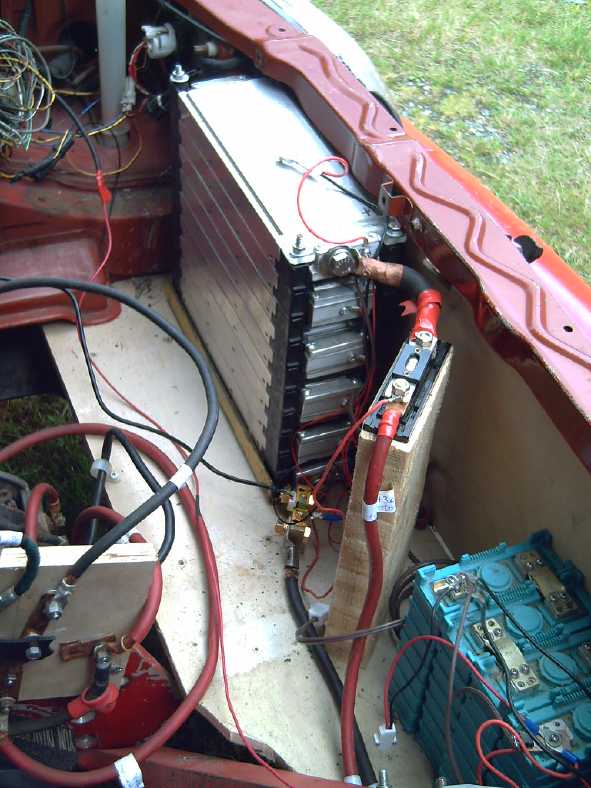

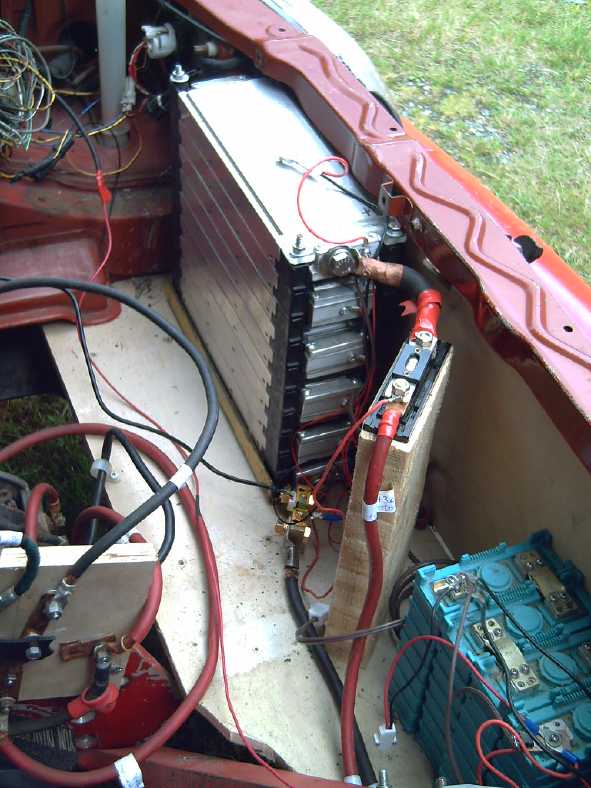

get the truck running again. I removed the

72V lead-acid battery charger. (New chargers?... later.) After that I

made better mounts for the two 36 volt, 120 amp-hour lithium ion

battery stacks and mounted them. I wired them up (in series, 72V) and

in testing found that it was in fact the charger of the 12 volt

battery, a DC to DC converter, that had drained the drive batteries

over time and destroyed 3000$ worth of them. It was turned ON all the

time! It had an "enable" input and should certainly have been turned on

and off with the ignition key. (Thanks, Miles! One of many small

"features" creating big headaches for customers. Small wonder they went

out of business.) I unplugged it - problem solved for now.

Then I had to

get the truck running again. I removed the

72V lead-acid battery charger. (New chargers?... later.) After that I

made better mounts for the two 36 volt, 120 amp-hour lithium ion

battery stacks and mounted them. I wired them up (in series, 72V) and

in testing found that it was in fact the charger of the 12 volt

battery, a DC to DC converter, that had drained the drive batteries

over time and destroyed 3000$ worth of them. It was turned ON all the

time! It had an "enable" input and should certainly have been turned on

and off with the ignition key. (Thanks, Miles! One of many small

"features" creating big headaches for customers. Small wonder they went

out of business.) I unplugged it - problem solved for now.

The motor wouldn't run because the brake fluid was empty

and there's an interlock. (notwithstanding that I had replaced the

brake line to the left rear wheel a couple of years ago. What year

vehicle was this again? 2009? TWO brake line leaks, Really?!?) I filled

the reservoir. From experience I knew I just had to wait.

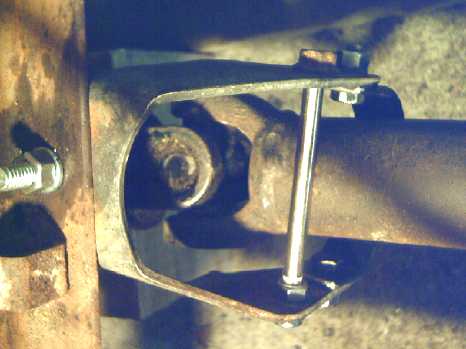

I connected the

planetary/magnetic drive to the motor and

rear driveshaft under the truck. I made a little bracket to keep the

front of the rear drive shaft from dropping down. Good enough for a

test or two!

3 days later, on the 19th, the brakes worked if I pumped

them, and the motor ran. (It has an "idle" speed/torque if you're not

pressing the pedal.) But the truck didn't move. I put a video camera on

the floor pointing under the truck at the drive, and tried a few more

times. I started thinking there just wasn't enough magnetic force to do

anything. If so the number and diameter of magnetism rotors needed was

going to make the idea prohibitive. Was it another disappointing

failure? But it turned out that the alume rotor had come loose and

wasn't spinning with the motor shaft - just rattling.

So far it was all just a theory. I had only a feeling and

a hope that the magnetic drag force between the two rotors would be

sufficient to make the truck move, and more than very feebly.

That evening I managed to position the disk and tighten

its set screw under the truck without removing the assembly. I started

the camera, got in and turned the truck on.

*** Lo and

Behold! When I pressed on the pedal, the truck moved! ***

Both directions. Smoothly. Without pressing down hard and revving it up

much.

Now the theory was a machine!

Next I tried running it over a couple of pieces of wood.

It had trouble with a 2 by 4 without taking a good run at it,

suggesting the magnetism was a little light. But it was in the

ballpark, and I had just found out that I could make a Halbach magnet

rotor with a greater field from the same magnets, so that wasn't too

concerning. A thicker alume disk (than 10mm) would also increase the

interaction. The mechanism had quickly moved out of the camera's field

of view. So I made a way to mount the camera upside down on the side of

the truck looking underneath, to stay with it as it moved.

The next morning I opened the garage door and backed out.

