Turquoise Energy News Report #194

Covering

Research & Development Activities of July 2024

(Posted August 9th 2024)

Lawnhill BC Canada - by Craig Carmichael

[Subscribe: email to CraigXC at Post dot com ; request

subscription]

Website: TurquoiseEnergy.com

Feature: Some Thoughts on DC Houses & DC Appliances

(Under Other Green & Electric Projects

-- also more on the subject under Cabin Construction & 36V DC

Wiring immediately following that, and in August in Brief)

Month In "Brief"

(Project Summaries etc.)

* New Chemie Batteries - DC Wiring Demo Panel - Cabin

DC Wiring & Construction

In

Passing

(Miscellaneous topics, editorial comments & opinionated rants)

* Scattered

Thots: What Makes an Inventor? - AC Body Voltage Levels - ESD

- Detailed

Project Reports

-

Electric

Transport - Electric Hubcap Motor Systems (no reports)

Other "Green"

& Electric Equipment Projects

* Some Thoughts on DC Building Wiring & DC Appliances

* Cabin Construction & 36V DC Wiring

* Gardening

Electricity Storage:

Batteries

* Various-Zincate cells - gold plating - Electrode Powder Compaction

Electricity Generation

* New Grid Tie(s) - My Solar Power System: - The Usual Latest

Daily/Monthly

Solar Production log et cetera - Monthly/Annual Summaries,

Estimates, Notes

New Chemie Batteries

One keeps seeing new battery developments in the news and

wonders whether a new "everlasting zinc" chemistry is still worth it

after all the years I've

spent on it and all the developments in other directions. Then one sees

articles about burning cars and e-bike batteries burning down homes or

even blocks of connected homes. I suppose such accidents are rare, but

they can be devastating. In addition to being intrinsicly cheap, a zinc

based aqueous battery is much safer. And a zinc-air battery would have

the energy density per weight to power quite long range electric

aircraft.

Now that the zinc side works, I'm still having a crazy

hard time with a positive electrode - which is known chemistry and

manufacture. It started to seem like I could only make a reasonably

good electrode from the nickel substance taken from commercial Ni-MH

dry cells, not from my own mixes. But why should that be? I've become

convinced that at least any of my nickel mixes or the nickel-manganese

oxide probably work fine chemicly. It must be all in the compaction. I

figured that with insufficient compaction one would simply get lower

current capacities. This seems to be a wrong assumption. Instead it

seems that at a certain minimum point, current capacity becomes good,

but there is still very low utilization of the electrode substance. To

get it all connected together and contributing to the amp-hours takes

much more pressure. At least, that is now my present supposition, since

only the zinc side seems to have much capacity regardless of there

being plenty of positive substance theoreticly to run a light load for

hours instead of the minutes I've been getting. (The zinc-zincate

electrode needs no pressure.)

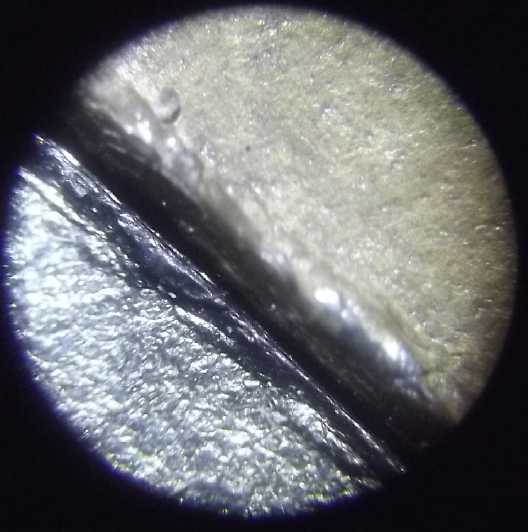

Early on battery developers noted that for both copper and

nickel oxides, tremendous pressure is needed to force the particles

together tightly enough for good connections - and those are the

substances I've been using. An Ovonics patent notes pressing their

nickel substance together to achieve a density of 3 grams per cc

instead of 2 and a bit. That must take tons per square centimeter of

pressure. The commercial dry cell nickel was doubtless pressed with

that sort of pressure, and the pieces retain some of that density in my

electrodes, so it works.

I've been pressing with much less force, and I discover

that with more force my supposedly compacted powder can be made much

denser. But I've always had a hard time trying to get the high

pressures I've wanted into an electrode. Flat electrodes bulged too

easily for any sort of home prototyping. 3D printed tube electrodes are

also too flimsy. The PVC pipes with drilled holes are probably strong

enough to hold material adequately - the electrode of commercial dry

cell nickel hydroxide continues more or less to work - but they

certainly won't take the pressure of sufficient initial compaction. And

if material is squeezed down in the tube (however inadequately), the

separator paper gets munched down with it.

One can make a compacted blob fairly easily, but to make

it with a hole for a current collector rod, and to slide it into into

an electrode tube without destroying the separator paper, are whole

additional challenges that I haven't mastered. Not only the 3D printed

tubes but the PVC ones with holes will burst at a much lower pressure

than seems to be required. I tried to make a set of telescoping

stainless steel pipes to press tall nickel oxide "donuts" to 5 tons of

force, but at about 3 tons the pipes bent and the ends mushroomed a

bit. And the piece was stuck inside the smooth tube. It just wouldn't

press out.

But a couple of days later I fixed up the 'tap & die'

and tried again, and got better results.

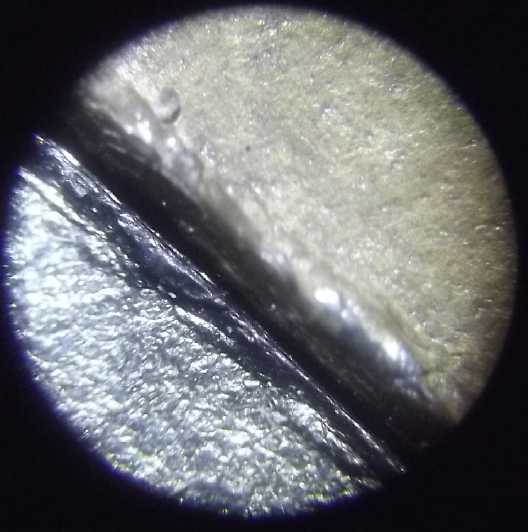

"Telecoping" compactor to make

"tall donuts" of

electrode material.

"Telecoping" compactor to make

"tall donuts" of

electrode material.

The inside of the large tube is the outer diameter of the donut.

The bolt fits in the bottom to form the hole for the carbon rod.

The smaller tube fits inside the larger and over the bolt,

and is pressed in to compact the material.

The hole in the plate is just slightly larger than the inner pipe.

The piece is pressed out of the pipe through the hole.

Ha ha.

At 3 tons the pressure stopped

going up. The

inner pipe was bending over.

At 3 tons the pressure stopped

going up. The

inner pipe was bending over.

And the pipe ends mushroomed a bit.

Apparently something heavier than "light" stainless steel pipes is

required?

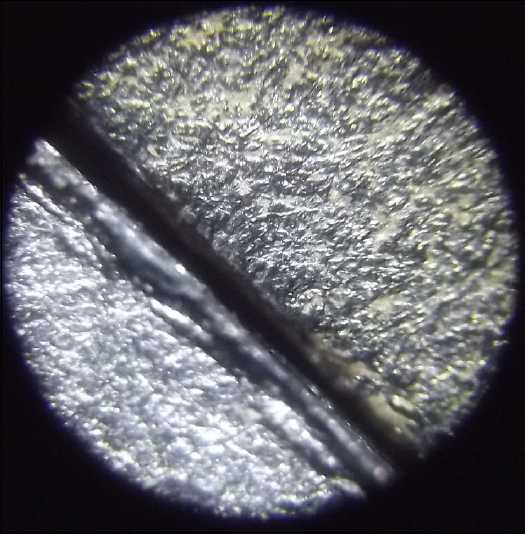

Later with small improvements

& just 2 tons

force, I successfully

Later with small improvements

& just 2 tons

force, I successfully

made a small "donut" of compacted nickel-manganese-oxide mix

that fit smoothly on a 5/16" carbon rod. (Another on the tapered

3/8" rod behind started breaking because the inner hole was 5/16".)

The solid cylinder at the bottom, with a bolt turned on the lathe

for a plunger, was successful but it would break up if drilling a

hole in it was attempted. (Rats)

2 tons seemed to be exactly right - at least for my

equipment and the size of the donuts. Any less and the donut crumbles

(I'm sure there's a pun there somewhere). Any more and the stainless

steel pipes start to bend. With the small surface area of the donut

hopefully it's about right for the electrode. (Calculated density of

the compacted nickel-manganese oxide based on the measured dimensions

and weights is about 1.9 g/cc, which is probably a bit under ideal but

in the right ballpark according to literature.) I discovered that

luckily the small donuts slide easily off the inner bolt and onto a

carbon rod. Yay! (I hope they make a good connection to the rod!)

Now to make the next electrode I need to make new

separator papers and a new tube, and it's high time to end this 'July'

report (August 8th). I think I'm on the right track.

DC Wiring Demo Panel

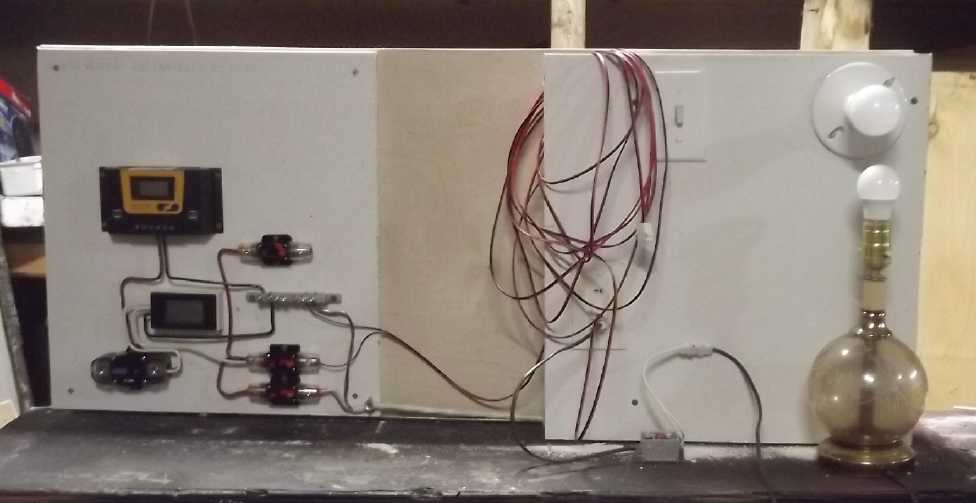

In addition to continuing to wire the cabin, I decided to

make DC demo panel for the Swilawiid green energy conference in

September. It progressed in a couple of work sessions. As I made it it

occurred to me that it was just about the same as actually wirng the

cabin except the wires were shorter.

