The copper block was totally black with oxide after being "too hot"

in the kiln. (First I dipped it half way in to show the effect.)

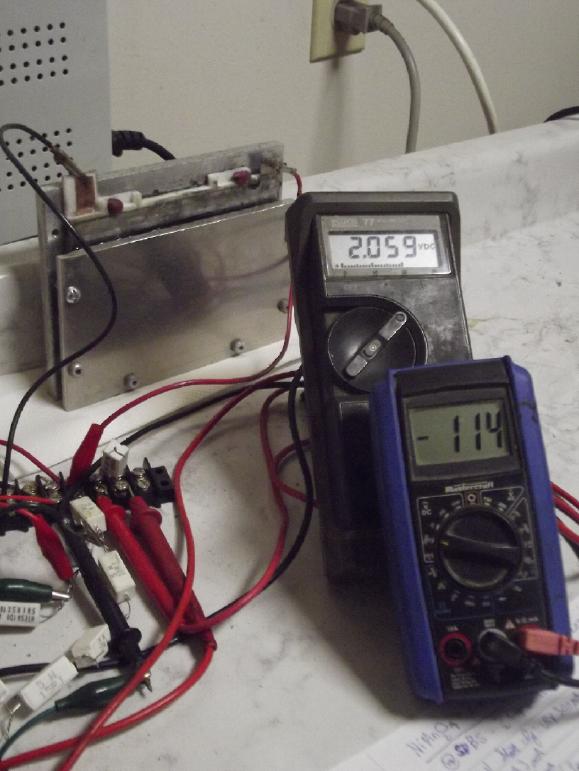

The battery seemed to work

quite well for a week or so... until I plugged all the openings and it

started to leak, probably having built up a bit of pressure. I think

chemicly the project is complete; essentially 100% working. I'm going

to try (probably next winter) plastic "popsicle" pocket electrodes in a

container I don't make myself so it shouldn't leak.

The battery seemed to work

quite well for a week or so... until I plugged all the openings and it

started to leak, probably having built up a bit of pressure. I think

chemicly the project is complete; essentially 100% working. I'm going

to try (probably next winter) plastic "popsicle" pocket electrodes in a

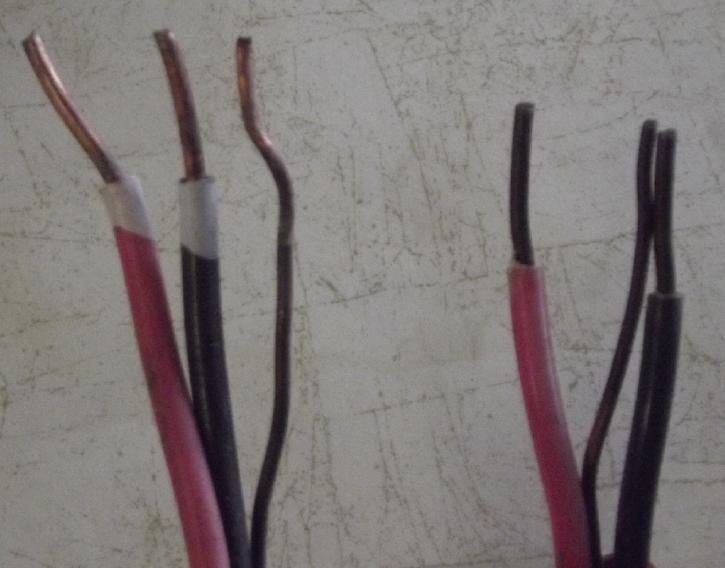

container I don't make myself so it shouldn't leak. Dan and I were

trying to clean off some heavy but fine

stranded copper wires whose surfaces were black with oxide. They won't

solder

and need to be at least somewhat clean for clamping. Cutting the wire

is often no help as the surface oxidation often travels into the wire

for many feet. Scotchbrite, sandpaper, scraping with a knife... These

are all a pain in the _. Dan asked if hydrogen peroxide might clean it

off. Aha!