I came to a virtual stop and then

backed up the shallow slope a little farther. I was pleased that it did

start moving fine going uphill - it wasn't so feeble as the 2 by 4 test

might have suggested. Then I drove in again. I only went 16 feet each

way, but the video showed the variable torque converter principle: as

the motor started, the body of the planetary spun backward, but as the

truck picked up even a little speed it stopped and reversed direction.

(and then spun fast as I took my foot off the pedal.)

The alume rotor was warm, maybe 40-45°C. With stronger

magnetic force the slippage and hence heating should reduce, so again I

wasn't much concerned.

That was it for tests until it all had a proper housing

with two rear steady bearings. But while it was apart, since the

magnetic force seemed a bit light, I would add 6 thin magnets on their

sides to the magnet rotor, to give it the Halbach effect: a larger

magnetic field to the front with a reduced field to the rear. By

September 30th I had split three magnets with the angle grinder and

epoxied them on. I don't think I need to resort to changing the disk to

copper or increasing rotor diameters and the number of magnets, but

there are such places to go if necessary and I don't see how this

torque converter can fail to be practical! (Assuming I build it well

enough, of course.)

The next day (with the epoxy still slightly tacky) I put

the assembly back together. I could feel that it was notably harder to

turn the magnetic rotors against each other except very, very slowly.

I'm not sure it would even want more magnetic force than that.

On October 2nd I was fitting it for the rear bearing

(seeing the wobble, this became two steady bearings - one at each end

of the

planetary) and a housing, and then decided to try just a short move

with the camera running. With the Halbach magnets added the body of the

planetary almost stopped even just "iding", moving slowly - the

planetary's design 5 to 1 reduction. That seems like about the right

amount of magnetic interaction. Above that speed it's going to be

turning more and more with the rest and headed for 1 to 1 reduction.

Barring unforeseen glitches, it's going to work great once the housing

is done!

-----

With the excitement of finally creating an automatic variable torque

converter transmission I didn't get anything done on the "Plastic

Recycling 2.0" project. The oven needs the foam insulation (which

didn't even like 150°C) replaced with fiberglass. One mold needs

the burnt plastic scraped off and the big plate mold (17" x 36") still

needs to be finished. Then it should be ready to produce

plates/tiles/slabs and so on. One project at a time, I guess!

Power Outage Preparedness

After a windstorm in the night, the power went off around

midnight on the 2nd/3rd and was off until the next afternoon. Being

concerned as it had already been off several hours when I first got up,

I started running freezers and fridge, one at a time, from the 36V

battery system with inverters.

The 600W inverter that I had tested to run the smallest

freezer with, this time would alarm and quit. Humpf! - a "nominal

36VDC" inverter that seemed to cut out when the voltage fell to about

35.9? - gee, thanks! I got out the 2500W one and more extension cords

and got the freezer going. Later I connected an unused ground wire in

the #10-2 cable to the DC outlet I had plugged the 600W inverter into,

to double up the minus wire, and after a couple of tries got the 65(?)

watt freezer running. Two freezers, maybe 65 and 115 watts, plus the

two inverters themselves brought it up to 210 watts.

It was dull and raining and the charge controller wasn't

even keeping up with one freezer. Part of the problem was the long,

thin charging cord to the batteries (#16 AWG extension cord). Using the

(2500W) inverter to power the soldering, I replaced that with a

considerably shorter #14-3 house wire cord, in which I doubled up the 4

wires (counting the bare ground wire), giving an effective #11 AWG two

wire cable. That helped perk up the charging. Then I turned off one

grid tie inverter and with alligator clip leeds, connected its 1000W

(my old 2012) solar panels on the roof in parallel with the three

panels on the lawn, which were probably in tree shadows as well as the

heavy overcast. That perked it up to 200 watts or so - almost keeping

even. I'm sure that wasn't optimized output from the 9 panels. (And

shows the weakness of having three separate solar panel installations

when wanting one maximized DC output.) In mid afternoon I switched from

the larger freezer to the refrigerator - also about 115 watts as long

as the 400W defrost coils don't come on - and got it cooling again.

Then finally the mains power came back on.

Switching power back and forth between 4 units would wear

thin pretty fast, and carries the danger of accidently leaving one

unplugged and having food thaw out - or simply running out of battery

& solar power, especially in winter. The fridge with its 400W

defrost coil could really be a killer. Hopefully if the power does ever

go off for a long time, by that time I'll be down to the two very small

65-75W freezers, having reduced the amount of frozen food I have. (Why

do I keep buying more? But they're not as full as they were.) One of

them will be turned down (up?) until it's a chest refrigerator instead

of freezer. The higher power units will be turned off.

While the power was out, I kept flipping on the light

switch every time I entered a room, of course to no effect. There is no

question

but that there will be much inconvenience if the power does go out for

a long time, even with all the prep so far. I hope others are doing

things to be ready, because the weather keeps getting more chaotic

causing vast crop failures, civilization is failing in front of us and

more and more we see some hard years - maybe a couple of decades -

coming. The social changes will be immense.

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

Proactive

Approach

to

Democracy

Interesting quote under a video

comment. Seems like how many "underhanded" projects in "democratic"

societies have been prosecuted for a century or more.

"We decide on something, leave it lying around and wait and see what

happens. If no one kicks up a fuss, because most people don't

understand what has been decided, we continue step by step until there

is no turning back. -- Jean-Claude Juncker, President of the EU

Commission 2014-2019

First, people will only "kick up a fuss" if what's been

decided seems to be against their best interests. But they may not

anyway, not because it's not understood, but because it's not worth any

one individual's time to take time and money out of his life to "kick

up a fuss" and fight a bad move that only affects him (along with

everyone else) just a little.

And if it's an agenda being diligently pursued, people can

fight and win the case, and then when everyone not invested in it and

not being paid heaves a sigh of relief and moves on, the proponents

just bring it

back in slightly different form a year or two later. The fight has been

knocked out of everyone, and no one has more energy to rise up again to

protest.

So, adverse decisions and actions pile up and make things

a little worse bit by bit and only over decades do people start to

think "Hey, society wasn't anything like this when I was young!"

This is a huge problem with today's essentially negative

approach to everything. No one except the people at the very center of

the governing structure has any positive power or influence to effect

changes or even to provide input. Everyone else can only protest -

another negative approach. The talent, leadership and organizational

energy from the whole of the general public - from the most thoughtful

and caring citizens, those knowledgeable in countless different special

areas - is cast aside, wasted.

We need to switch to a positive, proactive approach.

As I've suggested before (and am sure to do again), people

must form "ad hoc" organized local teams or committees, often outside

of all existing institutions and organizations, to study in depth

something they feel is important to them. If practical (except for

unique local issues) they then link by internet with similar groups in

other locations, and together present well thought out, well researched

and clear recommendations to government. Then government acts as a

coordinating agency to enact what these most interested and intelligent

members of the public have together agreed upon, issue upon issue, as

the members of the many and various teams most interested in each

aspect of organized society find important to themselves or to society.