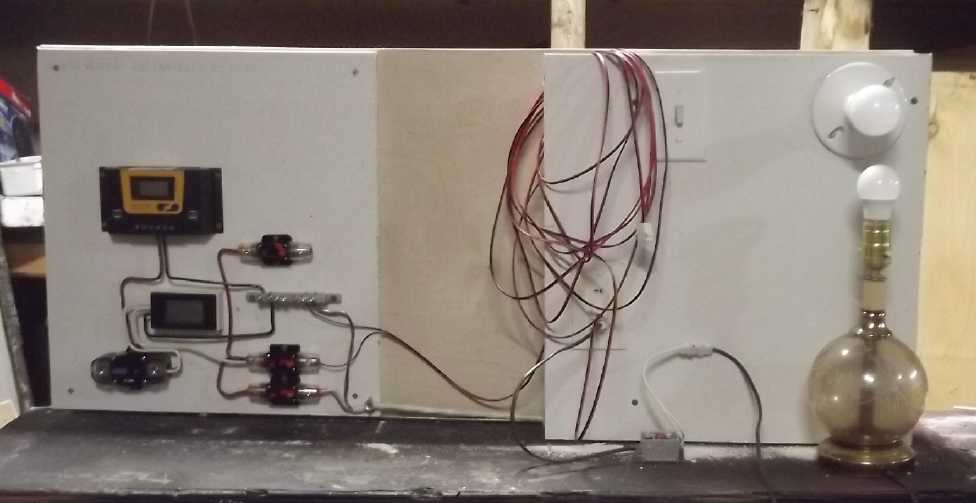

Sample house circuits on "wall"

at right;

"Wiring closet" wall mounting of equipment at left (gyproc for

Sample house circuits on "wall"

at right;

"Wiring closet" wall mounting of equipment at left (gyproc for

fire safety, over plywood to hold screws securely) starting with a

couple of surface mount circuit breakers and a ground bus bar.

Added charge controller and power

monitor,

"main" battery circuit breaker,

Added charge controller and power

monitor,

"main" battery circuit breaker,

a 12V lamp plugged in with DC to DC down converter.

Cabin Construction & DC Wiring

This is mostly covered in the feature article as well as

the detailed report in "Other Green Projects". Here is the brief view.

I continued adding to the surface

mounted wiring board. I installed the ground bus made in June. I 3D

printed a four-outlet wall plate to plug

several ceiling lights into rather than hard-wiring them. I suppose one

could fit 5 or 6 T-sockets on one wall plate. No "power bars" to get

enough outlets!

I continued adding to the surface

mounted wiring board. I installed the ground bus made in June. I 3D

printed a four-outlet wall plate to plug

several ceiling lights into rather than hard-wiring them. I suppose one

could fit 5 or 6 T-sockets on one wall plate. No "power bars" to get

enough outlets!

This box/plate is on

the charge controller's "output" circuit, which is set to shut off if

the battery gets the least bit low - which would probably be from

leaving too many lights on in the winter when solar power is scarce.

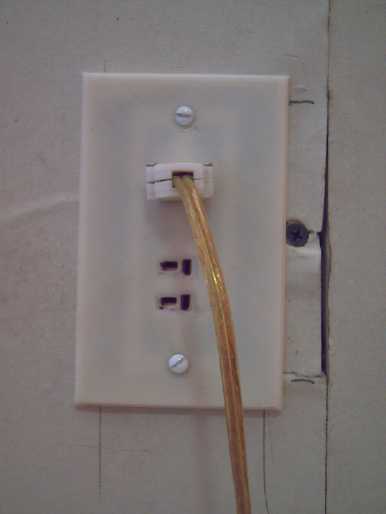

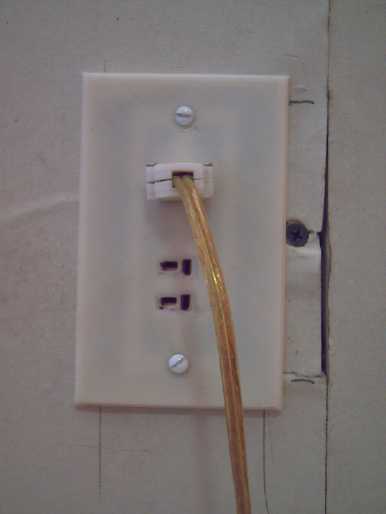

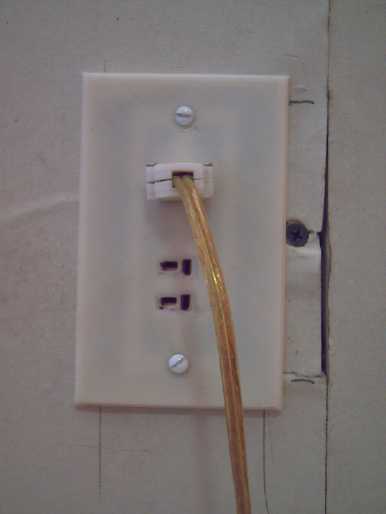

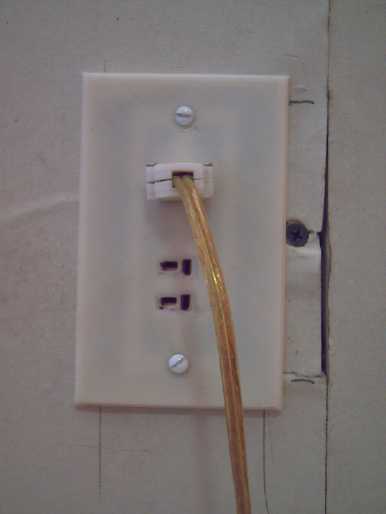

36 V DC Wall Receptacle

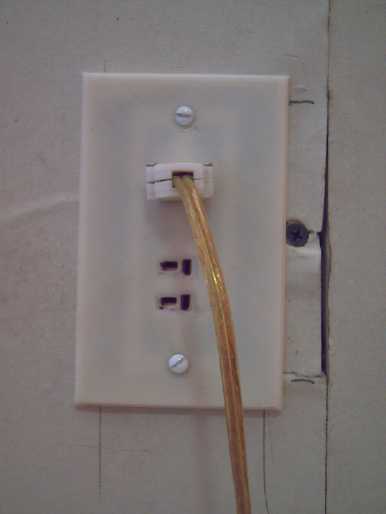

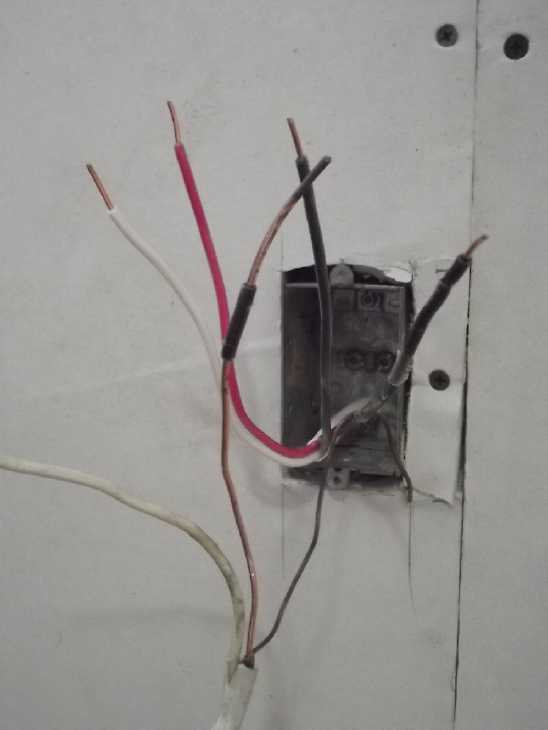

On the 10th I wired up a wall receptacle in the upstairs room. I took

off a piece of gyproc from under the window and screwed in an

electrical box. Underneath, the walls are still open and stringing the

wire through the 2 by 4s by drilling holes was easy.

On the 10th I wired up a wall receptacle in the upstairs room. I took

off a piece of gyproc from under the window and screwed in an

electrical box. Underneath, the walls are still open and stringing the

wire through the 2 by 4s by drilling holes was easy.

I used #14-3

cable, which is actually four wires counting the #14 bare "ground"

wire. I tied red and white together ("+"), and the black and the

bare after insulating it (two blacks, "-"), and tied them to the

pigtails soldered onto

the T-Plug (36V DC) wall plate. Double #14 AWG is the same as #11 -

good for about 25 amps. #12-2 (rated 20 amps) would be fine for 36 volt

- 20 amp outlets, too. #14-2 is a bit thin.

I used #14-3

cable, which is actually four wires counting the #14 bare "ground"

wire. I tied red and white together ("+"), and the black and the

bare after insulating it (two blacks, "-"), and tied them to the

pigtails soldered onto

the T-Plug (36V DC) wall plate. Double #14 AWG is the same as #11 -

good for about 25 amps. #12-2 (rated 20 amps) would be fine for 36 volt

- 20 amp outlets, too. #14-2 is a bit thin.

Enclosing wire joins in metal electrical boxes is still a

good idea. 36V may not electrocute, but arcs and sparks or heat from

poor connections, can still start fires if next to something flammable.

(But no need to ground the box.)

In early August I used the new outlet and a "double T-Plug" I made a

while back to power a

2500 W PSW inverter (36 VDC to 120 VAC) and vacuumed the room on

solar/battery power. The

double plug wanted to pull out at the slightest stress on the heavy

wires. (The "giant T-Plug" for

high currents is the real answer... but they need to be manufactured.)

In early August I used the new outlet and a "double T-Plug" I made a

while back to power a

2500 W PSW inverter (36 VDC to 120 VAC) and vacuumed the room on

solar/battery power. The

double plug wanted to pull out at the slightest stress on the heavy

wires. (The "giant T-Plug" for

high currents is the real answer... but they need to be manufactured.)

Most vacuum cleaners are somewhere near 1500 watts.