Wrong chemical... but a Great idea!

Dan and I were

trying to clean off some heavy but fine

stranded copper wires whose surfaces were black with oxide. They won't

solder

and need to be at least somewhat clean for clamping. Cutting the wire

is often no help as the surface oxidation often travels into the wire

for many feet. Scotchbrite, sandpaper, scraping with a knife... These

are all a pain in the _. Dan asked if hydrogen peroxide might clean it

off. Aha!

Wrong chemical... but a Great idea!

However, I was

unable to find such a thing on line. I did

find one that charged straight up thinner pine(?) trees at high speed

and sheared off all the skinny lower branches as it went. This was

doubtless specificly for tree plantations, in order to get lumber with

fewer knots.

However, I was

unable to find such a thing on line. I did

find one that charged straight up thinner pine(?) trees at high speed

and sheared off all the skinny lower branches as it went. This was

doubtless specificly for tree plantations, in order to get lumber with

fewer knots. There

was also one with diagonal wheels wrapping around

the tree that "corkscrews" its way up, going around and

around the tree faster than it climbs. (That was probably the machine

my friend meant.) It said it cuts off the branches as it goes up. The

chainsaw is simply held upright near

the trunk to get to any branch on any side - cool design! But it would

have trouble with heavy branches and it wouldn't cut the trunk - my

main objective!

There

was also one with diagonal wheels wrapping around

the tree that "corkscrews" its way up, going around and

around the tree faster than it climbs. (That was probably the machine

my friend meant.) It said it cuts off the branches as it goes up. The

chainsaw is simply held upright near

the trunk to get to any branch on any side - cool design! But it would

have trouble with heavy branches and it wouldn't cut the trunk - my

main objective! There was just

a picture or two and

the only link I could find to a video didn't work. Cutting the

trunk is the important and dangerous part of the job. But by climbing

and limbing as it goes, it may be a good

design/concept for one that does fell the top of the tree when it gets

to the right height. Or might that be a separate unit that is sent up

when the limber is finished?

There was just

a picture or two and

the only link I could find to a video didn't work. Cutting the

trunk is the important and dangerous part of the job. But by climbing

and limbing as it goes, it may be a good

design/concept for one that does fell the top of the tree when it gets

to the right height. Or might that be a separate unit that is sent up

when the limber is finished?

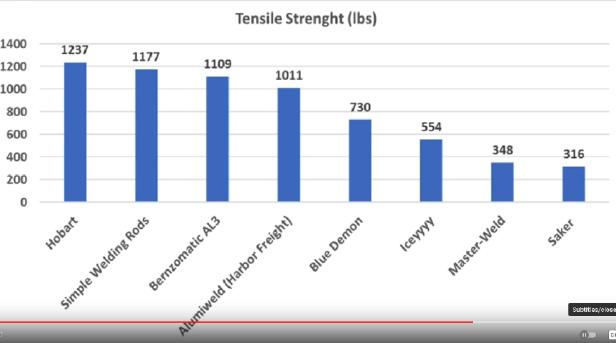

[9th] One day I saw Matt

and out of the blue he gave me a couple of "low temperature aluminum

welding rods", metal mixed with powdered flux. I looked these up and on

youtube I found this video showing that there are many varieties of

them, and showing how to use them. (It looked so easy!)

[9th] One day I saw Matt

and out of the blue he gave me a couple of "low temperature aluminum

welding rods", metal mixed with powdered flux. I looked these up and on

youtube I found this video showing that there are many varieties of

them, and showing how to use them. (It looked so easy!) In the evening

came a disaster. These days it's a time of day I've

usually quit working. I brought the kiln into the house, put the

heatsink with copper plate and weld wire in, and plugged it in. I was a

bit uneasy about doing it so late in the evening, but it should be

simple and short enough. And yet somehow I forgot to set the timer to

remind me. I absently went over to the computer and started reading

news on zerohedge.com, blanking out on present reality. Suddenly I

remembered the kiln -- not after 15 or 20 minutes, but after probably

well over an hour. And I hadn't put together the

temperature control, so it just got hotter and hotter. I unplugged it,

put on a glove and opened the door. It was much worse than I expected.