And if these teams perhaps continue to meet for some time,

they may measure the results of their original deliberations for

potential revisions. Or a new team may be formed to look at it anew.

This sort of review of results of often ill-conceived legislation

passed today just doesn't happen, and it is rare for any legislation,

whatever its results intended and unintended, to be repealed or

improved.

We might take the examples of IEEE and ASHRAE (Institute

of Electrical and Electronic Engineers, and the American Society of

Heating, Refrigeration and Air conditioning Engineers. ASHRAE groups

hold local dinner and other meetings and events. They are

voluntary, non-government, non-corporate bodies - just people

associated within a field - yet they set standards in the electrical

and

HVAC fields which are generally adopted by governments everywhere

without political comment, and

they amend them when they need modifications. Can we not extend this to

many other areas of interest - professional, economic, social, health,

educational and cultural?

There are of course further aspects to the reform of our

societies, but I see them as resolving themselves in the future. Some

can be addressed via the internet, but so far have not been.

One should be able to readily find the background

and real views and attitudes of all those running for an office at one

web location, not just hear the opinions of opinionated mass media, who

more and more today themselves have a stake in the outcome and can't be

relied on to provide information that is in any sense impartial or

fair. Today we have duplicitous "politicians" who say one thing on

camera to the public and something entirely different to each different

audience - to power brokers behind the scenes. They often have no

intention of doing what they told the public. Such behavior should be

exposed. What stances have they taken in previous issues? Do they make

decisions contrary to citizen groups' wishes? Are they giving away

public assets to their supporters? Do they have a criminal record?

Honesty and sincerity should be assets to a politician, not liabilities

or even disqualifications as they are today.

Special interest lobbying should be become obsolete as

organized citizen groups bring more balanced views on each issue. The

needs and wishes of the public and society at large should prevail over

special interests.

All voting should be by choice ranking (AKA "transferable

vote" and other names). While one can pick holes in any voting system

if one tries,

ranking the choices and recounting as many times as necessary (or

having

runoffs) to find the 50% majority consensus is the only one I've seen

where there is never a reason to vote any way except according to one's

true desires. No "strategic" voting for something you don't like best

in order to prevent something even worse. No voting for a "party"

rather than the best qualified person. (More aspects to our systems

being essentially negative.) In general today's politicians and

political party managers don't like choice ranking because it is also

the system least susceptible to manipulation and to big political party

hegemony over the electoral processes. And of course the voting system

must be honestly administered. Democracy is over when it isn't.

And of course the three branches of government should be

separated. One should vote for a civic, state/provincial and national

chief executive separately from one's legislative representative. And

many reforms could be suggested for the composition of our legislative

bodies. They should represent a cross section of the whole of society,

not be a bunch of clones beholden to a particular party line or

philosophy.

I should shut up here (if not sooner) - I could go on with

these known ideas largely kept from us by today's politicians and

political systems. The key new idea which is being

presented to us all is that of having organized peoples'

committees/societies/groups/teams, linked together by internet to form

national consensuses on all manner of national interests, and these

clearly expressed desires coming from the public being carried through

to becoming the policies of the government, which would then much

better represent the people who elect it. Government of, for and by

the people, in well organized channels.

Asteroid

Dimorphos:

Ahrrrg, Monochrome Again!!!

NASA decided to test the idea of diverting the course of an asteroid in

case one is ever heading too close to the Earth by crashing a space

probe into one. They chose one called Dimorphos, orbiting a larger one

called Didymus. (the only asteroid with a moonoid?) It took a series of

images as it approached at high speed. Thus we have a few very detailed

images of this asteroid from close ranges. The scene below is clipped

from the "penultimate" image, the last one before the crash. To a

casual glance - and I'm sure that's all anybody at NASA or JPL will

give it - the surface is a jumble of rocks.

I was pretty sure the orbit of this pair was too close to

the sun to host the sort of very alien airless world life detected

(even if no one seems to recognize it) on Ganymede and other airless

worlds in the Jupiter and Saturn regions, and of which a seed was

captured by a very high altitude balloon searching for alien life

("panspermia") in 2015 (TE News #85).

And

yet,

the

scene

on

close examination doesn't seem to be lifeless

rocks.

So here is the original monochrome image, and below it one

I've colorized to highlight a few of the features. (The brightness of

each feature is unchanged, but the gray has been shifted in hue, eg

++green,-red,-blue.)

Especially the green object with folded down 'jagged' edges has every

appearance of being a leaf. By their shadows, yellow objects especially

seem to be flat and off the ground rather than boulders, also

suggesting leaves. I thought the red objects looked like leaves coming

from central roots. and there are some things that look like striped

stems. There's

more of the same in the full image, but I thought this area was a good

illustration. (Consider in viewing that gravity is next to non-existent

and the contrast between light and shadow is very high because there's

no atmosphere to scatter light.)

And now I go back to my decades long lament: WHY oh WHY do

NASA, JPL et al think that monchrome images show us enough and that

color images are somehow "unscientific"? The only craft that have gone

to the

outer solar system that had proper color cameras were the Voyagers in

the 1970s, and they opened our eyes to many fascinating new worlds.

(And they only got color because of a couple of left-over color cameras

from

the Mariner mission to Mercury!) Oh wait... and the recent "New

Horizons"

probe to Pluto, which also showed us a fascinating sphere that

monochrome wouldn't have done justice to. But there are still no color

images below "continental scale" of any outer solar system world.

Billions of dollars for space missions and they can't even

throw on a 39.95 $ color camera?!? Again I am reminded of a monochrome

"picture of a cow" that our class was shown in high school. It looked

like a

piece of abstract art. Blotches of white and black. I was trying to

visualize some artist's abstract rendition of a cow. Only after every

feature was carefully pointed out to me (and just as the teacher was

snatching it away from me) did I suddenly recognize that it was a

perfectly clear, sharp photo of a cow standing in front of a fence!

(Other students had similar reactions - that sudden "OOHHH!") A color

image would have been perfectly clear and unambiguous.

Likewise, a color image would have immediately revealed

the true nature of this scene. this and many other planetary images in

which we seem to be blind to their true nature in the pathetic

monochrome renderings we've been handed.

Well, as my mom once said "Scientists are blind." She

should know. My dad was a mycologist (and often "blind") and they

were in the university's social circles/faculty club so she knew plenty

of them.

How

Famines

Develop

Rapidly

According to Michael Yon, From Video: "You're Going to See a Lot of

Starvation!!! | Jordan Peterson 2022"

https://www.youtube.com/watch?v=GdtWB8sE4q0&ab_channel=JohnnyBigger

(The above video was excerpted from another much longer video by Jordan

Peterson:)

" Cometh the Horsemen: Pandemic, Famine, War | Michael Yon | #274"

https://www.youtube.com/watch?v=R7gAEkzIgvw&t=490s&ab_channel=JordanBPeterson

Yon:

When people are hungry within 48 hours they're going to hit the

streets, right?

And they'll start robbing the stores. Then they'll start robbing the

trucks and the trains and the boats, and so then supplies stop going.