Theoreticly that

should have blown the 20 amp (36V) breaker with around 40 amps. In a

brief run it didn't. I used a vac that had 'up' & 'down' buttons to

increase or decrease

power & suction. At full power the inverter (2500W?!?) balked after

about half a

minute, quitting and saying "Fault", but if I turned the vac to setting

3 of 5, it ran fine and I did the job.

In

Passing

(Miscellaneous topics, editorial comments & opinionated

rants)

Scattered

Thots

What Makes an Inventor?

* What is it that makes an inventor? "IQ" and "Cognitive ability" are

certainly measures, but I think it's "associative ability" that sets

inventors apart. That's the mental quality of seeing "obscure"

connections between things that are apparently unrelated.

Just for example, in open loop air heat pumping, how are

indoor-outdoor heat exchange ventilators related to compressing air (or

refrigerant) to pump heat? These have always been separate, unrelated

concepts and systems. But it's combining the two that is the key. The

compressor heats already passively warmed air coming from outdoors,

radiates heat to the room, then sends it (still slightly warmer than

the room, still compressed) into the indoor-outdoor exchanger to cool

by warming the incoming air, then it decompresses (through a turbine to

extract even more energy) and finally it exhausts outdoors colder than

the outdoor air. The combined system should give a coefficient of

performance that heat pumping "experts" would deem "theoreticly

impossible", perhaps 10 to 1 or better, eg, 5000 watts of heat from 500

watts of electricity, even at freezing outdoor temperatures. (I must

get back to that project!)

I was once profiled as being in the top 1% of the population in

"associative ability". Others doubtless have more balanced or other

leaning mental abilities, but that one is surely what marks inventors.

Then of course, to invent one must begin to REALize the

concepts. It

is an iterative process where starting by DOing one thing, even

without a complete or concrete idea of what the result will be. This

causes more dots to connect and the creation to

improve. Back to the example, the first idea was that if an air

compressor compressed room air, it wouldn't have to heat it very much

to have it run a heat radiator, so the COP could be high. But how could

room air heat room air? The cooled air from the radiator, having

actually lost heat to the room, would be much cooler once it was

decompressed and would have to be vented outside. So cold air would

have to come from outside to replace it. At that point in the idea, it

sounded like it might be a "zero sum game". There some might think

"Yeah, that figures!" and go on to something else.

But while still compressed, that air still has compression

energy. So came the idea of having it somehow help to spin the

compressor - "ROVACS" and other compressor-decompressor ideas, "ending"

(as far as the concept has gone so far) with the idea of having it turn

a turbine that mechanicly helps turns the compressor. (probably by

being on the same shaft)

Also this compressed air from the radiator unit is still a

little warmer than the room air - more "waste" energy! The idea of the

passive heat exchanger came to me along with the other while putting

together the basic "compressor plus radiator" unit. Most of this

evolving concept can be seen in TE News issues from about January to

April 2020, with conceptual improvements to the rotary compressor, and

then the decompressor turbine idea, in more recent issues.

AC Body Voltage Levels

* It seems to me - speaking only for myself - that the ringing in my

ears is only just starting to fade perceptibly after 8 hours sleeping

in my

"Faraday cage" cabin (without AC wiring and where I generally measure

AC body voltages under around 15mV). And "perceptibly" is only because

I'm listening for it. But it gets louder again in under half an hour in

the house. (...where fields are mostly well over a volt and again

because I'm listening for it.) I might almost say - for me - "days to

fade, minutes to resume". If others are experiencing anything like

that, it's no wonder it's little understood where tinnitus comes from

since nearly all of us are so rarely out of electric AC voltage

gradient fields for any length of time.

The conductive fabric tuque/beanie actually helps more than I realized,

but it's not the same as just being away from electric fields. I didn't

realize how much it was helping until the day I washed it and set it

out to dry. The ringing was much worse after a day without it -- back

to how it used to be. Even overnight in the cabin only brought it down

somewhat. The tinfoil over the car's sun visor also seems to reduce the

ringing I notice after highway drives.

* I was guessing that the AC induced body voltage may tend to

cause tinnitus if it is over 20-50mV. One night in the cabin I felt by

3 AM the ringing didn't seem to be fading at all. It felt like my ears

were still "under attack". Why should that be? I had been working on

the siding and had plugged the angle grinder into the cord that ran

around outside the building. But I had brought it in in case it rained,

still plugged in. There was about 10 feet of energized cord on the

ground about nine feet directly under my bed. A meter said it was just

around 40mV of body voltage lying on my bed. Apparently that was enough

to be a problem! I unplugged it and it was still over 20mV coming from

the few, short cables with the plug-in grid ties in the corner over 20

feet from the bed. If 40mV was noticeably too much, even 20 probably

was having a mild but continuous deleterious effect. I unplugged the

building - the one plug in the far corner - and tossed the extension

cord outside. It went down to around 5mV.

Of course that's just me. I'm not sure where it might

start for others and for those most affected. Some are doubtless

unaffected for years at much higher levels, but it's starting to look

to me like many or most older people have ringing ears. It's just not

talked

about unless I bring up the subject. But I think the Greenhome

Institute is right: "no exposure" is under 10 mV, not 20 or 50 mV.

Greenhome Institute gives the following induced AC body voltages for AC

electric

field exposure:

0-10mV - no exposure

10-100mV - mild exposure

.1-1V - strong exposure

over 1V - extreme exposure

Induced AC Body Voltage is easily measured by connecting

one

probe of an ordinary AC voltmeter (precision preferably to .001 V AC)

to ground, wetting one's thumb and

finger, and gripping the other probe, and not moving during the

reading. (Don't touch the ground connection.) Ground may be actual damp

ground or the grounding pin of a power socket (can be an extension cord

ground pin). Position is important in stronger fields. Outdoors at

least, measured voltage is much higher when standing up than crouched

or sitting.

ESD

(Eccentric Silliness Department)

* In their protracted march of capturing or liberating (depending on

your point of view) Donbass towns and villages one by one (...more like

"liquidating" them where the fighting is hard), the Russians have

achieved pobieda (victory) in Pobieda, have progressed through

Progress, and now are in the middle of New York. (Wait, what?!?)

"in depth

reports" for

each project are below. I hope they may be useful to anyone who wants

to get into a similar project, to glean ideas for how something

might be done, as well as things that might have been tried, or just

thought

of and not tried... and even of how not to do something - why

it didn't

work or proved impractical. Sometimes they set out inventive thoughts

almost as they occur - and are the actual organization and elaboration

in writing of those thoughts. They are thus partly a diary and are not

extensively proof-read for literary perfection, consistency,

completeness and elimination of duplications before

publication. I hope they may add to the body of wisdom for other

researchers and developers to help them find more productive paths and

avoid potential pitfalls and dead ends.

Electric

Transport

No

Reports

Other

"Green"

&

Electric

Equipment

Projects

Some

Thoughts

on

DC

Houses & DC Appliances

36 V DC is the optimum voltage for most

in-home/in-building wiring.

IMHO. Since the electrification of everywhere a century ago we have

become so used to wiring with 120 VAC

everywhere (230V in much of the world) that we never think of doing it

any other way. The idea it's less than ideal and the whole thing ought

to be re-thought will probably come as

a shock to most people. The advantages of 36 volts DC haven't been

thought out by most

of us, but working with solar, and then discovering health reasons, I

was gradually led to this

logical conclusion and am wiring my cabin with it instead of 120 V AC.

What's good about it?:

1. DC doesn't induce oscillating electric fields into the body, which

may cause

tinnitus, ongoing vague feelings of stress and unease, and other health

effects whose cause is usually unrecognized. (See

GreenHomeInstitute.org

for more on this topic.) So AC wiring is to be avoided where practical,

including AC generated from a DC system with an inverter. Runs of AC

wiring should be kept very short and few, or made with shielded cables

and

cords, or run inside (grounded) metallic conduit pipe. In theory, it's

easy to avoid the need for AC except for higher powered equipment.

Lighting in particular is now very low power with LED's, which emitters

are already DC, and it is almost absurd to run 120 or 240 V AC wiring

to then be reduced to low voltage DC at the fixture or "bulb".

2. 36V DC nominal is the highest electricly "safe" voltage.

Electrocutions from

36V and below are not unheard of, but they are very rare. 48V DC or

higher building wiring would come with some electrocution death

statistics, as do the present 120V and 240V AC. (Think that if three

12V batteries

are under charge at 15V, nominal 36V would hit 45 actual volts, and

nominal 48V with four can reach 60 V. High DC voltages can be more

dangerous than AC.)

3. Line losses at 36V are much lower than with 12V, and substantially

lower than 24V.

Wire gauges for higher power appliances at 12V are huge. Consider

running an electric heater/kettle/toaster/burner of 1000 watts. This

requires a circuit of: 12v = 83 amps = #4 AWG wire = very heavy and

unwieldy; 24v = 42 A = #8

wire (better, #6); 36V = 28 amps = #10 AWG wire = much more managable.

(For off grid

situations, one probably would only use such high power for short

intervals, EG boiling water for coffee or tea, heating something in a

microwave or on a stove, vacuuming...)

4. From 36V it's easy to get any lower voltage, such as 12 or 24V for

12 or 24V DC appliances. There are low-cost (5$?) 20 amp screwdriver

adjustable DC to DC converters to go from any voltage up to 40, to any

lower voltage. These - just one device - can replace most any and all

"wall

wart" 120V AC to DC power converters to power a multitude of electronic

devices. And there are even cheaper ones (2$?) with lower current

ratings. So there would seem to be little reason to go to lower voltage

wiring across a home or building. (Prices are for the

electronics board only - as currently manufactured, 36V plug & 12V

socket, case (3D printed?) need to be added.

5. Ease of Mind. No worry about getting electrocuted by touching a

damp power cord in the rain, laundry or bathroom, or by flipping a

light switch with wet hands. Kids aren't going to shock themselves by

touching the wrong thing.

6. Today there are confusing choices for DC power of 12, 24, 36, 48

volts and

beyond. It is important to establish a "standard" wiring voltage for

DC in order to induce manufacturers to mass produce DC appliances. 36V,

while presently somewhat overlooked, is the best voltage to do that for

the

reasons above. It should be encouraged, promoted and adopted in new

power & building projects. It's only an uphill struggle until

there's enough momentum to reinforce the logic of it, then everyone

will jump aboard.