A waterfall of very melted alume poured out onto the woodstove hearth

where I had placed the kiln. The copper piece was sunk into the alume.

Luckily nothing cataclysmic happened. The hearth brick-faces didn't

explode under the pool of spilled alume (which could have splattered

molten alume around the room or at me) and no fire started. The melted

metal pool in the kiln was a little below the heating elements so it

didn't wreck the kiln. It did leave a mark on the bricks. Over the

years I have at many and various times

cursed my life-long absent mindedness. This was certainly one of those

times! I wish I had make the temperature control.

In the evening

came a disaster. These days it's a time of day I've

usually quit working. I brought the kiln into the house, put the

heatsink with copper plate and weld wire in, and plugged it in. I was a

bit uneasy about doing it so late in the evening, but it should be

simple and short enough. And yet somehow I forgot to set the timer to

remind me. I absently went over to the computer and started reading

news on zerohedge.com, blanking out on present reality. Suddenly I

remembered the kiln -- not after 15 or 20 minutes, but after probably

well over an hour. And I hadn't put together the

temperature control, so it just got hotter and hotter. I unplugged it,

put on a glove and opened the door. It was much worse than I expected.

A waterfall of very melted alume poured out onto the woodstove hearth

where I had placed the kiln. The copper piece was sunk into the alume.

Luckily nothing cataclysmic happened. The hearth brick-faces didn't

explode under the pool of spilled alume (which could have splattered

molten alume around the room or at me) and no fire started. The melted

metal pool in the kiln was a little below the heating elements so it

didn't wreck the kiln. It did leave a mark on the bricks. Over the

years I have at many and various times

cursed my life-long absent mindedness. This was certainly one of those

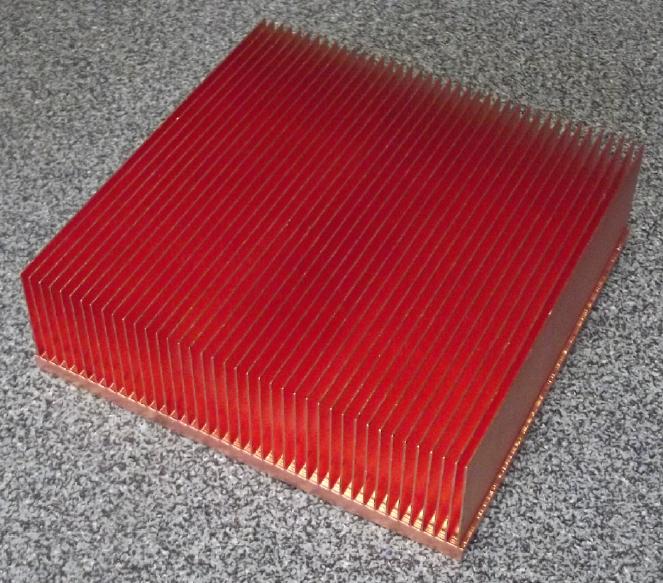

times! I wish I had make the temperature control. [10th] AM: Looking for a

replacement heatsink on AliExpress. That one

looks workable... Holy Bleep! A pure copper heatsink! It never ever

occurred to me somebody actually makes them - maybe tiny ones for CPU

coolers, but not larger ones. But here one was, 100x100x20mm! I found a

very few more choices, from a couple of stores, "Cooltex Thermal

Management Store", and "Yolowin". I ordered a 100x100x30mm from the

former. It has about 40 fins, meaning they're spaced only about 2.5mm

per fin!