Then governments always start taking food from the farmers.

[<snip> ...and control the food.] So people start robbing from

the farmers as well, right?

And then the farmers say, hey, I'm either bankrupt or I'm not making

any money. And so the farmers stop farming. So that's how you see we

get into the second season of this, right?

And so the famine creates more famine, just like fire creates fire.

And as [peoples'] nutritional, you know, resources diminish, so too

does their physical resiliance. And now they're open to disease. Many -

if not most - of the people who die in famines actually die from

[<> ...diseases] -- they call them "famine fevers".

<> ...and these sorts of things often lead to more war, right? So

it's a recursive sort of, you know, the factors just keep... <>

it's almost a fission reaction, right?

Jordan, I would not be surprised if by 2025 a billion people aren't

dead. I mean, we're really headed into the most epic famines that have

ever happened in human history.

======

Peterson thinks Yon's predictions are dire, but Yon isn't looking very

far down the road thinking only to 2025. As we are supposed to hit 8

billion people before the end of this year with climate mayhem and

failed crops just getting underway, digging out the dregs of the

remaining petroleum and other presently needed natural resources and

with the present people in positions of leadership in most nations in

it for themselves or actually bent on destruction and depopulation.

Probably around 6 billion will be gone before 2050. Well, that's almost

30 years with aging populations through the civilized parts of the

world, so an awful lot of us were or are going to die of old age

anyway. Still it's not going to be pretty. We should foster and

preserve all of nature and ecology that we can in the coming decade or

two. What if deer, kangaroos, wildebeest, elephants and so on (not to

mention the predator species that eat them) become extinct in the

desperate human hunt for food?

In a "steady state"

condition the world might support 3 billion people, but it's going to

dip way down under that owing to our degradation of the environment and

ecology. Some people think one billion or even fewer, but I expect

it'll be closer to two. (And after all according to official figures

it's just 95 years since we first hit 2 billion people.)

But again this is all part of Christ Michael's "Correcting Time" plan

to rehabilitate the few planets whose spirit leaders followed Lucifer

into

rebellion, now that the Lucifer Rebellion has been terminated and the

unrepentent arch rebels eliminated by the Ancients of Days. (...in or

about 1984 Earth time, and with their own agreement/acceptance that, as

they were unwilling to repent, there was no further place for them

anywhere in the universe.)

With better (human) leadership and global cooperation,

this die-off might be put off until the world was at 10 billion or more

people but the sooner it happens, the more will be left of the world's

ecology, the more species will remain and the more people will be left

by the end of it. If it was to hit 10 or 11 or 12 billion before the

population crashed, little would be left of nature and ecology and

those remaining (if any) would probably be small

isolated groups of people eking out meager livings, all fearing each

other and unable to resume any sort of global civilization. (It reminds

me of a bit in Matthew 24: "If those days had not been cut short, no

one would survive, but for the sake of the elect, those days will be

shortened." These would seem to be those days.)

With a collapse from the present population, a new and

better civilization can and will rise from the ashes of the old. People

will have learned a huge lesson that this world can only provide a

good quality, prosperous life to so many people at a time, without

overshooting

the global carrying capacity. And with good birth control now available

only wanted children will be born into good (and small) families from

where they will be raised to be productive and contented human beings

and at last population and ecological overshoots (the sad endings of

dozens of previous human civilizations) will be ended. So will wars.

Techniques of obtaining "free" energy which have been

withheld from us so far owing to our social and cultural immaturity and

the immensely destructive uses to which it could be put, will be

rediscovered and adopted, freeing the world from petroleum resource

dependency and depletion. And sometime in the coming decades in the

midst of our crises, a new Divine Son, the avonal son Monjoronson, will

appear. He is in fact already present on or about the planet as a

spirit being but he will not materialize until he will be welcomed.

Unlike Jesus he will appear as an adult, and he is expected to stay on

Earth for 1000 years and help guide our development into the beginnings

of a

golden age of Light and Life. (I'm sure we need all the help we can

get!)

Satellites

or

Drones?

On the evening of

the 13th at about 21:30-21:35 PDT, I happened to be outside and I saw a

string of lights, "stars" traveling across the sky, one after another

in a

perfect straight line. I counted 32. They seemed to go from the

west-southwest to the east-northeast, passing a

little to the southeast of me, seemingly very high up. They were moving

too fast to be satellites. At first they might have been every 3 or 4

seconds or less. One light in the line (5th or 6th one?) was missing,

making a double length gap.

Gradually they became more spread out, passing by maybe every 7 or 8

seconds. or longer. From where I was they appeared from behind a tree

branch, one after another. I thought maybe I heard jet engines, but it

was

high tide and with the crashing ocean waves sounding covering

other sounds, I really wasn't sure. But airplanes don't follow each

other in a straight line anything like that closely.

The direction said they started over the Pacific Ocean

somewhere (or Asia?) and that they were headed toward the Northwest

Territories... or over the pole and beyond toward Europe or Russia. I

don't

know what they were, but in today's political climate this unique event

was disquieting.

Then on the 15th I read about US Army Conducts Drone Swarm

Exercise with Armed Quadcopters.

(Zerohedge.com Sept. 14th, 8:20 PM) There were 40 drones in that - just

about the same number I saw. So I thought probably this was another

drone swarm exercise, with another batch of the same drones. So they

would have been lower and slower than I had thought, with the loud

waves masking their noise? I expect then that they flew from a ship

nearby off the coast and weren't going as far as I imagined.

Coming after Biden's inflammatory speech with the blood

red

background and marines standing behind him, I fear reader comments

under the article are right, which suggest the drones are going to be

used against Americans - that would doubtless be any and all who have

expressed criticism of the 2020 US elections and present government - a

new "night of the long knives" to silence thousands of critics all at

once. Before the 2022 US elections in November. To save democracy from

MAGA terrorists (adverse votes). Doubtless they have been compiling a

list. Canadians won't be left out I'm sure. Everybody has a cell phone

and their location can be pinpointed at any time. Sudden death without

warning from the sky. Think communist purges; Argentina, Chile,

Pinochet.

Well, some are saying these fast-moving in-line objects

are Elon

Musk's "starlink" satellites. They certainly followed an undeviating

straight line. Even if they are I will not retract the

above paragraphs. I will be very relieved if I'm wrong!

Smol

Thots

* I heard somewhere that humans account for 32% of the total land

animal mass on the planet.

Livestock makes up 67% and wild animals 1%. The percentage of wild

animals has plummeted in recent decades. (I suspect this statistic only

includes mammals - it wasn't specified.)