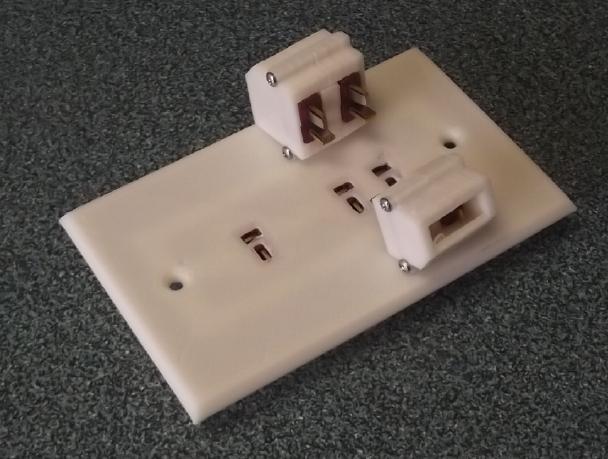

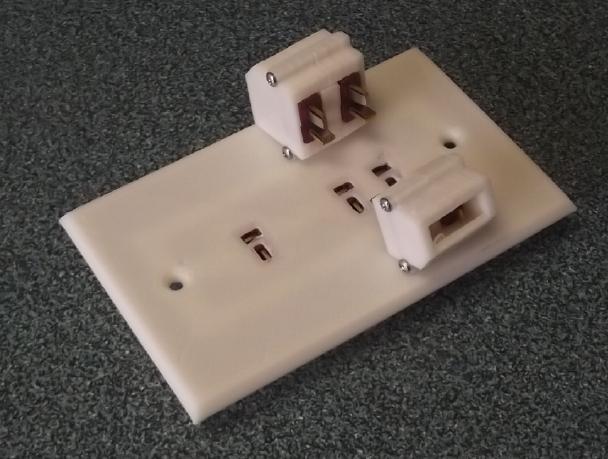

I myself have "adopted" T-Plugs/T-Sockets (AKA Deans Plugs) as the

standard for 36V house wiring. I have 3D printed triple and quadruple

wall receptacle plates, plug and socket shells and more to facilitate

adoption of 36 V. They should be good for up to 20 amps. ("Plus" is the

"cross" blade on the right in the image.)

I myself have "adopted" T-Plugs/T-Sockets (AKA Deans Plugs) as the

standard for 36V house wiring. I have 3D printed triple and quadruple

wall receptacle plates, plug and socket shells and more to facilitate

adoption of 36 V. They should be good for up to 20 amps. ("Plus" is the

"cross" blade on the right in the image.)

(I do recommend an improved version T-Plug be manufactured with 10mm

long blades instead of 8mm, because they are too easily pulled out of

the socket. Also other choices of plug styles are needed besides with

"solder pads" to attach wires to the plugs.)

And I created

a "giant T-Plug" & Socket for currents to 50 amps. These are harder

because everything is made from scratch - they need to be manufactured.

But manufacturing keeps getting easier as new techniques and tools are

created. (...and I must upload all the 3D print designs to

thingiverse.com for all to use!)

And I created

a "giant T-Plug" & Socket for currents to 50 amps. These are harder

because everything is made from scratch - they need to be manufactured.

But manufacturing keeps getting easier as new techniques and tools are

created. (...and I must upload all the 3D print designs to

thingiverse.com for all to use!)

Various power supplies can

be had to convert 120V AC from

the power company to DC. Of course, DC is an even better choice for

"off grid" wiring compared to 120V, which requires an inverter that

itself uses extra power. Lithium-iron phosphate

batteries (LiFePO3 - 12 cells) with a "balance charger" attached

presently seem to be the best and safest choice, now available with

ratings in hundreds of amp-hours. "Golf cart

batteries" or other Pb-Pb cell costs are rising and they have much

shorter life spans, while the price of LiFePO3 has come down

substantially and is still dropping. (With those, "36V" is generally

close to 40 volts if

they are charged, and I'm tempted to call LiFePO3 systems "40V" instead

of "36V". I think it sounds better! They can be charged to 42+ volts at

room temperature, but little energy is gained, they drop to ~40V at low

temperatures anyway and DC to DC converters are mostly rated only up to

40.0 volts.)

Having created wall outlets for 12 VDC ("micro T-Plugs"

& sockets) and 36 VDC ("T-Plugs" & sockets), and with wiring

the cabin for 36, I thought I'd look for DC appliances to match. Being

that there is no "consensus" DC wiring voltage, the confusion of

choices from 12 to 48 volts and beyond has made manufacturers hesitant

to make DC appliances.

Note for 24V DC: With no "standard" wall receptacles, sockets or

plugs being available, the 36V T-Plug outlets, cords and plugs could

well be used for 24 V as well. A number of useful circuits such as LED

"light bulbs" and DC to DC down converters to make 12V can be run from

either voltage or in between. It does however make a "user beware"

situation since one could easily plug in a 24V appliance into 36V or

vice versa, possibly destructively.

Lighting

This lamp

works the same,

looks the same as any other but

has a DC LED bulb, "T-plug" plug, and runs off 36 V DC

Now that LED's

have replaced most other

lighting technologies, DC lights are simple. LED's

are inherently low voltage DC components (generally 2.9V for lighting

LED emitters. A fast, simple way to get nice DC lamps is to take a nice

AC lamp, cut the plug off, and put on a 12V or 36V plug. Then one buys

a DC LED "light bulb" that screws into a regular ("E27") lamp socket.

There are "12V" bulbs, and there are "12 to 72V" bulbs, which are

ideal at 36V. (Note: These last are dimmer - lower power than labeled -

when run

at 12V.)

Now that LED's

have replaced most other

lighting technologies, DC lights are simple. LED's

are inherently low voltage DC components (generally 2.9V for lighting

LED emitters. A fast, simple way to get nice DC lamps is to take a nice

AC lamp, cut the plug off, and put on a 12V or 36V plug. Then one buys

a DC LED "light bulb" that screws into a regular ("E27") lamp socket.

There are "12V" bulbs, and there are "12 to 72V" bulbs, which are

ideal at 36V. (Note: These last are dimmer - lower power than labeled -

when run

at 12V.)

There are various 12V LED

lights (for automotive, marine,

off-grid...) which can be run off 36V using an adjustable DC to DC

converter set to 12-14V output. (A 20 amp adjustable DC to DC down

converter running off 36 or 24 volts can replace any "AC Power

Adapter".)

I bought some beautiful, bright, 30x60cm (1x2 feet) flat

LED light panels that work admirably at 36 volts, with just a 5Ω

resistor to limit the current and set them near or under their 24 watt

rating.

Blue emitters for LED lighting were invented in the 1990s

by a Japanese man (I forget his name) who pursued it for decades even

after everyone else had

given up. Without him we would still be using incandescent and

fluorescent lighting. His Nobel prize was well earned. They make

lighting colors

the same way fluorescent tubes do, by shining the single frequency LED

emitter on a phosphor that glows in a broad spectrum centered at the

desired color temperature. But unlike fluorescent lights, they don't

have a

strong spike of retina-degrading intensity at the mercury vapor arc

wavelength that comes right through the phosphor, and so they are far

more pleasant and beautiful. And incredibly efficient, requiring

perhaps 10-15% as much power as an incandescent light bulb of

equivalent brightness. Typical "color temperatures" (in degrees Kelvin)

available for LED lighting of any style include:

2700°K - orangeish/warm

3000-3300°K - yellowish/"warm white"

~4000°K - "neutral white"/mid-spectrum (sometimes seem faintly

greenish IMHO when seen next to yellowish & blueish. My favorite

for most lighting)

5000+°K - blueish/"daylight" (plant lights; some like even 6000K

for work

lights)

Wiring specificly for DC LED lighting (ie, wires not going

to

outlets or heavier loads) need not be heavy. I'm using #18 AWG speaker

wire. It looks patheticly thin, but #18 is rated for at least 5 amps,

and even

a bright 36 watt LED light draws only 1 amp. It's easy to run and

cheaper than heavy house wire. (I do wish I had a cable stapler for it

- even simpler.) For 36 volts, insulation need not be heavy as it is

with #18 "lamp cord" wire.

Fridges, Freezers, Washers, Dryers, et Cetera

For such actual high powered appliances, the pickings seem

quite slim. The are 12 & 24 volt fridges, freezers, washers and

dryers, but the usual price tag of several hundred dollars has a 1000

or 2000 $ amount added on the front. There will surely come a day when

36 volt

units with highly efficient BLDC motors will come on the market for

similar prices as 120/240 volt AC units, but

it's not yet. I did however buy a 24 volt BLDC deep well pump for just

300+$ - a bargain for any deep well pump - so there is progress. DC

power tools aren't available except those that have

their own battery - which is more convenient than a cord anyway when it

works for

your work.

Accepting a DC to AC inverter with its small but extra

continuous power

draw and what may someday be called "legacy" AC appliances seems to

be the only practical route today. One can of course turn off the

inverter except when an "on demand" use appliance is to

be used (ie, vacuum cleaner, not fridge or freezer), and if the cords

are kept short, they will generate little EMF

into the space except near and between the inverter and the

appliance(s).

Of course, having 36 V wall outlets doesn't preclude

running 24 or

12 volt appliances such as fridges and freezers by using a DC to DC

down converter "power adapter". But IMHO appliances would be better

made with 12 & 36 volt options rather than 12 & 24. Or be made

more flexible to handle 24 to 36 volts supply.

Electric Heaters

Electric heaters and hotplates having nothing but a

resistance heating element and mechanical switching controls can be run

at their

rated voltage or any lower one. At 38 volts, each unit will run at

1/10th of its 120 volt power rating. So a 1500 W heater will run at 36V

as a roughly 150 W heater.

I made a little "cheater cord" (from an only extension

cord) with a 36 V T-Plug on the end, to plug such appliances into 36 V

withut chopping of their regular plugs. This past spring I was heating

my bedroom at night

with two or three such heaters: 150, 80 & 50 watts - just about

200, 250 or 300 W on the consumption meter. The 290 AH, 36V battery is

recharged daily (usually by around noon) by five solar panels. This

certainly isn't enough heat

for winter, and the solar panels probably wouldn't charge it back up

daily in winter with this large all-night drain, but it's good in the

"shoulder seasons" when one only needs a little heat.

Okay... On AliExpress I've found low cost 12/24 V electric

heaters. Some are portable car heaters/window defoggers. There might be

some suitable; I'd have to check further. A 24V heater run at 36V would

be 2.25x the rated power and might burn out. A 48V heater run at 36V

would be 56% of the stated power. They seem to offer similar lower

power ranges to those I've been using.