[10th] AM: Looking for a

replacement heatsink on AliExpress. That one

looks workable... Holy Bleep! A pure copper heatsink! It never ever

occurred to me somebody actually makes them - maybe tiny ones for CPU

coolers, but not larger ones. But here one was, 100x100x20mm! I found a

very few more choices, from a couple of stores, "Cooltex Thermal

Management Store", and "Yolowin". I ordered a 100x100x30mm from the

former. It has about 40 fins, meaning they're spaced only about 2.5mm

per fin! At some point I tried this. After 15 minutes in the kiln

the weld wire hadn't melted, but at 20 the surface of the copper block

was

oxidized black. At 25 minutes the copper block seemed to have sunk down

toward the alume. I turned it off and let it cool. But the weld wire

had

only softened and flattened some more, not melted, and it hadn't

adhered to either metal. Could it even adhere to the black copper

oxide?

Would the alume heatsink melt next? I decided that the weld wire wasn't

for copper.

At some point I tried this. After 15 minutes in the kiln

the weld wire hadn't melted, but at 20 the surface of the copper block

was

oxidized black. At 25 minutes the copper block seemed to have sunk down

toward the alume. I turned it off and let it cool. But the weld wire

had

only softened and flattened some more, not melted, and it hadn't

adhered to either metal. Could it even adhere to the black copper

oxide?

Would the alume heatsink melt next? I decided that the weld wire wasn't

for copper.

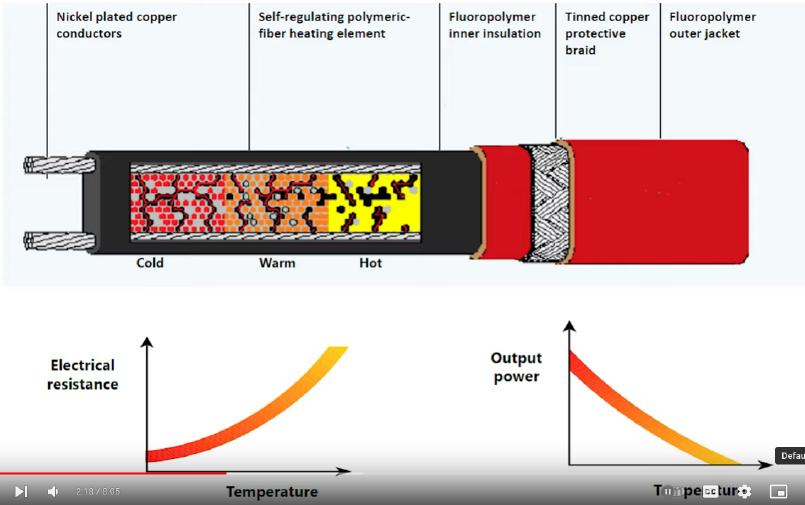

He also had a

solution to a major problem: condensation in

the outgoing air pipes, with water freezing and blocking the passages.

It seems you can buy low power heating wires

where the colder they are, the more power they use and the more they

heat up. It was only 15 watts or so in his exchanger once it was warm,

and since it's in the incoming air chamber much of the power is helping

to heat the air going into the room. I'll have to look these wires up

to buy.

He also had a

solution to a major problem: condensation in

the outgoing air pipes, with water freezing and blocking the passages.

It seems you can buy low power heating wires

where the colder they are, the more power they use and the more they

heat up. It was only 15 watts or so in his exchanger once it was warm,

and since it's in the incoming air chamber much of the power is helping

to heat the air going into the room. I'll have to look these wires up

to buy. I've never

used a large one myself, but apparently big rototillers with wheels

seem to be only for young, strong people. They can be hard to control.

My chief purpose is to break up grass and its roots so I can prepare

garden beds, which is almost impossible by hand. the grass is

inevitably tall and has deep, spreading, interlocked roots.

I've never

used a large one myself, but apparently big rototillers with wheels

seem to be only for young, strong people. They can be hard to control.

My chief purpose is to break up grass and its roots so I can prepare

garden beds, which is almost impossible by hand. the grass is

inevitably tall and has deep, spreading, interlocked roots. With the Stihl I've been

able to prepare much more garden bed this year than previously. Shown:

a patch of garden "Stihlled" I wasn't able to get the grass out of in

previous years. I later expanded on that patch and planted... just

potatos.