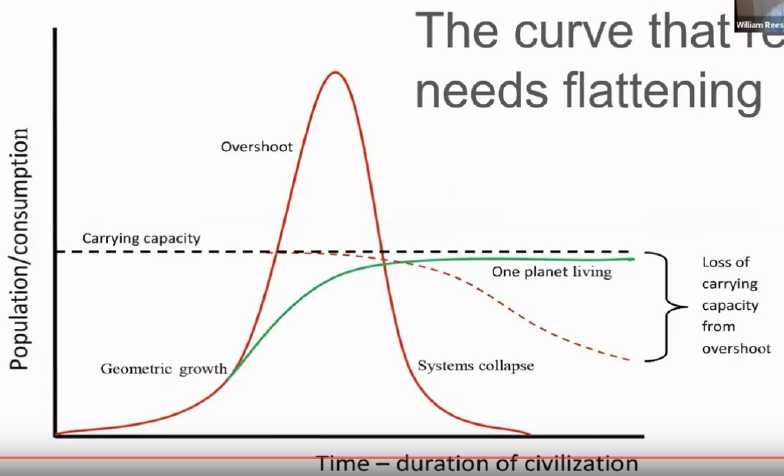

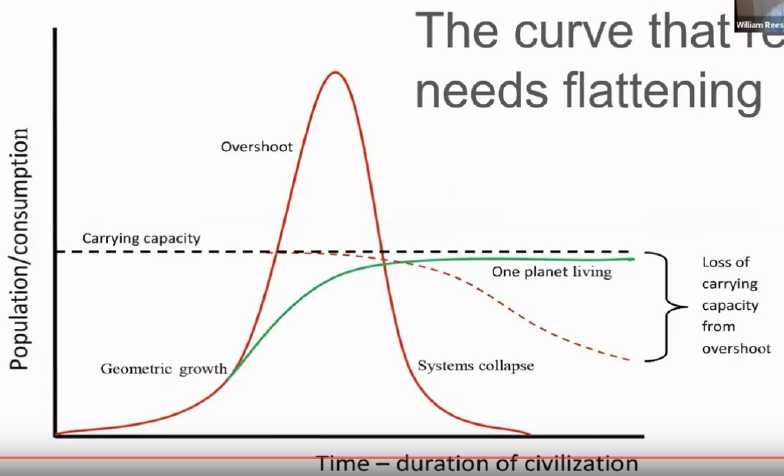

* Someone made this chart of the

"carrying capacity" of the Earth. (See Collapse in a Nutshell", youtube

channel "TheGreatStory" by Michael Dowd) At the left we start with a

low population, which gradually grows.

Then there are two scenarios. With the green line, the

population wisely stops growing before it gets too large. No more

resources are consumed annually than nature can replenish.

With the red line, the population continues to grow. When

it becomes too large it starts consuming more resources than are being

replenished, and starts degrading the ecology to sustain itself. When

it has finally used

up all the resources, or at least one or more necessary resource, there

is famine and the population crashes, and afterward the degraded

environment (dotted slope) can't support as many people as it could

before.

While illusrative, I would object to some of the details:

(1) The population on the left was never "minisule". If the North

American natives had an estimated 50 million hunter-gatherer people

before the Europeans came, why would the whole Earth only have had 10

or 20 million for most of a million years as most scientists seem to

suppose? Surely it (Asia, Europe, Africa) would have supported closer

to 500 million primitive hunter-gatherers?

(2) The "overshoot" looks almost like a part of a sine wave. In fact,

collapses of civilizations are generally extremely rapid compared to

the gradual growth and the line should go down very steeply, practicly

straight down.

(3) The "loss of carrying capacity" should drop during the

overshoot, after which it should (we hope) begin to recover, which

isn't shown. There is some "point of no return" (like making

most species extinct and cutting down every last tree on Easter

Island), and a "point of very, very slow return" (like the present

harsh desert the overpopulating Anasazi people made from a pine and

juniper forest). But short of those, it should gradually recover after

a population crash. I expect that will be the future scenario, although

we are losing species at a great rate at the present time.

Many have estimated 2 to 3 billion people as the maximum

carrying capacity. I lean toward the lower figure after the crash

(others say still lower) and the upper once things improve again, but

it is certainly a maximum. (According to one chart, we originally hit 2

billion in 1927 and 3 billion in 1960. Then 4 billion in 1974, 5 in

1987, 6 in 1999, 7 in 2011, and are expected to hit 8 billion this

year. And over half this bloated population can only eat thanks to

mining non-renewable resources which are now becoming quite depleted.

This is a

runaway train that can only end in a trainwreck.)

* It's interesting to click on youtube

on a video of some old celebrity. Soon you are seeing video suggestions

for all kinds of people you haven't heard anything of in decades - or

some who were famous before I was born. (Colonel Saunders

was a real person? Looked just like his picture. Virgil Earp, Wyatt

Earp's nephew, talks about being

a sherrif in the old west? Gasp!)

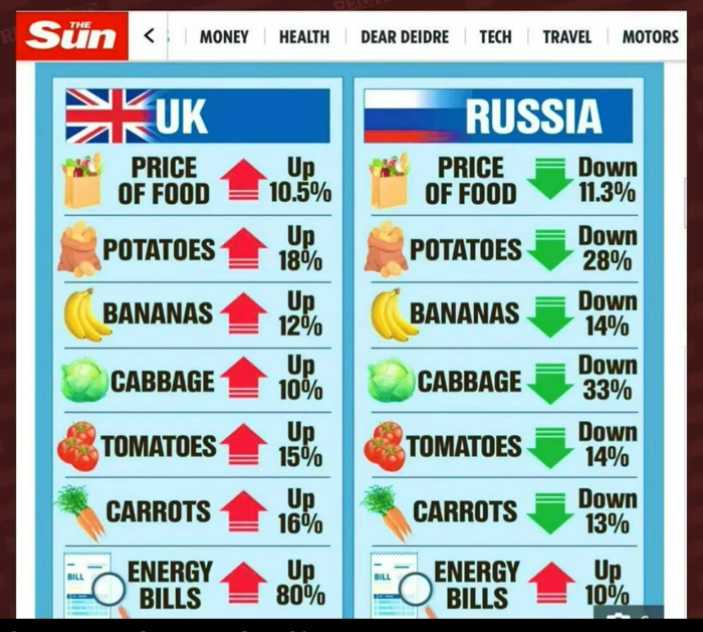

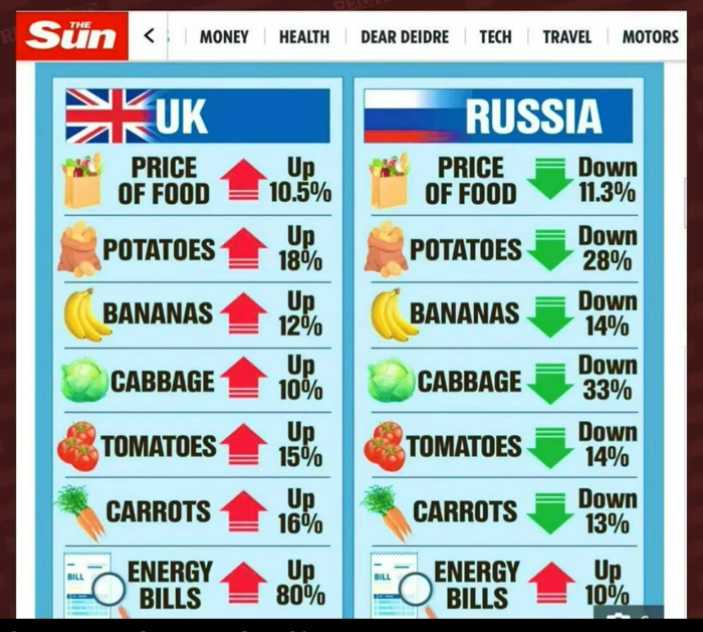

* The UN and the West were lamenting that because of the fighting in

Ukraine, grains from that country weren't reaching nations where

starvation is reaching epidemic proportions - North and Central Africa,

Pakistan, Bangladesh... Russia kept saying that for humanitarian

reasons it wouldn't stop grain shipments from Ukrainian ports and would

even lend minesweepers to help clear mines laid by Ukraine around their

own ports. Finally an agreement was worked out with Turkey as an

intermediary (I presume to ensure that the ships weren't being used to

smuggle weapons into Ukraine), and the grain began to flow.