Hotplates/Stove Burners

I put a cup of water in a pot, put it on an "1150 W, 120

V" simple burner hot plate, and plugged it into 36 V with a "cheater

cord", making it only ~115 watts. It took the better part of an hour

before the water was simmering softly. It's just not enough power - it

takes so long that much of the heat is radiated to the room while the

water is heating.

But I do see 12 & 24 volt hotplates ("DC Stoves") of

several hundred watts on AliExpress. There was a single burner

induction cooker "12/24/48 V". There was just one model, so it would

almost doubtless work also at 36V too. It looked promising as induction

transfers the heat really well to the pan (which has to be magnetic

metal), but it was over 200$C.

Hot Water Heaters

A 3000 W, 230 V water heater plugged into 36 volts would

heat unbearably slowly, at under 3% of its usual power. My own house

hot

water tank is powered by 120 V instead of 240 and is hence 750 watts

instead of 3000. When I turned it off and went away for a week, it took

8 hours to be hot enough for a shower. Except for that, with one or two

people I have never

been short of hot water. By using a lower power, if I use hot water

during the day, there's often enough power (ie, 750 W) coming from the

solar panels

through the grid ties that it's being reheated from them instead of

much of it coming from the power company. Water tank elements for

various low voltages are available too (eg, "Dernord" elements). I have

a 15 liter "under sink"

tank presently with its original 1200 W, 120 V heating element. At 38 V

that would be 120 watts. That will eventually heat the tank, so it

works well provided you don't need to use the hot water often, or use

more water than is held in

the tank. (I un-installed it from my kitchen owing to a well water

chemical issue - the hot water reeked.) At one time I had changed the

element for a 36 volt one (it had 3 x 400 W elements), but found 1200

or 400 watts was a bit much for my solar system with small batteries at

the time, so I ended up at around 150 W anyway by putting the three

elements in series instead of parallel, or 200 W with two in series.

One should be able to come up with almost any desired wattage range.

Cabin Construction & DC Wiring

Main Wiring Board/Closet

I

continued adding to the surface

mounted wiring board. I installed the ground bus made in June. I 3D

printed a four-outlet wall plate to plug

several ceiling lights into rather than hard-wiring them. I suppose one

could fit 5 or 6 T-sockets on one wall plate. No "power bars" to get

enough outlets! This box is on

the charge controller's "output" circuit, which is set to shut off if

the battery gets the least bit low - which would probably be from

leaving too many lights on in the winter.

I

continued adding to the surface

mounted wiring board. I installed the ground bus made in June. I 3D

printed a four-outlet wall plate to plug

several ceiling lights into rather than hard-wiring them. I suppose one

could fit 5 or 6 T-sockets on one wall plate. No "power bars" to get

enough outlets! This box is on

the charge controller's "output" circuit, which is set to shut off if

the battery gets the least bit low - which would probably be from

leaving too many lights on in the winter.

A problem I've run into is that I

always want to have a negative ground, but in most charge controllers

it's the negative side that switches, both for the solar panels and the

load output. They are "positive ground". The reason for this is that

n-channel MOSFETs are better for switching power than p-channel, so

it's easier or cheaper to manufacture. That doesn't mean it doesn't

create headaches. Does one ground the solar panels, the batteries, or

the main ground bus? What about the lights on the low-power switch-off

circuit? They can't be grounded.

The 36 volts "+" stays live when it's off, and the "-" becomes 36 volts

as well. If it was higher voltage it could be dangerous.

36 V DC Wall Receptacle

On the 10th I wired up a wall receptacle in the upstairs room. I took

off a piece of gyproc from under the window and screwed in an

electrical box.

On the 10th I wired up a wall receptacle in the upstairs room. I took

off a piece of gyproc from under the window and screwed in an

electrical box.

DC Wall Outlets/Wiring: Wire Colors and Connections

Since AC wiring uses different colors than DC wiring and

is the most commonly available wire, there is often no red wire. (What

bozo decided black should be the "hot" wire in AC wiring, anyway? It's

the color of no energy, of earth, absorbing all light -- and somebody

made it "hot"?!?)

For DC wiring we'll stick to black, or bare or green per

AC standard, for negative or ground. If using a bare wire, be sure it

can't short to anything.

The other normally available color is white, so that will

have to substitute for red in many situations. If deviating from this,

wires should be wrapped with colored tape to make their usage clear.

Black, bare, green: minus

Red, white: plus

What is the purpose of grounding the metal box with AC

wiring? My understanding is that it is so that if a "hot" wire touches

the box, it will blow the circuit breaker to avoid a shock hazard if

the box or a screw is touched. At 36 volts, there is no significant

shock hazard, so it's better to leave the box unconnected. If a +36V

connection (and no other) touches the box, no harm is done and the

breaker isn't needlessly blown.

As I see it, there are two distinct types of circuits for

DC wiring: "LED lighting only" circuits and "other appliance" circuits.

"Other appliances" using considerable power may need heavier wires than

for 120/240 V AC. (And allowing thinner wires is the main reason such

high voltages are commonly used.)

A single LED light of 24 watts is a pretty bright light,

yet the current to drive it at 36 volts is just 2/3 of an amp. Even

light #18 AWG "lamp cord" will handle 5 amps - enough for any typical

lighting. Plus, with no need for higher voltage insulation, even #18

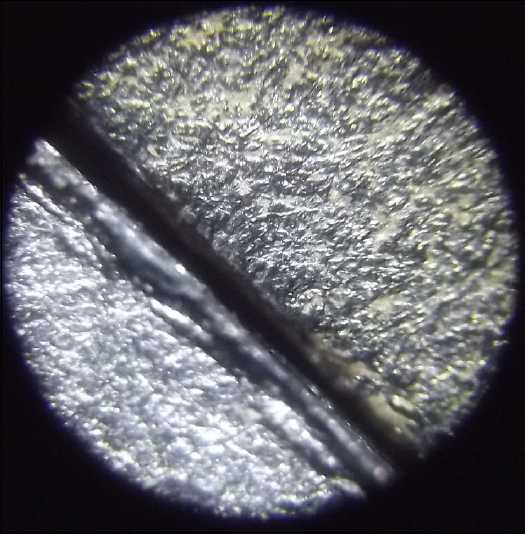

"speaker wire" is fine. (Note: Watch out for cheap non-copper speaker

wire. It is coated to look like copper wire, but the resistance is much

higher. Silvery color on cut ends betrays this "fake" wire. Even that

is probably sufficient for a lower power LED light or two.)

Wires for outlets or other applications that will or might

have higher power appliances connected need much heavier wires. (But

not so heavy as for 24 or 12 volts!)

We don't really know what appliances are or will become

available for 36 V DC power supplies. (We do know that 36 V DC can be

converted to any lower voltage for lower powered circuits with a low

cost power adapter, and that there are some 12 to 24 volt appliances

presently available. And or course 120 V AC appliances can be run with

a DC to AC inverter. 36 V to 120 V inverters are available.)

We typicly run circuits at up to 85% of the circuit

breaker current. #14 AWG wire running 12.5 amps at 120 volts is 1500

watts - the heaviest appliances commonly plugged into a 120 V AC wall

outlet. That current at 36 volts is just 450 watts. That's just enough

for a toaster, kettle, hot plate, microwave oven or coffee maker, or a

vacuum cleaner, but it will be a slow one. #12 wire (w. 20 amp breaker)

or heavier is preferable for wall outlets. Running 17 amps at 36 volts

would give appliances of just over 600 watts.

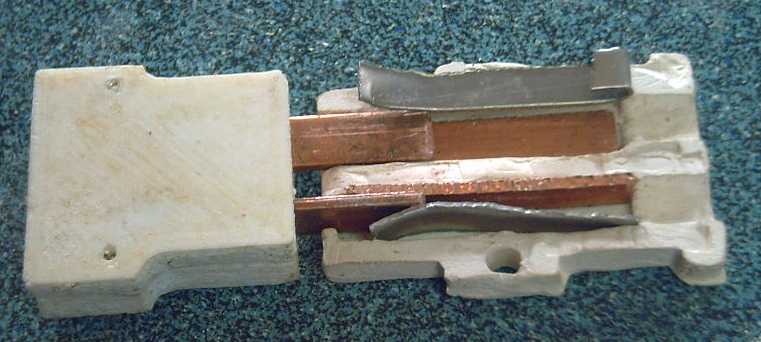

#10 wire (rated 30 amps, 30 amp breaker) allows 25.5 amps,

allowing just over 900 watt appliances.

Appliances over 1000 watts will need #8 AWG wire and heavier plugs,

like the "high current T-Plug" & socket I made just samples of by

hand some years back. ( TE News

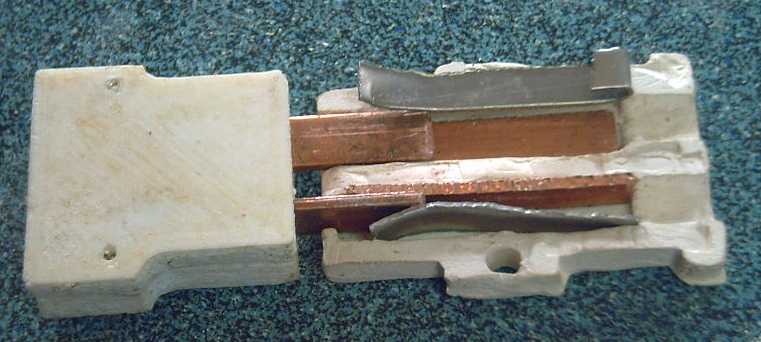

#161 ) To my chagrin the size specs are (presumably) in some

earlier issue I didn't readily locate. They are: blade protrusion, 2mm

x 8 mm x 15 mm; spacing between blade centers 12mm, making a 7mm gap.