With the Stihl I've been

able to prepare much more garden bed this year than previously. Shown:

a patch of garden "Stihlled" I wasn't able to get the grass out of in

previous years. I later expanded on that patch and planted... just

potatos. [29th] I had covered the "old garden"

field where I tried to grow potatos last year with flattened cardboard

boxes. I uncovered the first row, intending to rototill it. But I had

...what, "tennis elbow?", from too much rototilling, raking, shoveling

and

using the dirt sieve. I didn't get to it.

[29th] I had covered the "old garden"

field where I tried to grow potatos last year with flattened cardboard

boxes. I uncovered the first row, intending to rototill it. But I had

...what, "tennis elbow?", from too much rototilling, raking, shoveling

and

using the dirt sieve. I didn't get to it. Then I uncovered some more and

found little

yellow potato shoots, while the grass was definitely much reduced. I

decided to just fill a few gaps in the rows with more potatos and water

it. Soon the

potatos were well up and outgrowing the grass. Cool, no tilling!

Then I uncovered some more and

found little

yellow potato shoots, while the grass was definitely much reduced. I

decided to just fill a few gaps in the rows with more potatos and water

it. Soon the

potatos were well up and outgrowing the grass. Cool, no tilling!

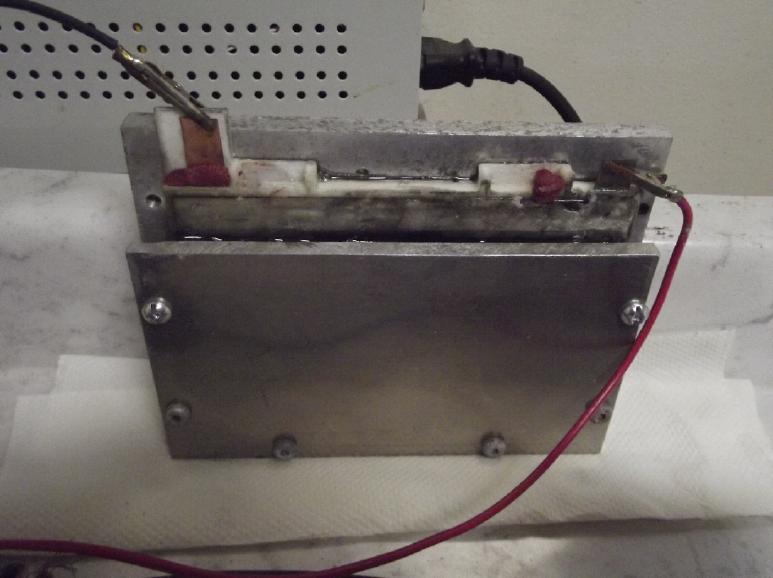

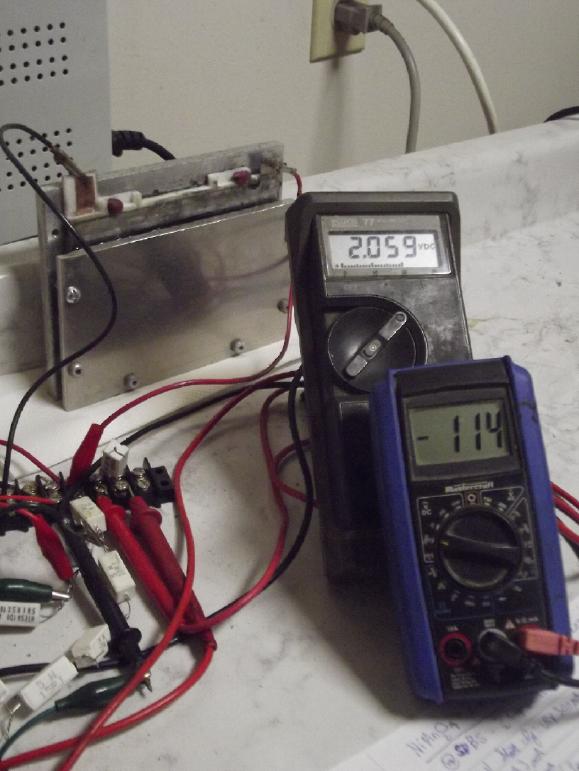

[11th] The cell has sat

ready to fill

for the better part of two months, but I had many things to do and was

loathe to add the checking, monitoring and testing that the new cell

would need. In the morning I finally mixed up 100cc of distilled water

with some KCl salt electrolyte. I added 1/2 a teaspoon of SDBS* to gell

the electrolyte. I drew some into the (blunted) syringe and filled the

cell. I tilted it a bit and filled through the upper hole until it

filled to the lower one.

[11th] The cell has sat

ready to fill

for the better part of two months, but I had many things to do and was

loathe to add the checking, monitoring and testing that the new cell

would need. In the morning I finally mixed up 100cc of distilled water

with some KCl salt electrolyte. I added 1/2 a teaspoon of SDBS* to gell