Of the first 80+ shiploads of grain leaving Odessa, all

but two went to European ports or to USA. Only 3% of the grain went to

the starving countries cited as being the reason Ukrainian shipments

were desperately needed. Is that pure hypocrisy, or is Europe, without

having admitted it, also in desperate need of grain? A desperate Europe

can doubtless afford to pay more for it than desperate Egypt, Central

Africa, Pakistan and the Middle East.

Sure enough, TFI Global had a headline on Youtube on the

14th, "Europe is Staring at an Intense Food Shortage".

* Furthermore, Russian grain shipments were supposed to be

un-sanctioned too as part of the deal, but so far they haven't been.

* As Ukraine counterattacked and took areas in the undermanned Kharkov

region, residents fled with the retreating Russians and headed across

the border into Russia, fearing reprisals from the Ukrainian forces or

administration - and no doubt future fighting in their towns - and of

possibly being conscripted into the Ukrainian army.

* RT-Russian has a map of Russia full of green dots showing

places/homes where Russians have volunteered to host refugees from

Ukraine/Donbass.

* Putin said there would be referendums in Lugansk, Donetsk,

Zaporizhzhia and Kherson to see if they want to join Russia. People in

these areas wanted them - have wanted them for some time. The USA said

in advance they wouldn't recognize the results regardless of anything.

Zelensky says if anyone participates

or votes in them, they will face 5 years in jail. Congratulations! You

have ensured a virtually 100% "Let's join Russia" vote. Who would vote

to be part of Ukraine and face prison time if they win the vote? Any

slim chance that Kherson or Zaporizhzhia might vote to stay in Ukraine

just went out the window. [29th] International observers were there.

The results came in. Only in Kherson was the vote under 90% to join

Russia at 85%. In Donetsk it was over 98%. If Ukraine had treated its

own citizens with common respect, no doubt the results would have been

quite different, or the referendums would never have been needed.

I am not in favor of the limited choices offered in the

referendum: Join Russia, "Da" or "Net". But if more choices were

offered it should have been on a choice ranking ballot. For example,

Donetsk could have been offered "rejoin Ukraine", "remain an

independent republic" (or perhaps "form a new republic of all the

Russian Ukrainian regions"?) or "join Russia". In this case I have

virtually no doubt the end result would have been the same, but we

might have learned more about the more exact sentiments of the peoples.

Some might have preferred to remain independent, and the less than 2%

"Net" might have become, say, 15% whose first choice might have been

for an independent "Eastern [Russian] Ukraine". (In Kherson,

"independence" might have been very popular.) And with more choices

revealing more about the real sentiments of the affected people, it

would be harder for the West and Ukraine to scream "Not Fair, Not Fair!"

* Putin announced a partial mobilization of Russian forces, calling up

of reservists, following on the retreat from Kharkov area. The former

head of defense of the Donetsk People's Republic (DPR) (whose name I've

forgotten) said right from the start that Russia hadn't committed

anything like enough troops for their operation to succeed. Looks like

he was right.

I guess if you're fighting with fewer forces

than the enemy but great equipment and tactics, you can win your

attacks even

against fortified positions and inflict great damage, but still not be

strong enough everywhere to hold the lines against a concentrated mass

attack at some point(s) along a long front. As some commenters have

noted,

ending the whole thing faster via increased force would result in less

pain (and lower costs) overall and for all. The retreat has been called

a sign of weakness and failure on Russia's part, and this is apparent.

If they didn't have adequate forces to hold the ground they took or at

least a reserve to quickly counterattack, they should have been

recruiting earlier.

It can also be said that in war, what you least want or least expect

the enemy to do is usually what they do. Churchill (somewhere in his

WWII memoirs) said something to the effect that wars consist largely of

a catalogue of blunders and disappointments. OTOH, even this small

mobilization of reservists has caused apparently considerable commotion

inside Russia.

* As Europe

heads into an extreme energy crisis that is crushing their entire

economies, Putin reminded them all they had to do to end it was drop

the sanctions and open the Nordstream 2 pipeline, already built and

sitting doing nothing. All they are doing by supporting Ukraine is

prolonging the fighting and causing severe crises for themselves. (Soon

after that the Nordstream pipelines were blown up!)

* As Europe

heads into an extreme energy crisis that is crushing their entire

economies, Putin reminded them all they had to do to end it was drop

the sanctions and open the Nordstream 2 pipeline, already built and

sitting doing nothing. All they are doing by supporting Ukraine is

prolonging the fighting and causing severe crises for themselves. (Soon

after that the Nordstream pipelines were blown up!)

* Why Europe continues to fight the US or international "deep state"

proxy war is beyond me. Especially puzzling were the unexpected moves

of Sweden and Finland to join NATO. I think I have the answer: bribery

of or threats (or both) to top officials including the leaders in those

countries. Maybe the old "I have a wad of money in this

pocket to do it our way or a gun for you and your family in this one.

Which do you choose?" trick. Anyway some kind of heavy pressure from

USA. Nothing else makes much sense to me. The idea that they are

suddenly terrified of an attack from a Russia that seems quite bogged

down just with Ukraine which they had good and explicitly stated

reasons for attacking, seems ludicrous.

* The fact that Europe has become so

reliant on Russian methane (AKA "natural gas") and oil is probably the

best indication of how far down the road of using up these

non-renewable energy sources the world has traveled, as well as to how

high the population has bloated. "Peak oil" is way behind us. Without

the Russian contribution,

there doesn't seem to be enough readily accessible fossil fuel anywhere

in the world to meet all the needs. OPEC raised its "production

cap", but it brought little more oil on line. If there even is

more, new extraction and refining facilities need to be created in

order to deplete the remaining reserves faster.

* Those running Washington DC who have left the US southern border wide

open as millions of unknown migrants come flooding in - and even flown

them in by the planeload - destabilizing the country like never before,

don't seem at all to like having governors of southern border states

shipping even a few of them - drips in the bucket - into the northern

states where they live. They're calling it "criminal acts".

("We welcome illegal immigrants but they can't stay here!")