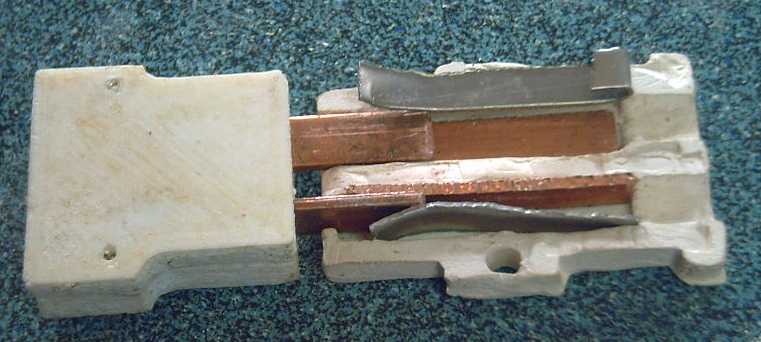

Appliances over 1000 watts will need #8 AWG wire and heavier plugs,

like the "high current T-Plug" & socket I made just samples of by

hand some years back. ( TE News

#161 ) To my chagrin the size specs are (presumably) in some

earlier issue I didn't readily locate. They are: blade protrusion, 2mm

x 8 mm x 15 mm; spacing between blade centers 12mm, making a 7mm gap.

3D printed nylon socket bodies should be acceptable. As I

didn't have nylon print filament when I was doing them, I made them of

porcelain. (On the plug the contacts are outside. On the socket they

are inside and heat from a poor connection could melt many plastics.)

(I really must upload all my designs to thingiverse.com for anyone to

use!)

Most off-grid installations will have

trouble supplying such higher-powered devices for extended periods. (Of

course "on grid" buildings could use the AC to drive a heavy 36 V DC

power supply and run all the DC things they wish at low voltage DC.) It

is especially desirable to keep AC wiring away from bedrooms (along

with WiFi and cell phones) for health reasons. Many people don't give

their bodies many breaks from such mild but eventually deleterious

emissions.

Most off-grid installations will have

trouble supplying such higher-powered devices for extended periods. (Of

course "on grid" buildings could use the AC to drive a heavy 36 V DC

power supply and run all the DC things they wish at low voltage DC.) It

is especially desirable to keep AC wiring away from bedrooms (along

with WiFi and cell phones) for health reasons. Many people don't give

their bodies many breaks from such mild but eventually deleterious

emissions.

I

also made a "double T-Plug" idea for heavier circuits, maybe 15 or 20

to about 30 amps. I thought it would be good because it uses the same

T-Plugs & Sockets. Frankly I don't think I recommend this, but it

consists of two T-Plugs/T-Sockets beside each other exactly 12mm apart.

I spaced some wall outlets that way and made shells to hold the T-Plugs

at that spacing.

I

also made a "double T-Plug" idea for heavier circuits, maybe 15 or 20

to about 30 amps. I thought it would be good because it uses the same

T-Plugs & Sockets. Frankly I don't think I recommend this, but it

consists of two T-Plugs/T-Sockets beside each other exactly 12mm apart.

I spaced some wall outlets that way and made shells to hold the T-Plugs

at that spacing.

The "giant T-Plug" is a better idea.

In early

August I used the new one upstairs in the cabin to power a 2500 W PSW

inverter (36 VDC to 120 VAC) and vacuumed the room. The double plug

wanted to pull out at the slightest stress on the heavy wires. (This is

why I wish the T-Plugs had 10mm blades instead of 8mm, but it would

have only been somewhat better. The "giant T-Plug" for high currents is

the real answer... but they need to be manufactured.)

In early

August I used the new one upstairs in the cabin to power a 2500 W PSW

inverter (36 VDC to 120 VAC) and vacuumed the room. The double plug

wanted to pull out at the slightest stress on the heavy wires. (This is

why I wish the T-Plugs had 10mm blades instead of 8mm, but it would

have only been somewhat better. The "giant T-Plug" for high currents is

the real answer... but they need to be manufactured.)

Most vacuum cleaners are somewhere near 1500 watts.

Theoreticly that should have blown the 20 amp (36V) breaker. I had a

lower powered shop vac (850 W), but also a vac that had buttons to

increase or decrease power. At full power the inverter (2500W?!?)

balked after about half a minute, quitting and saying "Fault", but if I

turned the vac to setting 3 of 5, it ran fine and I did the job.

For said wall

outlet I ran a #14 AWG - 3 wire cable from the DC "wiring closet" under

the stairs straight to the outlet box. Since the bare "ground" wire is

also #14, that makes four wires. The way "AWG" works, the diameter of a

wire is half of one three gauges down. This means that two #14 AWG

wires together have the same cross section as a single #11. Best

breaker rating for #11 would be 25 amps, allowing up to 900 watt

appliances to be plugged in.

For said wall

outlet I ran a #14 AWG - 3 wire cable from the DC "wiring closet" under

the stairs straight to the outlet box. Since the bare "ground" wire is

also #14, that makes four wires. The way "AWG" works, the diameter of a

wire is half of one three gauges down. This means that two #14 AWG

wires together have the same cross section as a single #11. Best

breaker rating for #11 would be 25 amps, allowing up to 900 watt

appliances to be plugged in.

I may want to run a low wattage electric heater at night

or potentially an inverter to run an AC vacuum cleaner. (I have a lower

powered 850 W shop vac. Many vacs need a full 1500 watts.)

I insulated the bare wire by stripping pieces of black

insulation from a scrap of #12 AWG wire (seen in front), which are just

a little fatter than #14 and slip on easily.

I tied red and

white together, and the two blacks, and tied them to the pigtails of

the T-Plug (36V DC) wall plate.

I tied red and

white together, and the two blacks, and tied them to the pigtails of

the T-Plug (36V DC) wall plate.

I used a

moderately deep box for the wires plus the sockets to fit into.

I used a

moderately deep box for the wires plus the sockets to fit into.

When I put the

wall plate on I discovered the box stuck way out of the wall. Oops!

When I put the

wall plate on I discovered the box stuck way out of the wall. Oops!

It worked but

after a couple of weeks I took the crumbling piece of gyproc off and

moved the box back. Still not quite flush. But much better. (How

can it be crooked when it's screwed to the wall stud, top and bottom?)

It worked but

after a couple of weeks I took the crumbling piece of gyproc off and

moved the box back. Still not quite flush. But much better. (How

can it be crooked when it's screwed to the wall stud, top and bottom?)

Cabin Construction

The end of the second set of ceiling sheets didn't quite

reach the last rafter, with this one central rafter gap being more than

24 inches wide. What to do? I finally opted for screwing in a 2 by 2

onto the side of the rafter an inch above the bottom, then screwing a 1

by 8 to that, horizontal, so it was flush with the bottom of the

rafter. That gave

10 inches width to screw ceiling panels to.

The end of the second set of ceiling sheets didn't quite

reach the last rafter, with this one central rafter gap being more than

24 inches wide. What to do? I finally opted for screwing in a 2 by 2

onto the side of the rafter an inch above the bottom, then screwing a 1

by 8 to that, horizontal, so it was flush with the bottom of the

rafter. That gave

10 inches width to screw ceiling panels to.

Horrid Fiberglass

[14th] I

finally got the nerve and put on crappy old clothes to

continue insulating the upstairs room ceiling. It was even worse than I

expected. I finally used the last loose pieces of R28 insulation I got

used, but the "new" bag was just as bad. It was hard to tell where one

so-called "batt" ended and the next began - they all just stuck

together almost as if one big fat piece. Whenever it was touched,

clouds of very fine dust came off it, and bigger bits continually fell

off like snow. Not only would it not stay put in the ceiling spaces

between the rafters, but it would hang from a string like a limp towel.

In the lower parts I could put in strips of plastic and then slide the

"batts" in, but I had to string the top part. I used some old twine and

roofing nails to hold it once in place.

[14th] I

finally got the nerve and put on crappy old clothes to

continue insulating the upstairs room ceiling. It was even worse than I

expected. I finally used the last loose pieces of R28 insulation I got

used, but the "new" bag was just as bad. It was hard to tell where one

so-called "batt" ended and the next began - they all just stuck

together almost as if one big fat piece. Whenever it was touched,

clouds of very fine dust came off it, and bigger bits continually fell

off like snow. Not only would it not stay put in the ceiling spaces

between the rafters, but it would hang from a string like a limp towel.

In the lower parts I could put in strips of plastic and then slide the

"batts" in, but I had to string the top part. I used some old twine and

roofing nails to hold it once in place.

This

particular

insulation reminded me of some from 1976-77 when manufacturers had

decided to used "recycled glass" to make fiberglass. It turned out that

many fibers were the same shape and size as asbestos, hence were

carcinogenic. I had used that horrid stuff under my house in

1977-78, and this "new" stuff didn't seem any better. What luck! Hmm...

had it lain around all these years since that period? I

finally thought to look for a URL on the packages. If there wasn't one,

it could potentially be that old. There wasn't, but there was a date:

Dec. 2001. Maybe it had degraded over a couple of decades of imperfect

storage?

This

particular

insulation reminded me of some from 1976-77 when manufacturers had

decided to used "recycled glass" to make fiberglass. It turned out that

many fibers were the same shape and size as asbestos, hence were

carcinogenic. I had used that horrid stuff under my house in

1977-78, and this "new" stuff didn't seem any better. What luck! Hmm...

had it lain around all these years since that period? I

finally thought to look for a URL on the packages. If there wasn't one,

it could potentially be that old. There wasn't, but there was a date:

Dec. 2001. Maybe it had degraded over a couple of decades of imperfect

storage?

I had to vacuum up the "snow"

that fell in

simply cutting

I had to vacuum up the "snow"

that fell in

simply cutting

one batt into four short pieces with a clean, sharp knife.

I tried my very best to get almost any nicer insulation

than fiberglass. I finally decided dried lawn grass (~R3 per inch -

investigated in TE News #170

& previous, two years ago) just wasn't good enough for the walls,

no

one in northern BC would sell me common cellulose fiber loose fill (R4

per inch), and nice looking organic fiber batts (cellulose, wool...)

that I saw on line in Europe likewise aren't to be had around here. The

only

other choice is mineral wool batts, which cost substantially more

instead of less. So I ended up with

fiberglass, bad enough any time, and someone who was moving sold me his

old R28 batts for the ceiling, cheap. (It wouldn't have been so bad

under the floor, or at least in the walls! I'll have to seal the

ceiling

really well.) I opened a "new" bag for two more batts and found big rat

holes in them. Yetch!

Having managed to put in thirteen fiberglass batts and

three sheets of coroplast ceiling, my endurance completely ran out and

I had to leave the last three batts and last sheet for the next morning.

Having managed to put in thirteen fiberglass batts and

three sheets of coroplast ceiling, my endurance completely ran out and

I had to leave the last three batts and last sheet for the next morning.

[15th] I was very glad to finish the job and clean up and vacuum the

room. I went for a walk then started checking out the window frame.