the electrolyte. I drew some into the (blunted) syringe and filled the

cell. I tilted it a bit and filled through the upper hole until it

filled to the lower one. Then I put the cell on charge from 2.25V through a 1Ω

resistor. The current dropped as the voltage rose, and a couple of

times I added ~5cc more electrolyte, then ~3cc of just water. It didn't

seem to leak, but in the initial charge the chemistry was bound to be

out of balance and it was using up water and oxygen or hydrogen was

gassing off. (So I should only be adding water.) As the charge current

dropped substantially I switched the charging resistor to .1Ω.

(Measuring the charge current is more practical by measuring the

voltage across a "shunt" resistor.)

Then I put the cell on charge from 2.25V through a 1Ω

resistor. The current dropped as the voltage rose, and a couple of

times I added ~5cc more electrolyte, then ~3cc of just water. It didn't

seem to leak, but in the initial charge the chemistry was bound to be

out of balance and it was using up water and oxygen or hydrogen was

gassing off. (So I should only be adding water.) As the charge current

dropped substantially I switched the charging resistor to .1Ω.

(Measuring the charge current is more practical by measuring the

voltage across a "shunt" resistor.)| Days of __ KWH |

May 2023 (18 collectors) |

April 2023 (18 solars) |

May 2022 (18 s. panels) |

| 0.xx |

|||

| 1.xx |

|||

| 2.xx |

|||

| 3.xx |

|

||

| 4.xx |

|||

| 5.xx |

2 |

2 |

|

| 6.xx |

3 |

||

| 7.xx |

1 |

1 |

|

| 8.xx |

1 |

2 |

|

| 9.xx |

1 |

1 |

|

| 10.xx |

1 |

1 |

1 |

| 11.xx |

1 |

||

| 12.xx |

1 |

3 |

2 |

| 13.xx |

3 |

3 |

|

| 14.xx |

1 |

2 |

1 |

| 15.xx |

4 |

2 |

|

| 16.xx |

2 |

2 |

|

| 17.xx |

1 |

1 |

3 |

| 18.xx |

2 |

1 |

3 |

| 19.xx |

1 |

4 |

|

| 20.xx |

2 |

||

| 21.xx |

1 |

2 |

|

| 22.xx |

1 |

1 |

|

| 23.xx |

2 |

1 |

1 |

| 24.xx |

3 |

2 |

|

| 25.xx |

1 |

|

1 |

| 26.xx |

3 |

|

|

| 27.xx |

3 |

1 |

|

| 28.xx |

2 |

|

1 |

| 29.xx |

1 |

1 |

|

| Total KWH for month |

642.52 (another all-time record!) |

408.83 |

547.74 (18 panels: - all-time record!) |

| Km Driven on Electricity |

1207.4 Km (175 KWH?) |

1038.7 Km (160 KWH?) (ODO: 94576) |

934.1 Km (~140 KWH?) |