* I feel sorry for those migrants as well as the Americans being

overwhelmed by the flood. The USA is falling apart before our eyes.

They've been promised more than US citizens are now able to procure for

themselves or will be able to give them. Will they not all soon be

starving, the population and the migrants alike? It seems almost like a

trap.

* Near the end of the month both Nordstream methane gas pipelines were

blown up under the sea. Now it doesn't matter what Germany decides

about maintaining sanctions against Russia or not: Europe is screwed.

Germans and other Europeans are going to freeze to death this winter.

They will burn down the remainder of Europe's forests in quest for

firewood. Countries will collapse into chaos.

The USA is selling liquified methane ("LNG") to Europe at

exorbitant prices. Biden, in mid February, publicly threatened to "shut

down Nordstream 2" "if Russia attacks Ukraine" and to a question of

"How?" just said

"I promise you, we will do

it." Few are buying the story that Russia blew up its own 20 + 15

billion dollar pipelines... the "plausible deniability" is implausible

and the escape goat is escaping!

ESD

(Eccentric Silliness Department)

* Real versus Imaginary Numbers:

McRancher: "Yessir, I have over 50 head of cattle on this ranch!" --

McJealous: "Ya? Well, I have 5000 head of cattle on my

ranch!"

* Q: Why is it that whatever you're looking for is always in the very

last place you look? A: Because after that you stop looking.

"in depth reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

Variable Torque Converter with Planetary Gear: a Magnetic Method

(It Works Great!)

(Plus Miles ZX40 EV Truck Renovations)

The Truck (in 2016): The test

vehicle for the

torque converter

The Truck (in 2016): The test

vehicle for the

torque converter

Variable Torque Converter Project

Review

As I recall I started the "variable torque converter"

project in June 2009 when I realized that the "Electric Hubcap" axial

flux BLDC

motors I had started creating the year before couldn't have the torque

to start a car rolling directly coupled to a wheel, but couldn't safely

or efficiently

rev up to higher thousands of RPM during high speed travel if they were

geared down a lot. Axial flux BLDC is the most efficient type of

motor in various EV operating conditions including in regenerative

braking, but they're most efficient at lower RPMs, eg, under 2000. And

at lower RPMs rotor inertia isn't a serious problem. A continuously

variable automatic variable torque converter sounded like the ideal

solution, and I was sure there

had to be some relatively simple way to make a good one. The

designs

others have come up with were anything but simple, effective and

efficient. They include:

* The fluid torque converter (anything but efficient and with only a

limited range of ratios)

* special steel belts and cones (Honda cars)

* a V-belt and centrifugal varying pulleys (snowmobiles, etc.)

* Constantinesco's 1920s variable pendulum mechanism that worked well

but put heavy stresses on the materials (apparently wore out fast).

* an amazingly complex gear system that had to have a second motor spin

a small gear to vary the main ratio (AFAIK only a sample prototype was

ever made)

* Toyota's dual planetary gear system, which again was driven by two

motors and an engine rather than by a single motor - complicated.

In fact I was sure there must be multiple ways it could be

done. But I had

no idea what any of them might be. Apparently neither did anyone else,

or someone would have already built something better. On actual

examination good solutions were elusive. So I seemed to be

(as I often am)

in uncharted territory.

While I blundered down many blind alleys, I consider that

some of the ideas in 2009, 2010 and beyond had merit. They were

components of potentially good ideas. My first idea of

a magnet rotor driving an alume disk on the car wheel by magnetic drag

had the essential "magneticly variable" part, but it started with 1 to

1 gearing that didn't actually magnify the motor's torque when the

wheel was turning slower than the motor.

The idea of slipping a planetary gear body backward to

increase its gear ratio was also a good one, but I was trying to drag

it to a stop as speed increased. The idea was it could have an

"infinitely" high ratio dropping down to its designed ratio. But I

wasn't

actually getting that, mostly just making heat. It could have worked by

having a generator slow the body and return the power the batteries,

but that seemed too complicated to build. I didn't come up with

the idea of having it slip forward against another of its own

gears to reduce the designed ratio until much later. Then I

finally

realized that if it

could be made so that all the elements spun in unison, it would start

from some higher ratio and finally at highway speeds all elements would

spin at or near 1 to 1. This was a key concept. But I still hadn't

combined the ideas. And the fabrication situation was complicated by

wanting to drive the chain I had made connecting to the differential of

the Sprint

car, which was of course off to the side rather than in-line, using

what is naturally an in-line mechanism. Putting the "in line to wheel"

planetary

gear in the Chevy Sprint (seemingly an unrelated side project) started

also lining

things up in my head.

Finally I realized that the plan from a very few years ago

for combining a planetary gear with all elements spinning and the big

centrifugal clutch should work with the new in-line drive in the

Sprint. But the project got put off by difficulties of construction and

layout,

and other events and projects. And the big clutch was mechanicly

cumbersome and I was pretty sure it would be noisy and would wear out

quickly - but if it did the job, it would be worth it. It could be

improved later for production if it made for a good variable

transmission.

Then just last month (August 2022) I thought of using a

planetary gearset the same way (all elements spinning) but with magnetic

drag rotors between two elements in place of the centrifugal

clutch. The potential quietness and smoothness of operation with no

mechanical wear were much more appealing. I searched around my shop and

storage and soon located all the needed components. Nothing had to be

made from scratch and nothing had to be ordered. (Wow!) And then I saw

that there was room under the Miles ZX40 electric mini-cargo truck to

install the whole mechanism, and furthermore to do so utilizing what I

had already fabricated for the truck just to put a fixed 5 to 1

reduction planetary

gearset on it. So it not only seemed like a highly promising design

concept, but it also looked like it should be a rapid fabrication to

the point of initial prototype testing instead of a long, drawn out

project that would get put off and put off again by other priorities.

Jury-rigged Planetary-Magnetic

Torque Converter

Jury-rigged Planetary-Magnetic

Torque Converter

being tested under the truck

And within a month I've

proved it works. In retrospect a design quite plain and simple, where

in the

future people will look and say "Of course that's how it's done!" Yet

no one else has ever come up with anything like it, and it took me over

13 years. My vague 2009 variable torque converter conception was

finally vindicated in tests on the 19th and 20th.

Videos:

As per the theory, in the

brief actual tests in the explanatory video, especially the last test,

one can see the body of the planetary gear start to turn backward, then

slow to a stop and reverse direction (adjusting the "gear ratio" on the

fly) as the speed and torque changes. More work is of course required

to make it practical and roadworthy, but the use of one highly

efficient automaticly

variable gearset with magnetic rotors to replace an entire vehicle

transmission will allow

more optimized electric drive motors to be used, operating in their

optimum RPM range at all vehicle speeds. This will reduce vehicle

energy consumption, reducing required motor size and power and

increasing range, and hence improve the entire automotive industry.

AFAIK no one else else has come up with such a fabulous

and simple design. The result is surely worth all the years it took to

get

here. Of course it wasn't my only project in all that time. Sometimes

one experiments and sometimes one does other things and waits upon

inspiration and a more advanced concept before proceeding. But without

the effort of trying things out and pushing the bounds to flesh out

possibilities, the inspirations for how to go farther won't come.