I

stepped into the house just in time to hear the last ring before the

answering machine came on. It was McKenzie furniture with the "Ashley

Pillowtop 2.0" mattress, and they were just down the road! I opened the

gate and walked down to the highway to see the truck just

coming around the bend! The big mattress came in a small, very heavy

box. (14" x 14" x queen mattress width) Was that really it? All of it?

It was all vacuum packed and rolled

up to an amazingly small size. When I got it out of the box, unwrapped

the wrap and cut into the plastic bag, air hissed in and it started

expanding. Then it started to look like a real, thick, plush mattress.

"Allow

24-48 hours for full recovery." Amazing!

Owing to it being an ucky construction site I left it in

the plastic. But I brought down some old bedding and had a nap there,

and then started "camping" in it at night. I put a plastic tarp over

the whole bed during the days.

It could

almost be my imagination that my tinnitus is quieter by morning, but

it's definitely not imagination that it gets louder fairly rapidly when

I get back into "normal" electric fields. The conductive fabric

tuque/beanie actually helps a lot, but it's not the same as just being

away from electric fields. (I find this especially on the day I've

washed it and set it out to dry. The ringing is much worse after a day

without it.) Lots of older people say they have ringing in their ears

when I bring up the subject. "Oh, ya, my ears are whistling away as we

speak." The more I know and experience, the more I think 120/240 VAC

wiring should be eliminated throughout most of most dwellings.

[17th] I had a double pane

window which had been two parts, one

sliding, one fixed. I had split the double pane and got it out of the

frame successfully (to clean the inside -- in spite of the sticky black

tape/goo). Now I cut the

frame down to use just the fixed part and spent the day roughing it

into

place for the bedroom window. I had to cut a small notch in the rafter

and trim the ceiling a bit,

so it was certainly the biggest window that could fit. I put the frame

in backwards so that I could put in or remove (to clean) the window

glass from inside instead of from the outside on a tall ladder.

[17th] I had a double pane

window which had been two parts, one

sliding, one fixed. I had split the double pane and got it out of the

frame successfully (to clean the inside -- in spite of the sticky black

tape/goo). Now I cut the

frame down to use just the fixed part and spent the day roughing it

into

place for the bedroom window. I had to cut a small notch in the rafter

and trim the ceiling a bit,

so it was certainly the biggest window that could fit. I put the frame

in backwards so that I could put in or remove (to clean) the window

glass from inside instead of from the outside on a tall ladder.

Now the midges

("no-see-ums") would have a much harder time freely zipping in and

biting me, which makes me horribly itchy.

Only a little triangle space was left above the window to

place a vent that would open. I guess it will have to do!

[19th] I

continued sleeping in the cabin. This gave me great incentive to finish

the last wall. I made a bizarre mistake on the framing under the center

beam: the space was 49 inches tall. Four inches had to be subtracted

from the studs for the 2 by 4's, and somewhere overnight my mind had

imprinted "39 inches". I never questioned or verified it so of course

it came out 6 inches too short. I put it up anyway. The top part with

the angles and every post a different length didn't go perfectly

either, but it ended up right.

[19th] I

continued sleeping in the cabin. This gave me great incentive to finish

the last wall. I made a bizarre mistake on the framing under the center

beam: the space was 49 inches tall. Four inches had to be subtracted

from the studs for the 2 by 4's, and somewhere overnight my mind had

imprinted "39 inches". I never questioned or verified it so of course

it came out 6 inches too short. I put it up anyway. The top part with

the angles and every post a different length didn't go perfectly

either, but it ended up right.

I ran the

gyproc verticly, floor to ceiling, which essentially nullified the

framing mistake. I also found I could remove the heavy beam joiner on

the bedroom side, leaving just the one on the other side and here just

bolt ends to be plastered over.

I ran the

gyproc verticly, floor to ceiling, which essentially nullified the

framing mistake. I also found I could remove the heavy beam joiner on

the bedroom side, leaving just the one on the other side and here just

bolt ends to be plastered over.

(Only one sheet of badly stored gyproc that got wet left to use up.

Yay!)

Gardening

The raspberries are

producing far more than I wanted to devote the time to pick. Still,

I've filled some margarine tubs and put them in the freezer in addition

to frequently having a good helping of them with cereal. Friends who

dropped by picked a bread bag full one day. Judging by the canes

growing for next year, I may have to get a ladder to pick them!

Corn

By mid July

the corn was starting to grow ears! To my

surprise, the ones nearer the back were doing much better than the ones

at the front, some of which had actually died in the spring. Was not

enough light coming in near the front... or did it get colder around

the

edges in the spring? Hmm... There were pretty big cracks around the

edges. I thought they'd be fine, but the stalks in the middle and

toward the back probably

stayed warmer. Next year I'll reuse the same 'greenhouse box' [TE News #191 - scroll to bottom

of "April in Brief"] but close around the edges

better. (And maybe find something that lets more light through for the

sides?)

By mid July

the corn was starting to grow ears! To my

surprise, the ones nearer the back were doing much better than the ones

at the front, some of which had actually died in the spring. Was not

enough light coming in near the front... or did it get colder around

the

edges in the spring? Hmm... There were pretty big cracks around the

edges. I thought they'd be fine, but the stalks in the middle and

toward the back probably

stayed warmer. Next year I'll reuse the same 'greenhouse box' [TE News #191 - scroll to bottom

of "April in Brief"] but close around the edges

better. (And maybe find something that lets more light through for the

sides?)

On August 7th I picked and cooked my first delicious cob

of corn.

Sweet Potatos

My friend Kamil said he had some sweet potatos from the

store that were starting to sprout. I've never seen them sprouting

before, so that was interesting. My brother says he grows them in his

greenhouse in Toronto. But I was sure it was too cool to grow them

here. He reminded me that I had some all-styrofoam cooler box cubes. If

I covered them with a sheet of glass and put dirt in them, the sun

would heat up the dirt and they would stay warm inside.

My friend Kamil said he had some sweet potatos from the

store that were starting to sprout. I've never seen them sprouting

before, so that was interesting. My brother says he grows them in his

greenhouse in Toronto. But I was sure it was too cool to grow them

here. He reminded me that I had some all-styrofoam cooler box cubes. If

I covered them with a sheet of glass and put dirt in them, the sun

would heat up the dirt and they would stay warm inside.

That sounded like a plan. So I cut a hole in the bottoms

of two and lined them with clear LDPE, and put in a few inches of old

compost, and half a tuber with some good eyes in each. I put the boxes

in the greenhouse, watered them and put a couple of broken glass or

acrylic plastic over them.

In a week they were both sprouted! The dirt

is pretty shallow but can be deepened as they grow, and it will

hopefully fill with tubers. (Now, what about yams? I think they need it

even warmer, but might it be worth a try? I guess I should see how

these do first.)

In a week they were both sprouted! The dirt

is pretty shallow but can be deepened as they grow, and it will

hopefully fill with tubers. (Now, what about yams? I think they need it

even warmer, but might it be worth a try? I guess I should see how

these do first.)

In a couple of weeks the leaves were pressing on the glass.

Someone suggested just using soft plastic so they could lift it and

keep growing. That seemed to work well, and then I added some dirt to

each box.

The coffee

bushes flowered and started growing new beans. I saw some nice flower

petals but when I finally went to get a picture they were gone.

The coffee

bushes flowered and started growing new beans. I saw some nice flower

petals but when I finally went to get a picture they were gone.

I've given them bone meal, lime, nitrogen and so on, but

they could really use bigger pots. Then what when they get too tall for

inside under lights in winter?

Electricity

Storage

The

Copper Oxyhydroxide

Nickel-Manganates

Nickel Hydroxide

Nickel Oxide - Zinc

Zincate Cells

Zincate

I have already made a hugely important advance in battery

technology by creating a zinc electrode that will last 'forever'. (How

could it possibly have taken 16 years?) I think I'll call it the Zincate

electrode to distinguish it from all the "failed" (single use or short

cycle life) Zinc electrodes out there. After all, the

key is that when

discharged the zinc substance remains as a "supersaturated" zincate

solution that never turns into zinc oxide.

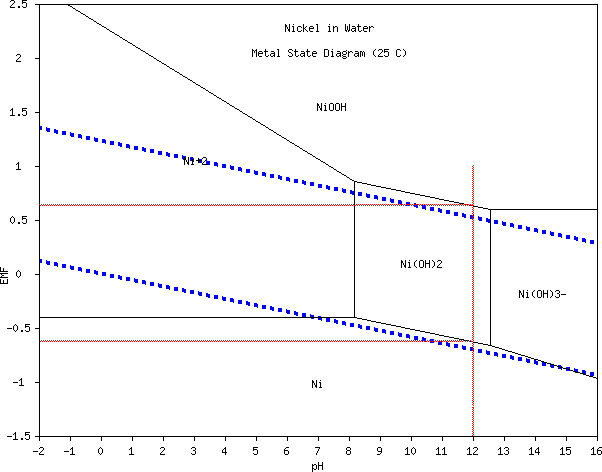

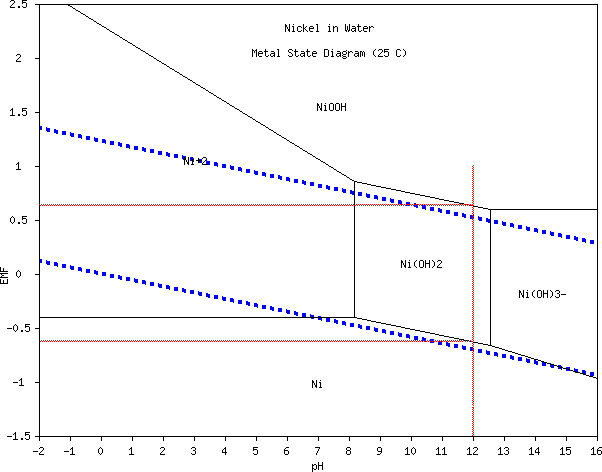

Nickel Manganese Oxides

[12th] After months and months with little progress I decided I was

fed up with trying to get

copper hydroxides to work - for the moment - and to try a tube

electrode with nickel-manganates again. (eg, NiMn2O4... oxidation state

varies with state of charge.) I had always tried charging these cells

up to nickel oxyhydroxide voltage (w. zinc, almost 2.0V) instead of to

manganese dioxide voltage (1.4-1.5V), and now I'm pretty sure that was

wrong. I may have been charging the manganese into soluble forms,

MnO4-, MnO4--, which would gradually migrate to the minus electrode,

reduce, and coat it with Mn(OH)2 to block the electrolyte.

In the cupboard I found a jar with a good quantity (187g)

of mix I had made in December 2022 (TE News #175), which apparently was

made with Mn substance from old dry cells using the following

percentages:

Ni(OH)2 - 29 g

Dry cell Powder ("MnO2" + CCB) - 63g

Sm2O3 - 3 g

Additional Graphite or CCB power - 5 g

(proportions of Ni to Mn are approximate)

There was no mention of acetone in #175, so I must have

discovered acetone after that. Powders simply mixed together aren't the

same as when chemicly combined. I have the impression that's another

reason the cells degraded with cycling. Acetone dissolves the oxide

powders and as it evaporates they combine them into epitaxial

co-precipitated crystalline forms. At least, this is what I think

happens - the supposition under which I'm doing it.

So that was the first step. It's amazing how crunchy

powders dissolve into a smooth paste in acetone. But it would need a

couple of days to evaporate, so I wasn't going to slap together a

NiMn2O4 electrode in an hour in the morning as I had unthinkingly

thought.

Being solid substances with no dissolving ions, probably

this electrode would work fine without osmium and SDBS. OTOH, if I used

SDBS in the separator, hopefully anything that did dissolve would stay

within the electrode anyway, and the 'forever' life of a gelled

electrode might apply.

[14th] I keep stirring it. Getting to be more of a loose powder again.

Still a faint smell of acetone... I spread some over the bottom of a

shallow container. By night the smell there was little.

[15th] The tube with the

carbon rod weighed 30.90 grams. I added

NiMn2O4(?) powder mix and it was 42.75, so 11.85 grams of mix. Plunging

in the tapered rod and then the tapered carbon rod... and scraping some

out with a screwdriver because the rod wouldn't go in far enough... I

think I got it pretty compacted, and about 10mm below the top. I topped

it up with heat glue.

[15th] The tube with the

carbon rod weighed 30.90 grams. I added

NiMn2O4(?) powder mix and it was 42.75, so 11.85 grams of mix. Plunging

in the tapered rod and then the tapered carbon rod... and scraping some

out with a screwdriver because the rod wouldn't go in far enough... I

think I got it pretty compacted, and about 10mm below the top. I topped

it up with heat glue.

I put it in the cell and after bubbling a while it read

about 1.28V. That seemed promising. I briefly tried a couple of loads:

with 50 Ω it dropped by about 100mV and with 10 Ω, 350mV. Most of the

drop

was the NiMn2O4 side. The two old zinc tubes were pretty good. I set

the

power supply to 1.6V to charge it knowing that Mn-Zn is about 1.5V

almost regardless of pH, and that I am expecting to get a rechargeable

version of MnO2 with the mixed NiMn2O4 oxide. It started charging at

~50mA [9:35 PM PST], limited by crappy alligator clip connections and

other resistances, since the voltage only read 1.55V instead of 1.6V.

This rose toward 1.6 as the charge current dropped. (If I start

soldering connections to the cell, it gets hard to replace electrodes.)

(Note: from here, ' =

minutes, " = seconds...) In 15' of charging (which dropped to

20mA) I tried a 20 Ω load test. It started out at 1.45V O/C and dropped

to

1.1V in 1'. After 4' it was down to .977V and I stopped. This seemed

about right since it was discharging at over 50mA after such a short

charge. It recovered to 1.206V in one minute and started recharging at

60mA. Would it continue performing similarly but run longer with more

charge, or disappoint me like my copper "+" trodes? After another 30'

of charging (down to 15mA) I tried again and it ran 5', staying over

1.1V for 2'. Recovery 1.184V. Recharge started at 82mA (momentary

max.). Another test... only slightly better. ...Mañana is good

enough for me!

[16th] A test early in the mañana yielded only slightly better

results than the ones charged just half an hour. Huh? I did another run

with 50 Ω instead of 20, and it ran down to 1.000V in 20.0'. As

anticipated, it doesn't seem to be as good as the copper when that is

working well. [Later: But it also just didn't seem much good. It was

disheartening.]

How many square centimeters of interface area was there,

anyway? The last CNC cut tube had 19 rows of 18 holes, 342 holes. I

measure the drill bit as about 2.75mm (.275cm).

.275 ^sq. * π/4 = .0594 sq.cm. - per hole

.0594 * 342 = 20.3sq.cm. ... The tube was just about the same as the

50x50mm square electrodes. That is assuming of course that the holes in

the "+" tube are the greatest bottleneck, the point of least area. It's

harder to calculate for the 3D printed "minus" 'trodes but there are

two zinc "minuses" in the cell.

But this (earliest) tube had many smaller holes. Maybe 15

sq.cm? Then, it

put out 300mA into ".1Ω", which is just 20 mA/sq.cm. Of course, I

probably should try it without soduim sulfate in the electrolyte. I

had added that since it seemed to do a good job of changing copper into

CuOH. ...or does that make any significant difference?

Surely I'm stumbling around in the dark. None of the

positive electrodes of whatever chemistry I try seem to have even a

fraction of the amp-hours that I think they ought to, deteriorating

performance, and (except for using cupro-nickel sheet metal), very low

current drive as well. The commercial dry cell nickel oxyhydroxide

worked better than my homemade "+" 'trodes, but not nearly as well as

it did in the original Ni-MH dry cell. What am I missing? Could

it simply be that I couldn't seem to seal the lids to keep air out?

Could a bit of air getting into the electrolyte really matter? After

all, most of the early researchers had open top beakers and jars. But

what if it affects the charging, hour after hour? There was the next

thing to try!

Surely I'm stumbling around in the dark. None of the

positive electrodes of whatever chemistry I try seem to have even a

fraction of the amp-hours that I think they ought to, deteriorating

performance, and (except for using cupro-nickel sheet metal), very low

current drive as well. The commercial dry cell nickel oxyhydroxide

worked better than my homemade "+" 'trodes, but not nearly as well as

it did in the original Ni-MH dry cell. What am I missing? Could

it simply be that I couldn't seem to seal the lids to keep air out?

Could a bit of air getting into the electrolyte really matter? After

all, most of the early researchers had open top beakers and jars. But

what if it affects the charging, hour after hour? There was the next

thing to try!

This jar had a plastic lid. I drilled appropriate hole in

it, filled the jar almost to the brim, poked the terminals through the

holes and screwed the lid on. Then set it on to charge again.

That done, it was much weaker. It seemed the carbon rod

just wasn't making as good a connection inside the electrode. When I

pushed on it, performance improved again. When I was done, it was about

what it was before. The idea behind tapered rods was that when pushed

in, they would compact against the electrode substance and connect

better. The flip side is if it comes out a bit, it loses connection all

around. Is there some better way to do it? (How about carbon rods with

screw threads? Well, they'd probably break putting them in.) But there

seems to be a limit beyond which pushing the rod in farther or harder

is no help. I guess at that point it's already as connected as it gets.

[17th] As I rather expected since I couldn't think of any chemical

problem except very, very gradual CO2 contamination of the KOH, the lid

on the jar seems to do nothing but keep the electrolyte from

evaporating... which anyway is a blessing. After taking out the "+"

trode and pushing the rod in pretty hard, there was no improvement over

the previous day. Once again I'm baffled as to why it doesn't perform

far better than it does.

I had the CNC machine drill

out another electrode tube. I

adjusted a setting and got 18 holes and 26 rows, 468 holes times .0594

sq.cm per hole - about 28 sq.cm.

Except maybe the drill didn't go quite deep enough and left many

'bottoms' attached. They only went back flat into the holes when

rubbed. I poked ?150? "hanging chads" with a paper clip to get them

standing up inside again and then scraped them off with a curved file.

I put in a separator paper with all including osmium.

When the tube was ready I put in 100% the old monel mix

from long ago - the baked/fried mix. It didn't work any better.

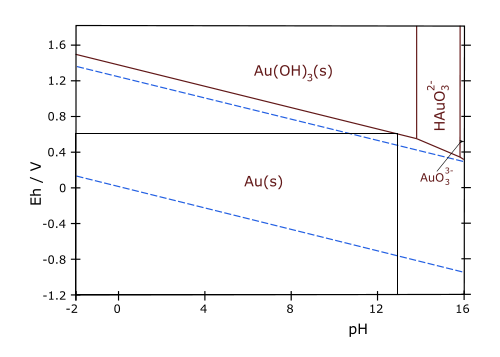

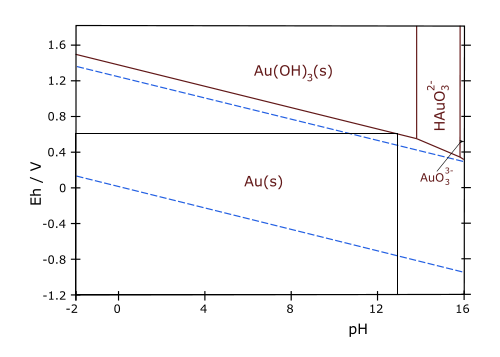

The Path of Lowest Resistance: Tried and True Nickel Oxyhydroxide

[18th] OKAY... The zincate was the vital thing. I've been unable to

improve on the other side of the cell, the positive electrode, with a

new and better chemistry.

The nickel manganates doesn't seems to work well - at

least, not if only charged to MnO2 voltage. In previous experiments at

nickel oxides voltages it had seemed to deteriorate. The copper

hydroxides/copper ions electrode seems to deteriorate and I don't see

why and haven't found a solution.

There is almost surely some way or multiple ways to make

either and both of these things work, but

for myself, I think it's time to give up on them. I've simply had

enough of failures.

At this point, I think there are two choices:

1. Delve into the uncharted realms of zinc-air cells. This probably has

even more hurdles and unknowables than what I've already been doing. I

think I'll pass. Hopefully the U of Waterloo is still carrying on their

zinc-air research and I've written to them with my good 'everlasting

zinc' suggestions.

2. Take the path of least resistance on the positive electrode... Tried

and Tested, well known and long used Nickel Oxyhydroxide, NiOOH. (AKA

nickel hydroxide. Oxyhydroxide is the charged form.) A nickel-zincate

cell that lasts "forever", or at least for many thousands of cycles,

would be a fabulous battery. It would be notably lighter, cheaper,

higher voltage and higher energy than nickel-metal hydride, and surely

less costly and safer than lithium types. The PVC plastic pipes with