The Fabrication

I got something of a mental

block about starting building this. Probably too many disappointments.

over too many years. But I told myself "a little bit every day and

it'll be done before I know it!" (Then I can start on installing

batteries and chargers to get the truck running again.)

[4th] I had previously pulled the gearset and shaft out of the truck.

Now I pulled the extended motor shaft off the planetary.

[5th] I fit together

"assembly #1", the alume disk on the motor shaft.

It's a very long shaft taking up the length of the original

transmission on the truck, with one end to fit the motor socket splines

and the other to fit into the planetary gear input (sun gear). I was

"lucky" how well these parts fit together, except I've tried to

"standardize" my experiments with 1.0" shafts and I bought those

washers exactly because they did fit on the taper of SDS taper lock

hubs. So only the

"almost" fit of the alume disk over the large part of the SDS hub was

completely fortuitous. I turned the 1" shaft down (long ago for

something else) a

bit much in the area where the hub must sit, but it should be close

enough, and again it was fortuitous that it needs to sit right where it

was turned down, with maybe 1/4" sliding room to play with magnet gap

adjustments.

[5th] I fit together

"assembly #1", the alume disk on the motor shaft.

It's a very long shaft taking up the length of the original

transmission on the truck, with one end to fit the motor socket splines

and the other to fit into the planetary gear input (sun gear). I was

"lucky" how well these parts fit together, except I've tried to

"standardize" my experiments with 1.0" shafts and I bought those

washers exactly because they did fit on the taper of SDS taper lock

hubs. So only the

"almost" fit of the alume disk over the large part of the SDS hub was

completely fortuitous. I turned the 1" shaft down (long ago for

something else) a

bit much in the area where the hub must sit, but it should be close

enough, and again it was fortuitous that it needs to sit right where it

was turned down, with maybe 1/4" sliding room to play with magnet gap

adjustments.

Before I finished I roughed up the end of

the shaft with

the grinder because it was so prone to slipping, the planetary having a

socket with just a clamp

with one screw and no key slot or even set screws to affix it more

securely.

Before I finished I roughed up the end of

the shaft with

the grinder because it was so prone to slipping, the planetary having a

socket with just a clamp

with one screw and no key slot or even set screws to affix it more

securely.

[6th] I had to drill a hole

in the side of the "hat" on the magnet

rotor. Otherwise there was no way to both mount it on the planetary and

tighten the clamp that holds the motor shaft. Both had to be done

"first" - unless the allen wrench could go in through the hole. I went

into town to find some hardened #10-32 machine screws. They only had

the same cheap ones I already had. I finally decided they were

ridiculously small for the amount of torque they needed to withstand

and drilled out the holes to the same depth and tapped them for 1/4"-20

bolts. That's much better.

[6th] I had to drill a hole

in the side of the "hat" on the magnet

rotor. Otherwise there was no way to both mount it on the planetary and

tighten the clamp that holds the motor shaft. Both had to be done

"first" - unless the allen wrench could go in through the hole. I went

into town to find some hardened #10-32 machine screws. They only had

the same cheap ones I already had. I finally decided they were

ridiculously small for the amount of torque they needed to withstand

and drilled out the holes to the same depth and tapped them for 1/4"-20

bolts. That's much better.

I mounted the

magnet rotor and then re-attached the shaft,

with the alume disk on it. The hole for doing up the clamp bolt seemed

to work - if I shone a flashlight into it to see when the bolt's hex

socket was lined up. I got the shaft in pretty tight after I cut the

more and more rounded end off my allen key.

I mounted the

magnet rotor and then re-attached the shaft,

with the alume disk on it. The hole for doing up the clamp bolt seemed

to work - if I shone a flashlight into it to see when the bolt's hex

socket was lined up. I got the shaft in pretty tight after I cut the

more and more rounded end off my allen key.

The disk had to be brought farther down the shaft to get

it close to the magnet rotor, and the shaft was turned too small in

that area. The

SDS hub slit was closed to nothing and it was still loose. I put a

long set screw into the hole for one and tightened it up with around a

4mm gap. (At least, I thought I tightened it - see later.)

I cut a flange off the side

of the rear steady bearing to shorten it a

bit. The output shaft from the planetary gearset could stand to be

about 2 inches longer. Now I have to kludj the truck's high-torque main

drive shaft to the gearset with less than an inch of shaft and the two

were never made to fit together. Why does everybody make such short

shafts on their equipment?

Next question: was the force needed to turn the rotor

against the disk enough to balance the planetary and get the truck to

move from a tough spot, instead of just turning the two rotors against

each other without it moving? Was it anything like enough force?

Well, the only thing to do was to build the housing and

see. ...Or could I just jury rig something up all in the open for a

quick

test? It just needed to hold the truck's drive shaft in place. That

would also keep the assembly from moving backward and falling out of

the motor shaft. Yes, that should be sufficient for initial tests

before discovering a lot of work had to be redone - or even, was in

vain!

Hmm... I guess putting in the batteries and getting the truck motor

running is next!

[9th] I wired up and connected the balance charger unit to the battery

stack that didn't have one yet. (It had been in parallel with the other

stack in the Sprint.) Charged it to test it.

[11th] I removed the "Delta Q" 72V lead-acid battery charger from the

truck before

installing the new batteries. It's the wrong type for lithium ion cells.

I reinstalled the front battery stack. The negative cable

turned out to be about an inch too short! But, but ...I had had one in

there before and it reached! I looked at the three stacks. On two the

bolt was on the right end of the bottom block. On the one in the Sprint

it was on the left, gaining just the needed couple of inches. That must

have been the one I had used! I thought that to flip the bottom block

around

(seemingly a simple thing) without shorting the screws to the next

block up as they were undone - not to mention the screwdriver - I would

have to disassemble the entire stack. But I looked and found that on

the bottom, negative end, block only, the screws were from the bottom

instead of the top. I could change it - whew! (I would still have to

pull the stack out again to get at them.)

[12th] I changed it, but in the process decided the bits of alume and

thin plywood under it for a mounting were inadequate underside

protection. I'd like to seal them off from the road. I spent a

fair while scraping and brushing out road grit (and or lead acid

battery overflow crap) from the inside of the angle iron frame. I cut a

new piece of 1/2 inch plywood to cover the entire opening, and put the

alume bars to mount the battery on top of that. This of course raised

the battery stack up 1/2 inch and now it wouldn't fit under the steel

floor cover. It held it up off its seatings.

After pondering this a while I decided to abandon the

steel, which fit flush with the rest of the floor, and fit a piece of

3/4 inch plywood that would fit over top of the opening. That would be

just high

enough. And I started to think that after all, the steel floor over the

batteries

was always a bad idea. The high chance of shorting out cells when

pulling it off or replacing it was always there. And I noted that the

original hold-down screws (which had never been in place since I bought

it) had to be put in and removed from under the truck, right between